A connection structure of a near-suction range hood that can meet the small volume packing of the whole machine

A connection structure and range hood technology, applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of high manufacturing additional cost, high packaging cost, unfavorable environmental protection, etc., to reduce the packaging volume, reduce the effective volume, The effect of high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

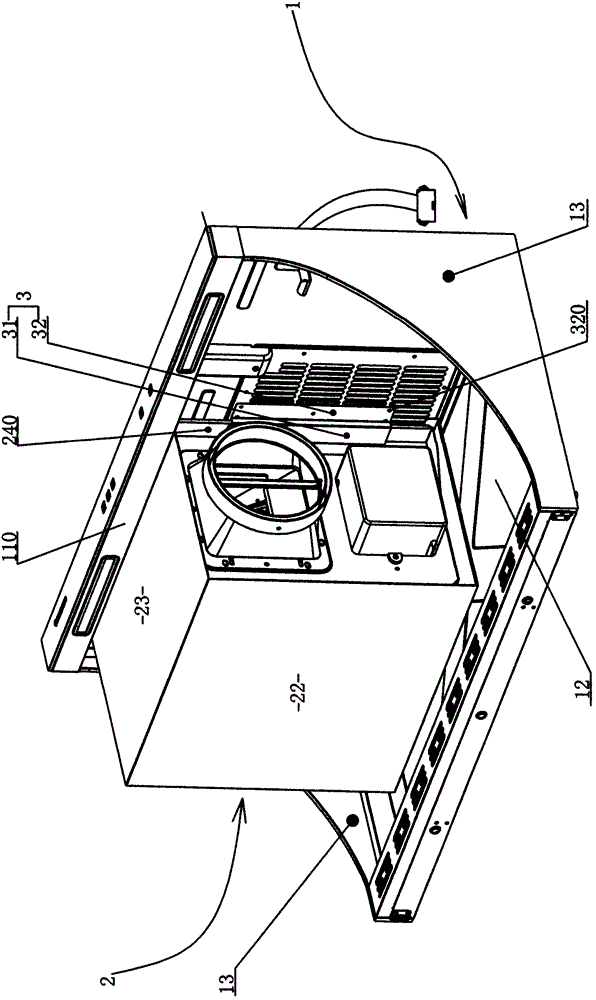

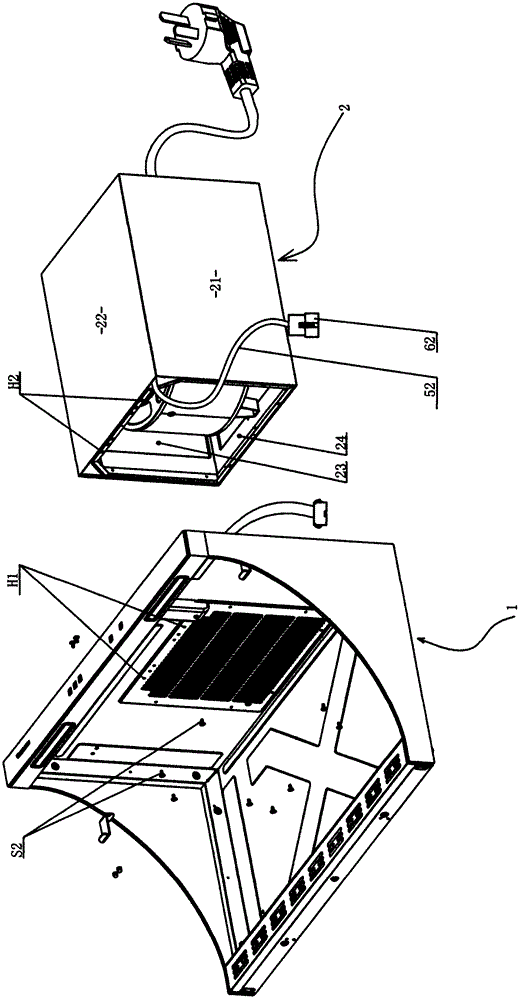

[0022] In the following, the overall dimensions of the smoke collecting cavity assembly 1 are 900mm (length) × 450mm (width) × 500mm (height), and the overall dimensions of the bellows assembly 2 are 380mm (length) × 295mm (width) × 460mm (height) for implementation An example will be described in further detail, but the embodiments of the present invention are not limited thereto.

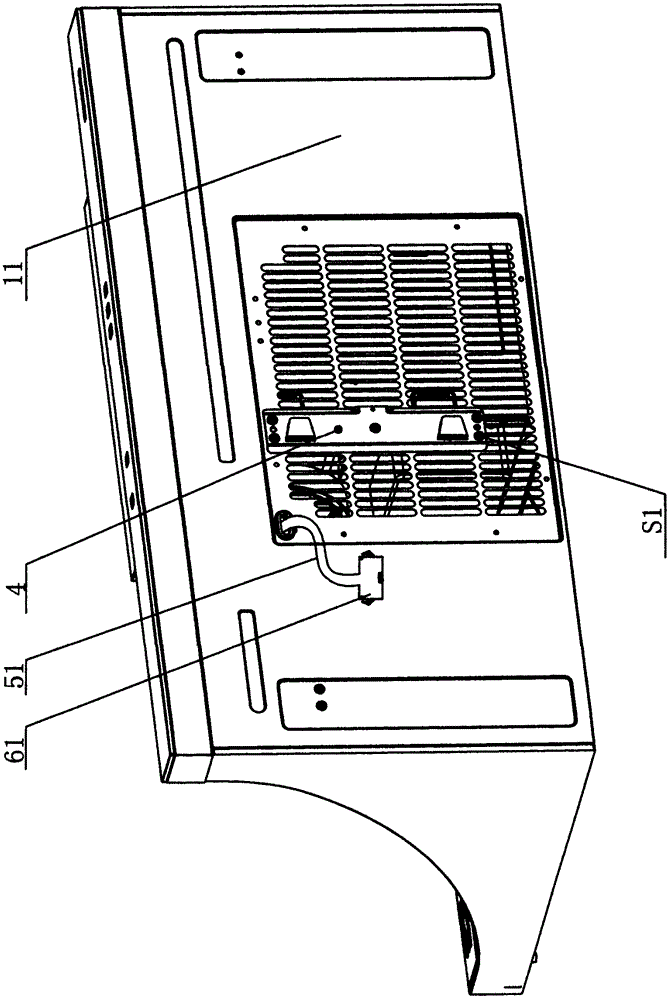

[0023] see figure 1 , 2 , 3, and 4, a connection structure of a near-suction range hood that can meet the small-volume packing of the whole machine is implemented for the preparation of the whole machine packing before leaving the factory, including the smoke collecting chamber assembly 1 and the decorative cover. The bellows assembly 2 and the decorative cover are surrounded by four side panels 21, 22, 23, and 24. The smoke collecting cavity assembly 1 has a top plate 11 and a back plate 12 that are at right angles to each other, and a folded plate is provided on the inner wall of the top plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com