Improved process for recovering zinc from zinc-containing feedstock

A raw material, zinc-rich technology, applied in the direction of improving process efficiency, can solve problems such as high infrastructure costs, achieve the effect of optimizing capital and operating expenses, and optimizing the requirements of fire protection components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0163] Example 1. Recovery of ultrapure zinc according to the method of the present invention

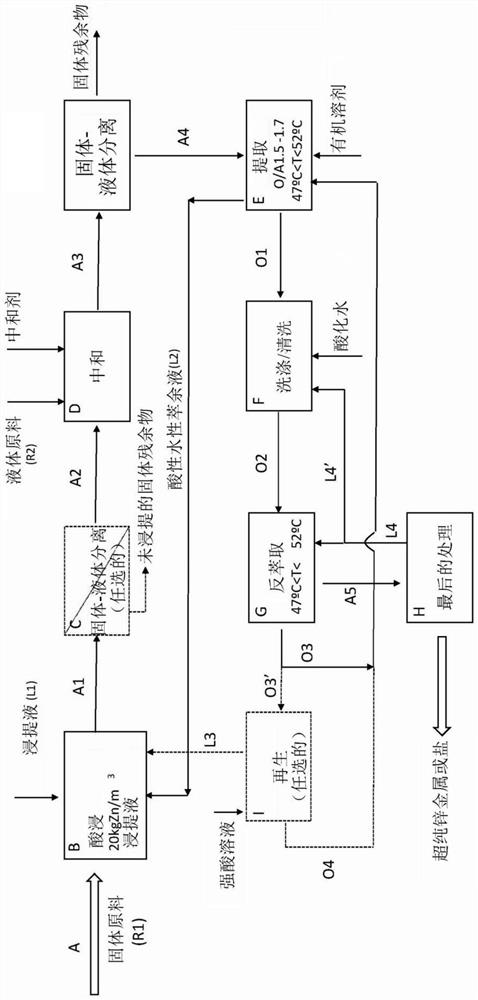

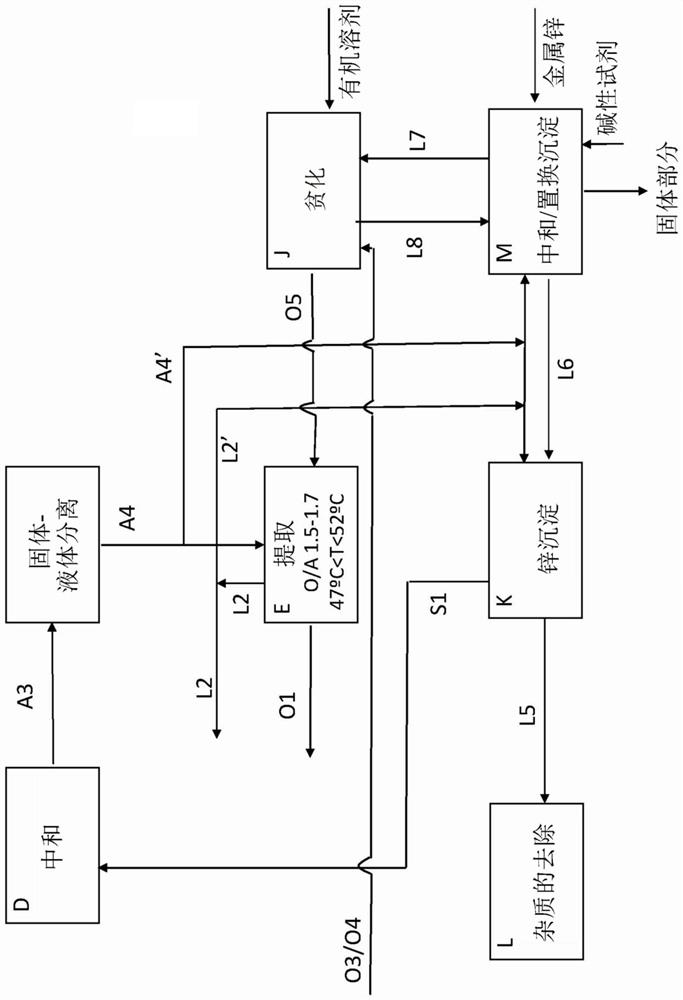

[0164] The invention will be better understood by the examples in which the improved method according to the invention is described and the results compared to the previous method as defined in EP1361296. figure 1 and figure 2 Also used as a support to understand the different steps and flows resulting from the method described in this example, where all operating elements are denoted by capital letters.

[0165] This example relates to the production of Special High Grade zinc from secondary zinc-containing materials using the following operating units:

[0166] - Raw material leaching to convert zinc from solid to liquid

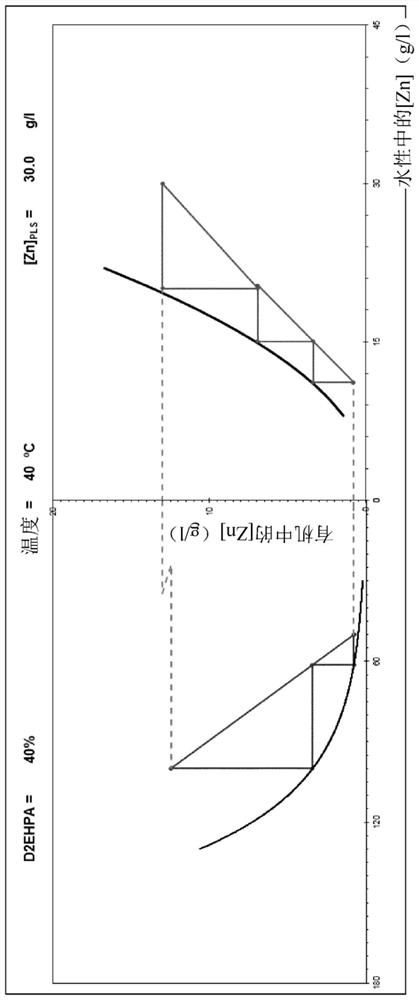

[0167] - Extraction of Zn from aqueous solution into organic extractant (D2EHPA)

[0168] - The zinc is stripped from the extractant using an acidic treatment, so the organic solution can be recycled back into the extraction

[0169] - SHG Zn production usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com