Patents

Literature

84results about How to "Full heat absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

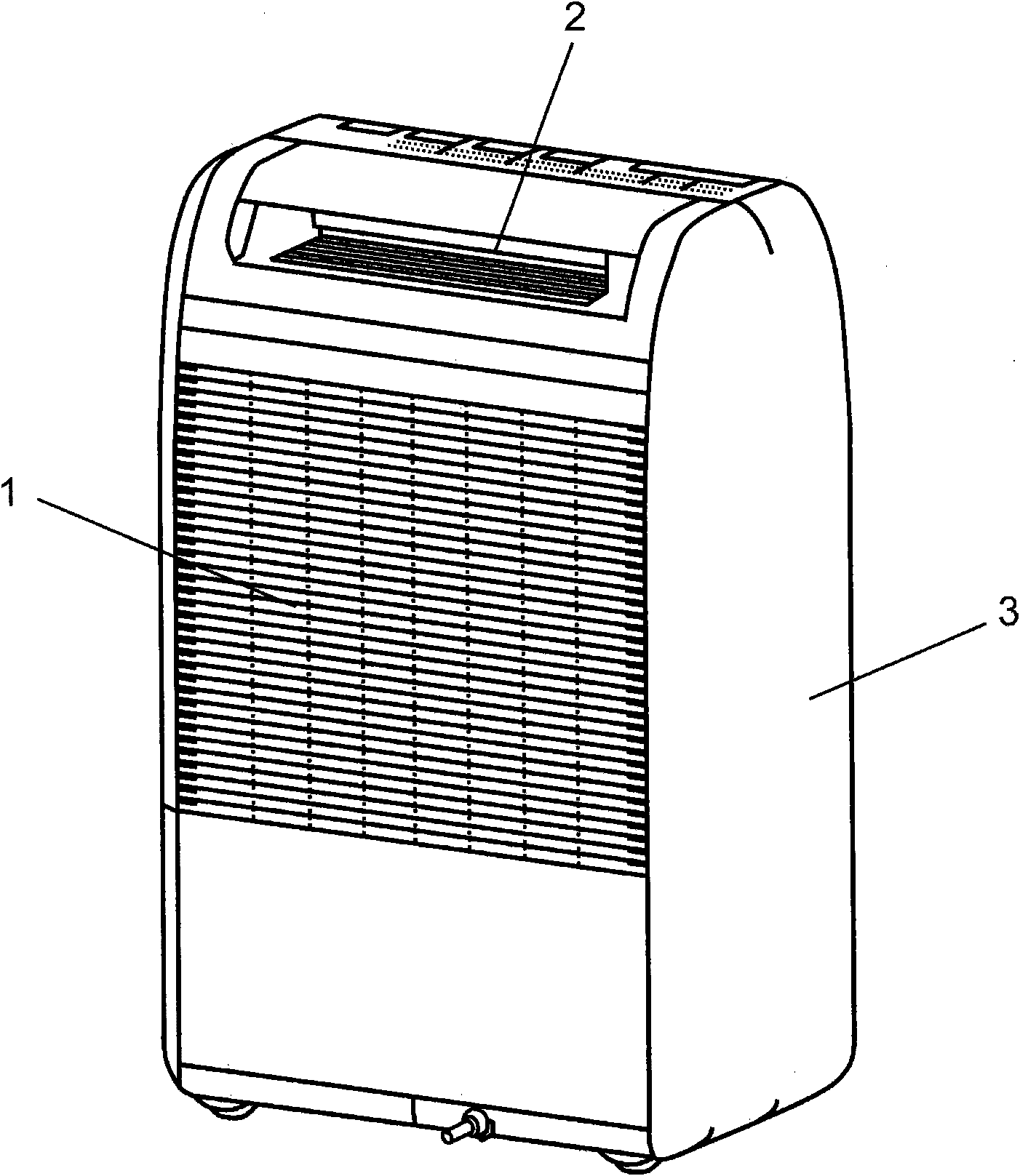

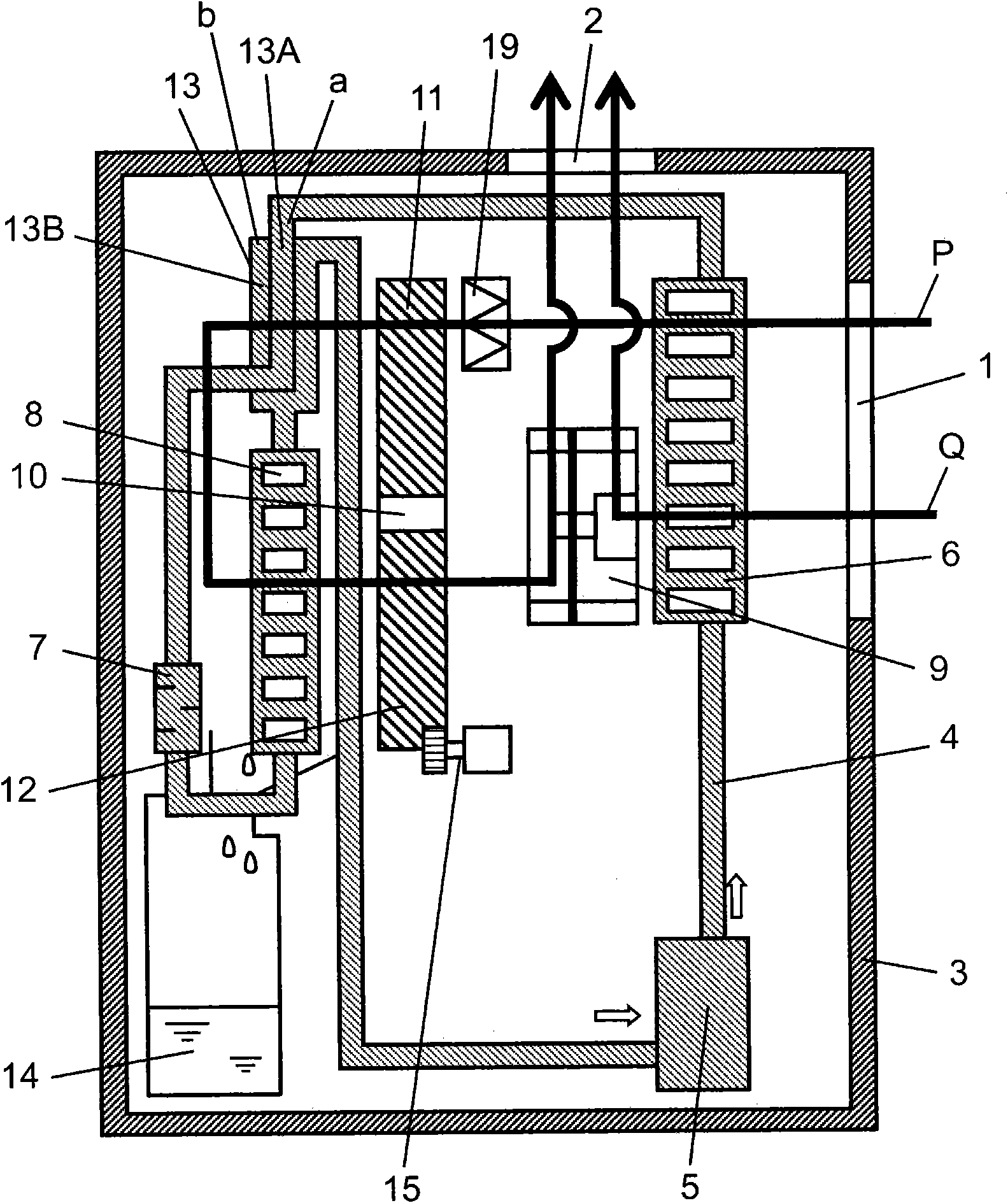

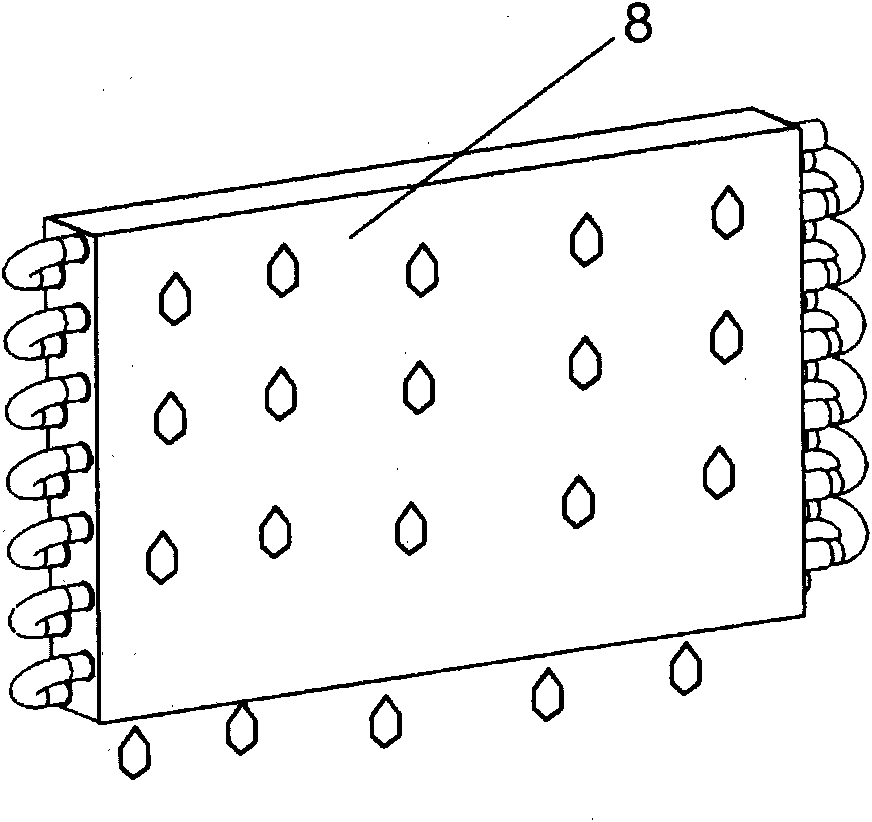

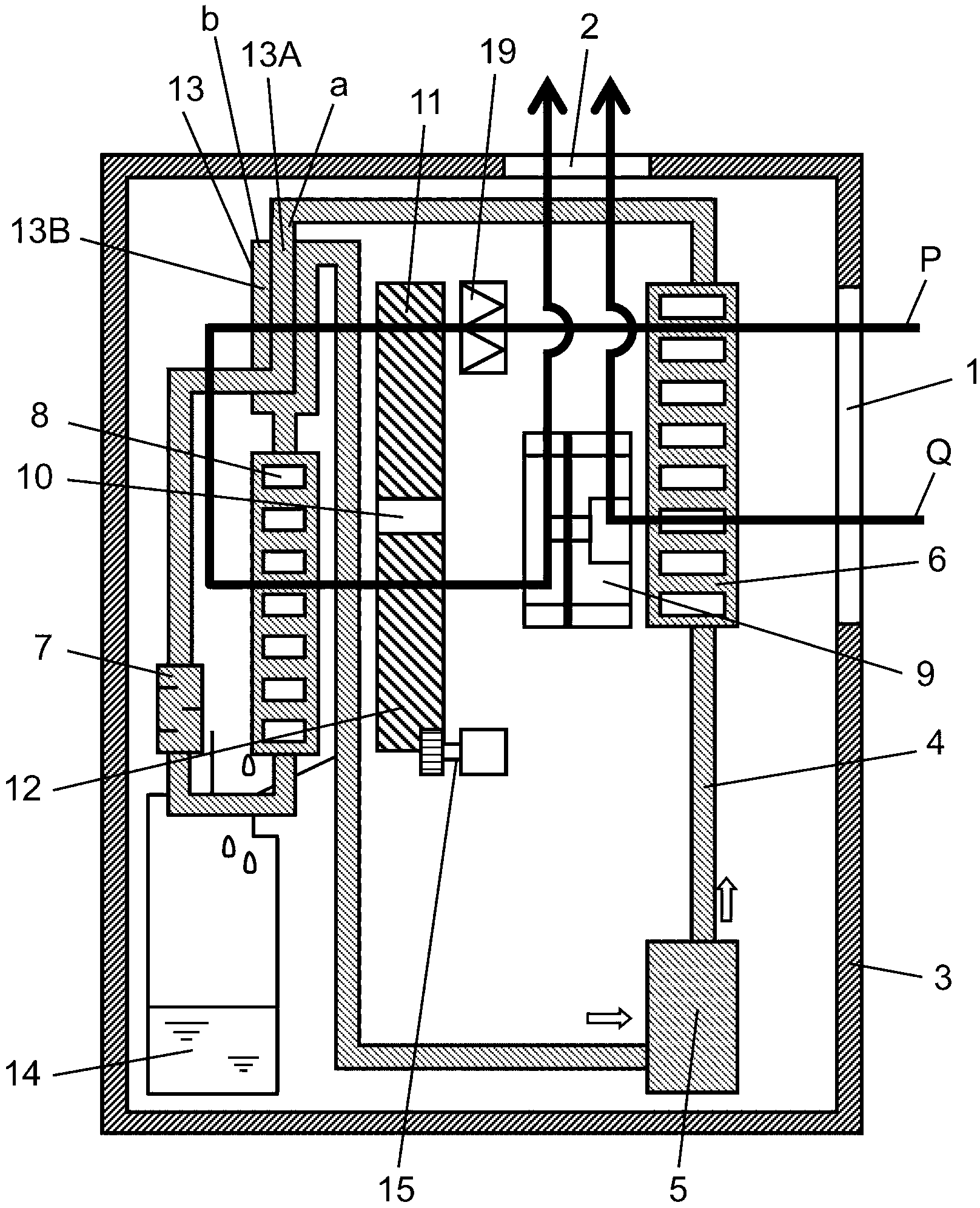

Dehumidifying device

A dehumidifying device achieves improved dehumidifying ability by having a body case (3) provided with a suction opening (1) and a discharge opening (2), a refrigeration cycle mechanism (4) provided in the body case (3), a fan (9) for sucking air into the body case (3) from the suction opening (1) and forming an air flow path in which the sucked air is sent to the discharge opening (2) after being passed through a heat dissipater (6) and a heat absorber (8) in that order, a moisture releasing section (11) of a dehumidifying rotor (10) located in the air flow path and provided between the heatdissipater (6) and the heat absorber (8), a moisture absorbing section (12) of the dehumidifying rotor (10) located in the air flow path and provided between the heat absorber (8) and the discharge opening (2), and a refrigerant heat exchanger (13) located in the air flow path and provided between the humidity discharging section (11) and the heat absorber (8).

