Device integrating temperature control and stirring

An integrated tank technology, applied in the field of temperature control and stirring devices, can solve the problems of low steam utilization rate, unsuitable for large-scale production, poor uniformity, etc., and achieve uniform material composition and temperature, stable pressure, and uniform temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

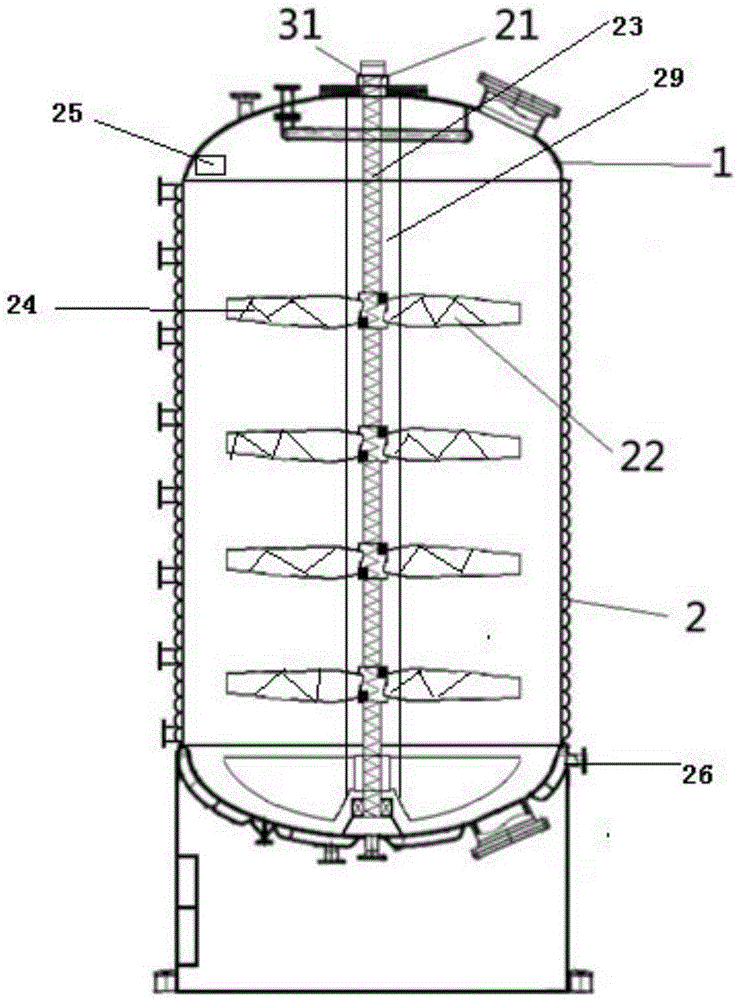

[0040] This example provides A device integrating temperature control and stirring , Such as figure 1 ,include,

[0041] The tank body 1 has an accommodating space;

[0042] An external heating device is arranged around the outer wall of the tank body 1;

[0043] The first rotating shaft 21 is vertically arranged at the center of the tank body 1 and can be driven by the power device to rotate. The first rotating shaft 21 is provided with a number of paddles 22. The first rotating shaft 21 and paddle The blade 22 is made of heat-conducting material, and both the first rotating shaft 21 and the paddle blade 22 have cavities;

[0044] The second rotating shaft 29 is sheathed on the outer wall of the first rotating shaft 21, forms a ventilation space with the first rotating shaft 21, and has several hammer-shaped air injection ports communicating with the ventilation space;

[0045] The internal heating device includes a first heating wire 23 insulated in the cavity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com