Patents

Literature

101results about How to "Speed up liquefaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

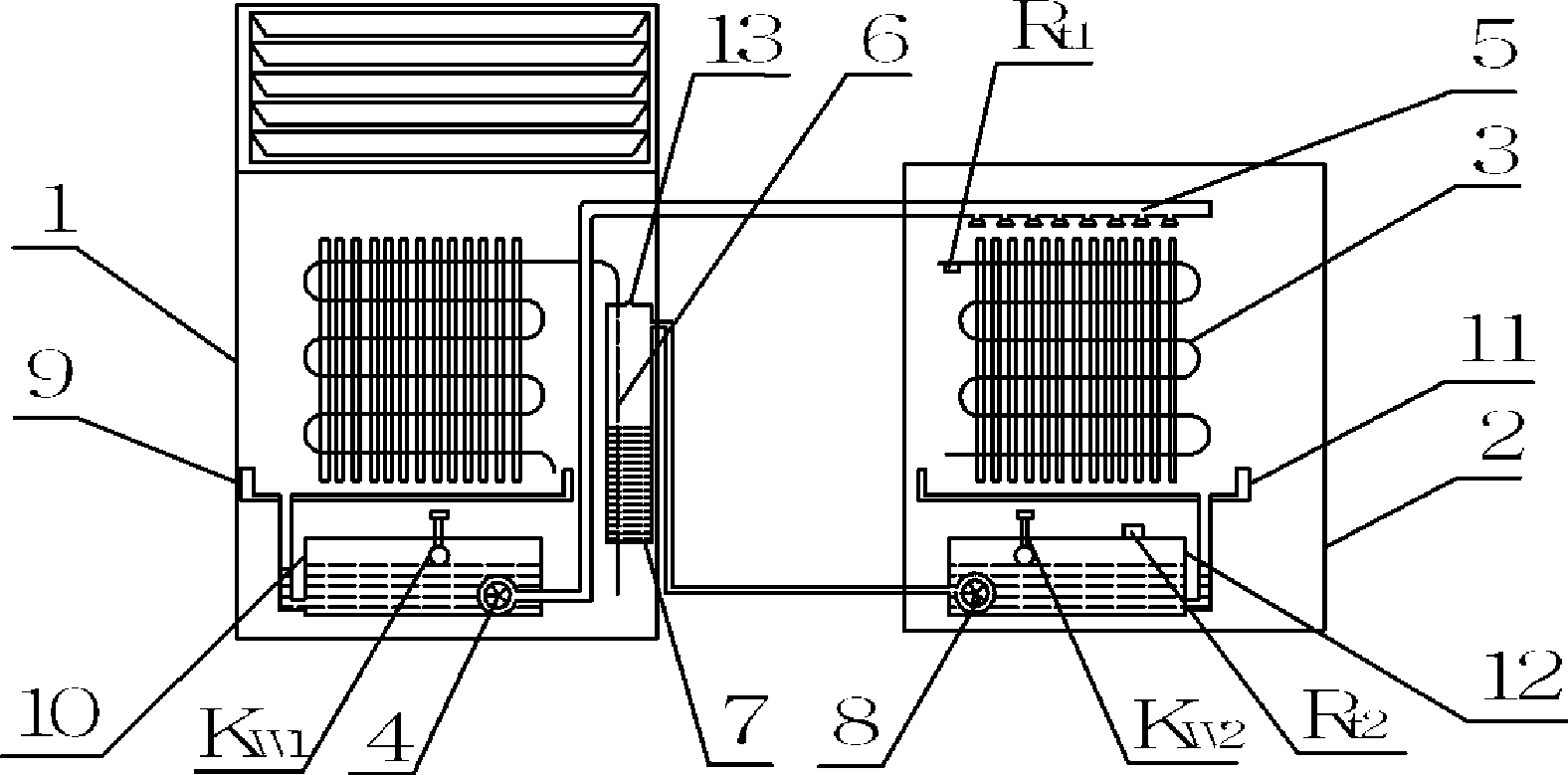

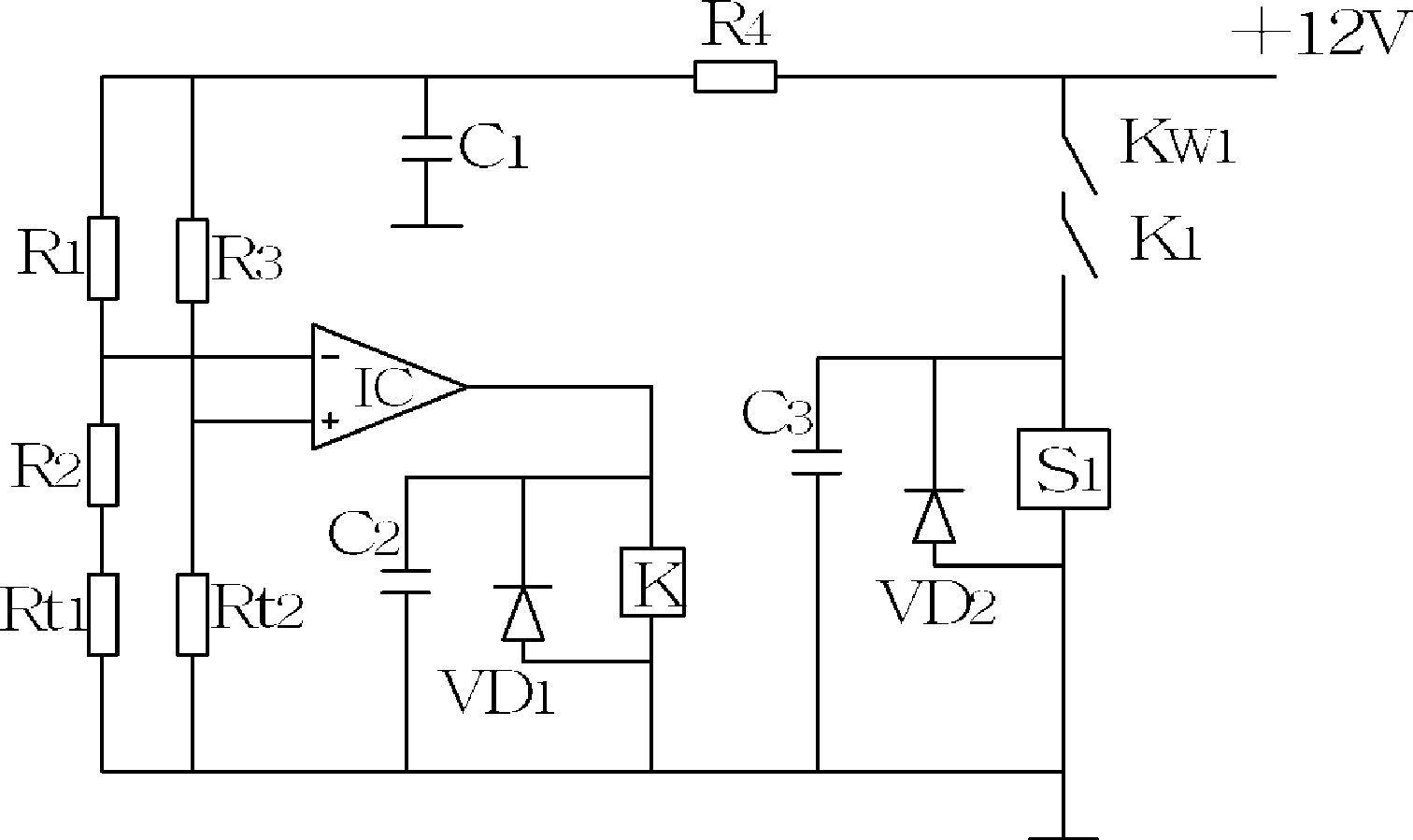

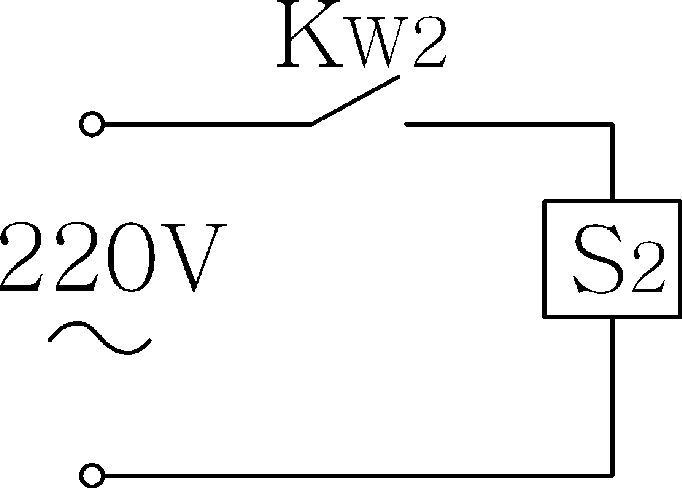

Domestic air conditioner condensate water processing method and apparatus

InactiveCN101387434ASolve drainage problemsReduce surface temperatureCondensate preventionSpace heating and ventilation safety systemsEngineeringWater processing

The invention discloses a treatment method and a treatment device for condensed water of a household air conditioner. The method comprises the following steps: when the air conditioner is used for refrigeration, the condensed water generated from an indoor unit of the air conditioner is collected, then is drained to outdoors, and is sprayed on a condenser of an outdoor unit of the air conditioner, the high temperature of the condenser of the outdoor unit of the air conditioner is utilized to evaporate the discharged condensed water and discharge the condensed water into the air, and the temperature of the condenser of the outdoor unit of the air conditioner is reduced at the same time; when the air conditioner is used for heating, the condensed water generated from the outdoor unit of the air conditioner is collected, then is conveyed indoors, and is evaporated by utilizing the high temperature generated by the pipe wall of a radiating pipe during the heating to increase the humidity of indoor air, and the temperature of the radiating pipe of the indoor unit of the air conditioner is reduced at the same time. The device can automatically recover and utilize the condensed water, thereby solving the water drain problem of the condensed water; and the device can protect the environment indoors and outdoors, save energy and reduce consumption, improve the work efficiency of the air conditioner, and can maintain the moisture of the indoor air when the air conditioner is used for heating.