Owner:PANASONIC CORP

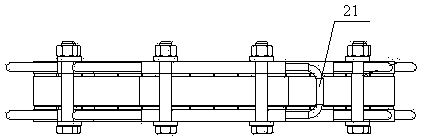

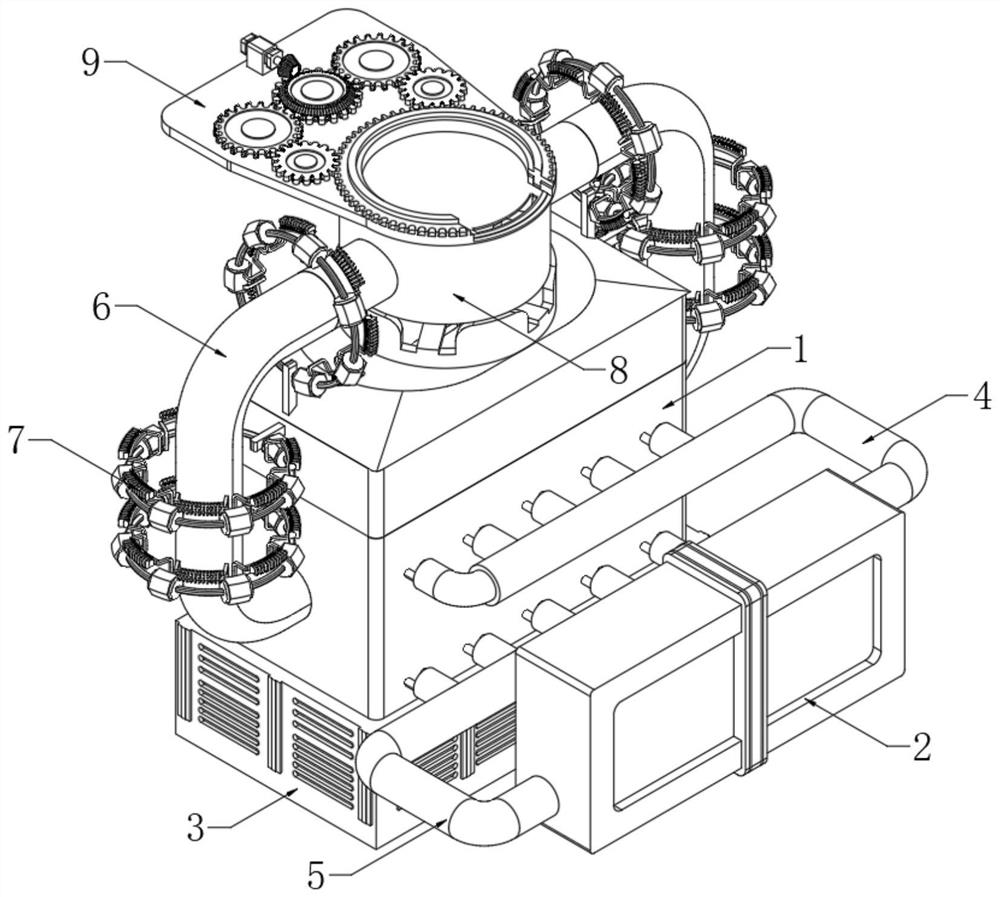

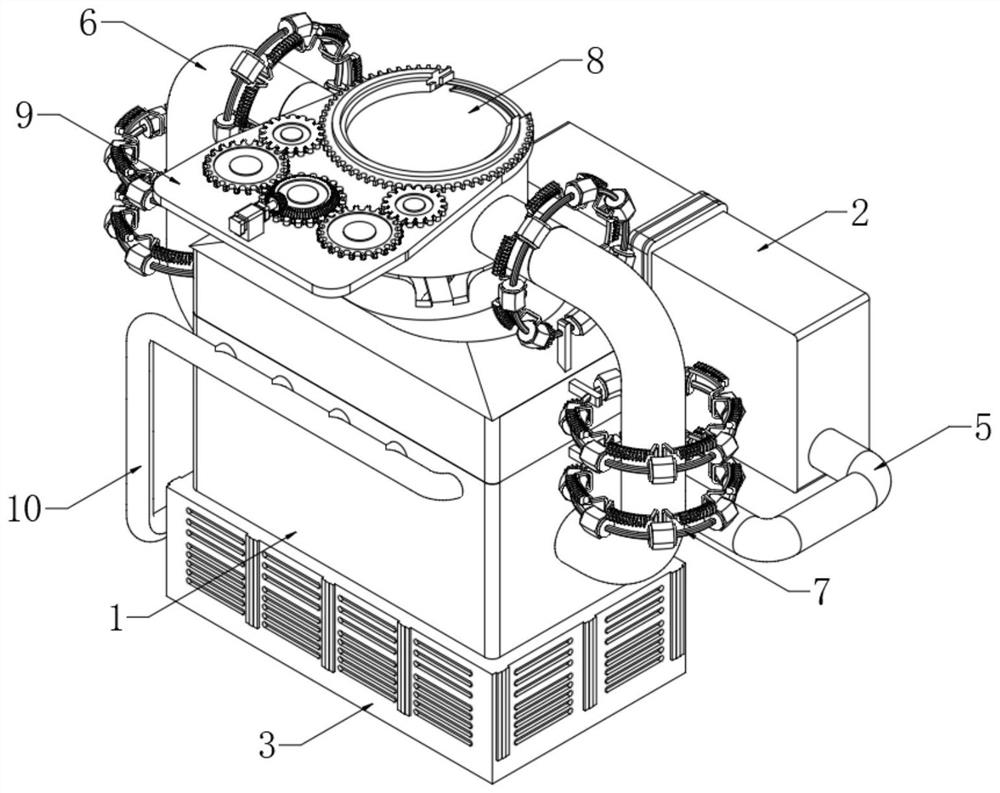

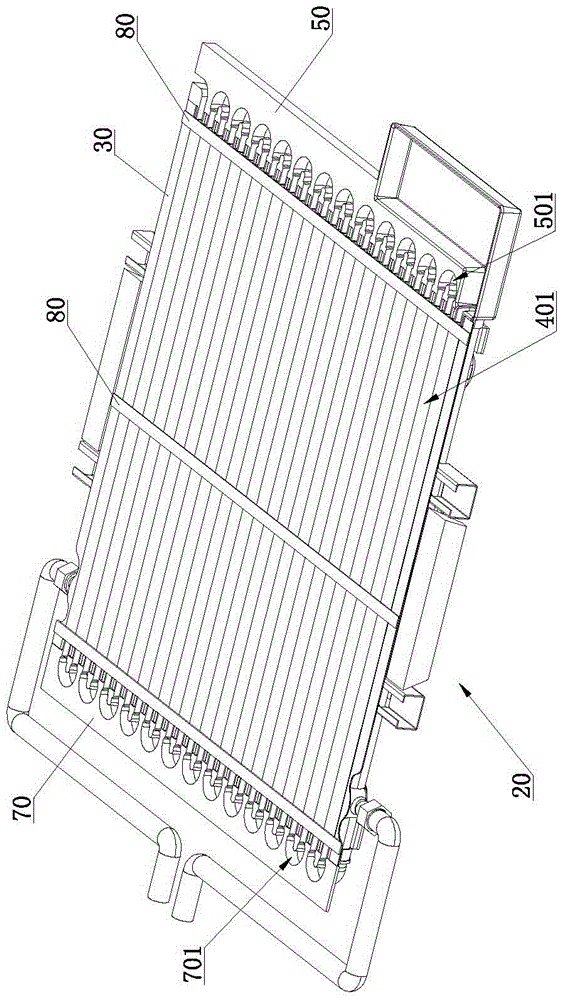

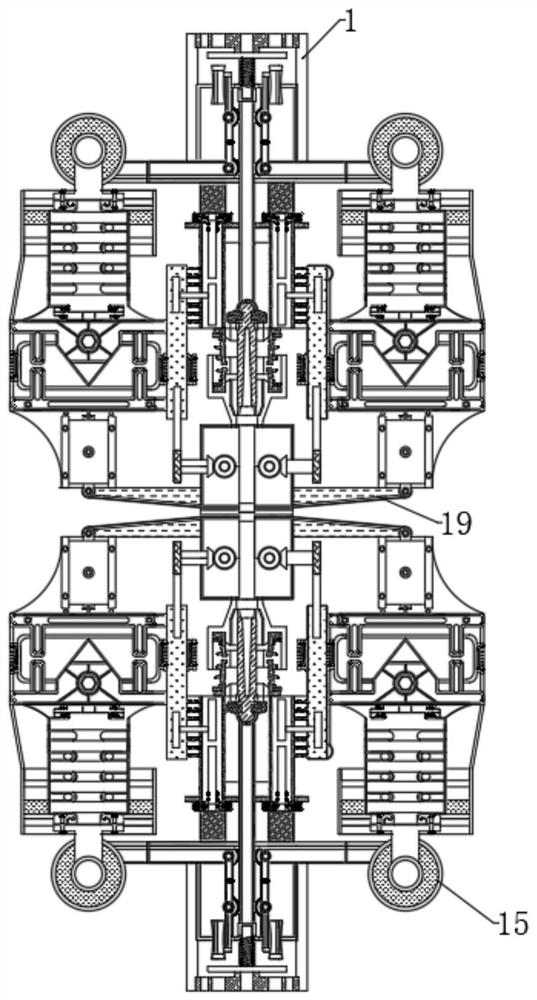

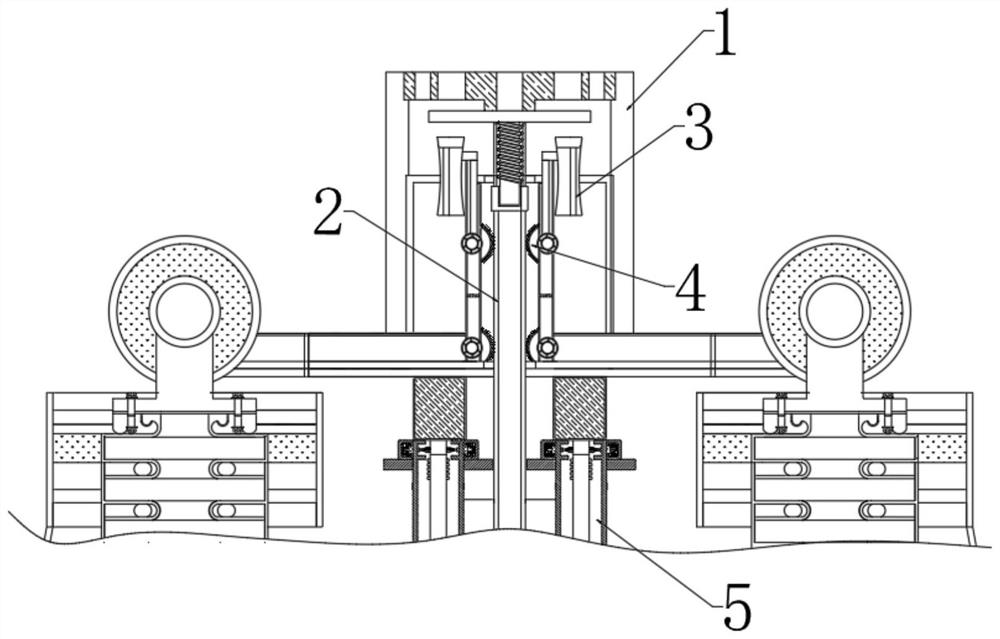

Temperature difference power generation device and vehicle-mounted tail gas waste heat temperature difference power generation system

InactiveCN103904949AIncrease profitImprove power generation efficiencyInternal combustion piston enginesExhaust apparatusTemperature differenceEngineering

