Liquefied natural gas leakage recovery and boil-off gas recovery device

A technology for liquefied natural gas and evaporated gas, which is applied in liquefaction, refrigeration and liquefaction, gas treatment/storage effects, etc. It can solve the problems of LNG leakage recovery, long recovery time, and inability to realize recondensation and liquefaction recovery of LNG tankers, and achieve reduction Harmful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

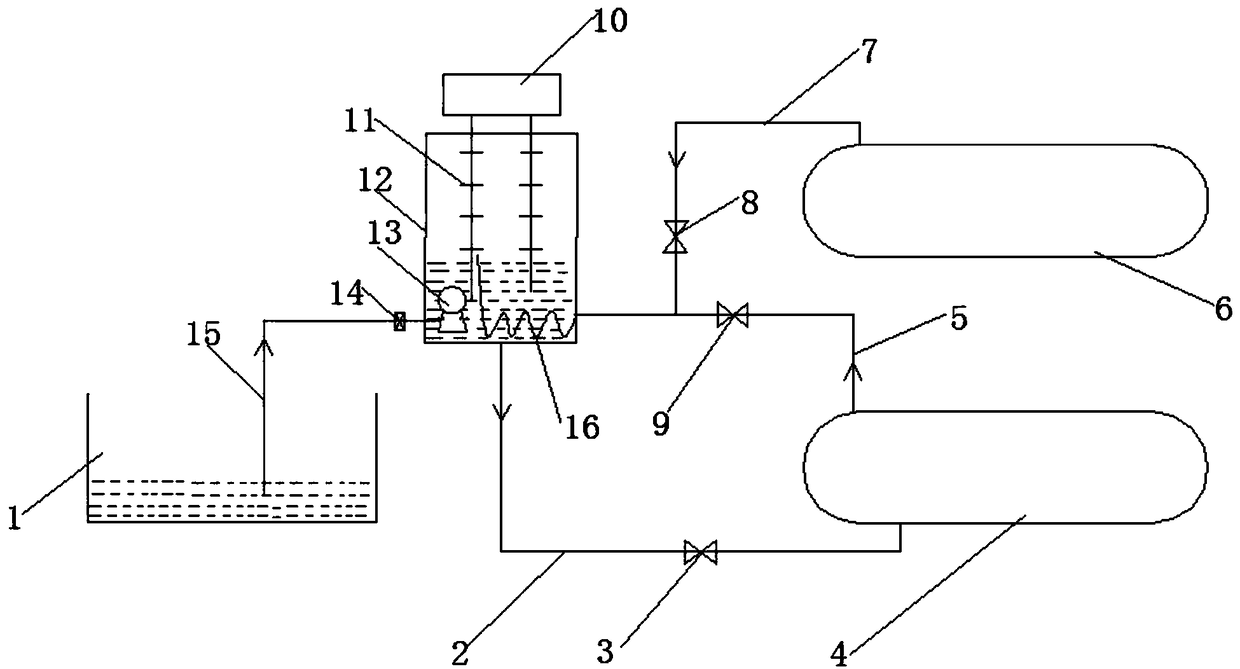

[0031] Such as figure 1 As shown, a liquefied natural gas leakage recovery and evaporated gas recovery device includes a buffer insulation tank 12, a low-temperature refrigerator 10 is arranged on the buffer insulation tank 12, and a cold head extending to the inside of the buffer insulation tank 12 is arranged on the low-temperature refrigerator 10 The heat exchanger 11 and the cold head heat exchanger 11 extend into the liquefied natural gas; the inside of the buffer insulation tank 12 is provided with a cryogenic submersible pump 13 and a casing heat exchanger 16, and the amount of liquefied natural gas maintained in the buffer insulation tank 12 is over When the cryogenic submersible pump 13 and casing heat exchanger 16, the amount of liquefied natural gas maintained in the buffer insulation tank 12 and the amount of bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com