Owner:肖克贤

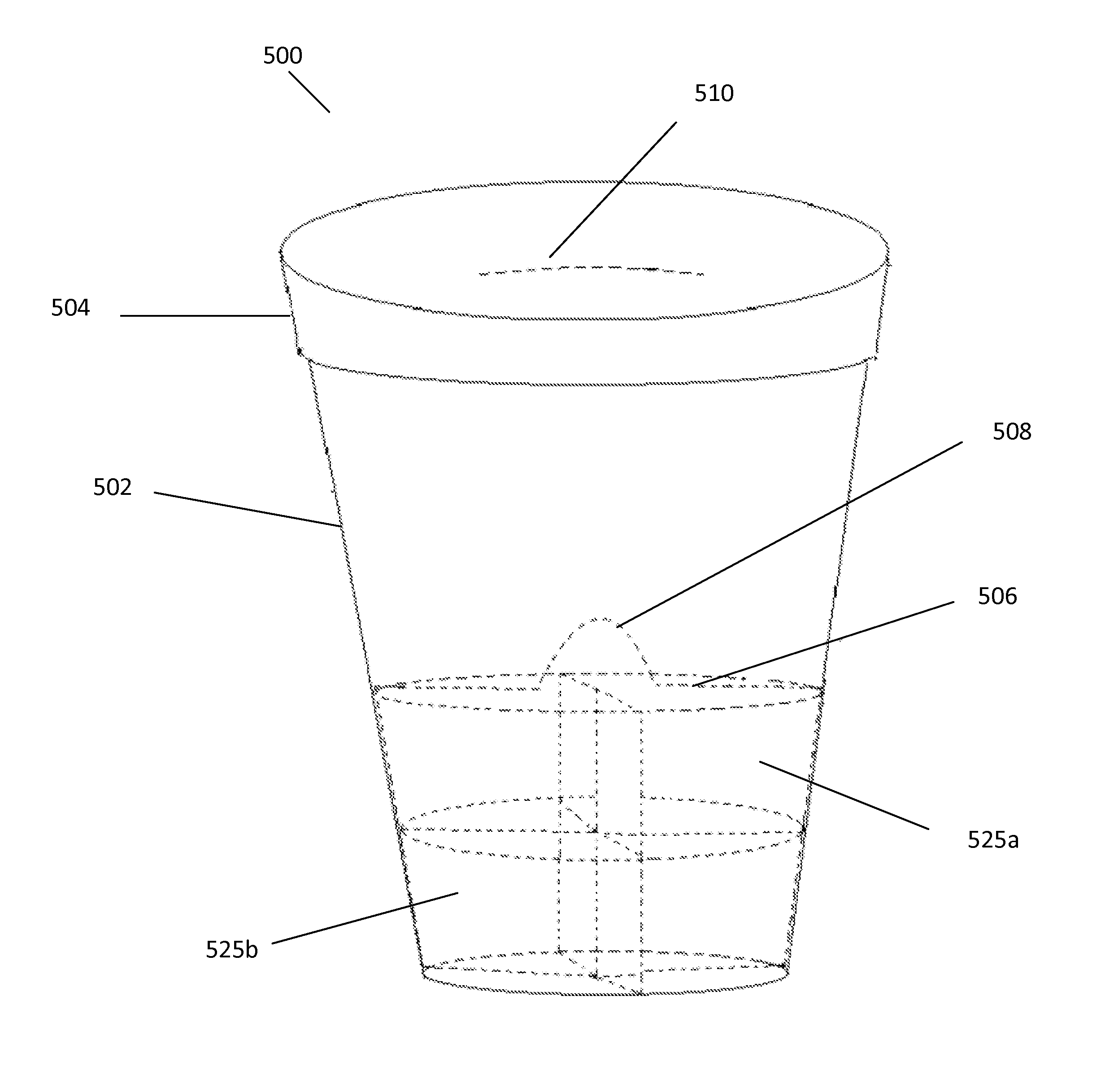

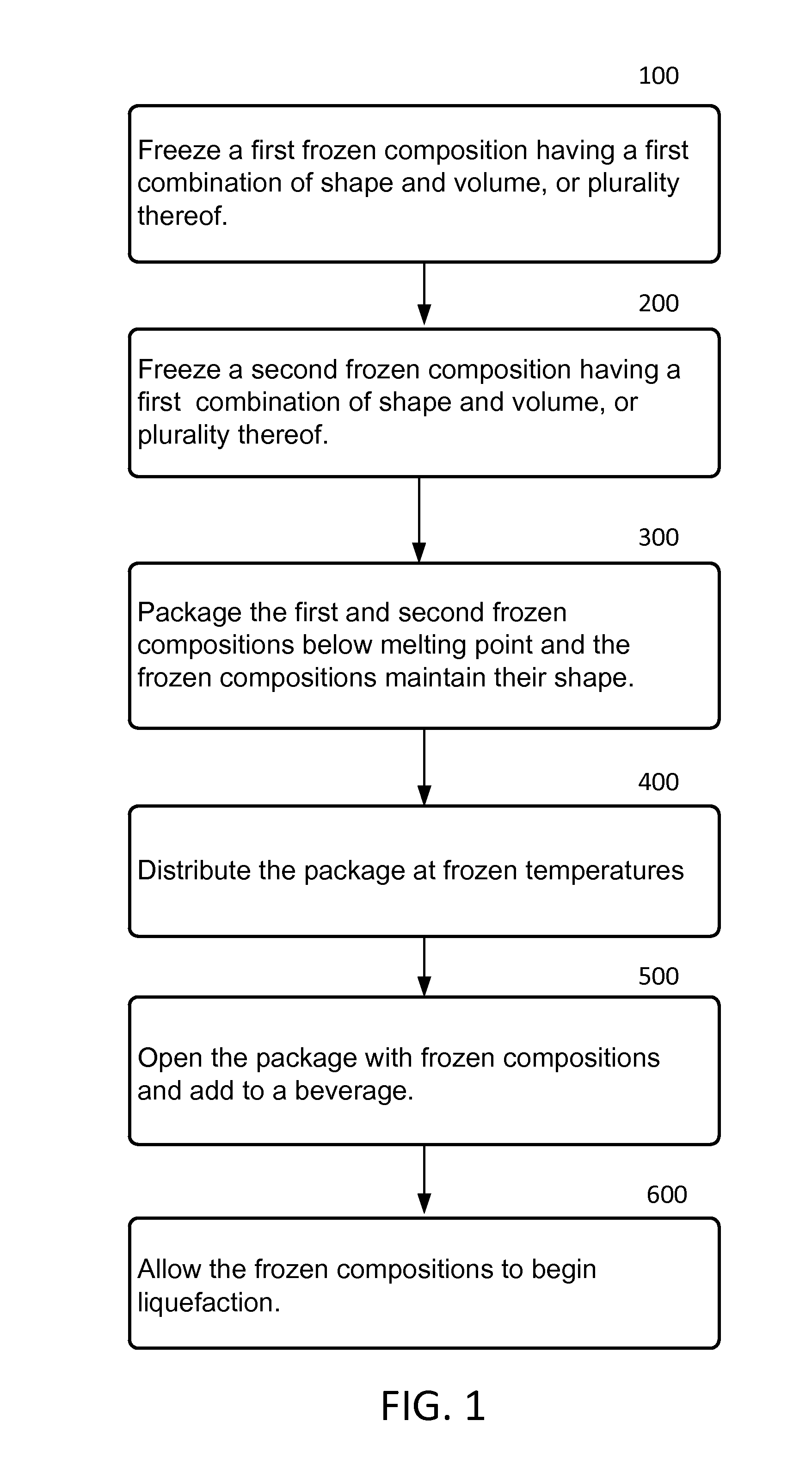

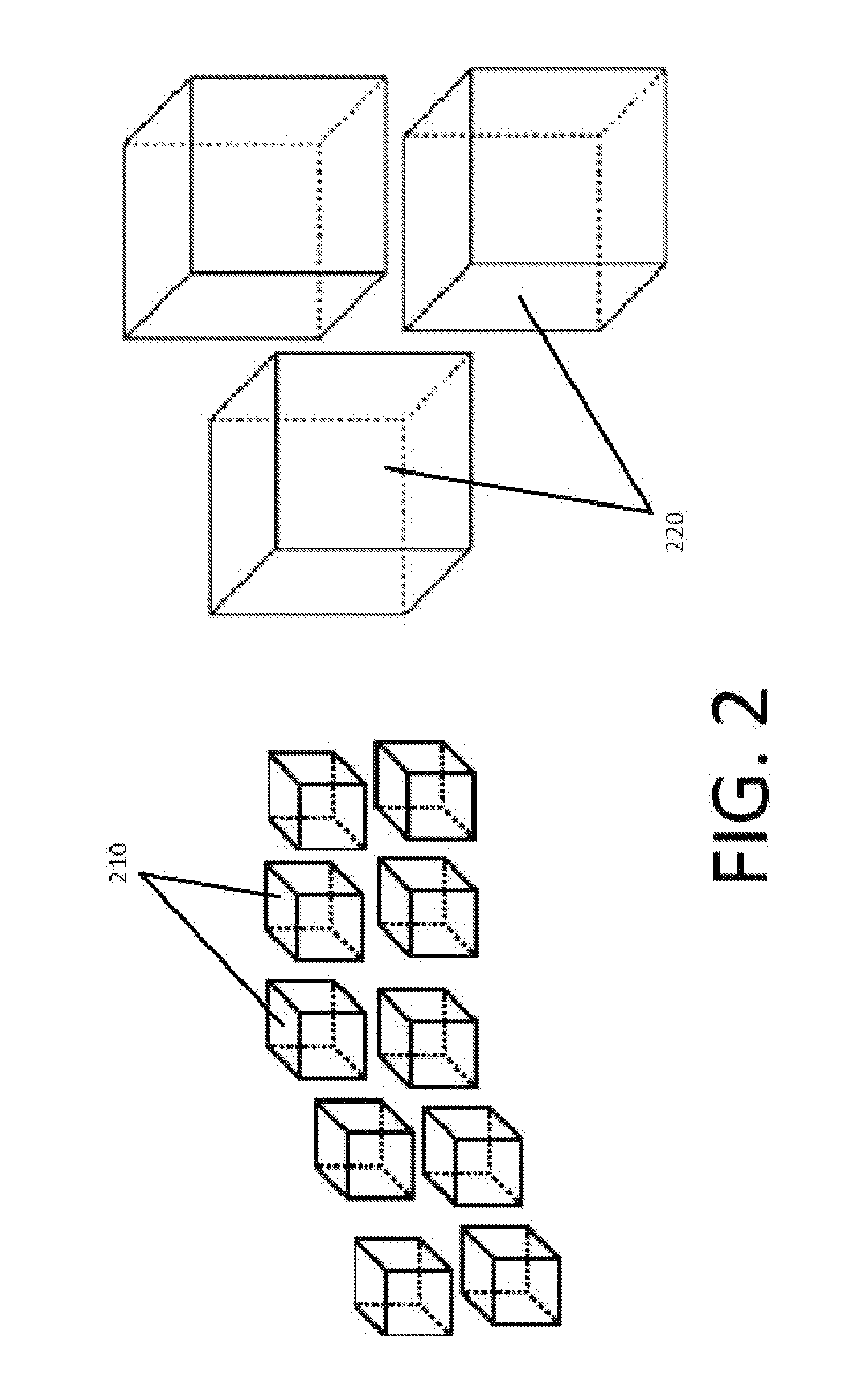

Beverage Supplement and Method for Making the Same

InactiveUS20140106033A1Reduce dilutionExpedite complete liquefactionReady-for-oven doughsPre-extraction tea treatmentFlavorLiquefaction

A beverage supplement and method for making the same is disclosed. In some embodiments the beverage supplement is comprised of a first frozen composition made from at least one additive mixed with at least one liquid and a second frozen composition made from at least one additive mixed with at least one liquid, wherein the resulting frozen compositions may have different / varying surface areas, shapes, volumes, flavors, and concentrations. Varying the combination of surface areas, shapes, volumes, formulas, flavors, and concentrations of frozen compositions influences the duration of complete liquefaction and the release of additives, allowing a user to create an iced beverage with greater flavor control.

Owner:COMETEER INC

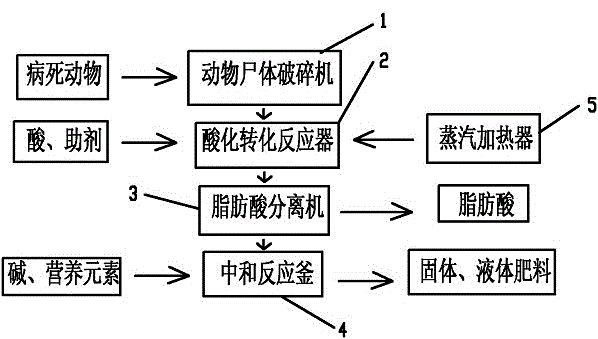

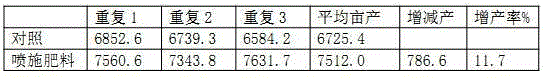

Method for harmlessly preparing fertilizer through carcasses and special equipment

InactiveCN105084986AGood effectImprove fertilizer efficiencyAnimal corpse fertilisersClimate change adaptationPhosphateWater soluble

The invention discloses a method for harmlessly preparing fertilizer through carcasses. The method comprises the steps that carcass fragments are firstly subjected to heat treatment conversion in an acid environment, the reaction environment is controlled to enable animal fat to be converted into fatty acid, and animal skin, fur and meat are converted into amino acid and humic acid, and animal bones are converted into water-soluble calcium salt and phosphate; the fatty acid is separated, and alkali is added to left amino acid and humic acid mixed liquid for neutralization. Special equipment of the method comprises a carcass crusher, an acidizing reaction kettle, a fatty acid separator and a neutralization reaction kettle which are connected in sequence. The method has the advantages of free of pollution, fast, thorough, efficient, high in quality and the like.

