Intelligent efficient ultrasonic atomization industrial humidifier

An ultrasonic and humidifier technology, applied in the field of ultrasonic atomization industrial humidifiers, can solve the problem of inability to know the operation status of the humidifier, and achieve the effect of enhancing humidification, speeding up and improving the speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

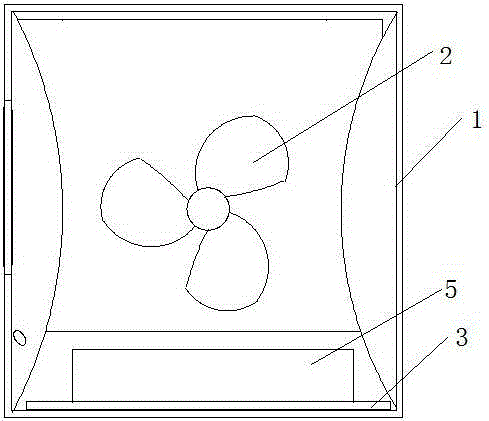

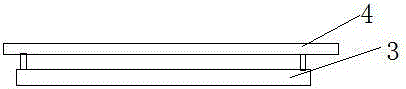

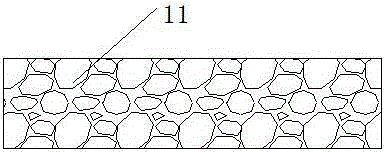

[0031] like figure 1 , figure 2 and image 3 A high-efficiency and intelligent ultrasonic humidifier shown includes: a box body 1, a fan 2, a control circuit board 3, an integrated atomization component 4 and a control device 5, and the top of the box body 1 is provided with an exhaust port 11, the fan 2 is set inside the box body 1, the control circuit board 3 is set at the bottom of the box body 1, the integrated atomization assembly 4 is set on the control circuit board 3, the The control device 5 is set in the control box inside the box body 1, the control circuit board 3 is also provided with a high-frequency electronic oscillation circuit and a transducer sheet, and the integrated atomization component 4 is equipped with an integrated atomization Movement; the control device is composed of an induction module, a self-detection module, an alarm, an operation control module and a control module, the induction module is connected with the operation control module, the se...

Embodiment 2

[0037] The structure of the highly efficient and intelligent ultrasonic atomizing industrial humidifier in the working method of the efficient and intelligent ultrasonic atomizing industrial humidifier described in this embodiment is the same as that in Embodiment 1.

[0038] like figure 1 , figure 2 and image 3A high-efficiency and intelligent ultrasonic humidifier shown includes: a box body 1, a fan 2, a control circuit board 3, an integrated atomization component 4 and a control device 5, and the top of the box body 1 is provided with an exhaust port 11, the fan 2 is set inside the box body 1, the control circuit board 3 is set at the bottom of the box body 1, the integrated atomization assembly 4 is set on the control circuit board 3, the The control device 5 is set in the control box inside the box body 1, the control circuit board 3 is also provided with a high-frequency electronic oscillation circuit and a transducer sheet, and the integrated atomization component 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com