Structure for heat radiation middle frame or heat radiation rear case, heat radiation middle frame or heat radiation rear case and manufacturing method of heat radiation middle frame or heat radiation rear case

A rear shell and heat dissipation plate technology, which is applied in the fields of telephone structure, cooling/ventilation/heating modification, modification with liquid cooling, etc., can solve the problem of limited thickness design space, difficulty in effectively exerting the heat dissipation effect of gas-liquid change circulation, and hollow sealing Cavity deformation and other problems, to achieve the effect of accelerating heat circulation and dissipation, contributing to the efficient circulation of gas and liquid, and reducing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

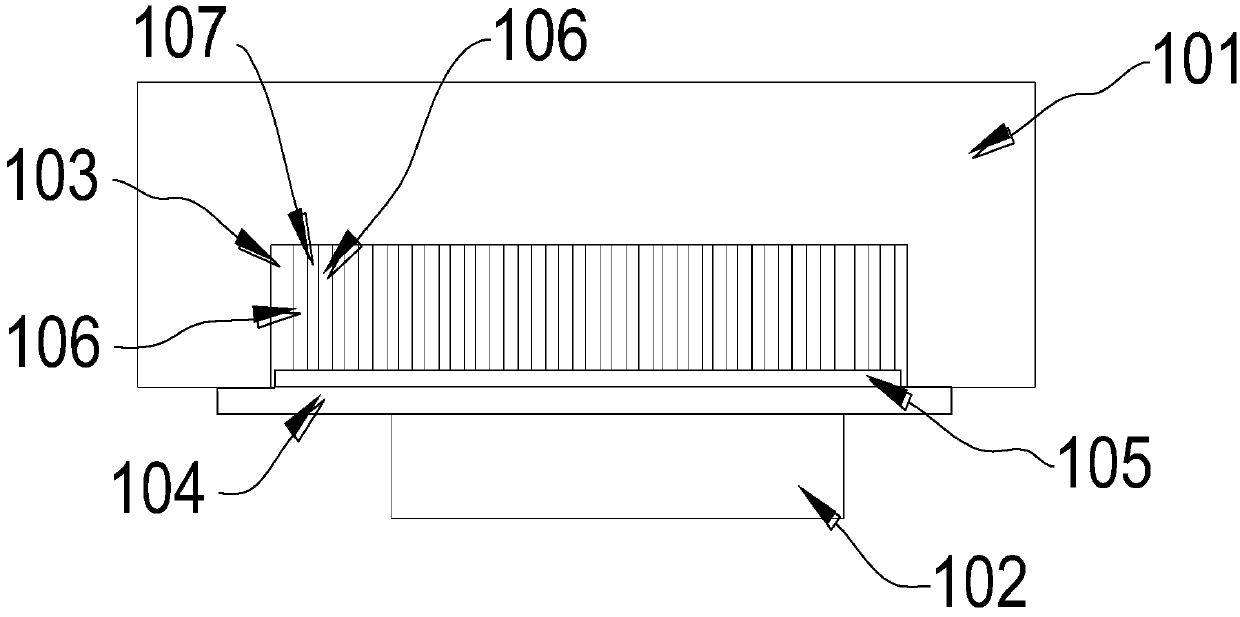

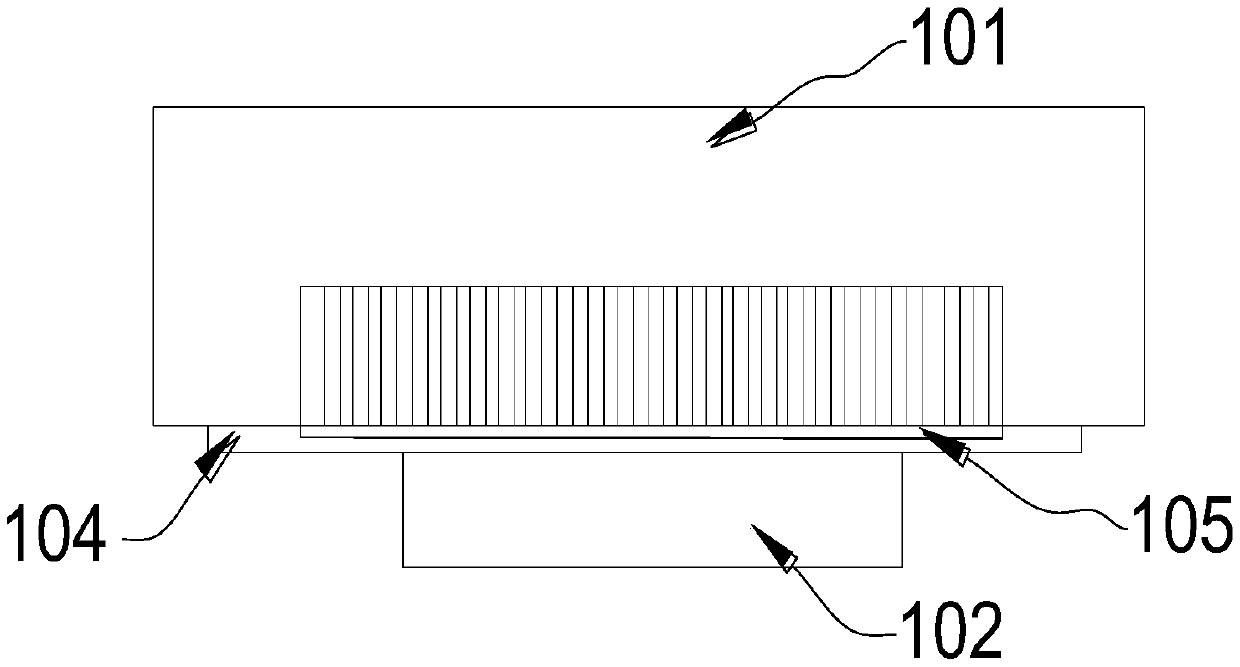

[0027] An embodiment of the present invention provides a heat dissipation middle frame. The heat dissipation middle frame is a heat dissipation middle frame of an intelligent electronic device, especially a heat dissipation middle frame of a smart phone. The heat dissipation middle frame is used to provide a carrier for a circuit board or an electronic component. After the electronic components are installed in the heat dissipation middle frame, the main board of intelligent electronic equipment is formed, such as the main board of a mobile phone, which has extremely high heat dissipation