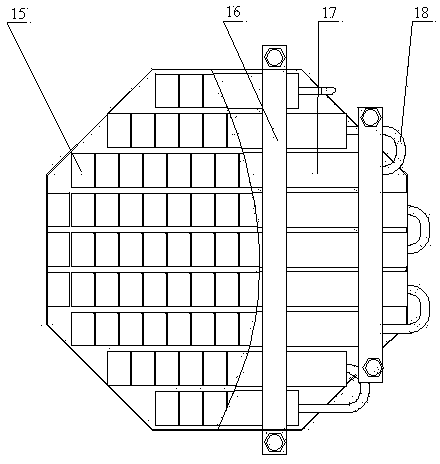

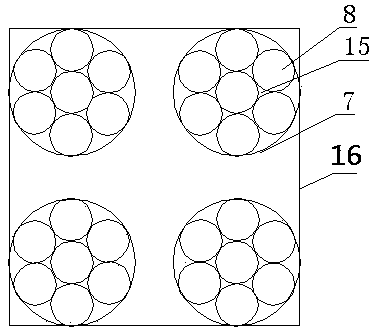

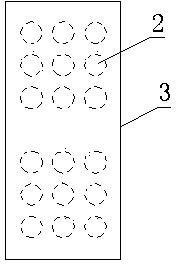

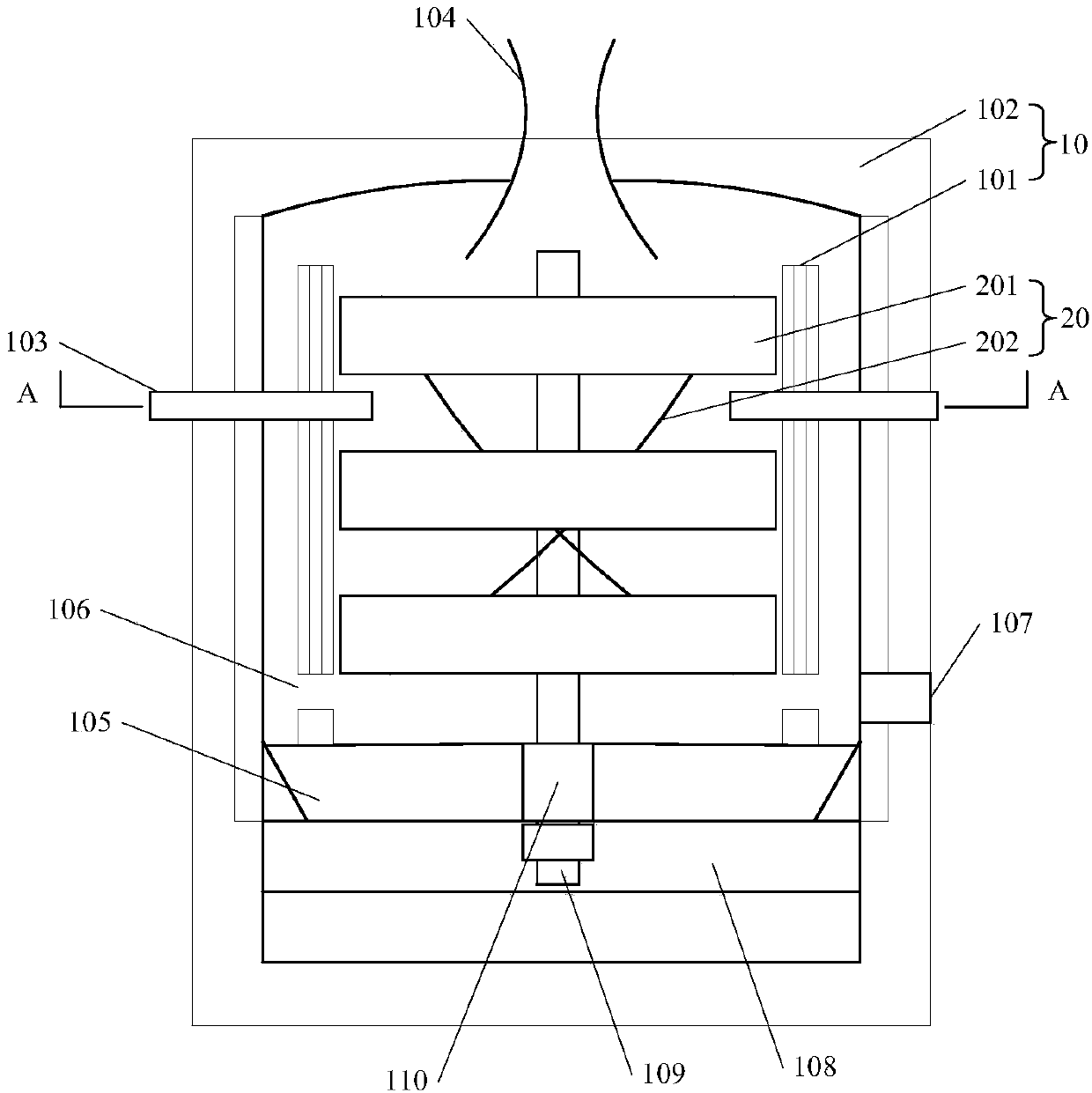

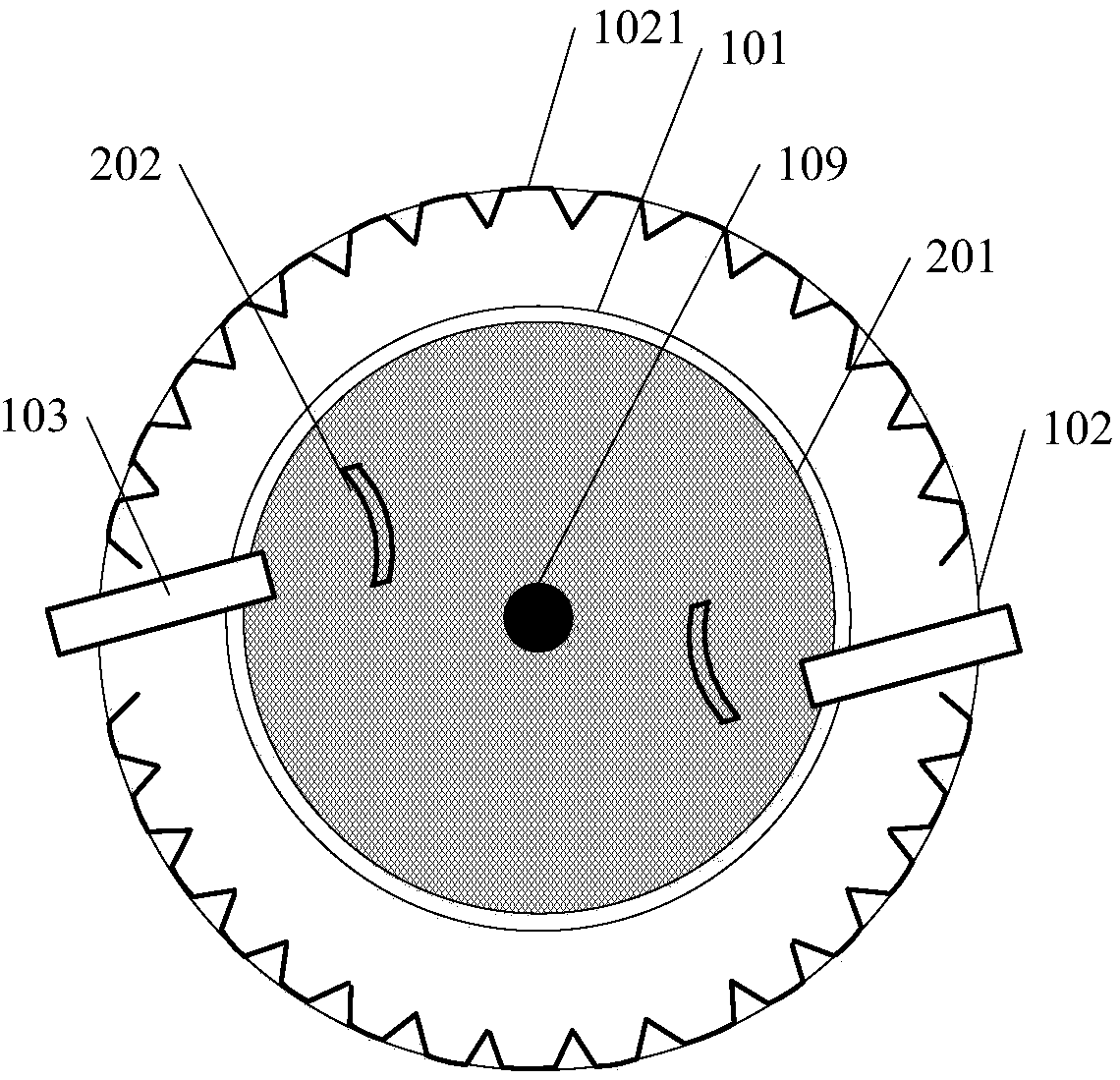

The invention discloses a temperature difference power generation device which comprises a tail gas tank, a cooling water tank assembly, a temperature difference power generation module assembly and a clamping plate. The two ends of the tail gas tank are provided with an intake manifold and an exhaust manifold respectively, and the tail gas tank comprises a gas tank body, a shunt fin, a flow guide fin and an afflux fin; the two ends of the cooling water tank assembly are provided with a water inlet manifold and a water outlet manifold respectively, the cooling water tank assembly comprises multiple cooling water tanks, and each cooling water tank comprises a water tank body and a flow guide plate; the hot end of the temperature difference power generation module assembly is attached to the two sides of the tail gas tank, the cold end of the temperature difference power generation module assembly is attached to one side of the cooling water tank assembly, and the temperature difference power generation module assembly comprises multiple temperature difference power generation modules; the clamping plate is arranged outside the cooling water tank assembly, and the two ends of the clamping plate are locked through bolts. The structure of the temperature difference power generation device is optimized and improved, power generation efficiency is improved, and the aim of improving the energy utilization rate is achieved.

