Water supply unit of washing machine and washing machine

A water supply unit and washing machine technology, applied in the field of washing machines, can solve the problems of potential safety hazards, weakened condensation effect, and inconspicuous effect, and achieve the effects of obvious condensation effect, simple structure, and simplified installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

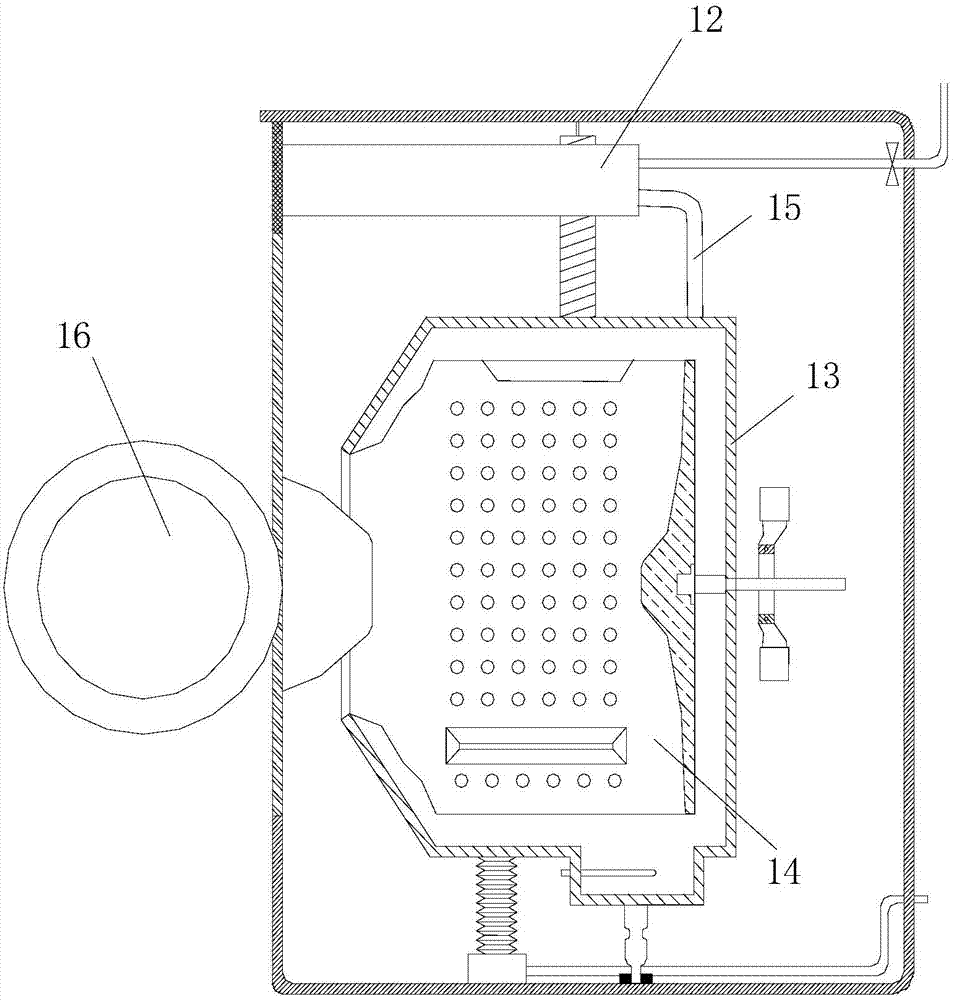

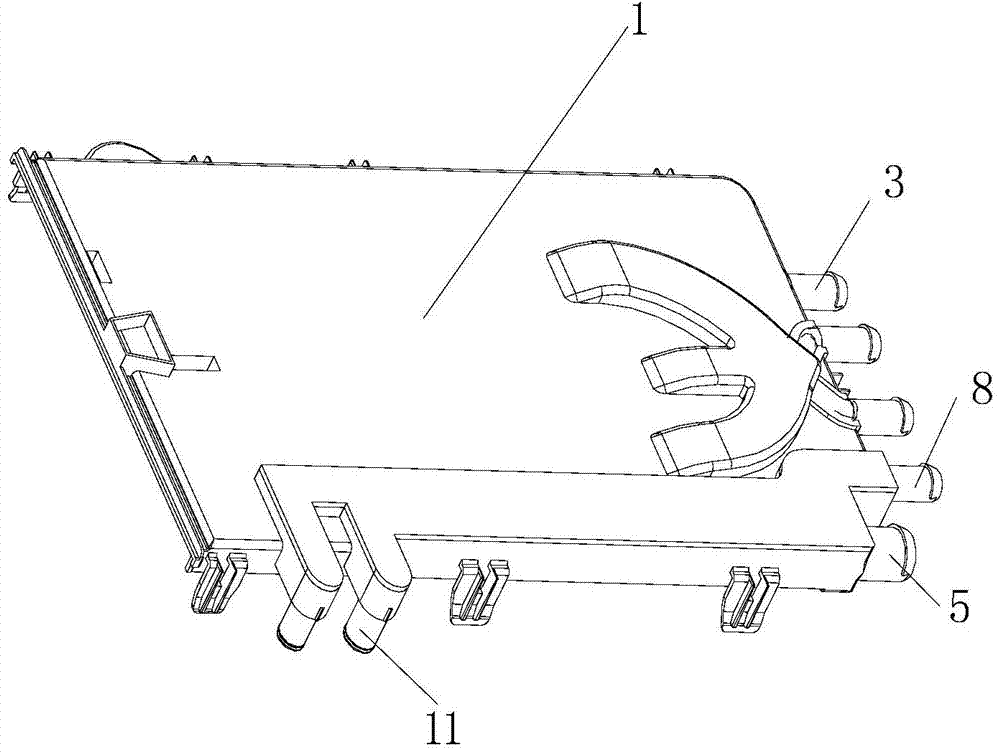

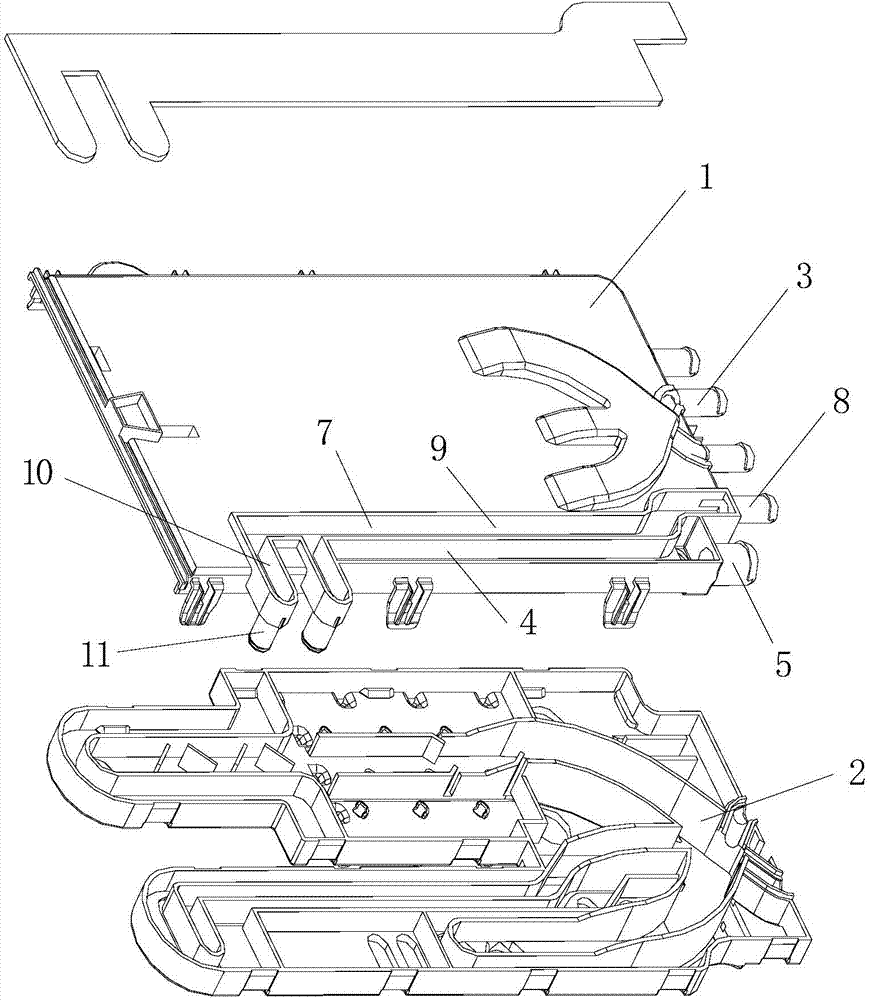

[0028] Such as figure 1 , 2 , 3, the vent hole 5 is set on one side of the cover plate of the water supply unit, and at least one side wall adjacent to the vent hole 5 is provided with a condensation pipeline 4, and the condensation pipeline 4 discharges the hot steam discharged from the outer cylinder 13 liquefaction.

[0029] Such as figure 1 , 3 , 4, and 5, the cover plate of the water supply unit also includes an upper cover 1 and a lower cover 2. The upper cover 1 has a certain thickness. The lower cover 2 is combined to form a water chamber. The upper cover 1 is provided with a condensing pipeline 4 and an air vent 5. Preferably, the condensing pipeline 4 is arranged on the upper surface of the upper cover, fully utilizing the upper space of the water supply unit, and the air vent 5 is arranged on the upper cover and on the side adjacent to the upper surface. The water inlet 3 is arranged on the upper cover 1, and is arranged on the same side as the vent hole 5.

...

Embodiment 2

[0039] The vent hole 5 communicates with the water cavity, which is a condensing pipeline for condensing and liquefying the hot steam. Ventilation hole 5 guides the hot steam discharged from the outer cylinder into the water chamber, and the hot steam gradually liquefies in the water chamber, from hot steam to liquid water, and the liquefied water flows out through the water outlet at the bottom of the water chamber together with the cold water circulating in the water chamber , make full use of the space in the water chamber to condense the hot steam, and the condensation effect is obvious.

[0040] A washing machine is provided with the above-mentioned water supply unit in the washing machine, the water supply unit includes a cover plate of the water supply unit, a water box is arranged under the cover plate of the water supply unit, and the liquefied water of hot steam liquefied by the cover plate of the water supply unit flows into the water inside the box for recycling. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com