requirements. There is no doubt that the heat dissipation middle frame is made of a metal material with high thermal conductivity and weldable, which can be an alloy material ,like figure 1 As shown, the middle frame 101 is used as the carrier of the electronic components 102, and the electronic components 102 are installed on the surface of the middle frame 101 as a heat source, and a receivi...

Embodiment 2

[0035] An embodiment of the present invention provides a method for manufacturing a heat dissipation middle frame or a heat dissipation rear case, including the following steps.

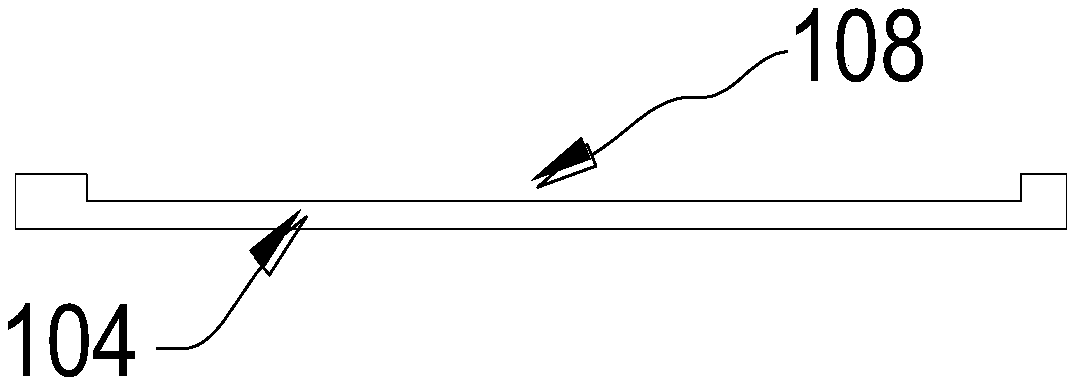

[0036] First, prepare the materials for the production of heat dissipation middle frame or heat dissipation rear case. According to the design requirements of intelligent electronic devices, such as the installation position of the mobile phone’s heating chip on the middle frame, or the position of the corresponding rear case, in the heat dissipation middle frame or heat dissipation The housing groove is etched on the back shell and the pillars are also etched to make the channel unobstructed, and to ensure a more stable structure and not easy to be damaged. According to the thickness requirements of the heat sink, choose to sinter at least one layer of copper wire mesh or copper powder on the heat sink to form an adsorbent for absorbing liquid, which can have a capillary structure and increase the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com