Method for liquefying high-low pressure nitrogen double-expansion natural gas

A natural gas, high and low pressure technology, applied in the field of high and low pressure nitrogen double expansion natural gas liquefaction, to achieve the effect of good liquefaction effect and high liquefaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

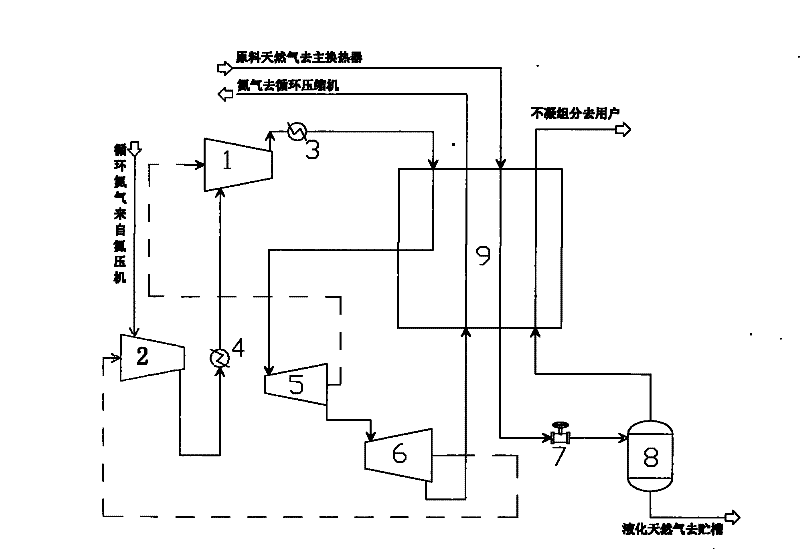

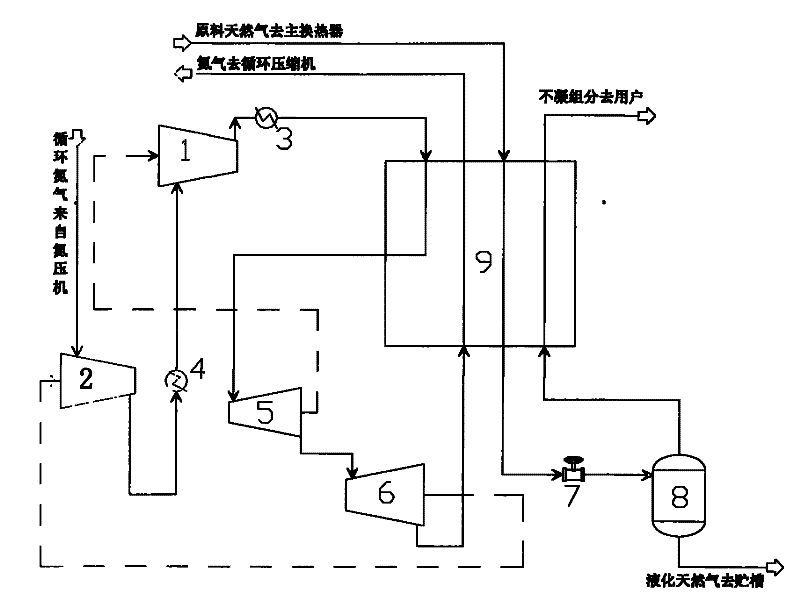

Image

Examples

Embodiment 1

[0019] The high and low pressure nitrogen double expansion natural gas liquefaction method comprises the following steps:

[0020] a. Nitrogen is compressed to 2.0MPa and cooled to 30°C;

[0021] b. After the nitrogen gas obtained in step a enters the booster end of the low-pressure booster 2 for pressurization, it is cooled to 30°C by the second aftercooler 4, and then enters the booster end of the high-pressure booster 1 to obtain 3.6MPa high-pressure nitrogen. , 3.6MPa high-pressure nitrogen is cooled to 30°C by the first aftercooler 3;

[0022] c. The cooled high-pressure nitrogen gas enters the main heat exchanger 9 and 1.0MPaMpa raw natural gas is cooled to -30°C by the 0.4MPa low-pressure nitrogen gas at the outlet of the low-pressure expander 6, and then one stream is drawn out and sent to the high-pressure expander 5 for high-pressure expansion Machine 5 expands and refrigerates at a high pressure of 4.0MPa and a high temperature of -50°C, with an expansion ratio of ...

Embodiment 2

[0025] The high and low pressure nitrogen double expansion natural gas liquefaction method comprises the following steps:

[0026] a. Nitrogen is compressed to 3.0MPa and cooled to 45°C;

[0027] b. After the nitrogen gas obtained in step a enters the booster end of the low-pressure booster 2 for pressurization, it is cooled to 45°C by the second aftercooler 4, and then enters the booster end of the high-pressure booster 1 to obtain 5.3MPa high-pressure nitrogen. , 5.3MPa high-pressure nitrogen is cooled to 45°C by the first aftercooler 3;

[0028] c. The cooled high-pressure nitrogen gas enters the main heat exchanger 9 and 1.0MPa ~ 10Mpa raw natural gas is cooled to -70°C by the 0.6MPa low-pressure nitrogen gas at the outlet of the low-pressure expander 6, and then one stream is drawn out and sent to the high-pressure expander 5. The high-pressure expander 5 expands and cools at a high pressure of 4.0 MPa and a high temperature of -50°C, with an expansion ratio of 3, and th...

Embodiment 3

[0031] The high and low pressure nitrogen double expansion natural gas liquefaction method comprises the following steps:

[0032] a. Nitrogen is compressed to 2.5MPa and cooled to 35°C;

[0033] b. After the nitrogen gas obtained in step a enters the booster end of the low-pressure booster 2 for pressurization, it is cooled to 35°C by the second aftercooler 4, and then enters the booster end of the high-pressure booster 1 to obtain 4.0MPa high-pressure nitrogen. , 4.0MPa high-pressure nitrogen is cooled to 35°C by the first aftercooler 3;

[0034] c. The cooled high-pressure nitrogen gas enters the main heat exchanger 9 and the 1.6Mpa raw natural gas is cooled to -40°C by the 0.5MPa low-pressure nitrogen gas at the outlet of the low-pressure expander 6, and then a stream is drawn out and sent to the high-pressure expander 5 for high-pressure expansion Machine 5 expands and refrigerates at high pressure 4.0MPa and high temperature -50°C, with an expansion ratio of 2.5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com