A method for arranging ultraviolet lamps in secondary water supply ultraviolet disinfection equipment

A technology for ultraviolet disinfection and secondary water supply, applied in water/sewage treatment equipment, chemical instruments and methods, water treatment sites, etc., can solve the problem of damage to lamp tubes and quartz sleeves, incorrect calculation methods, and reduced floor space and other issues to achieve the effect of eliminating the influence of uncertain factors, ensuring scientificity and accuracy, and being easy to produce and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The invention discloses a method for arranging ultraviolet lamps in secondary water supply ultraviolet disinfection equipment, which comprises the following steps:

[0047] Step 1. Detect the ultraviolet intensity at different distances from the center point of the ultraviolet lamp tube in tap water. When testing, first set up multiple detection points according to the different distances from the center point of the ultraviolet lamp tube, and then detect the corresponding value of each detection point. The ultraviolet intensity, the distance between the detection point and the center point of the ultraviolet lamp tube will be used as the farthest vertical distance between the tap water in the disinfection container and the center point of the ultraviolet lamp tube in the later design.

[0048] Step 2. According to the result of step 1, calculate the irradiation time required for the tap water to receive the effective dose of safe ultraviolet light at different distances...

Embodiment 2

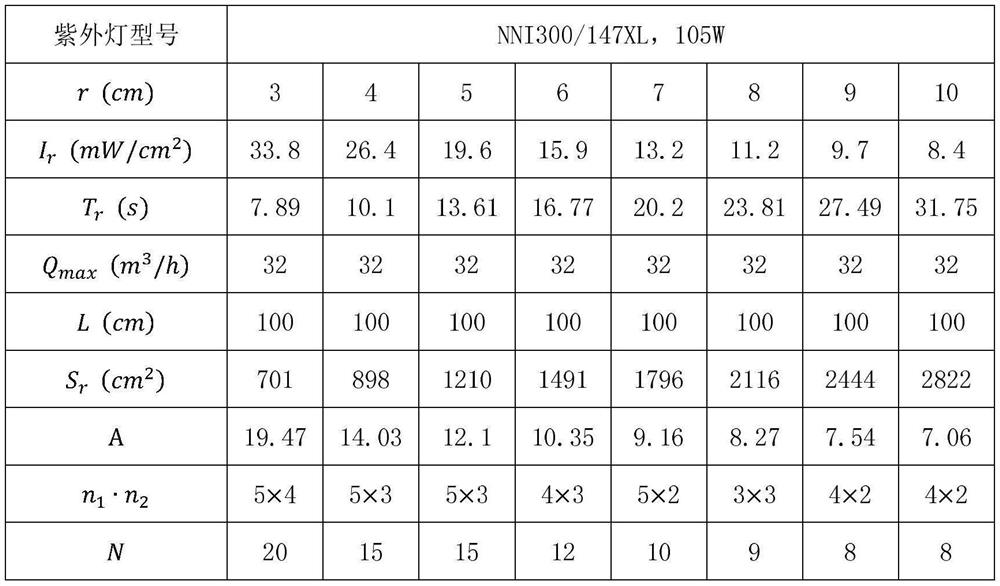

[0073] This embodiment is further described on the basis of embodiment 1 in conjunction with specific actual data, specifically as follows:

[0074] Step 1: Detect the ultraviolet intensity at different distances from the center point of the ultraviolet lamp tube in the tap water.

[0075] In this step, the ultraviolet lamp is a low-voltage, high-intensity ultraviolet lamp with a UVC output power of 105W and a model number of NNI300 / 147XL produced by Heraeus Special Lighting Co., Ltd., and the quartz tube is a product produced by Foshan Kewei Optoelectronics Co., Ltd.

[0076] The center point of the lamp tube refers to the midpoint of the axis of the UV lamp tube. The detection point is selected on the normal line of the lamp tube. The normal line of the lamp tube refers to the straight line passing through the center point of the lamp tube and perpendicular to the axis of the lamp tube; After the quartz sleeve is finished, put it in a special water tank and start running. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com