Owner:高洁

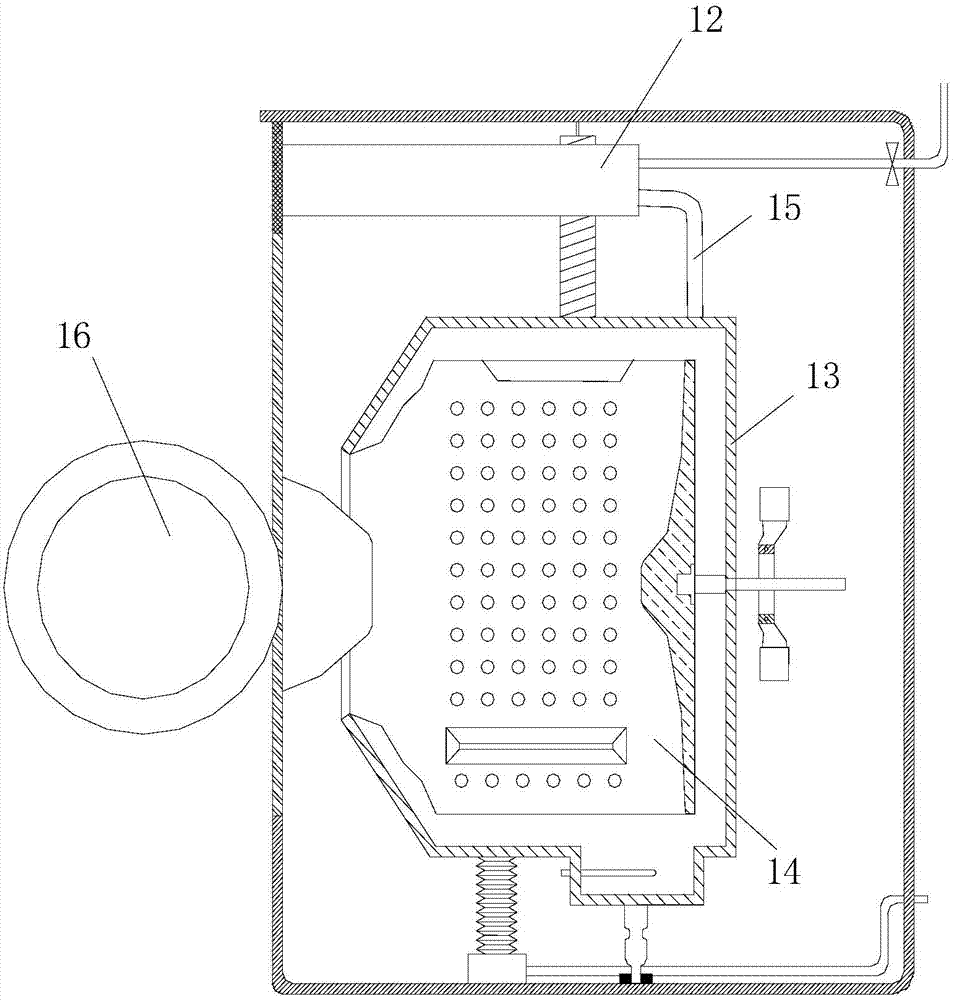

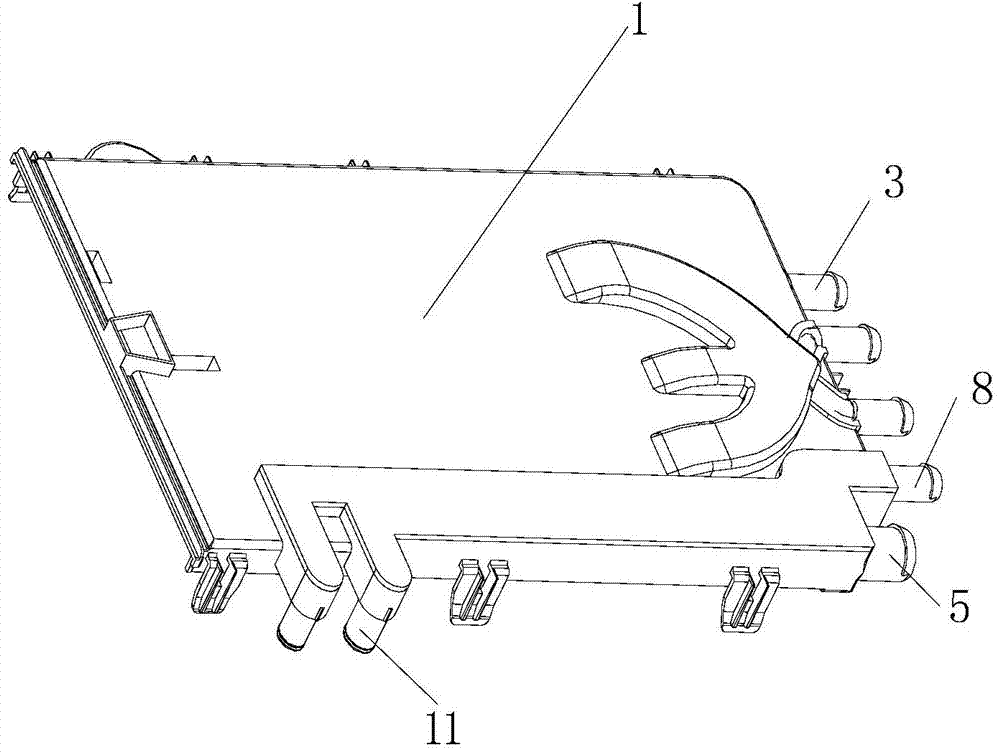

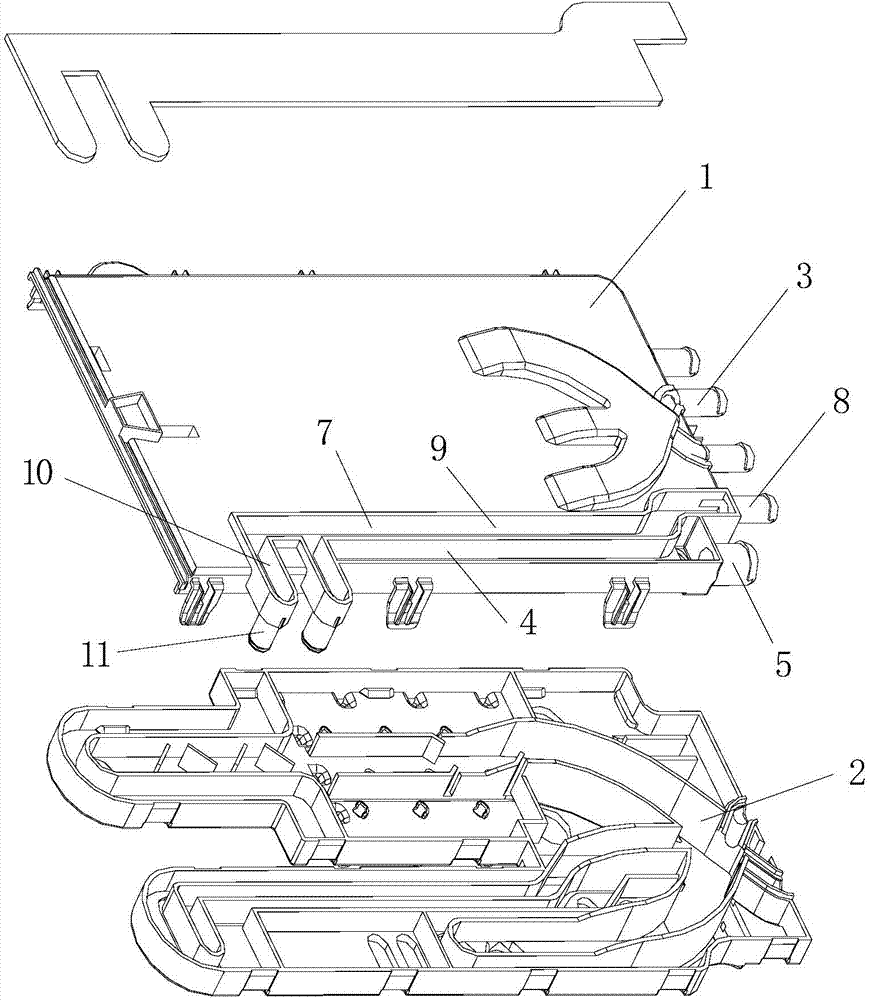

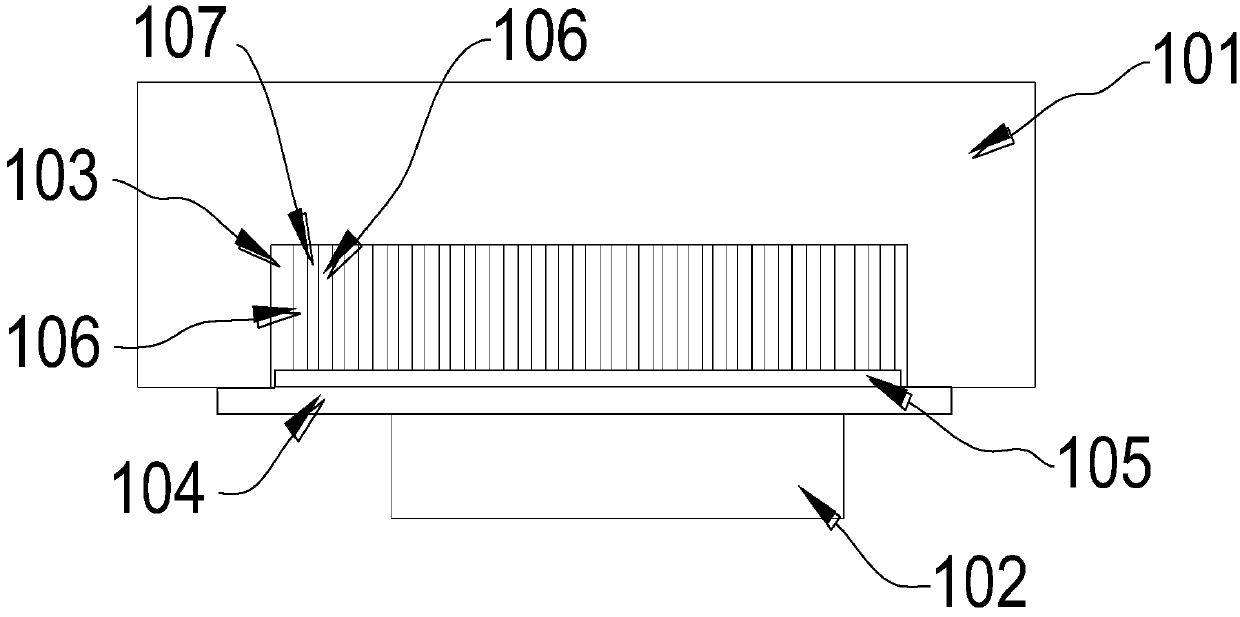

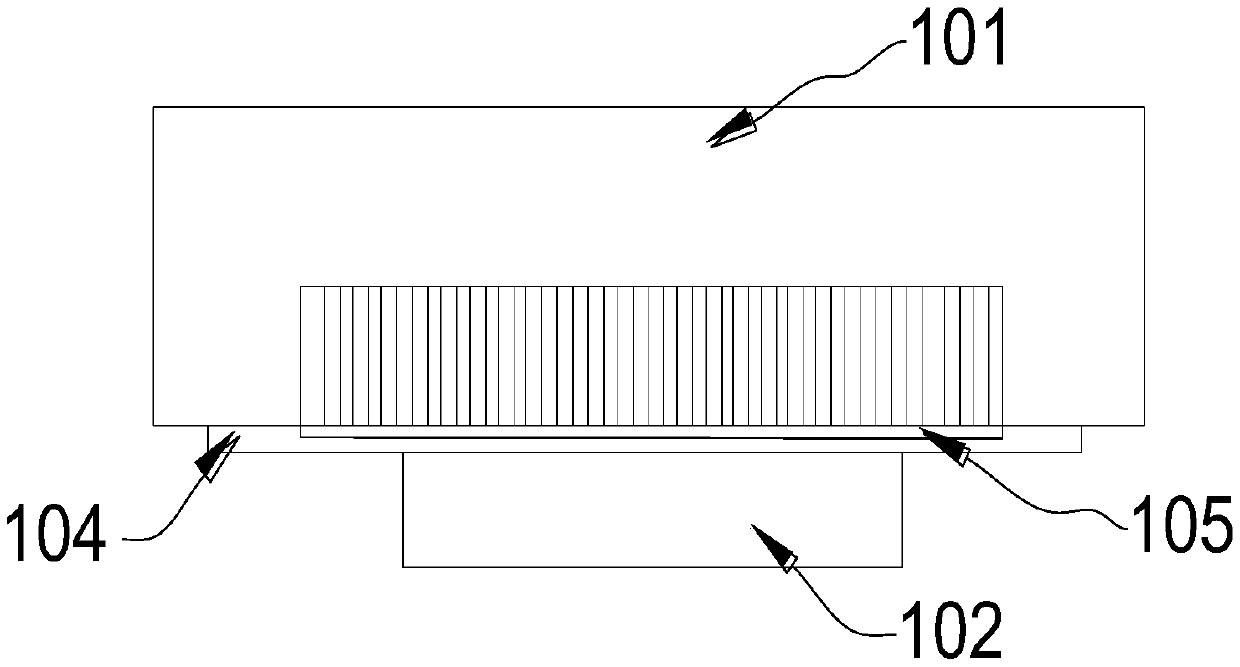

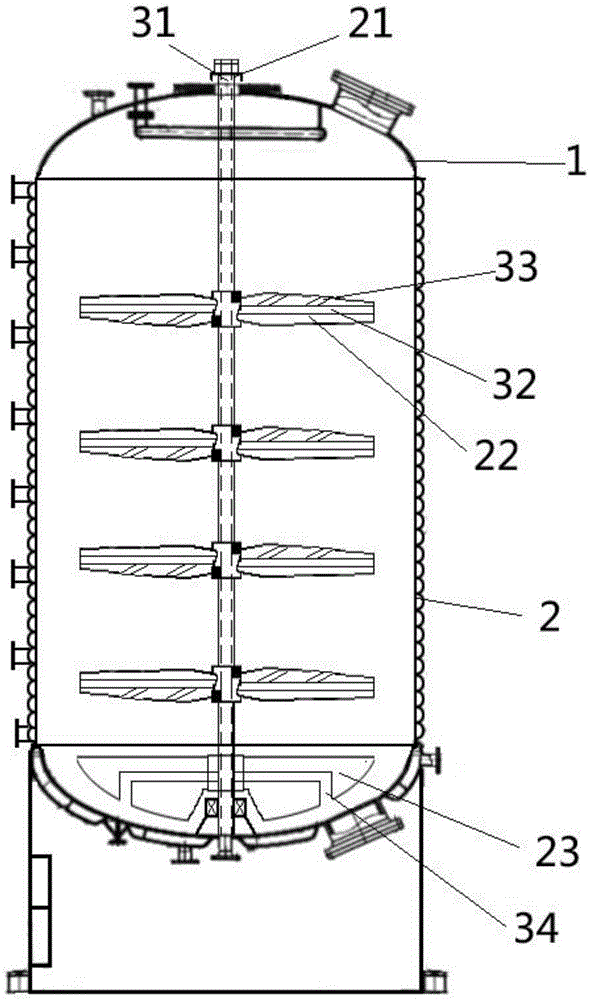

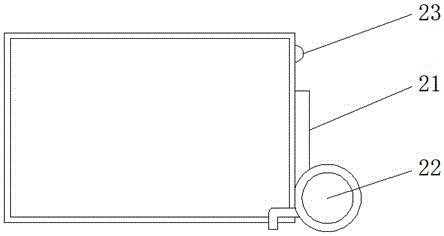

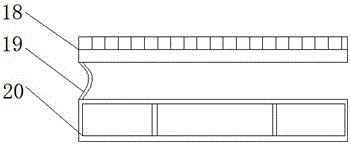

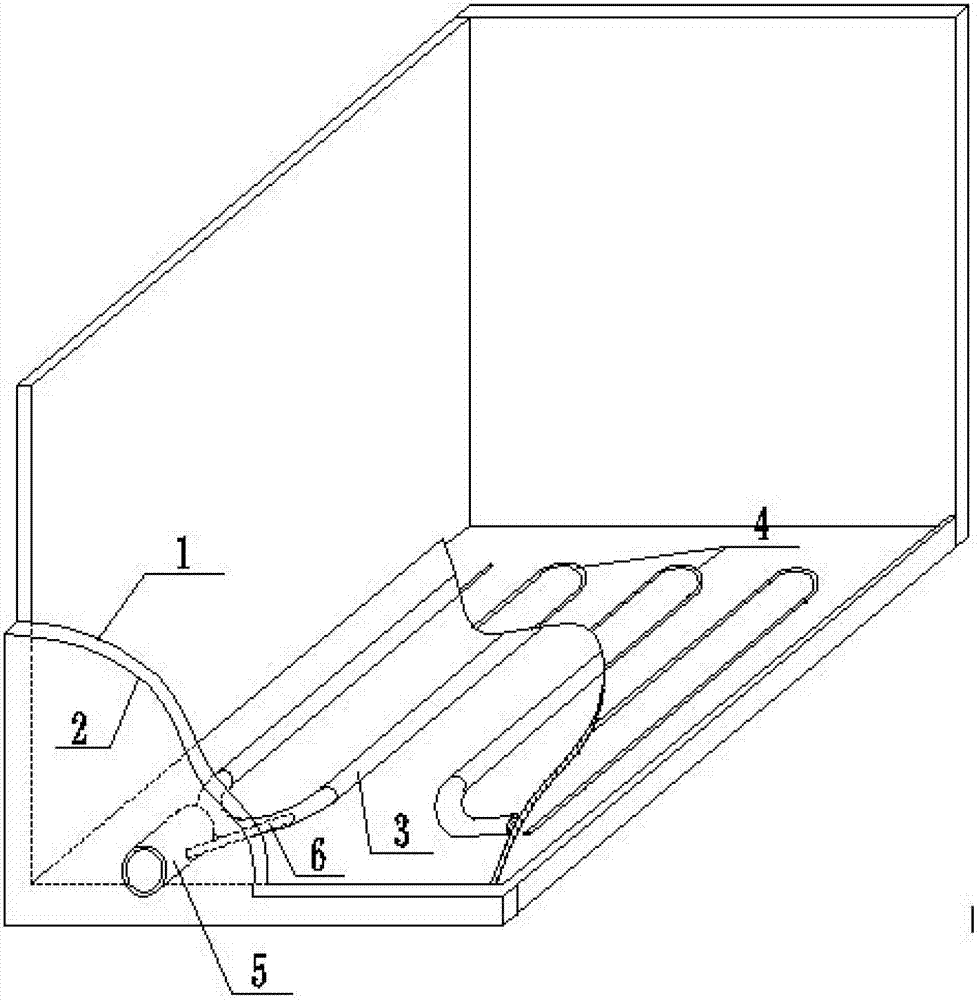

Water supply unit of washing machine and washing machine

ActiveCN104775281ASpeed up liquefactionEfficient condensation effectOther washing machinesTextiles and paperWaste managementWater supply

The invention provides a water supply unit of a washing machine. The water supply unit comprises a water supply unit cover plate, wherein the water supply unit cover plate comprises a water cavity which enables cold water to circulate, a water inlet is formed in one side of the water cavity, a water outlet is formed in the bottom part of the water cavity, and a ventilating hole which is used for feeding hot steam exhausted by an outer drum into the water supply unit cover plate so as to carry out condensation and liquification is also formed in the water supply unit cover plate. The invention also discloses the washing machine with the water supply unit. According to the water supply unit and the washing machine, disclosed by the invention, the structure is simple, the condensation effect is obvious, the installation technology is simplified, and the production efficiency is increased.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

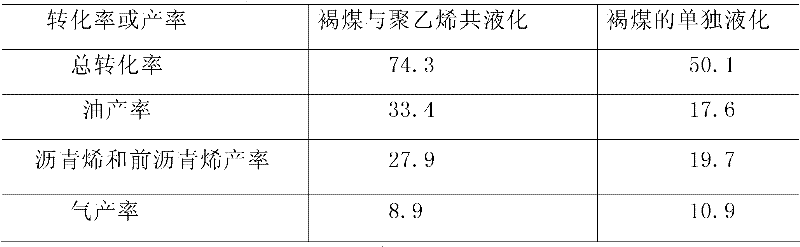

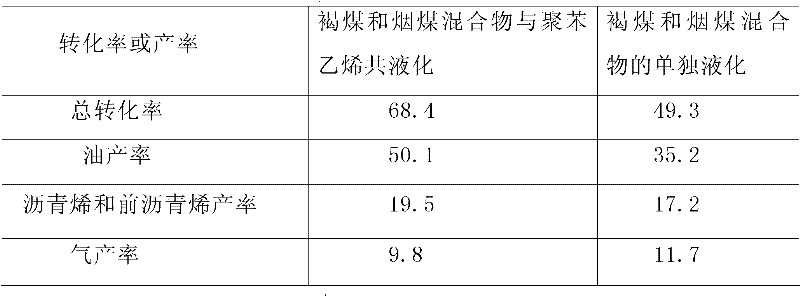

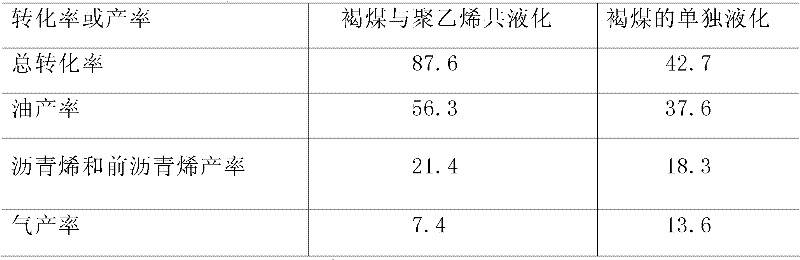

Method for co-liquefaction of coal and waste plastics under mild condition

InactiveCN102344823AHigh yieldIncrease profitLiquid hydrocarbon mixture productionDepolymerizationGas phase

The invention is a method for co-liquefaction of coal and waste plastics under a mild condition, which comprises the following steps: adding coal, waste plastics, lignosulfonate, a catalyst, and a solvent into an autoclave, introducing hydrogen to increase the pressure to 1.0-10.0 Mpa, heating to 300-450 DEG C for a liquefaction reaction, collecting the gas after the hydrogenation liquefaction test in the autoclave, analyzing the gas phase composition by a gas chromatography, collecting all the other liquefaction products in a filter paper cylinder, performing hexane and tetrahydrofuran solvent extraction in order by a soxhlet extraction device, wherein the substance soluble in hexane is oil, and the substances soluble in tetrahydrofuran but insoluble in hexane are asphaltene and preasphaltene, and calculating the total conversion rate of the liquefaction by using the amount of the insoluble substances in tetrahydrofuran. The invention allows the coal to perform a depolymerization reaction at a low temperature, and to be co-liquefied with waste plastics; the extraction rate of coal by solvents such as pyridine and the like is increased, and the coal liquefaction process is accelerated; not only the hydrogen consumption and production cost for coal liquefaction are greatly reduced, but also white pollution caused by waste plastics is solved.

Owner:LIUPANSHUI NORMAL UNIV

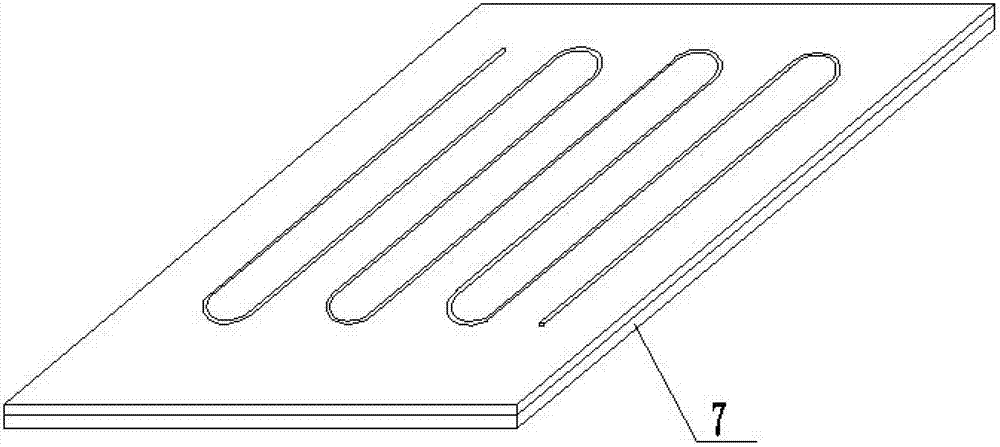

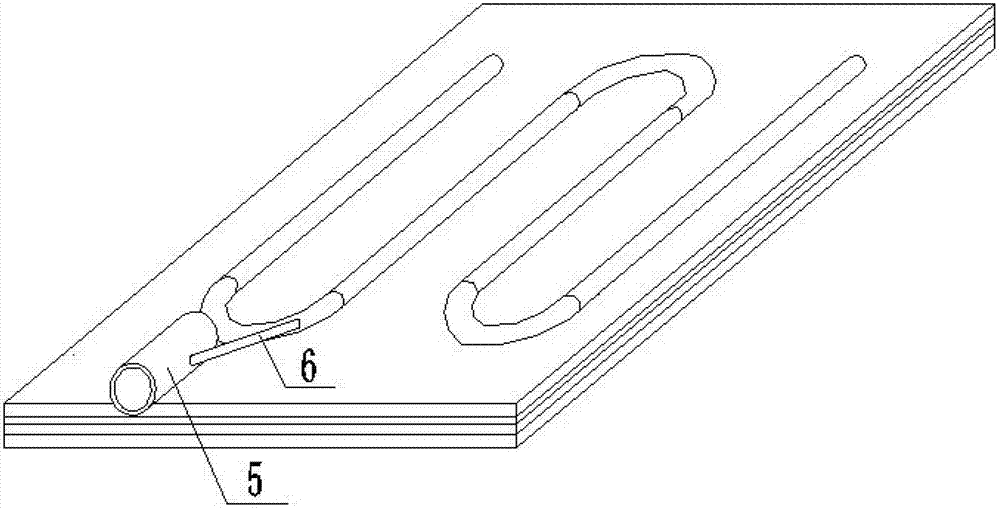

Structure for heat radiation middle frame or heat radiation rear case, heat radiation middle frame or heat radiation rear case and manufacturing method of heat radiation middle frame or heat radiation rear case

PendingCN109673136AContributes to the efficient circulation of gas and liquidAccelerate heat circulationModifications using liquid coolingModifications by conduction heat transferVacuum pressureEngineering

The invention discloses a structure for a heat radiation middle frame or a heat radiation rear case, the heat radiation middle frame or the heat radiation rear case and a manufacturing method of the heat radiation middle frame or the heat radiation rear case. According to the structure, an accommodating groove is formed in the middle frame or the rear case, the opening of the top of the accommodating groove is sealed by a heat radiation plate; the lower surface of the heat radiation plate is provided with an adsorption element used for adsorbing liquid; a support post used for preventing the heat radiation plate from sinking into the accommodating groove is arranged in the accommodating groove; the accommodating groove of the middle frame or the rear case forms a vacuum cavity with the heat radiation plate; heat absorption liquid capable of being evaporated is injected into the accommodated groove. The heat radiation middle frame or the heat radiation rear case of intelligent electronic equipment is directly used as a design carrier of the heat radiation structure; the vacuum cavity is formed by the arrangement of the accommodating groove and the heat radiation plate on the heat radiation middle frame or the heat radiation rear case; the support post is arranged in the vacuum cavity; the influence on the inside gas-liquid circulation by vacuum cavity space compression due to the heat radiation plate sinking during vacuum suction caused by vacuum pressure can be effectively prevented; meanwhile, the support post can further form the gas-liquid circulation passage; the gas-liquid efficient circulation is facilitated; the heat circulation radiation is accelerated.

