A fuel vapor liquefaction recovery device and its fuel evaporation discharge system

A fuel vapor, recovery device technology, applied in the charging system, condensed fuel collection/return, combustion air/combustion-air treatment, etc., can solve the problems of reducing the residual amount of carbon powder, high cost, rising cost, etc. Effective volume, increase the degree of liquefaction, and accelerate the effect of fuel liquefaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

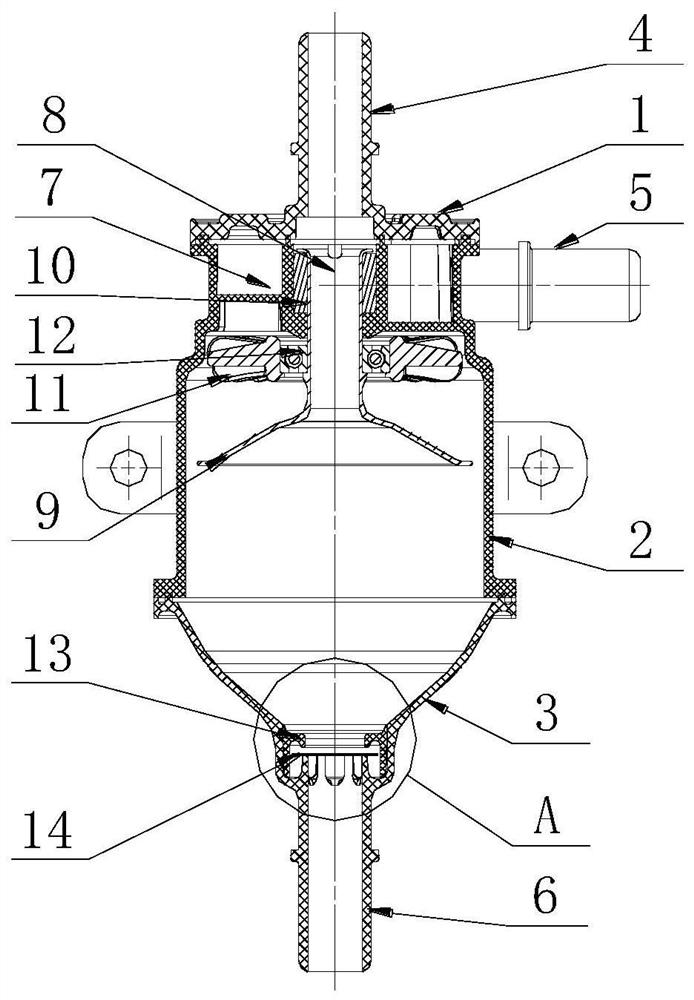

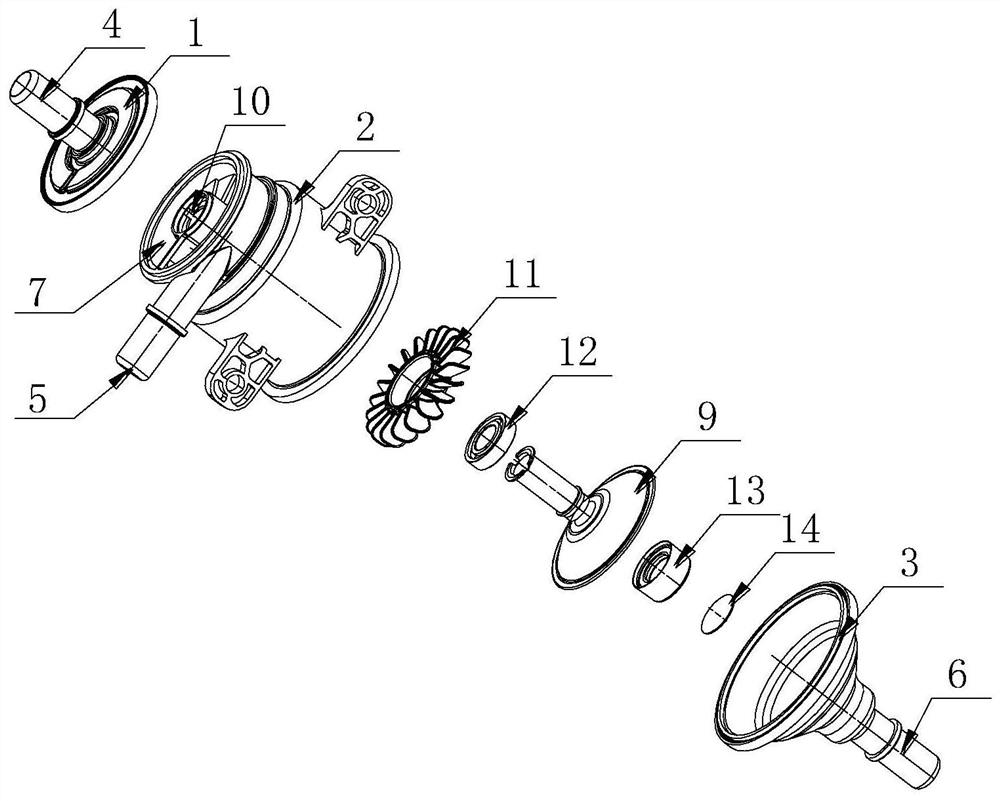

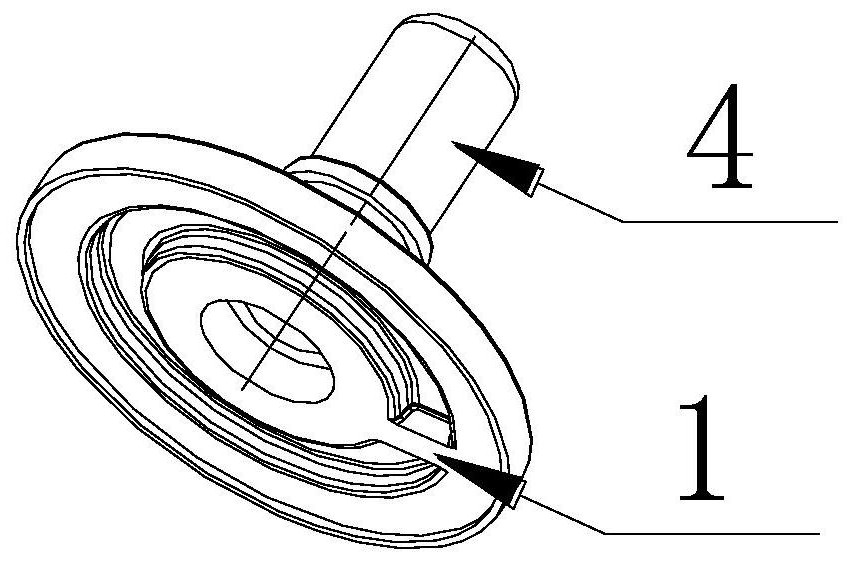

[0047] Such as Figure 1-2 As shown, the present invention provides a fuel vapor liquefaction recovery device, which includes an upper end cover 1, a housing 2, and a lower end cover 3 connected sequentially from top to bottom to form a sealed cavity, and the upper end cover 1, housing 2, and lower end cover 3 are respectively A first pipe joint 4, a second pipe joint 5, and a third pipe joint 6 are provided; an annular self-rotating separation chamber 7 corresponding to the second pipe joint 5 is provided in the housing 2, and the self-rotating separation chamber The inner edge of 7 surrounds and forms a hollow part 8 that penetrates up and down. The upper end of the hollow part 8 communicates with the first pipe joint 4. The casing 2 is provided with an impeller assembly for centrifugal separation and the centrifugally processed Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com