Owner:WUHAN UNIV OF TECH

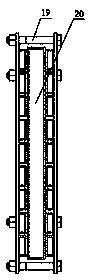

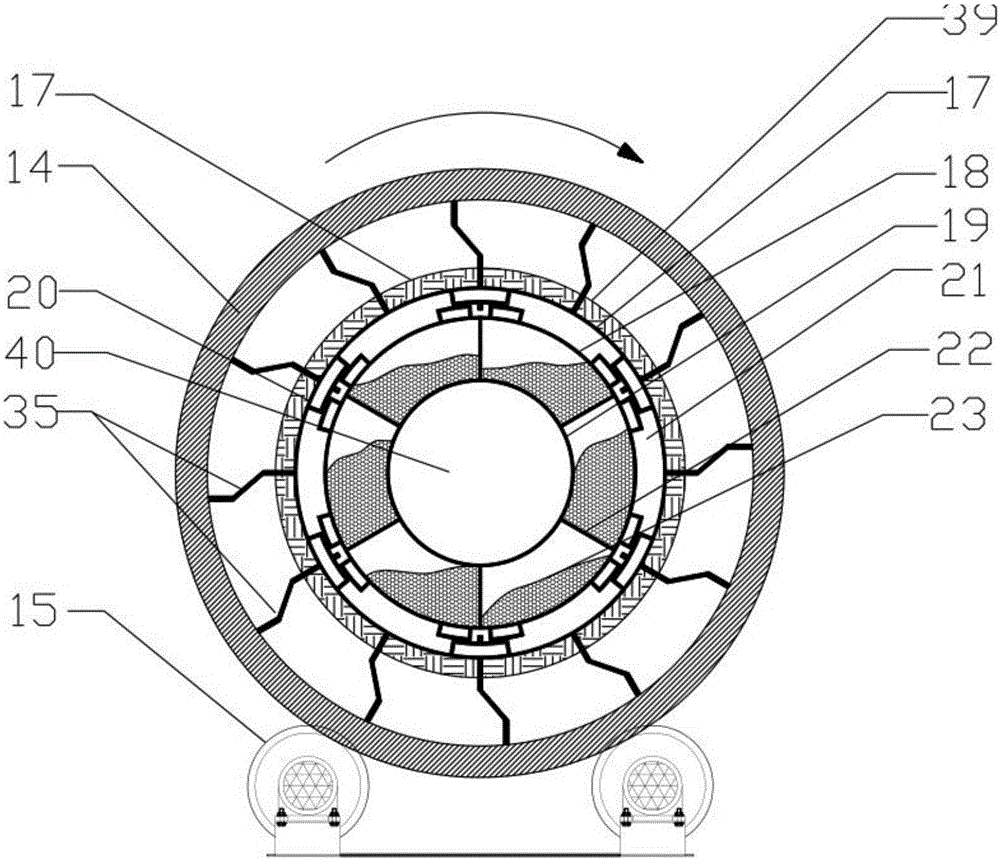