Owner:SHENZHEN HFC SHIELDING PRODS CO LTD

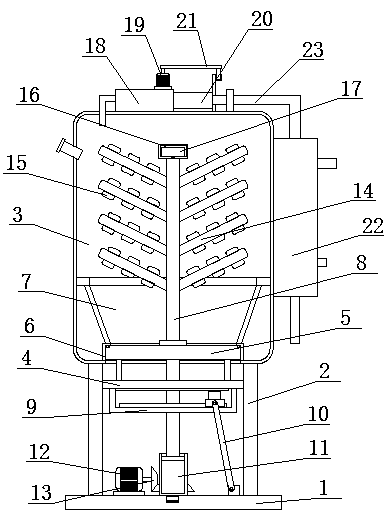

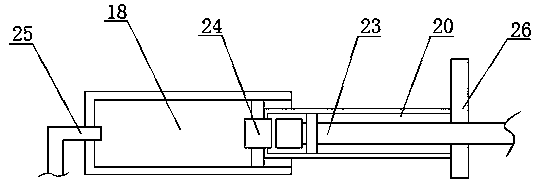

Device integrating temperature control and stirring

ActiveCN105617968AUniform temperatureKeep the temperature constantChemical/physical/physico-chemical stationary reactorsInert gas productionTemperature controlFluid phase

The invention relates to a device integrating temperature control and stirring. The volume of a tank body can be larger; an external heating device performs temperature regulation on liquid phase from the tank body; a stirring device is used for performing mechanical stirring on the liquid phase; an internal heating device is used for performing internal heating; gas is introduced to the inside of the tank body through a gas introducing space between a first rotating shaft and a second rotating shaft; the gas stirring is performed. By reasonably controlling the heating power of the external heating device and the internal heating device, the temperature of the liquid phase in the liquid phase reaction container maintains constant. The liquid phase reaction container is suitable for large-scale production, so that inside liquid phase substance ingredients and temperature are uniform.

Owner:LIAOYANG BEST CHEM IND CO LTD

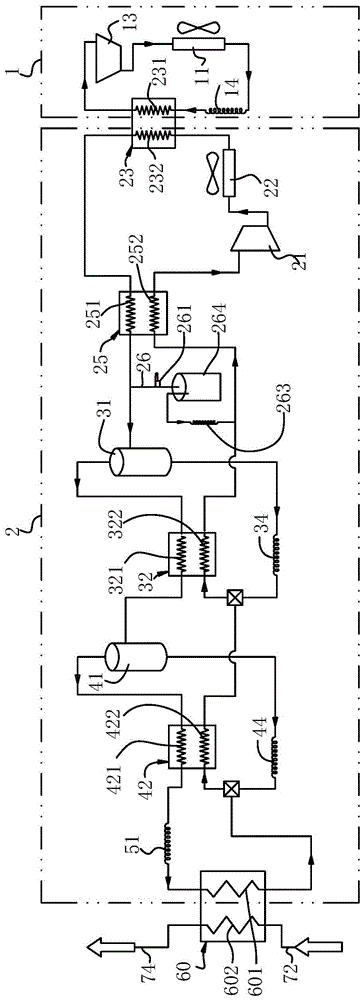

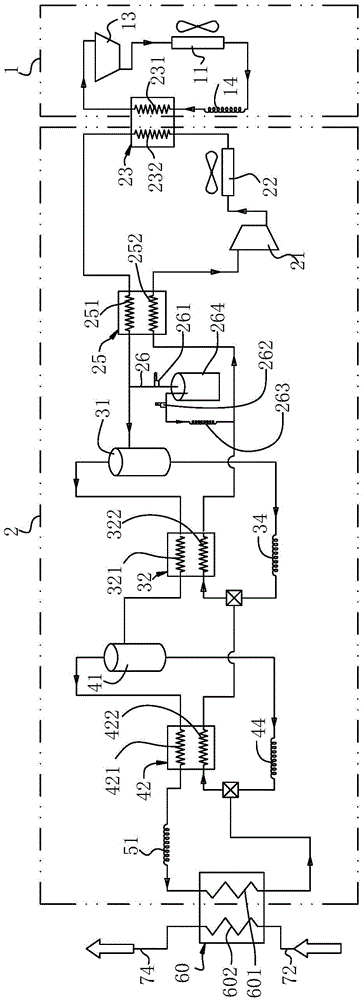

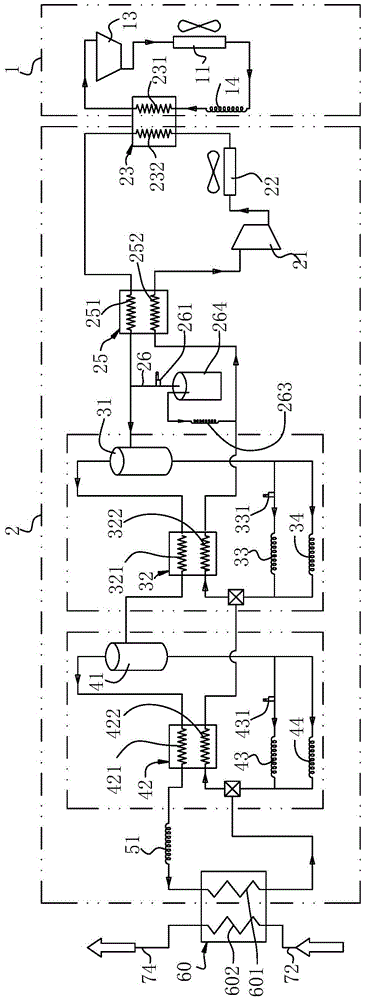

Ultralow-temperature auto-cascade type refrigerating device and refrigerating method

ActiveCN105605819AReduce startup timeImprove efficiencyMechanical apparatusCompression machines with cascade operationVapor–liquid separatorStart time

The invention provides an ultralow-temperature auto-cascade type refrigerating device and a refrigerating method. The refrigerating device comprises a pre-cooling unit and a multi-element refrigerant circulating unit connected with the pre-cooling unit through a pre-cooling heat exchanger. A main compressor, a main condenser, a medium passage I B of the pre-cooling heat exchanger, a regenerator, a first gas-liquid separator, a high-temperature medium flow passage I A of a first secondary heat exchanger, a second gas-liquid separator, a high-temperature medium flow passage I A of a second secondary heat exchanger, a main throttling element, a medium passage II A of a main evaporator, a low-temperature medium flow passage II B of the second secondary heat exchanger, a low-temperature medium flow passage I B of the first secondary heat exchanger and a medium passage III B of the regenerator are connected in sequence. A pressure release valve, a liquid storage tank and a pressure release bypass of a second throttling element are arranged between the outlet end of a medium passage III A and the inlet end of the medium passage III B and are connected in sequence. The invention further provides a refrigerating method using the refrigerating device. The refrigerating device and the refrigerating method have the advantages that starting time is short, a target temperature can be rapidly reached, and operation is safe and saves energy.

Owner:NANJING FORESTRY UNIV +1

Traditional Chinese medicine thread for treating sore and ulcer diseases and preparation method thereof

The invention discloses a traditional Chinese medicine thread for treating sore and ulcer diseases and a preparation method thereof. The traditional Chinese medicine thread is formed by dipping and attaching the following raw materials in parts by weight on a medical thread: 8-4 parts of roots of lilac daphne, 5-1 part of brucea javanica kernel, 5-1 part of croton seed, 5-1 part of Uroctea charcoal, 5-1 part of charred schizonepeta and 8-4 parts of dragon's blood. When the traditional Chinese medicine thread is used in clinic, the acute and chronic stages of sore and ulcer diseases are effectively considered, and the traditional Chinese medicine thread has the composite treatment effects of removing necrotic tissues, detoxifying, expelling pus, stopping bleeding, astringing and promoting tissue regeneration.

