Self-cleaning fluidized bed reactor for carbon nanotube production

A fluidized bed reactor and carbon nanotube technology, applied in the field of nanomaterials, can solve problems such as easy accumulation of carbon nanotubes, affecting heat transfer and mass transfer of the reactor, and achieve the effect of improving use efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

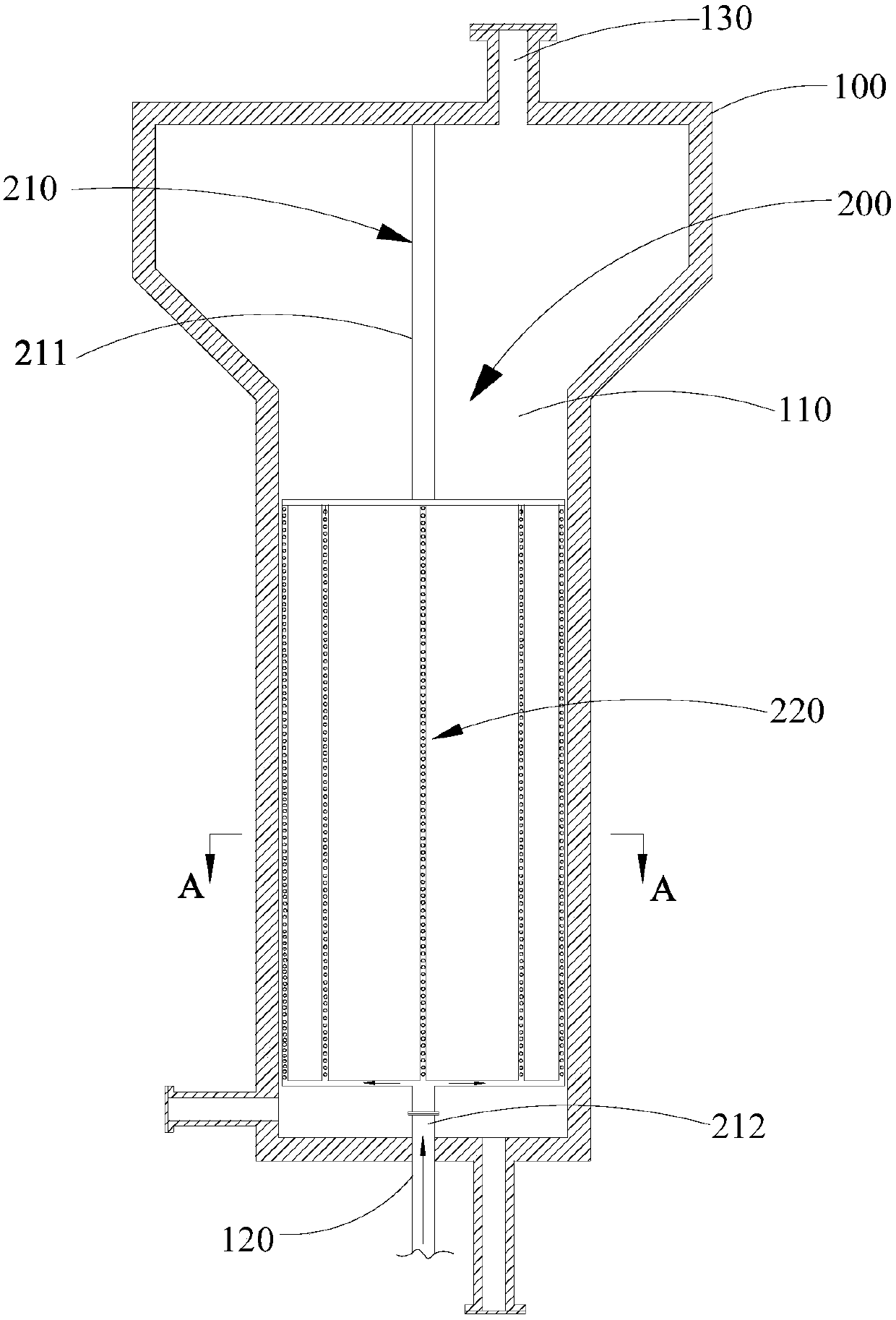

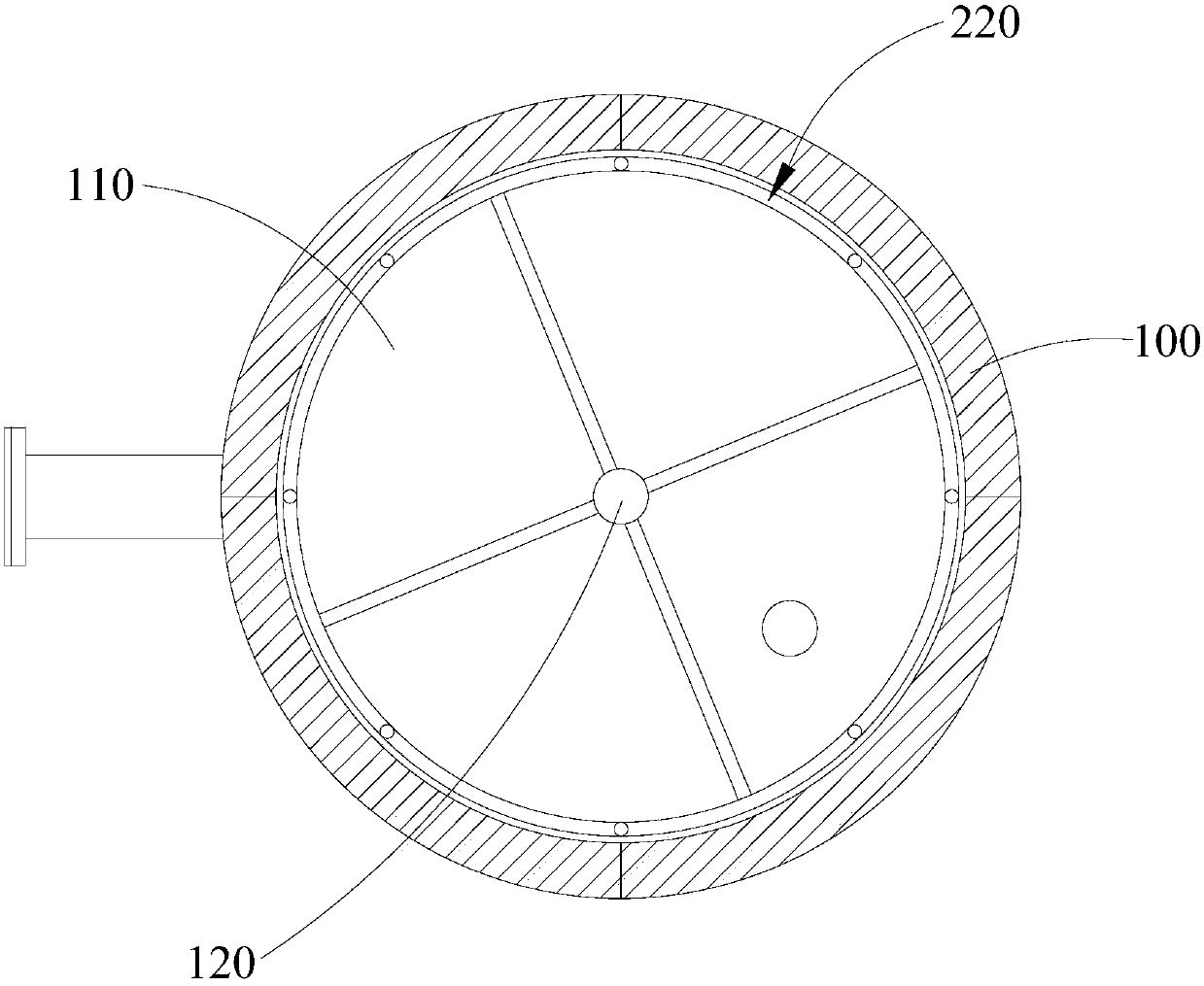

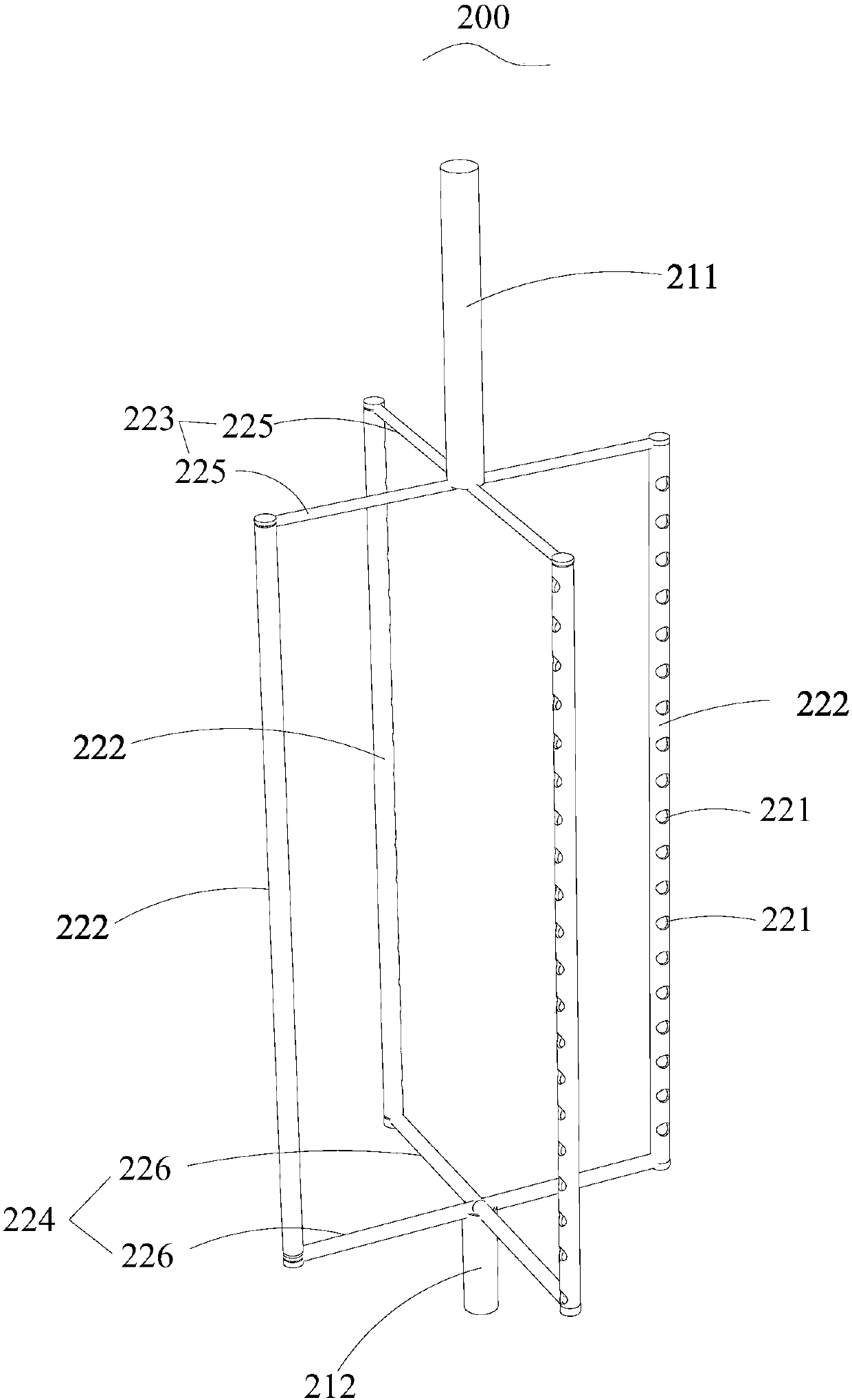

[0033] refer to figure 1 , figure 2 The self-cleaning fluidized bed reactor for carbon nanotube production provided by Embodiment 1 of the present invention includes a fluidized bed reactor body 100 having a reaction chamber 100 and a rotating device 200 disposed in the reaction chamber 100 . The rotating device 200 includes a rotating shaft 