Method utilizing phosphate mineralized bacteria to solidify and loosen loose sand particles

A technology of mineralizing bacteria and phosphate, applied in the direction of chemical instruments and methods, applications, soil protection, etc., to achieve the effect of not being easy to secondary pollution, low cost, and small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

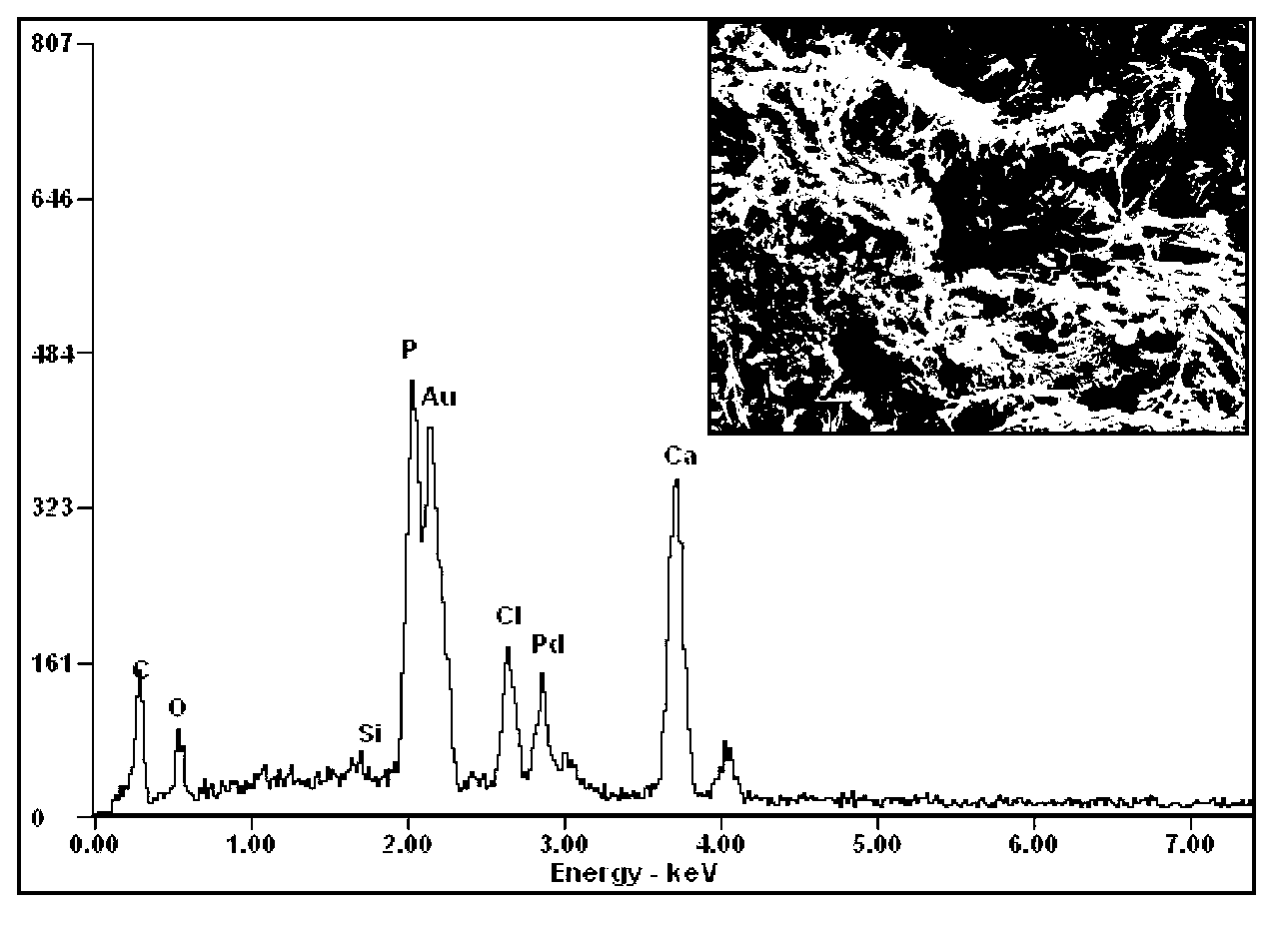

[0040] (1) Weigh 5g of peptone, 3g of beef extract and 1000ml of distilled water to prepare a medium, adjust the pH to 7.0, sterilize and dry, inoculate Bacillus subtilis into the prepared medium, and carry out shaking culture at 30°C , the oscillation frequency is 170r / min, cultivated for 24h; then weigh 4g of disodium phenyl phosphate and put it in the 100mL bacterial liquid prepared above to obtain the bacterial liquid containing disodium phenyl phosphate;

[0041] (2) Configure CaCl 2 The solution concentration is 0.5mol L -1 ;

[0042] (3) Weigh 56.56g of sand with a particle size below 0.15mm and 23.44g of sand with a particle size of 0.15-0.3mm, and put them into a 60ml disposable syringe in three times, and tap the outside of the syringe during each loading process to The loaded sand is densely packed, and the tight void ratio is 43.1%;