Owner:川北医学院附属医院

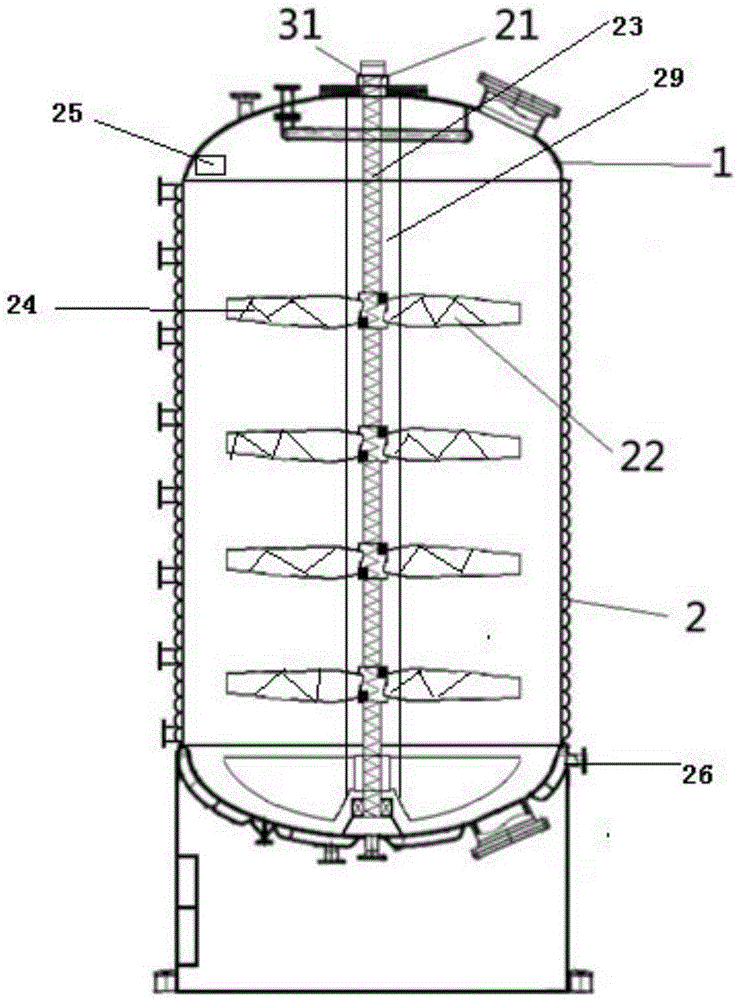

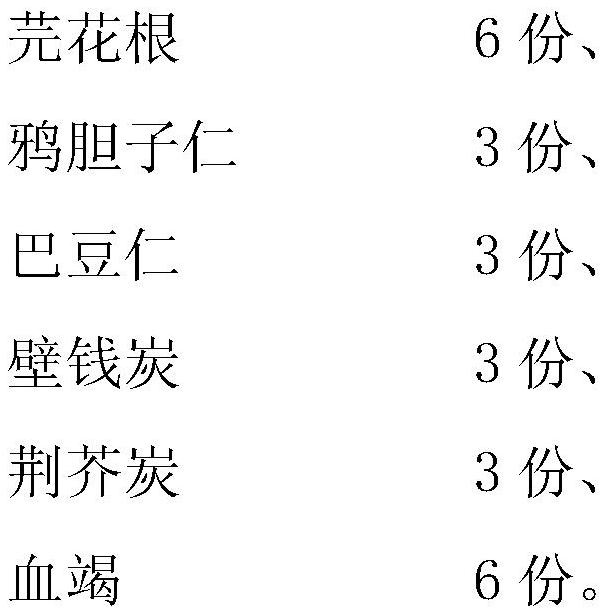

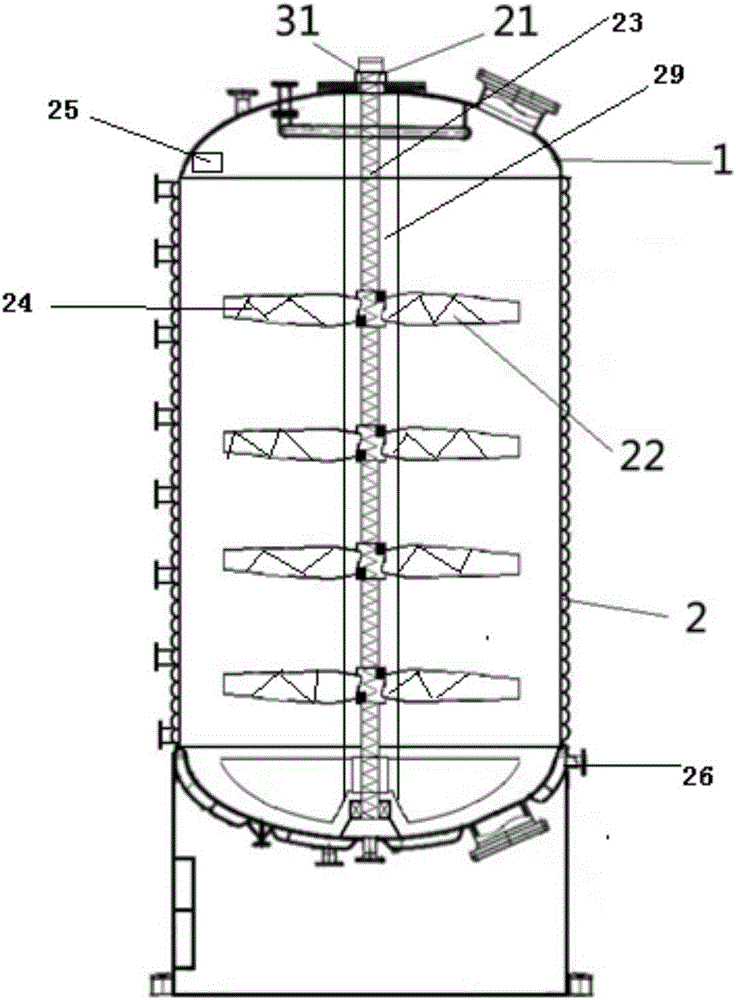

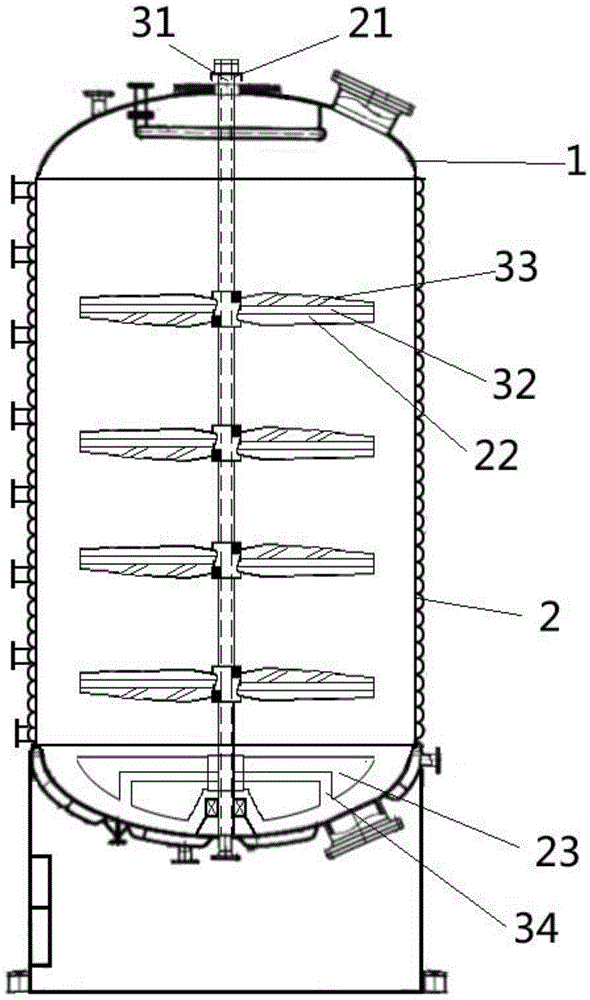

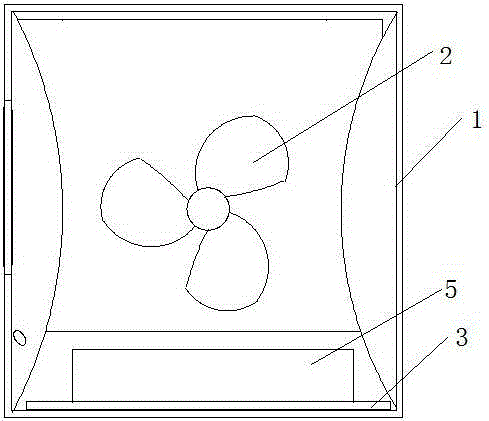

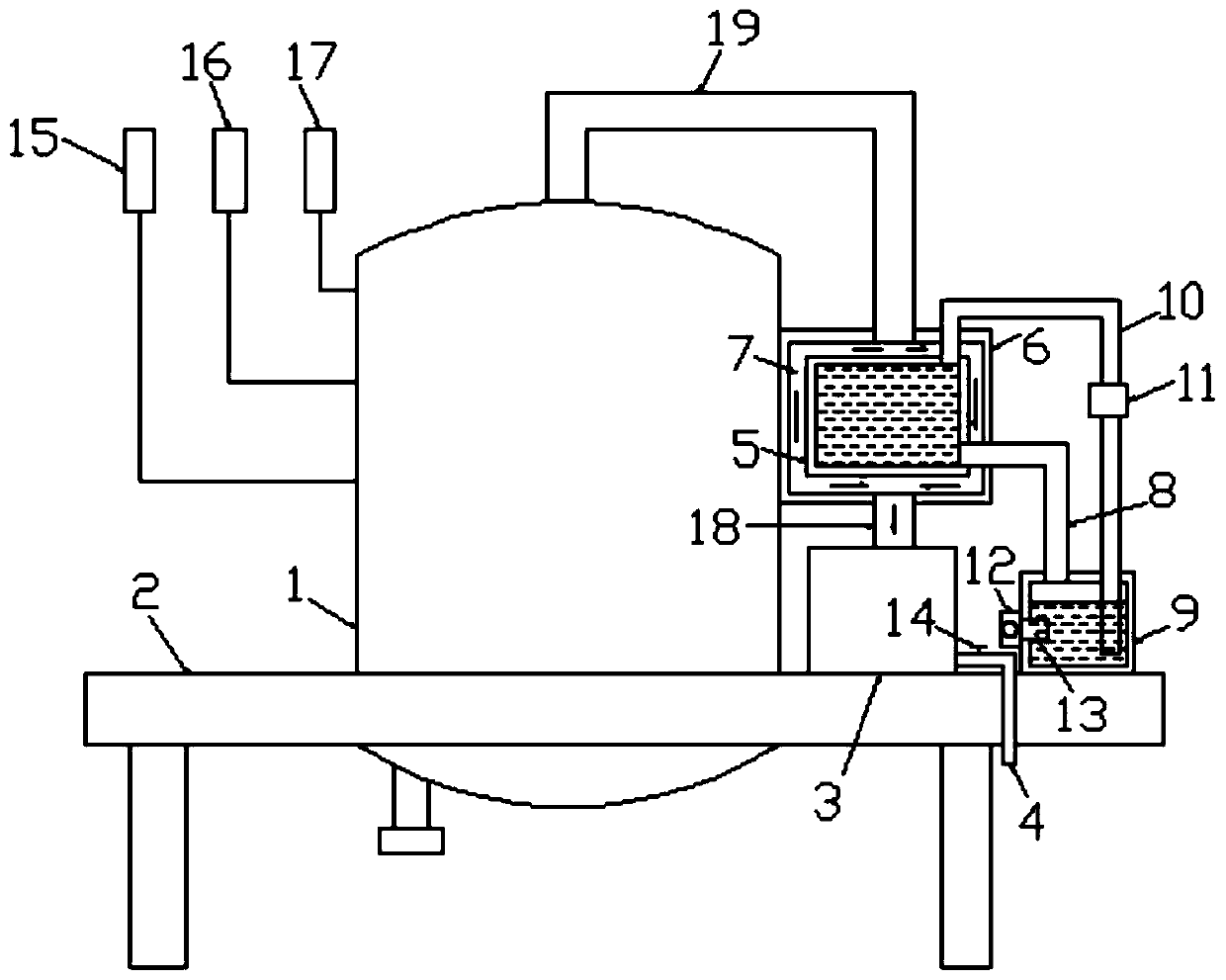

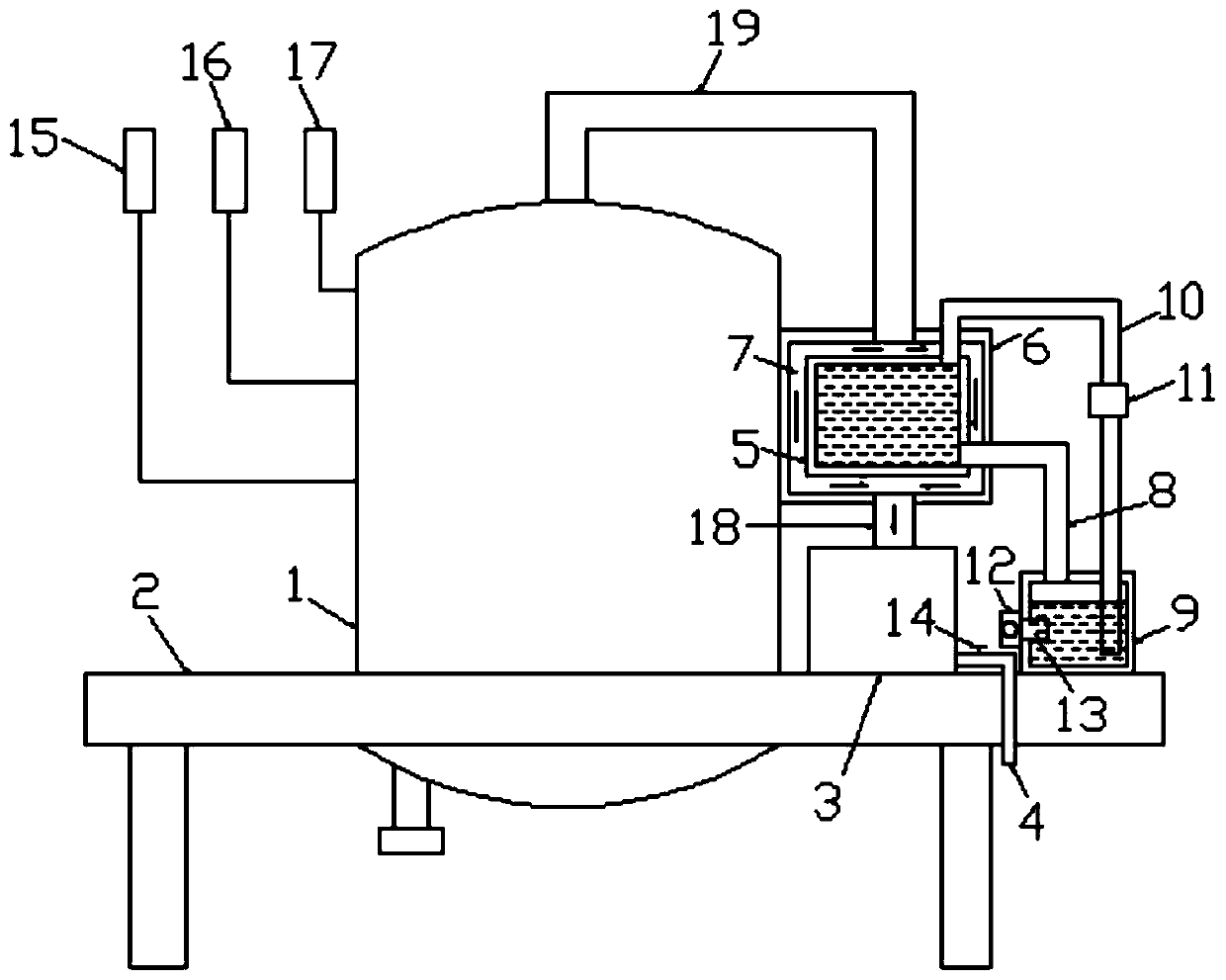

Reaction tower with pneumatic stirring device

ActiveCN105478070ASpeed up liquefactionEasy to liquefyTransportation and packagingMixer accessoriesMain channelEngineering

The invention relates to a reaction tower with a pneumatic stirring device, comprising a tower body and a stirring device, wherein the tower body is a cylinder and has a holding space; the stirring device comprises a rotary shaft which is arranged at the center position of the tower body along a vertical direction and capable of rotating under the driving of a power device and a plurality of paddles arranged on the rotary shaft at intervals along the axial direction of the vertical direction of the rotary shaft; the rotary shaft is hollow to form an air passage, main channels arranged along the axial directions of the paddles and lateral channels arranged by forming a certain angle with the main channels are formed in the paddles, the main channels are communicated with the air passage and extend towards the axial directions of the paddles to form main air nozzles, and the lateral channels are communicated with the main channels and extend towards the radial directions of the paddles to form lateral air nozzles.

Owner:金爱莲

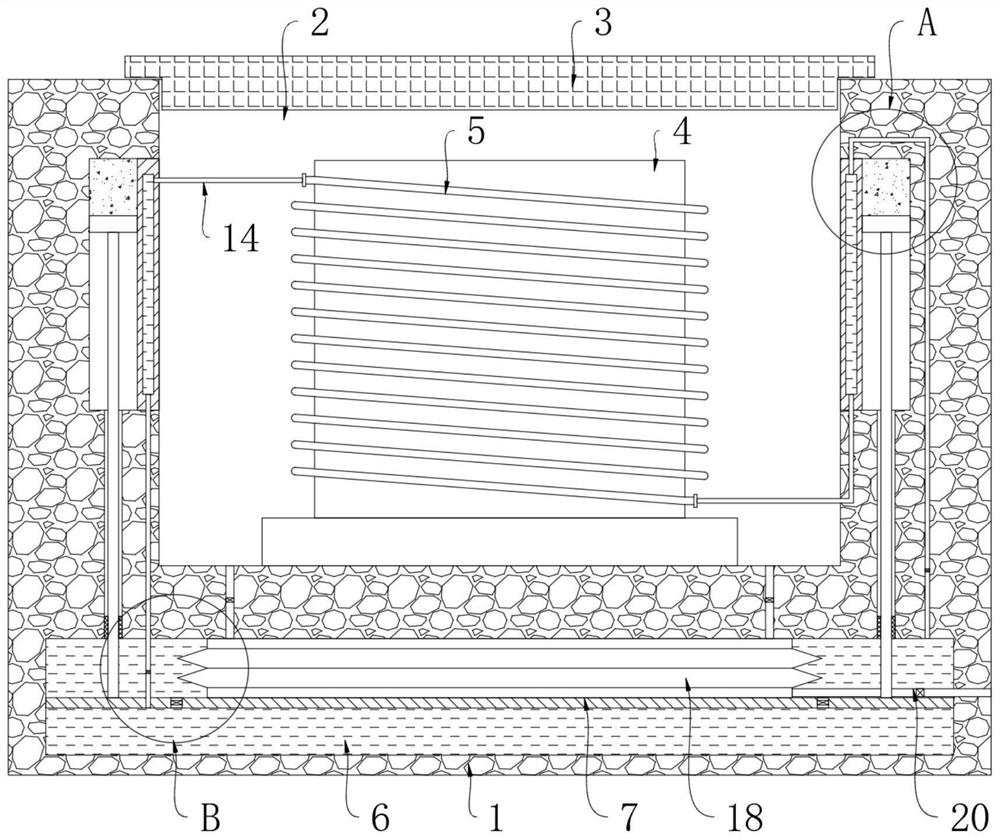

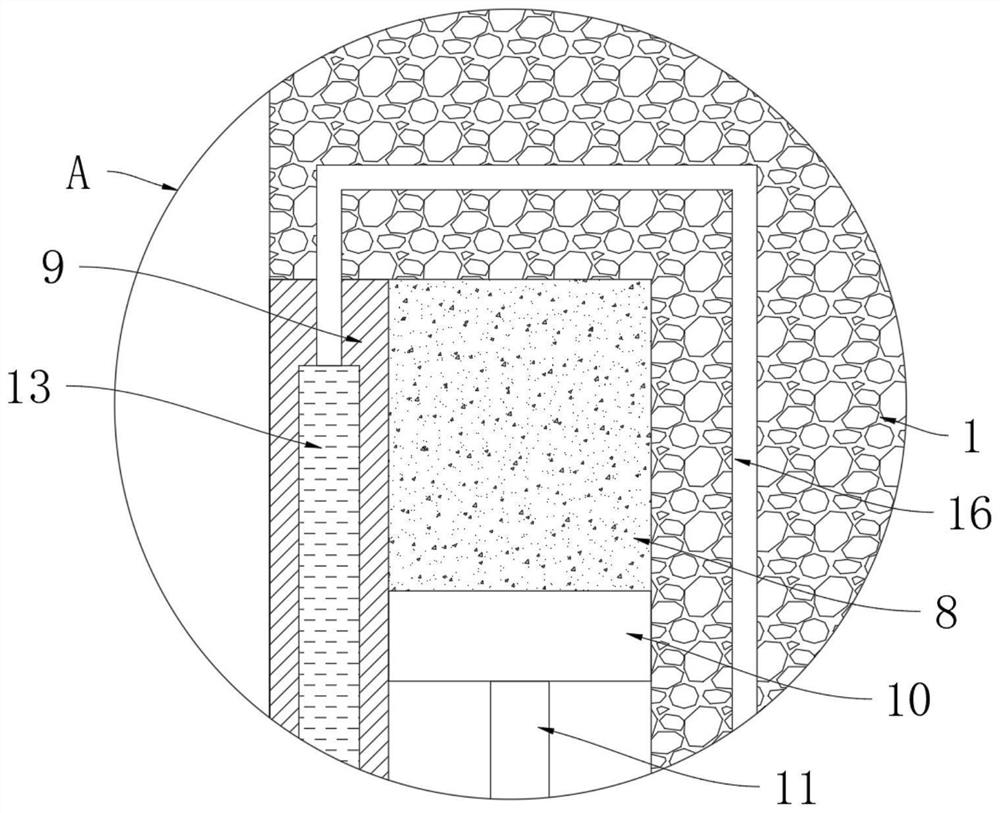

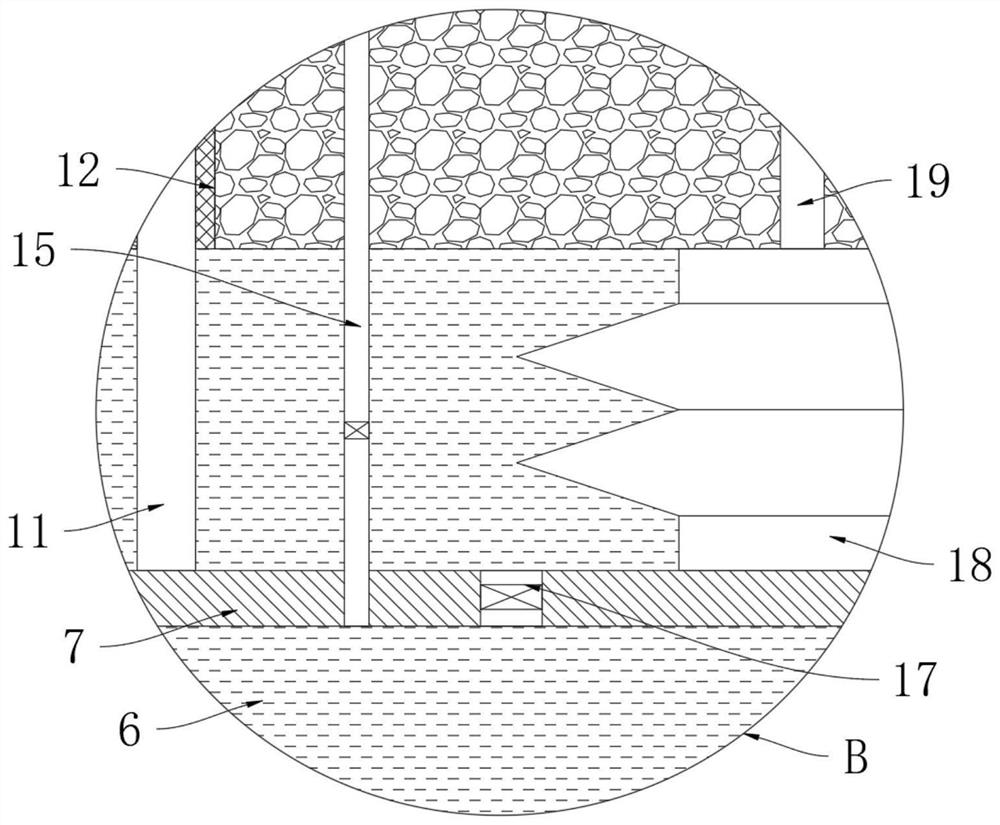

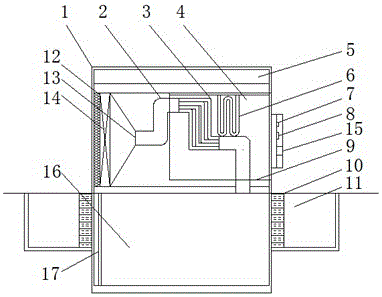

Buried waterproof heat dissipation type electrical cabinet

PendingCN113161880AIncrease the ambient temperatureGuaranteed to workSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsThermodynamicsEngineering

The invention discloses a buried waterproof heat dissipation type electrical cabinet which comprises a foundation, wherein an equipment groove is formed in the upper end face of the foundation, a cover plate is installed at a groove opening of the equipment groove, an electric power element is installed in the equipment groove, and a heat exchange pipe is arranged outside the electric power element in a winding mode. According to the invention, when the power element works at a high load and generates a large amount of heat in a short time, a driving agent absorbs the heat to cool the equipment groove again, and meanwhile, the driving agent drives a movable plate to move downwards to generate high pressure in a driving area and generate negative pressure in a driven area after absorbing the heat, so that the cooling liquid in the driving area flows through a heat exchange pipe, then heat dissipation and cooling can be further carried out on the power element, and the power element is prevented from being damaged due to overheating.