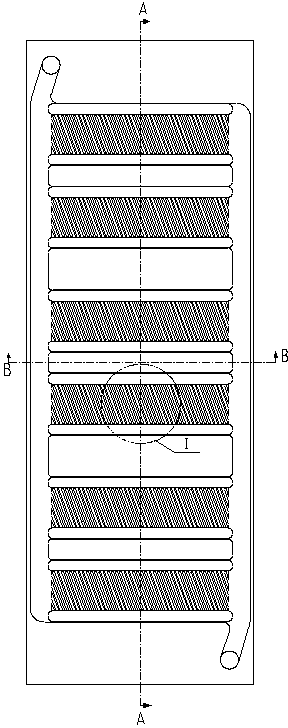

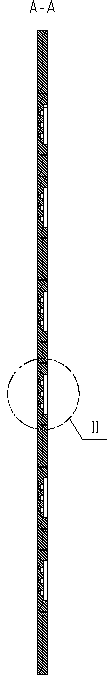

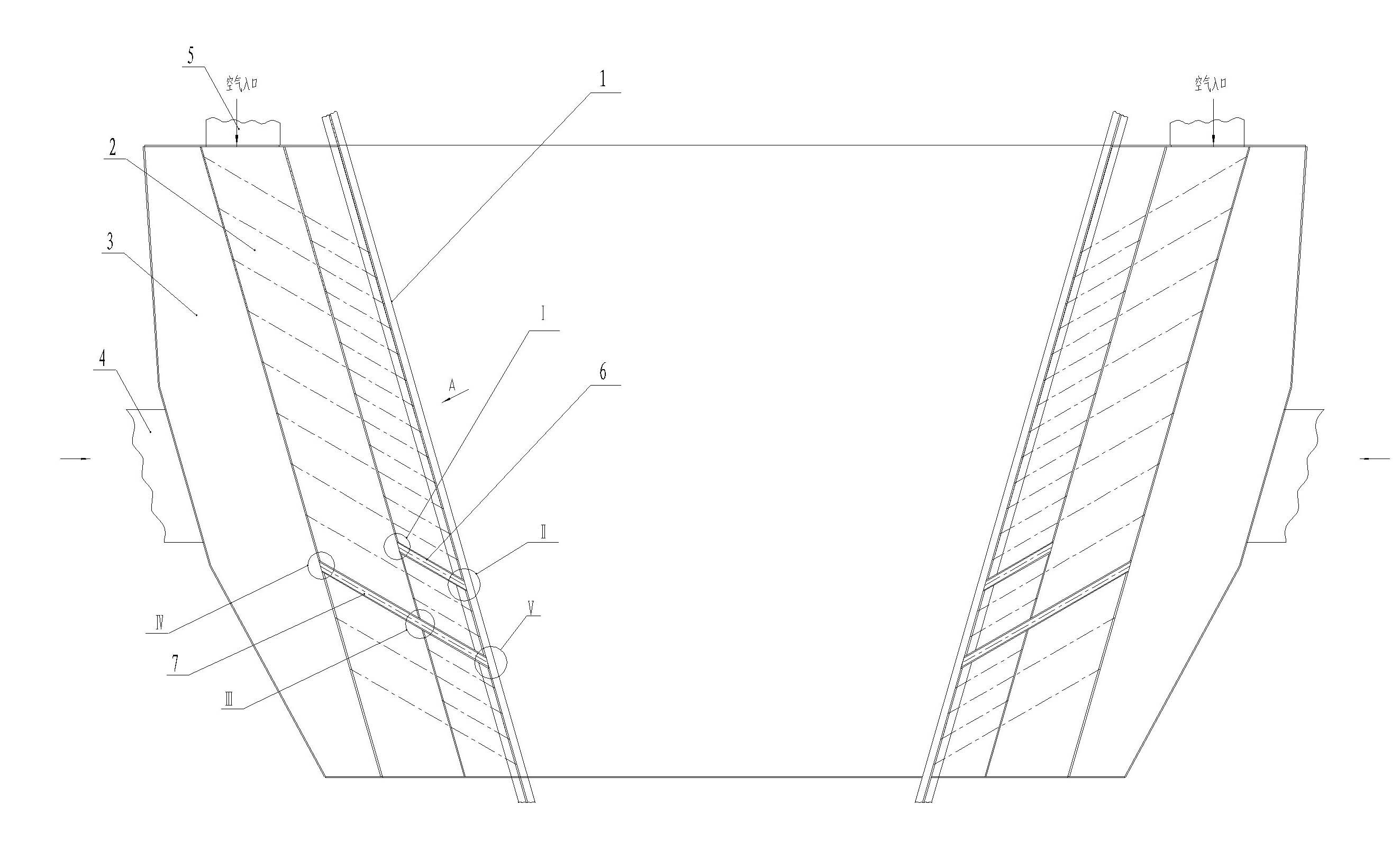