210 longitudinally arranged along the center of the reaction chamber 100 and a rotating body 220 connected to the rotating shaft 210 and capable of rotating driven by the rotating shaft 210 . The bottom of the reaction chamber 100 is provided with an inflow port 120 for the gas to flow in, and the top of the reaction chamber 100 is provided with an outflow port 130 for the gas to flow out. The rotating shaft 210 communicates with the inlet 120 , the rotating body 220 communicates with the rotating shaft 210 , and the rotating body 220 is provided with a plurality of air holes 221 facing the inner wall of the reaction chamber 100 and comm...

Embodiment 2

[0045] refer to Image 6 The self-cleaning fluidized bed reactor for carbon nanotube production provided by Embodiment 2 of the present invention differs from Embodiment 1 in that the structure of the rotating body 220 is different. In this embodiment, the rotating rod 222 in the rotating body 220 is curved. This curve design increases the number of air holes 221 per unit length at the same height of the rotating body 220 , the distribution of gas flowing out of the air holes 221 is more uniform, and the flushing efficiency of the gas is higher.

[0046] In addition, the structure of the upper connecting rod assembly 223 and the structure of the lower connecting rod assembly 224 are also different from the first embodiment. In this embodiment, the upper connecting rod assembly 223 includes a circular first upper connecting rod 2231 and two straight second upper connecting rods 2232. The upper ends of the four rotating rods 222 are connected to the first upper connecting rods....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com