Owner:吴聪聪

Method for preparing purple sweet potato concentrated clear juice

The invention discloses a method for preparing purple sweet potato concentrated clear juice. The method comprises the following steps: pre-treating raw materials, crushing the raw materials, performing primary enzymolysis, squeezing, performing pasteurization, performing secondary enzymolysis, performing enzyme deactivation, performing ultra-filtration, concentrating, and filtering, so as to obtain a green and addition-free purple sweet potato concentrated clear juice product. The method is simple in process, vitamin C is used in the raw material crushing process so as to prevent product oxidation, nutrient substances in the raw material are extracted to the maximum extent by using enzyme, and the product clarity can be improved in a manner combining ultra-filtration and plate-frame filtration. According to the method, nutrition components in purple sweet potatoes can be extracted and maintained to the maximum extent, the concentrated juice is good in taste, and requirements of customers can be met.

Owner:威海元盛生物科技有限公司

Alcohol fermentation method

InactiveCN108165585AIncrease productionIncrease its profitsBiofuelsFermentationAlcoholPropanoic acid

The invention provides an alcohol fermentation method. The alcohol fermentation method comprises the following steps: a, slurrying: obtaining a starchy raw material, crushing the starchy raw material,and mixing with blending water to form a starch solution; b, liquefying: adding liquefying enzyme into the starch solution to obtain a liquefied solution, c, saccharifying: adding saccharifying enzyme into the liquefied solution to obtain a saccharified solution; d, fermenting: adding propanoic acid into the saccharified solution, and then inoculating with seed liquid for alcohol fermentation. Bythe alcohol fermentation method, through addition of the propanoic acid into the saccharified starch solution, the starch conversion rate during the alcohol fermentation can be increased to 90% or above; in addition, the added propanoic acid is low in cost, so that increase in the yield of alcohol and the profit thereof is facilitated.

Owner:江苏金茂源生物化工有限责任公司

Water-collecting device for arid area

InactiveCN105887971AIncrease contact surfaceSpeed up liquefactionBatteries circuit arrangementsGeneral water supply conservationActivated carbonEngineering

The invention discloses a water-collecting device for an arid area. The water-collecting device comprises a device body, an upper cover, an air guide pipe and a water tank, wherein an exhaust fan is arranged on the left side of the device body; a filter screen is arranged on the right side of the exhaust fan; an air inlet is formed in the right side of the device body; the right side of the air inlet is connected with the air guide pipe; a condenser box is mounted in the device body; a condensing rack pipe is mounted in the condenser box; a separating plate is mounted in the device body; the water tank is mounted at the bottom end of the separating plate; water-collecting boxes are mounted on the two sides of the device body; an activated carbon box is arranged in each of the water-collecting boxes; a water pump is arranged on the right side of the device body; the water pump is connected with the water tank through the water pipe; the upper cover is arranged at the top end of the device body; an automatic switch is mounted on the right side of the device body. A capillary tube is arranged in the air guide pipe of the water-collecting device for the arid area, the capillary tube is arranged in the condenser box, the contact area between the cold gas and the air is increased and the liquification rate is increased.

Owner:HARBIN GONGYANG SCI & TECH CONSULTATION CO LTD

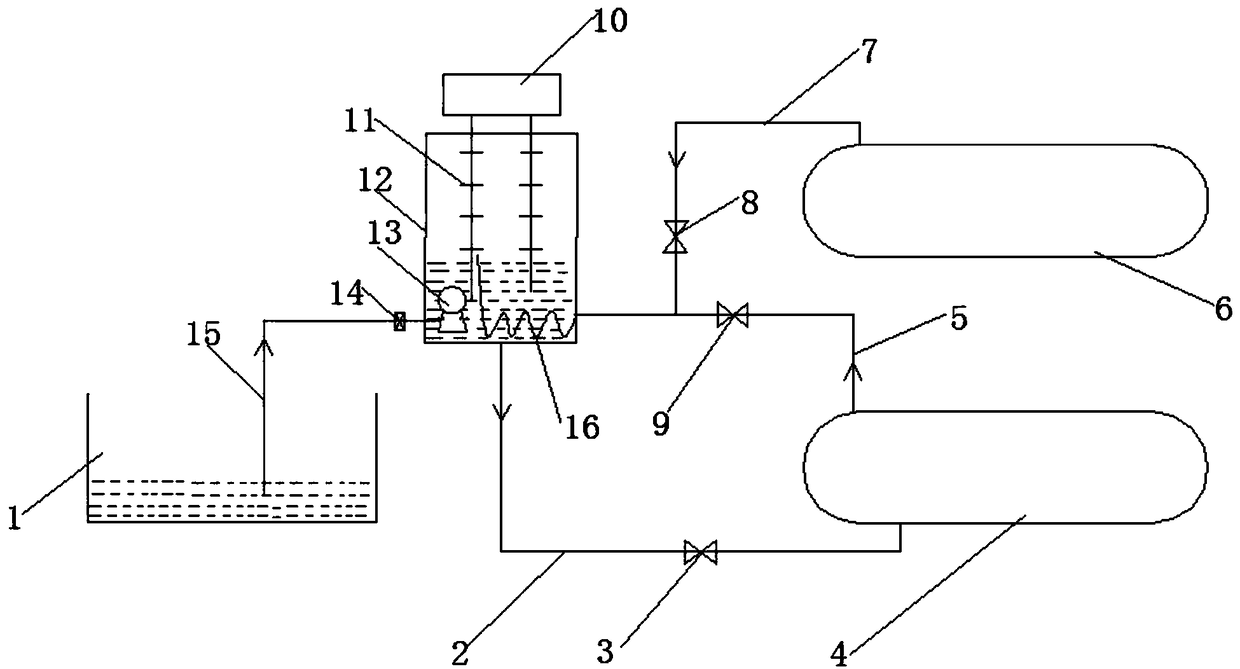

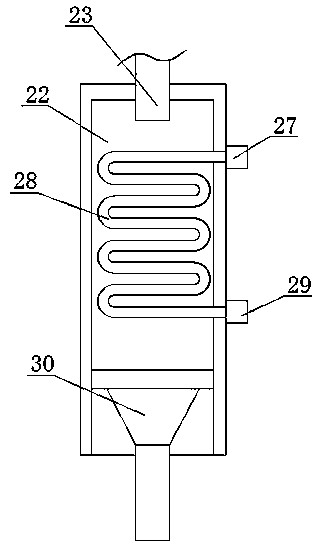

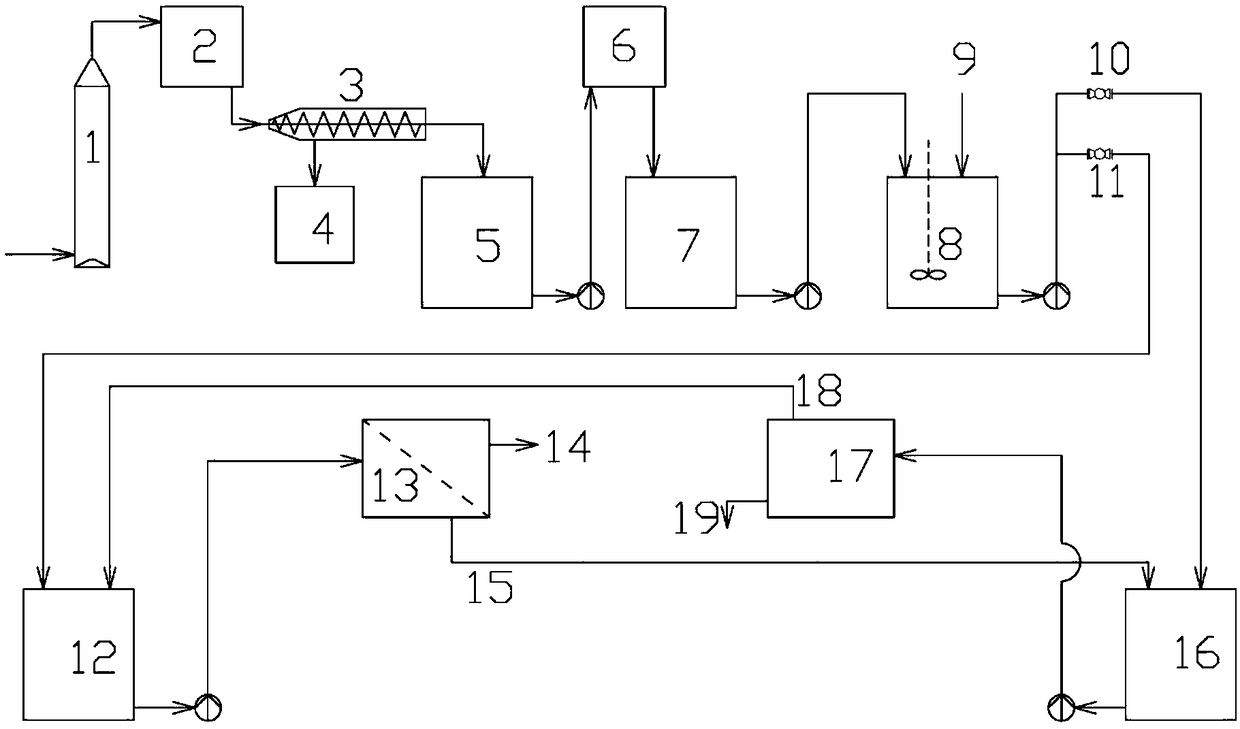

Liquefied natural gas leakage recovery and boil-off gas recovery device

InactiveCN108799823AAchieve recyclingHarm reductionSolidificationLiquefactionInlet valveProcess engineering

The invention discloses a liquefied natural gas leakage recovery and boil-off gas recovery device and particularly relates to the technical field of leakage recovery of liquefied natural gas (LNG) andrecondensation and liquefaction recovery of boil-off gas (BOG). The liquefied natural gas leakage recovery and boil-off gas recovery device comprises a buffer adiabatic tank, and a cryogenic refrigerating machine is arranged on the buffer adiabatic tank. A cold head heat exchanger extending to the inner part of the buffer adiabatic tank is arranged on the cryogenic refrigerating machine, and a cryogenic immersed pump and a double pipe heat exchanger are arranged in the inner part of the buffer adiabatic tank. A liquid inlet pipeline, a liquid return pipeline, a storage-tank boil-off gas inletpipeline and a tank-car boil-off gas inlet pipeline are connected on the buffer adiabatic tank. The tail end of the liquid inlet pipeline is connected with the cryogenic immersed pump, and the tail end of the storage-tank boil-off gas inlet pipeline and the tail end of the tank-car boil-off gas inlet pipeline are both connected with the double pipe heat exchanger. A liquid return control valve isarranged on the liquid return pipeline, a storage-tank gas inlet valve is arranged on the storage-tank boil-off gas inlet pipeline, and a control valve is arranged on the tank-car boil-off gas inletpipeline.

Owner:CHINA PETROLEUM & CHEM CORP +1

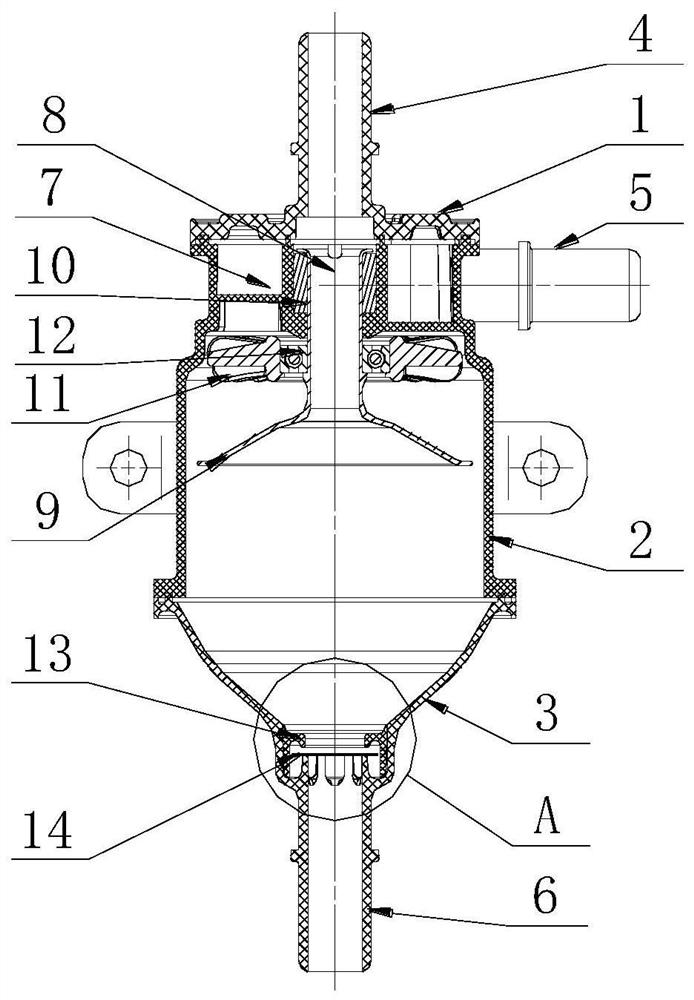

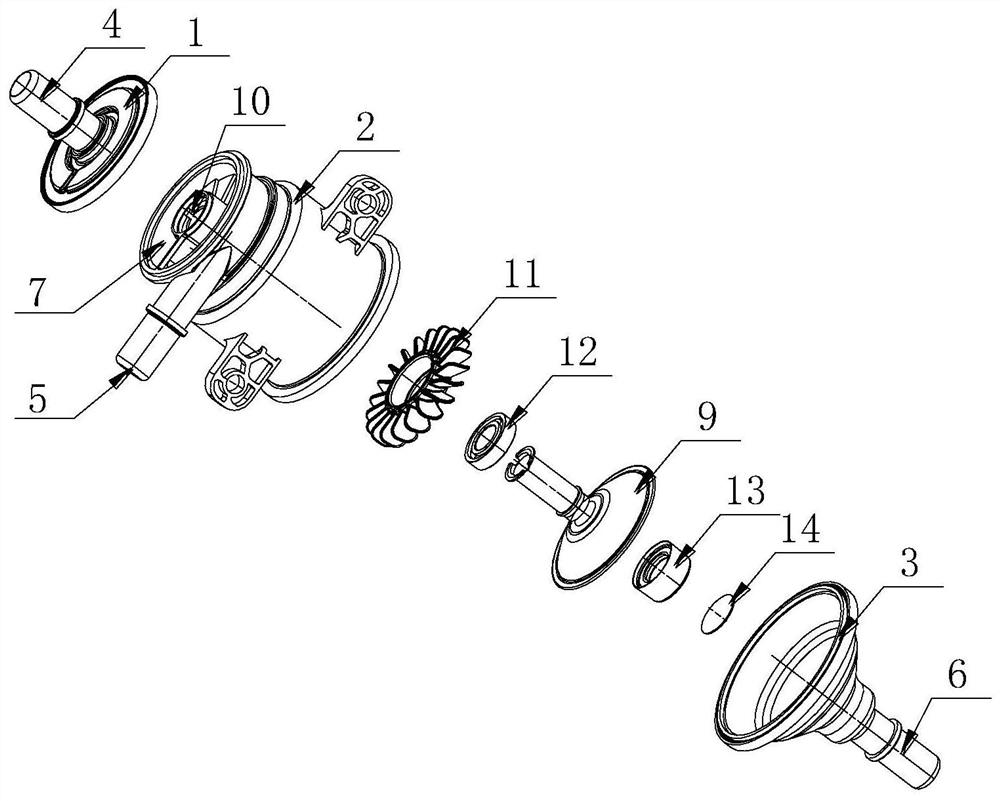

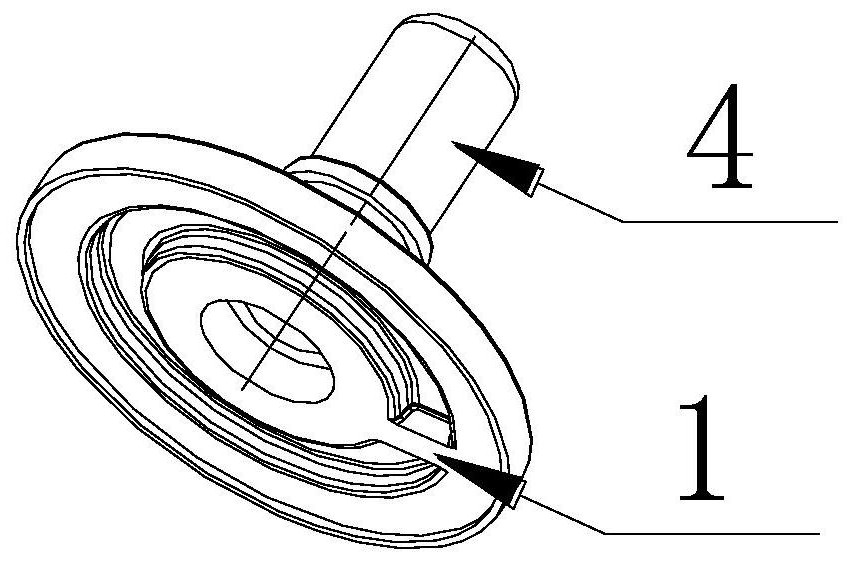

A fuel vapor liquefaction recovery device and its fuel evaporation discharge system

