Process for corn starch sugar by enzyme method

A corn starch sugar and process technology, applied in the production of sugar, sugar production, glucose production, etc., can solve the problems of slow protein denaturation, no shear force, and unfavorable removal of protein, etc., and achieves high cooking temperature. Product quality and economy with remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

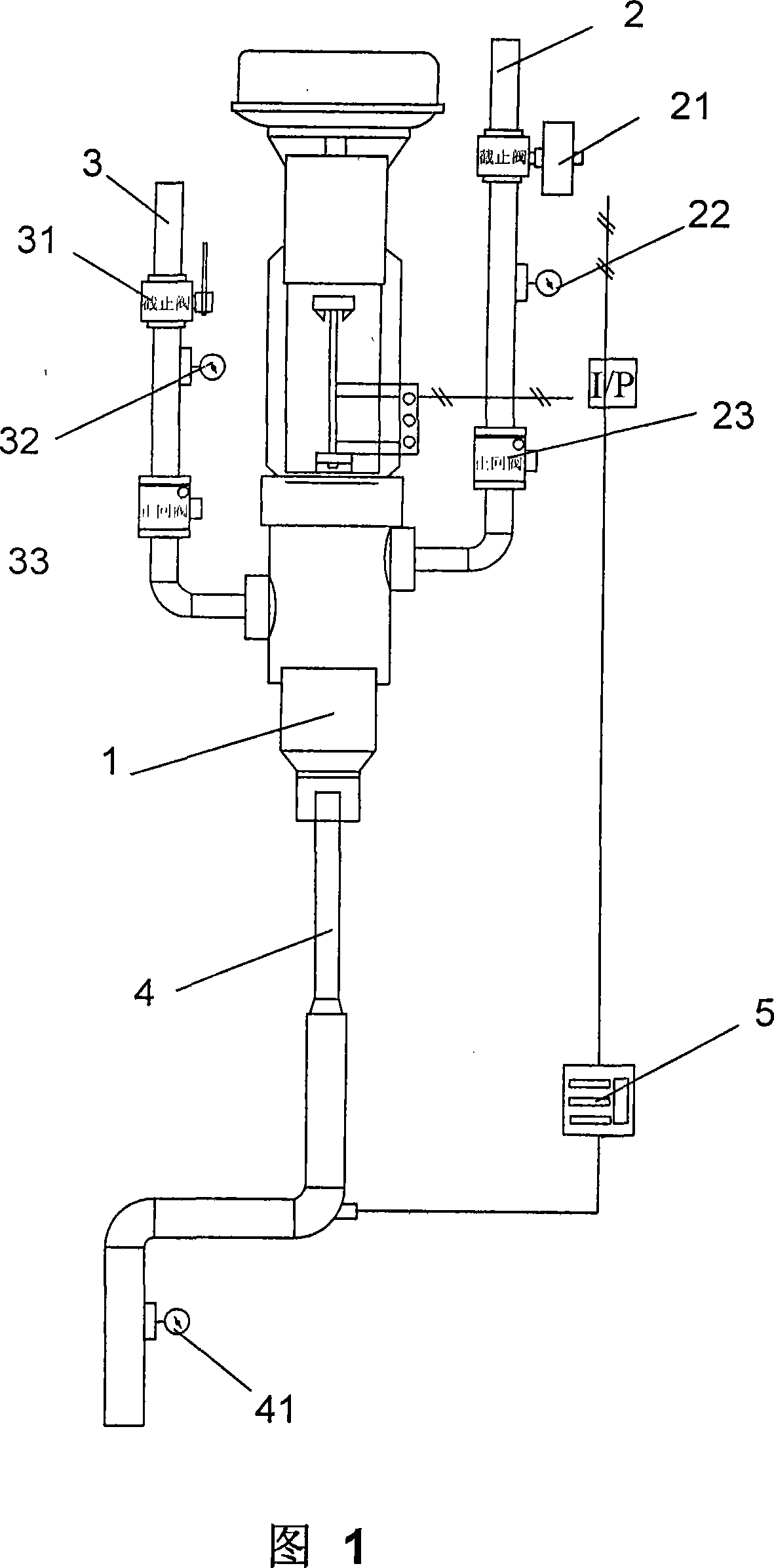

Image

Examples

Embodiment 1

[0018] Using corn starch as raw material, take a certain amount of corn starch, add water to prepare 16-20Be' starch milk, add β-amylase, adjust the pH value to 6.0-6.4, import it into the water heater for hydrolysis and liquefaction, and adjust the water heater The upper material enters the distance, controls the pressure difference between the inlet and outlet materials to 0.20MPa, adjusts the pressure and temperature of the steam introduced into the water heater, and controls the primary cooking temperature to 120°C. The clear liquid of the lower layer of the hydrolyzed liquefied product liquefied liquid is pumped to the flash tank for flash evaporation, and the protein slag flocculated in the upper layer is extracted and removed. The material after flash evaporation is then introduced into the saccharification tank for saccharification, and then undergoes decolorization, ion exchange and concentration to obtain a kind of maltose.

Embodiment 2

[0020] Using cornstarch as raw material, take a certain amount of cornstarch, add water to make 16-20Be' starch milk, add glucoamylase, adjust the pH value to 6.0-6.4, import it into the water heater for hydrolysis and liquefaction, and adjust the temperature of the water heater. The material enters the distance, controls the pressure difference between the inlet and outlet materials to 0.18MPa, adjusts the pressure and temperature of the steam introduced into the water heater, and controls the primary cooking temperature to 125°C. The clear liquid of the lower layer of the hydrolyzed liquefied product liquefied liquid is pumped to the flash tank for flash evaporation, and the protein slag flocculated in the upper layer is extracted and removed. The material after flash evaporation is then introduced into the saccharification tank for saccharification, and then undergoes decolorization, ion exchange and concentration to obtain a kind of glucose.

Embodiment 3

[0022] Using corn starch as raw material, take a certain amount of corn starch, add water to make 16-20Be' starch milk, add isomerized glucose enzyme, adjust the pH value to 6.0-6.4, import it into the water heater for hydrolysis and liquefaction, and adjust the water heater The upper material enters the distance, controls the pressure difference between the inlet and outlet materials to 0.16MPa, adjusts the pressure and temperature of the steam introduced into the water heater, and controls the primary cooking temperature to 130°C. The clear liquid of the lower layer of the hydrolyzed liquefied product liquefied liquid is pumped to the flash tank for flash evaporation, and the protein slag flocculated in the upper layer is extracted and removed. The material after flash evaporation is then introduced into the saccharification tank for saccharification, and then undergoes decolorization, ion exchange and concentration to obtain a kind of fructose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com