Sludge anaerobic digestion additive and method for promoting methane production through additive

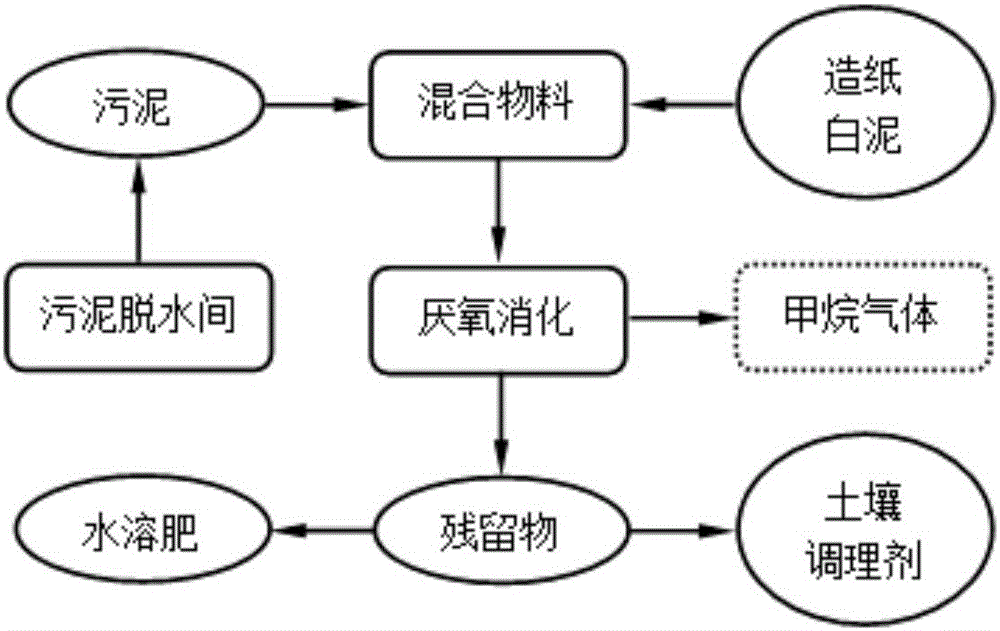

An anaerobic digestion and additive technology, applied in biological sludge treatment, waste fuel, etc., can solve the problems of high energy consumption and low utilization rate of raw materials, and achieve the effect of simple operation, low cost, and pH value improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

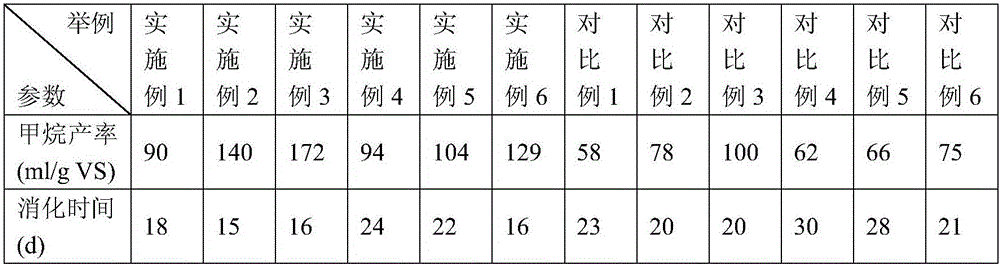

Embodiment 1

[0032] (1) Get 400g of sludge with a water content of 80% (organic matter content in the sludge is 60%) and add 200ml of water, then add papermaking white mud, the amount of papermaking white mud added is 0.75% of the sludge mass, papermaking white mud It is fully mixed with the sludge by stirring, and the pH value and solid content of the obtained mixed material are 7.9 and 13.8%, respectively.

[0033] (2) Put it into a sealed anaerobic digestion equipment, control the culture temperature at 53°C, carry out anaerobic digestion of the sludge by stirring, the digestion time is 18 days, and the methane yield is 90ml / gVS.

[0034] Using the above-mentioned treatment method, the sludge methane yield is reduced by 22% and the methane yield is increased by 55% compared with the working condition without adding papermaking white mud.

Embodiment 2

[0036] (1) Get 300g of sludge with a water content of 90% (organic matter content in the sludge is 45%) and add 200ml of water, then add papermaking white mud, the amount of papermaking white mud added is 0.5% of the sludge mass, papermaking white mud It is fully mixed with the sludge by stirring, and the pH value and solid content of the mixed material are respectively 7.5 and 5.4%.

[0037] (2) Put it into a sealed anaerobic digestion equipment, control the culture temperature at 55°C, carry out anaerobic digestion of the sludge by stirring, the digestion time is 15 days, and the methane yield is 140ml / gVS.

[0038] By using the treatment method as described above, the sludge methane yield is reduced by 25% and the methane yield is increased by 80% compared with the working condition without adding papermaking white mud.

Embodiment 3

[0040] (1) Get 400g of sludge with a moisture content of 85% (organic matter content in the sludge is 79.6%) and add 100ml of water, then add papermaking white mud, the amount of papermaking white mud added is 0.6% of the sludge mass, papermaking white mud It is fully mixed with the sludge by stirring, and the pH value and solid content of the obtained mixed material are 7.6 and 12.2%, respectively.

[0041] (2) Put it into a sealed anaerobic digestion equipment, control the culture temperature at 55°C, carry out anaerobic digestion of the sludge by stirring, the digestion time is 16 days, and the methane yield is 172ml / gVS.

[0042] Using the above-mentioned treatment method, the sludge methane yield is reduced by 20% and the methane yield is increased by 72% compared with the working condition without adding papermaking white mud.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com