ActiveCN111336040BSmall effective volumeLow costMachines/enginesCondensed fuel collection/returnImpellerEngineering

Owner:DONGFENG MOTOR CORP HUBEI +1

Container with bottom auxiliary heating device and auxiliary heating method

ActiveCN102730346ALiquefaction in timeUnload in timeLarge containersTank wagonsInsulation layerAuxiliary heating

The invention relates to a container with a bottom auxiliary heating device and an auxiliary heating method realized by using the container. The container with the bottom auxiliary heating device comprises an inner container body, an outer container body, a heat insulation layer, a heating pipe and the auxiliary heating device, wherein the outer container body is sleeved at the outer part of the inner container body, the heat insulation layer is arranged between the inner container body and the outer container body, the heating pipe is arranged at the inner part of the inner container body, and the auxiliary heating device is arranged between the bottom of the container and the insulation layer. Materials deposited at the lower part of the heating pipe at the bottom of the inner container body are heated, the materials at the bottom are liquefied in time and conveniently and promptly unloaded in time and the residue amount of the materials at the bottom of the container is decreased by the auxiliary heating device.

Owner:TIANJIN ZHAOHUA LOGISTICS CO LTD

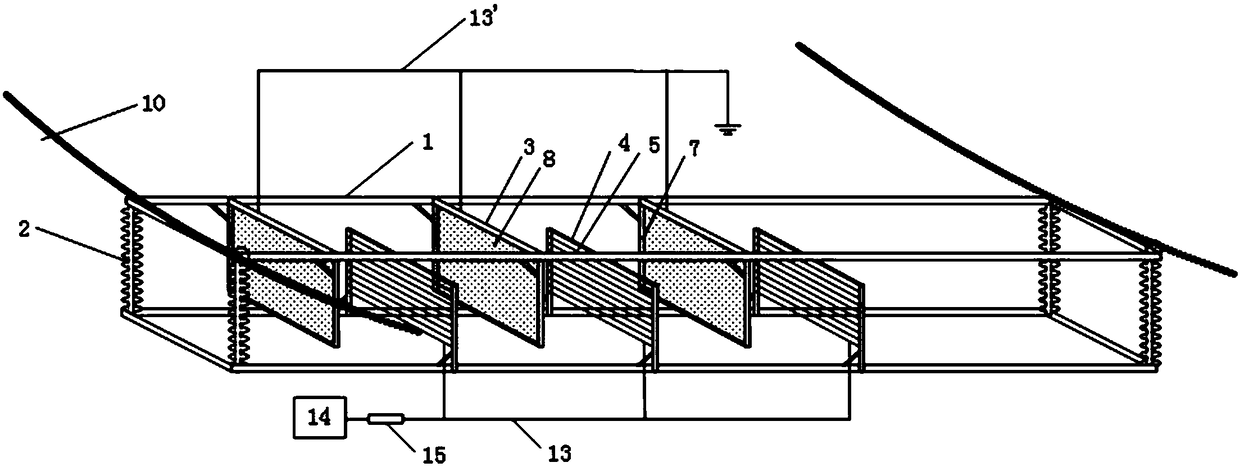

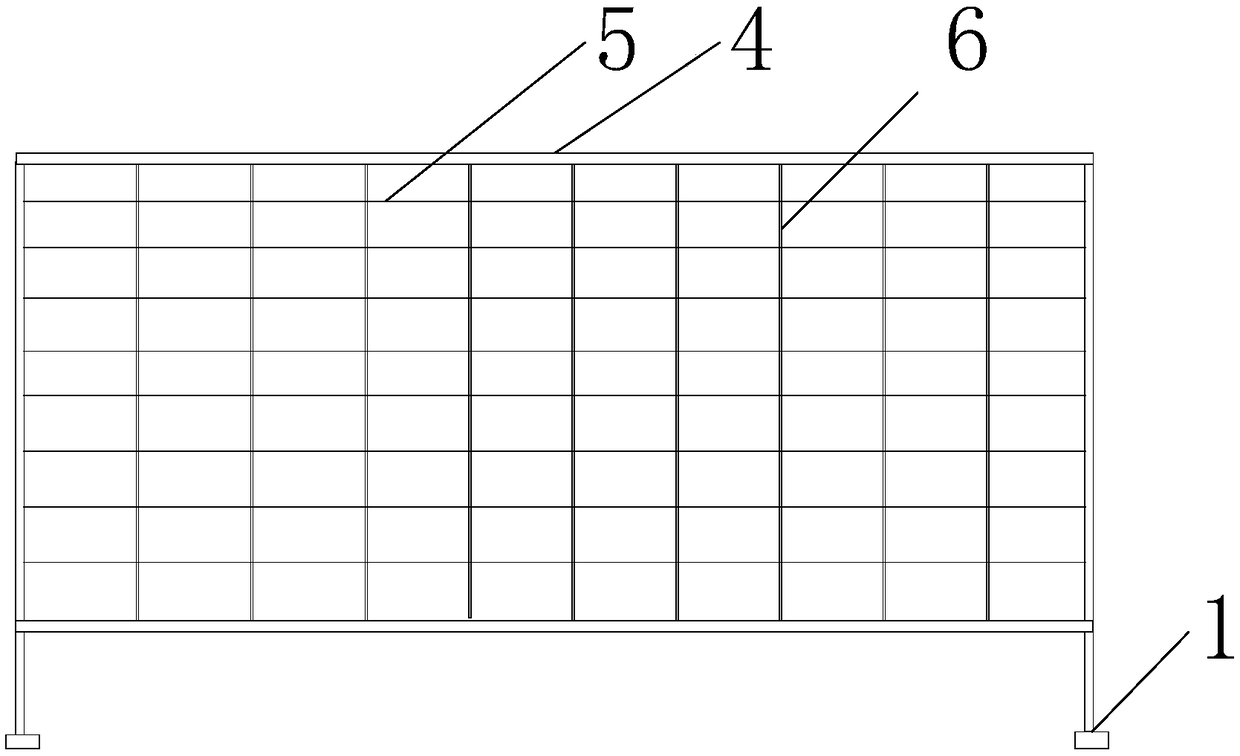

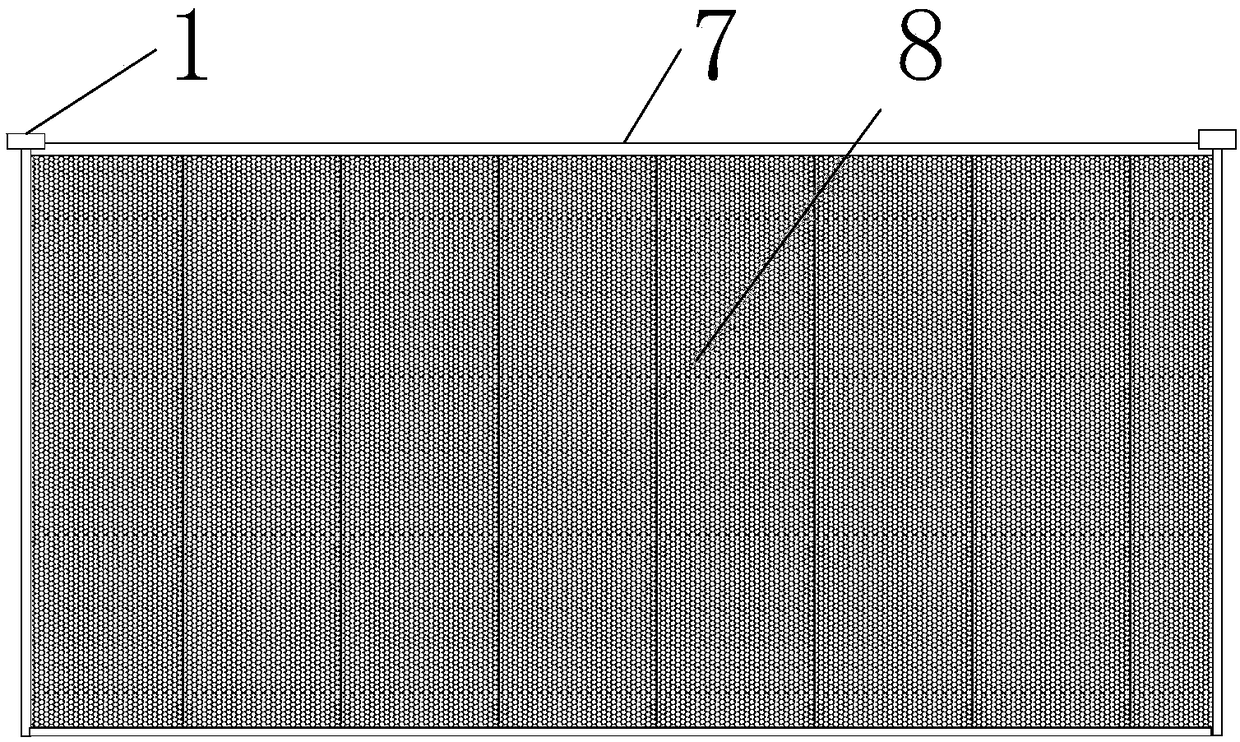

A multi-stage parallel multi-line-water film electrode ion wind cooling tower water recovery device

ActiveCN105890437BImprove recycling efficiencyIncrease collisionTrickle coolersCooling towerEvaporation

The invention discloses a multistage, parallel and multiline-water film electrode ion wind cooling tower water recovery device which comprises a multiline-water film electrode module set formed by connecting multistage and multiline-water film electrode modules in parallel. The multiline-water film electrode module set is arranged on the top of a large natural ventilation cooling tower. Each multiline-water film electrode module comprises silicon rubber compound insulator strings arranged on the periphery of a module supporting bracket, wherein multiple water film electrodes perpendicularly distributed are arranged in the module supporting bracket in parallel; multiline electrodes which are parallel to the water film electrodes and have an electrode interval are arranged at intervals along the water film electrodes; the multiple multiline electrodes are connected in a high-voltage direct-current power source in parallel through a connecting wire; and the water film electrodes are connected with the ground through a connecting wire. The multiple module supporting brackets are connected in a multistage and parallel manner through a supporting rope and conduct covering along the surface of an ion wind excitation area of the cooling tower. By means of the device, a multiline-water film electrode manner is adopted, generated ion jet flow and water mist in up flow of the cooling tower are combined, and the evaporation water damage recovery rate of water is increased by 12% to 45%.

Owner:XI AN JIAOTONG UNIV

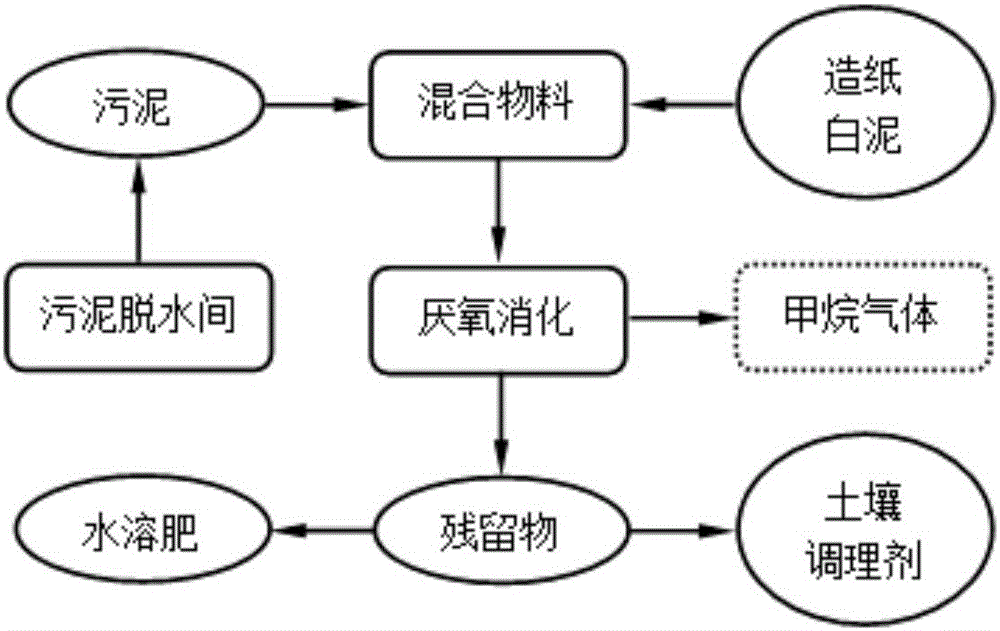

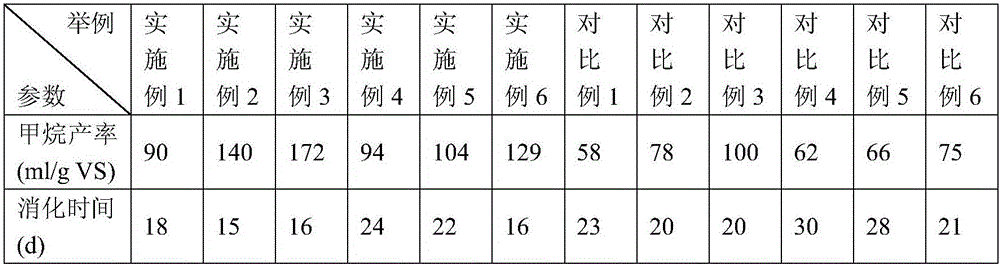

Sludge anaerobic digestion additive and method for promoting methane production through additive

ActiveCN105693057AAccelerates the rate of hydrolysis and acidificationIncreased methanation efficiencyWaste based fuelBiological sludge treatmentMethanationMethane yield

The invention relates to a sludge anaerobic digestion additive and a method for promoting methane production through the additive. The method includes the steps of putting 0.1-1.0% of dry papermaking white mud in sludge to be stirred with water to obtain a mixture material with the pH value of 7.5-8.0 and the solid content of 5-15%, putting the mixture material in an anaerobic reactor, and conducting sludge anaerobic digestion over stirring at a constant temperature of 35-38 DEG C or 53-55 DEG C. Papermaking white mud produced in sulfate method pulping, papermaking and causticizing procedures serves as the sludge anaerobic digestion additive, and the dynamic balance of sludge hydrolytic acidification and methanation is regulated and controlled in an oriented mode; the digestion time is shortened by 15-25%, and the methane yield is increased by 40-80%. Operation is easy, running expenses are low, and the pollution of papermaking white mud and sludge to the environment is reduced; after residues produced after sludge anaerobic digestion are subjected to solid-liquid separation, biogas residues serve as a soil conditioner and are directly applied to soil, and biogas slurry is directly used as water-soluble fertilizer.

Owner:QILU UNIV OF TECH

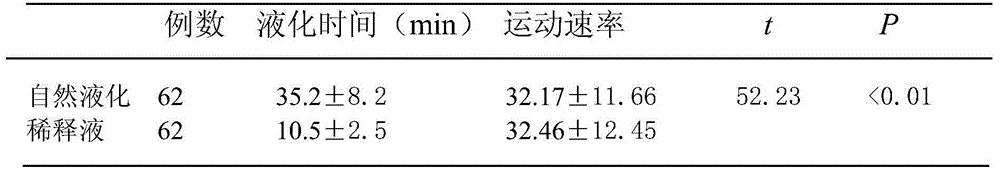

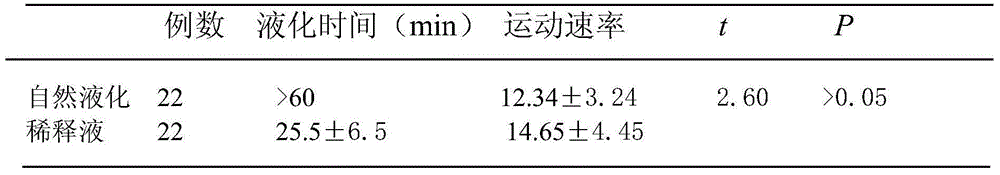

Sperm diluent preparing method

The invention discloses a sperm diluent preparing method and belongs to the technical field of medical examination. A diluent prepared with the method contains substances such as glucose, citric acid, sodium citrate, yolk, glycerol, N-acetyl-L-cysteine, penicillin and the like. The diluent does not affect motility and quality of sperms and can shorten the semen liquidation time and the patient waiting time, detection of indexes such as the number, the motility, the malformation condition and the like of the sperms can also be performed on a patient whose semen is not liquidized, and the motility of the sperms can be kept for a long time. The detection method which is simple in pretreatment, quick, sensitive, cheap and capable of realizing long-acting preservation is applicable to conventional detection of the semen.