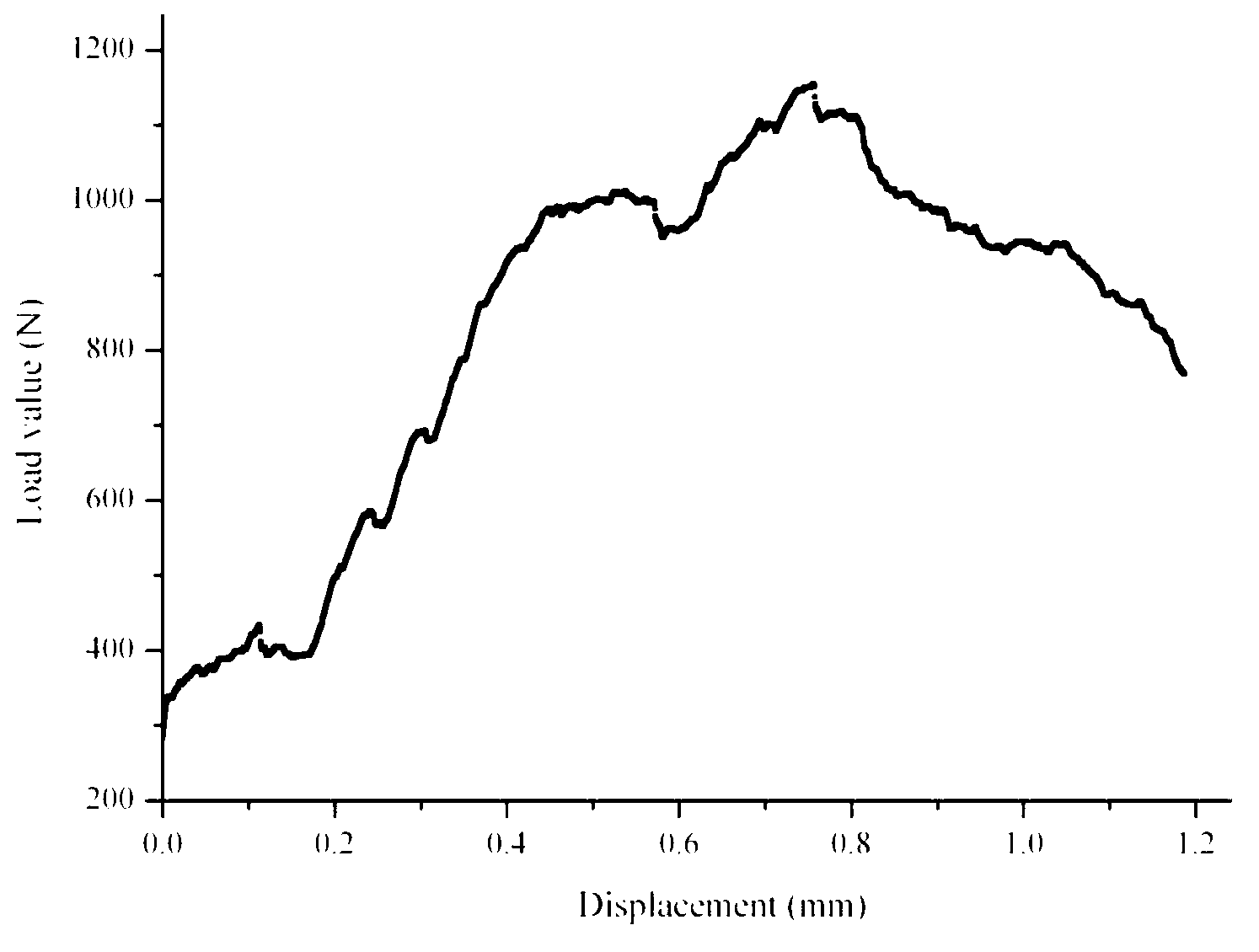

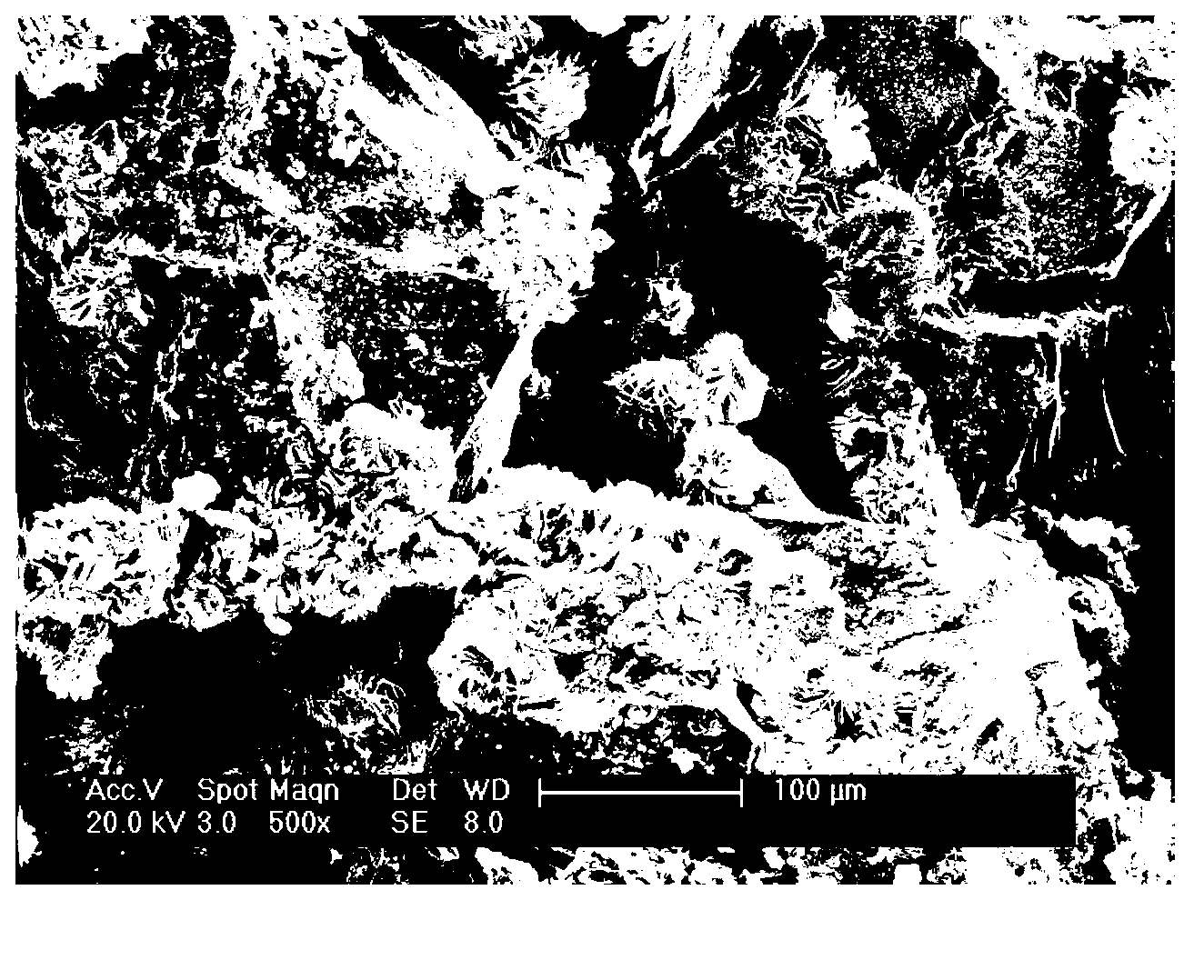

[0043] (4) Connect the bottom of the syringe with a peristaltic pump, inject the bacterial solution containing disodium phenyl ph...

Embodiment 2

[0047] (1) Weigh 5g of peptone, 3g of beef extract and 1000ml of distilled water to prepare a medium, adjust the pH to 7.0, sterilize and dry, inoculate Bacillus subtilis into the prepared medium, and carry out shaking culture at 30°C , the oscillation frequency was 170r / min, and cultured for 16h; then weighed 5g of disodium phenyl phosphate and put it in the 100mL bacterial liquid prepared above to obtain the bacterial liquid containing disodium phenyl phosphate;

[0048] (2) Configure CaCl 2 The concentration of the solution is 1mol L -1 ;

[0049] (3) Weigh 63.63g of sand with a particle size below 0.15mm and 26.37g of sand with a particle size of 0.15-0.3mm, and put them into a 60ml disposable syringe in three times, and tap the outside of the syringe during each loading process to The loaded sand is densely packed, and the tight void ratio is 42.8%;

[0050] (4) Connect the bottom of the syringe with a peristaltic pump, inject the bacterial solution containing disodium...

Embodiment 3

[0052] (1) Weigh 5g of peptone, 3g of beef extract and 1000ml of distilled water to prepare a medium, adjust the pH to 8.0, sterilize and dry, inoculate Bacillus subtilis into the prepared medium, and carry out shaking culture at 30°C , the oscillation frequency is 170r / min, and cultured for 24h; then weigh 6g of disodium phenyl phosphate and put it in the 100mL bacterial liquid prepared above to obtain the bacterial liquid containing disodium phenyl phosphate;

[0053] (2) Configure CaCl 2 The solution concentration is 1.5mol L -1 ;

[0054] (3) Weigh 49.49g of sand with a particle size below 0.15mm and 20.51g of sand with a particle size of 0.15-0.3mm, and put them into a 60ml disposable syringe in three times, and tap the outside of the syringe during each filling process to The loaded sand is densely packed, and the tight void ratio is 42.6%;

[0055] (4) Connect the bottom of the syringe with a peristaltic pump, inject the bacterial solution containing disodium phenyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com