Owner:TIANJIN BAODI HOSPITAL

Preparation method of silicon carbide press balls

The invention discloses a preparation method of silicon carbide press balls used in steel-making deoxygenation, which is implemented by smashing bulk silicon carbide into granules with diameter being within 3mm to be as ingredient and sieving; mixing starch weighing 2-3% of silicon carbide ingredient and water weighing 5-7% of silicon carbide ingredient in a container and agitating to made starch slurry to be as adhesive; taking fluorite powder weighing 5-10% of silicon carbide ingredient to be as auxiliary material; adding sieved silicon carbide granules, auxiliary material fluorite powder and adhesive starch slurry into a drum-type agitator for agitating for 15-20 minutes; taking uniformly agitated silicon carbide doped with starch slurry and fluorite powder out of the agitator and directly putting into a ball press for wet pressing; and drying the formed press balls until moisture is within 0.5%. The silicon carbide press balls in the invention has equal size and uniform chemical ingredient content, thus enhancing molten steel quality and easiness of steel-making time control, lowering melting point of silicon carbide, reducing dust and improving operating conditions of workers.

Owner:西峡县合力冶金辅料有限公司

Temperature control and stirring integrated device

InactiveCN105688782AGuaranteed uniformityMaterial composition and temperature uniformityChemical/physical/physico-chemical stationary reactorsInert gas productionEngineeringHeating power

The invention relates to a temperature control and stirring integrated device. The volume of a tank can be huge; an external heating device is used for adjusting temperature for the liquid phase from the exterior of the tank; a stirring device is used for mechanically stirring the liquid phase; an internal heating device is used for internally heating; a ventilating space between a first rotating shaft and a second rotating shaft is utilized to introduce air into the tank, for performing air stirring. The temperature of the liquid phase in a liquid phase reaction vessel can be kept constant by reasonably controlling the heating power of the external heating device and the internal heating device. The liquid phase reaction vessel is fit for mass production and is capable of causing the components and temperature of the inner liquid phase matters be uniform.

Owner:山东瀚华工程设计有限公司

Sewage treatment device for environmental engineering

InactiveCN111072085AAchieve clearingSpeed up liquefactionWater/sewage treatment by heatingWater/sewage treatment apparatusLiquid waterSewage treatment

The invention discloses a sewage treatment device for environmental engineering. The sewage treatment device comprises a base. Two stand columns are symmetrically and fixedly mounted at the top of thebase; the same evaporation box is fixedly mounted at the top ends of the two stand columns; the sides, close to each other, of the two stand columns are slidably connected with the same moving plate.A sealing plate is fixedly installed at the top of the moving plate, a sealing ring is fixedly installed on the inner wall of the bottom of the evaporation box, a moving hole is formed in the inner wall of the bottom of the evaporation box, and the top of the sealing plate extends into the sealing ring and is attached to the inner wall of the sealing ring in a sealed mode. The evaporation principle is utilized, water can be heated into gas to be separated from silt, and steam can be quickly cooled to form liquid water under the action of condensation so that existing filtering equipment is not needed for filtering in use, the silt can be thoroughly separated from the water, and the device is very convenient to use.

Owner:南京瑞碧斯生物科技有限公司

High-molecular-polymer reaction vessel

ActiveCN105617938AAdequate responseUniform responseChemical/physical/physico-chemical stationary reactorsPressure vessels for chemical processSoft waterEngineering

The invention relates to a high-molecular-polymer reaction vessel. A stirring device and a steam leading-in mechanism are integrated, high-temperature steam circulating channels are formed in a rotating shaft and paddles of the stirring device, and high-temperature steam is sprayed out from steam spraying openings in the paddles; as the multiple paddles and the multiple steam spraying openings are located inside a tank, the effect of dispersing steam can be achieved, liquidation of the steam in the tank is promoted, heat carried by the steam is fully released into the tank, and soft water serving as a production raw material of a high-molecular polymer is formed after the steam is liquefied; in addition, the paddles and the steam spraying openings can rotate along with the rotating shaft, the steam more evenly reaches all the parts in the tank, the stirring effect of the high-temperature steam on the raw materials of the high-molecular polymer in a kettle is improved, the high-molecular polymer is more fully and evenly reacted accordingly, the content of un-reacted polymeric monomers is low, and the molecular weight of the high-molecular polymer is even.

Owner:山东万达化工有限公司 +1

High-yield glucose production method

The invention discloses a high-yield glucose production method. The method comprises the following steps of: starch mixing; jet liquefaction; flash evaporation thickening; primary enzyme inactivation; saccharification; filtering; secondary enzyme inactivation; decolorizing; ion-exchange impurity removal; evaporative crystallization; and drying, wherein the jet liquefaction comprises primary jet liquefaction and secondary jet liquefaction; and the flash evaporation thickening comprises primary flash evaporation after the primary jet liquefaction and secondary flash evaporation after the secondary jet liquefaction. By using an integrated production process of the secondary jet liquefaction and liquefaction evaporation, the method improves liquefaction and saccharification effects, product quality and the yield, wherein the yield of glucose reaches 108 weight percent; and the method effectively utilizes the energy resource in the production and reduces the energy consumption in the production.

Owner:WEIFANG SHENGTAI PHARM CO LTD

Intelligent efficient ultrasonic atomization industrial humidifier

ActiveCN105276739AAccelerateImprove the humidification effectMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringUltrasound

The invention discloses an intelligent efficient ultrasonic atomization industrial humidifier. The intelligent efficient ultrasonic atomization industrial humidifier comprises a tank, a fan, a control circuit board, an integrated atomization assembly and a control device, wherein an exhaust opening is formed in the upper portion of the tank; the integrated atomization assembly is arranged on the control circuit board which is further provided with a high frequency electronic oscillating circuit and an energy conversion sheet; the integrated atomization assembly is provided with an integrated atomization movement. According to the intelligent efficient ultrasonic atomization industrial humidifier, the fan is arranged above the tank, water vapor atomized by the integrated atomization assembly can be quickly discharged out of the humidifier, and both the water vapor discharge speed and the water vapor liquidation speed are increased, so that the humidification effect of the humidifier is enhanced. Meanwhile, a sensing module, a self-detection module and an alarm are additionally arranged, so that the whole humidifier operates automatically and intelligently and meets the demands of customers better.

Owner:苏州腾辉环保科技有限公司

Device and method for preparing starch sugar for high-temperature corn drying

ActiveCN108893509AReduce modified starch contentSpeed up liquefactionBioreactor/fermenter combinationsBiological substance pretreatmentsFlocculationProduction effect

The invention relates to a device and method for preparing starch sugar for high-temperature corn drying. The method comprises the following steps: increasing the input concentration of coarse starchmilk which is processed from corn, separating the coarse starch milk through a disk type separator to obtain starch milk with reduced content of gluten water and modified starch; liquifying and separating the starch milk to obtain a starch milk light phase; saccharifying the starch milk light phase, performing protein flocculation on the saccharified liquid, and performing post-treatment to obtainthe starch sugar. According to the method, the content of modified starch in starch milk can be reduced, the liquifying and saccharifying effect can be greatly improved, and the integral production effect is remarkably promoted.

Owner:国粮武汉科学研究设计院有限公司

Method for producing glucose

The invention discloses a method for producing glucose. The method comprises the following steps of: mixing starch, performing jet liquefying, thickening through flash evaporation, killing enzyme for the first time, saccharifying, filtering, killing enzyme for the second time, decoloring, removing impurities through ion exchanging, evaporating and crystallizing and drying, wherein in the step of starch mixing, starch raw material powder is mixed with water so as to obtain farinaceous size which is mixed with amylase so as to obtain a mixture, in the step of jet liquefying, the mixture is liquefied through jetting so as to obtain a primary mixture, the primary mixture and the amylase are mixed and then liquefied through jetting for the second time so as to obtain a secondary mixture, and the step of thickening through flash evaporation comprises primary flash evaporation after jet liquefying for the first time and secondary flash evaporation after jet liquefying for the second time. According to the method, the production technology integrating jet liquefying for two times and liquefying evaporation is adopted, so that the liquefying and saccharifying effect is improved, the product quality and the product yield are improved, the yield of the glucose reaches 108wt%, furthermore, the energy source in the production is effectively used, and the energy consumption for production is lowered.

Owner:郑全来

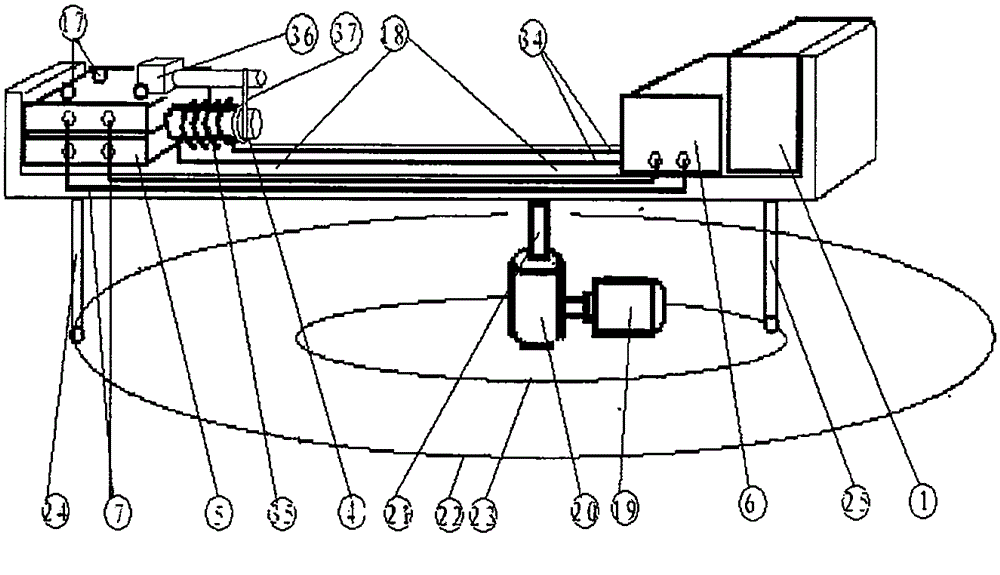

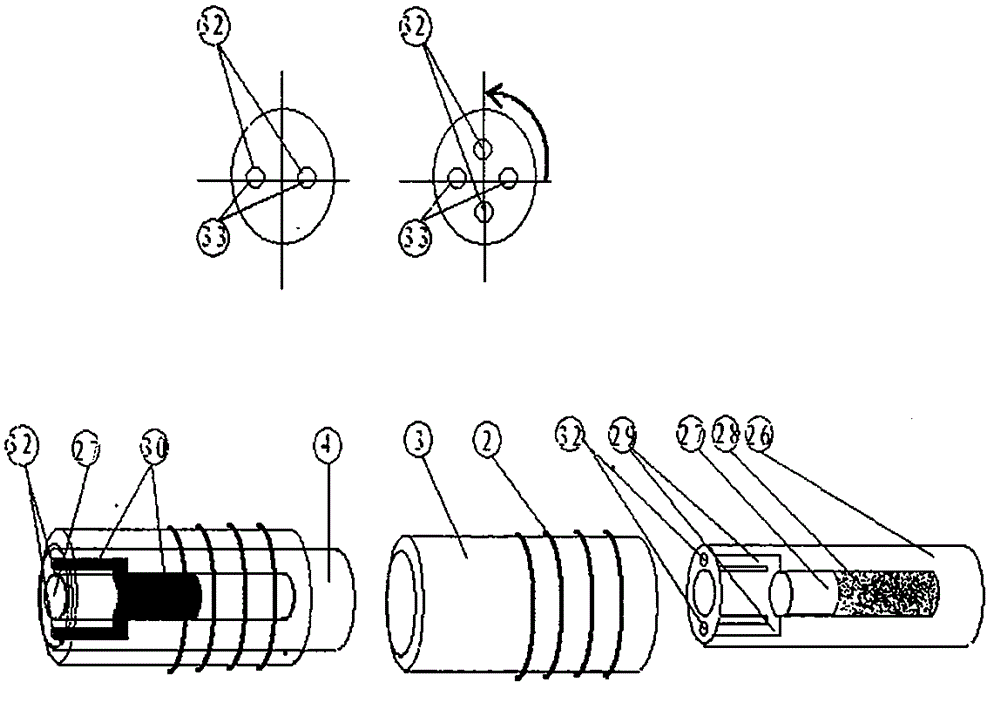

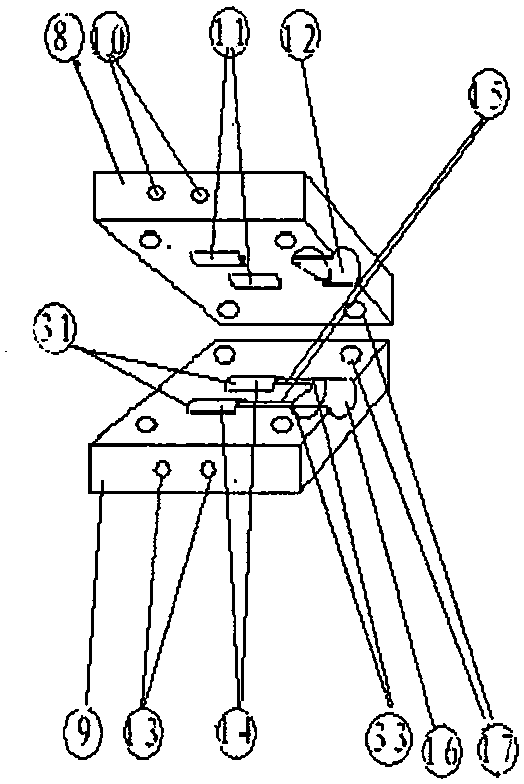

Manufacturing method and device for mono-crystal-like turbofan aviation engine blade

The invention designs a method and device for forming and casting a turbofan aviation engine blade with performance similar to that of monocrystal metal alloy materials at a time by using low-specific-gravity large-bulk non-crystal metal alloy as raw materials and simulating the work environment of an airplane engine blade ruing load operation through the adoption of the technology of integration of a high speed centrifuge, a high-frequency rapid melting furnace and a constant-temperature metal mold, and the like. The blade does not have a metal crystal structure and does not have lattice imperfection, either. The blade has the unique whole-body consistency characteristic of monocrystals. Compared with an existing alloy blade and an existing monocrystal alloy blade, the rigidity, the elasticity, the tenacity, the high-temperature resistance and the fatigue resistance are better, and one-time forming can be achieved; and the manufacturing technology is simplified, the performance is improved, and manufacturing cost is also reduced. Thus, the invention has the dual functions of new material manufacturing and new material application, belongs to the technical field of new metal materials and is suitable for producing and manufacturing various types of turbofan engines in the spaceflight and aviation field and the like.

Owner:刘南林

Recovery device for methyl tert-butyl ether

PendingCN111153777AGuaranteed cooling effectSpeed up liquefactionVapor condensationEther preparation by compound additionWater pipeMethyl palmoxirate

The invention belongs to the field of chemical production devices, and concretely discloses a recovery device for methyl tert-butyl ether. The recovery device comprises a reaction kettle and a supporting frame; a collecting box and a circulating water tank are arranged on one side of the top of the supporting frame; a discharging pipe is arranged at the bottom of one side of the collecting box, the top of the collecting box is communicated with a cooling box mechanism through a first connecting pipe, the cooling mechanism comprises an inner cooling box and an outer cooling box, and a cavity isformed between the inner cooling box and the outer cooling box; a drain pipe is arranged on one side of the outer cooling tank; one end of the drain pipe is connected with the circulating water tank;a water inlet pipe is arranged in the circulating water tank, and the top end of the water inlet pipe penetrates through the circulating water tank and is connected with the inner cooling box; a refrigerator is mounted on one side of the circulating water tank; the output end of the refrigerator is inserted into the circulating water tank and is connected with a cold water pipe; and the top of the reaction kettle is connected with a second connecting pipe, and one end of the second connecting pipe is communicated with the cavity. The collection speed of methyl tert-butyl ether generated by the waste is increased, and the recovery efficiency is improved.

Owner:ANHUI HAIDE PETROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com