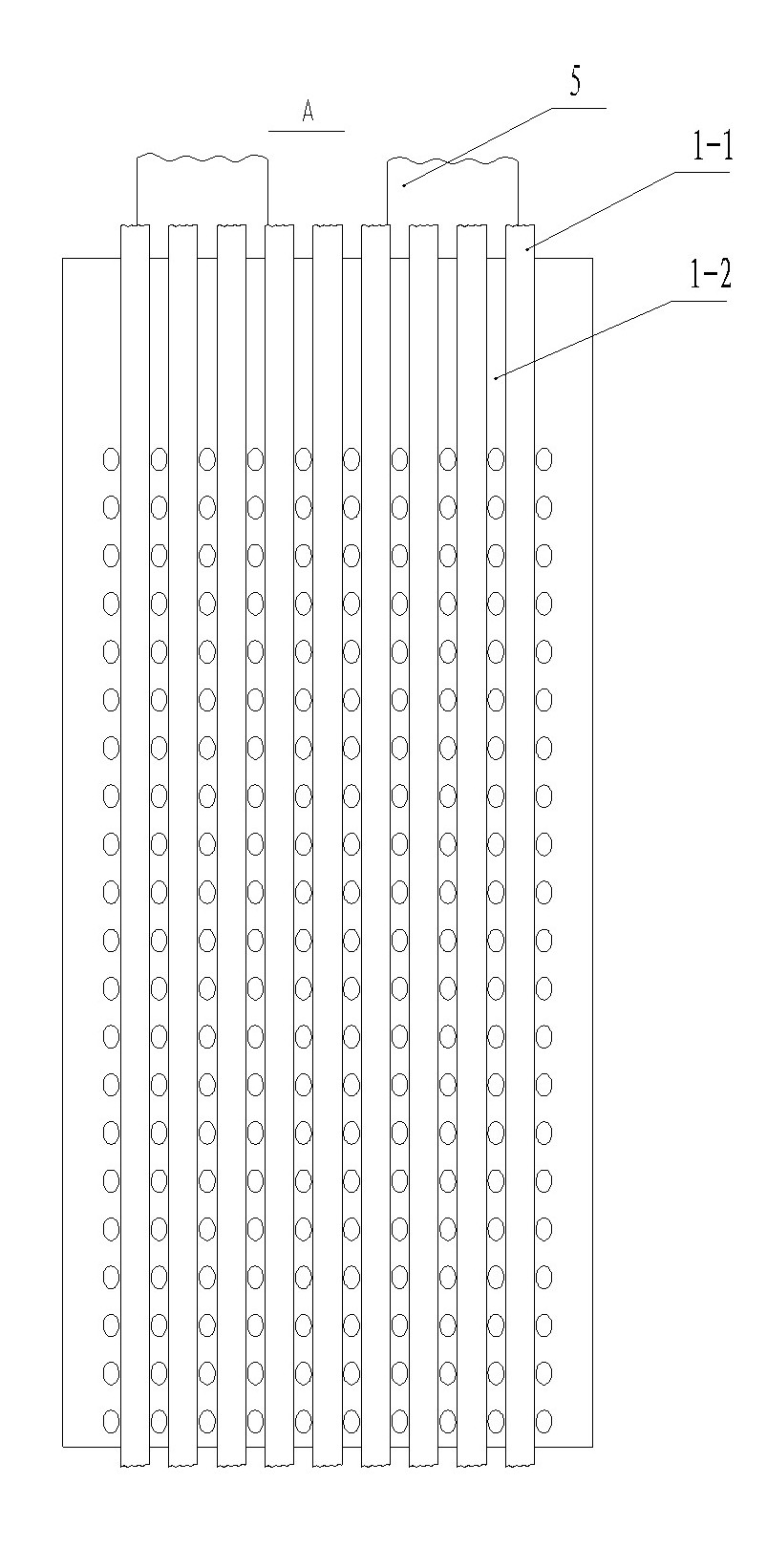

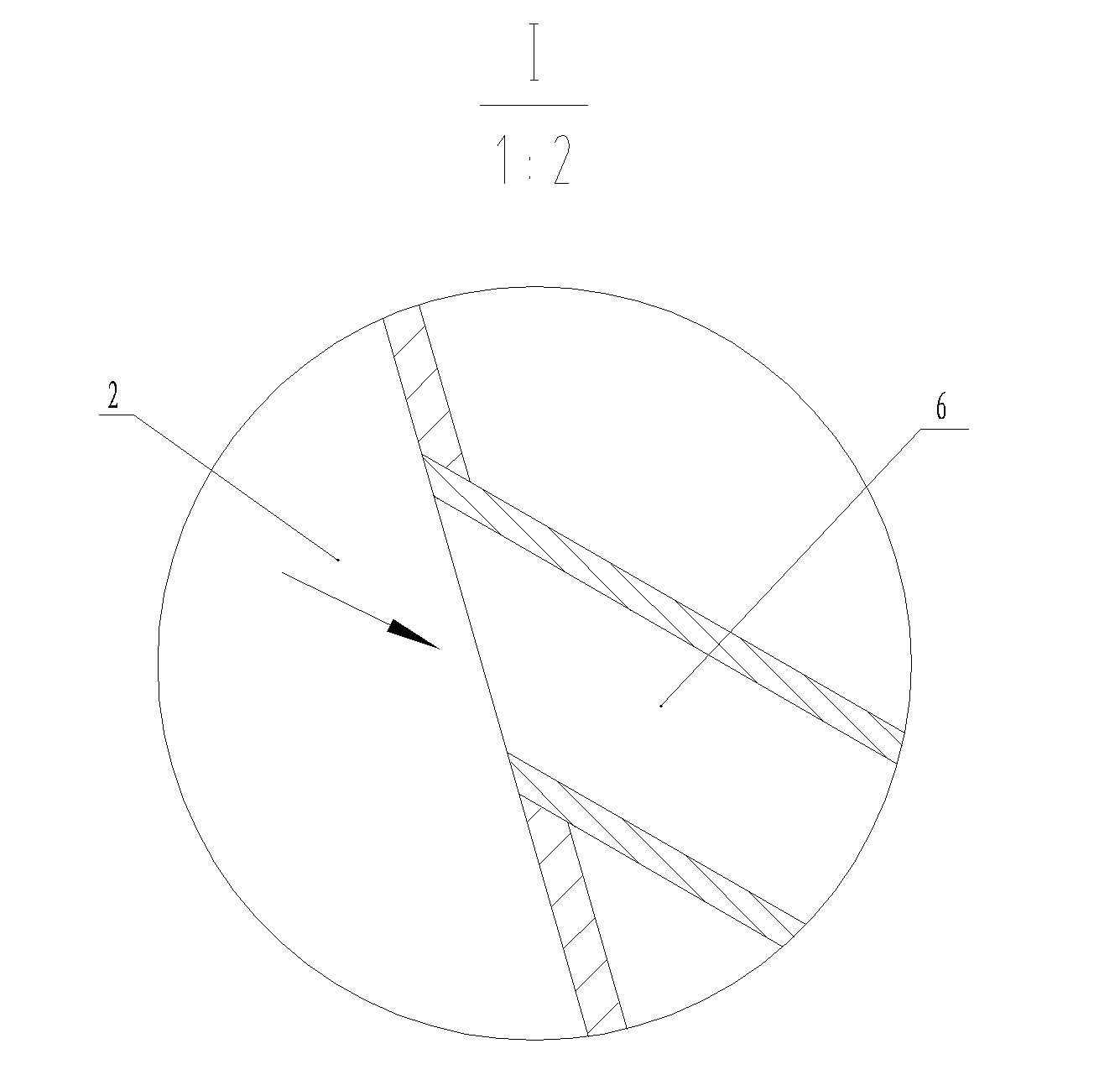

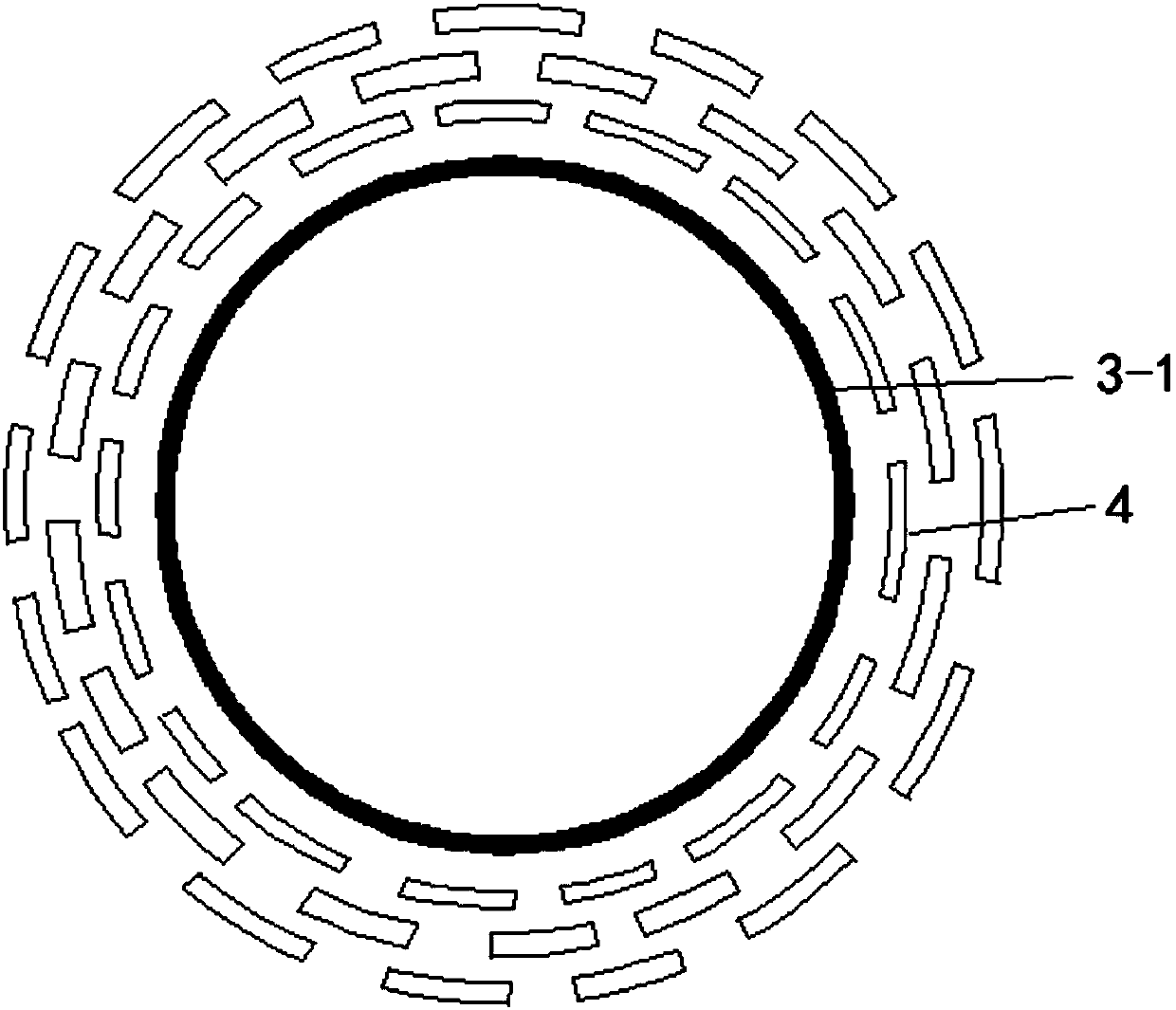

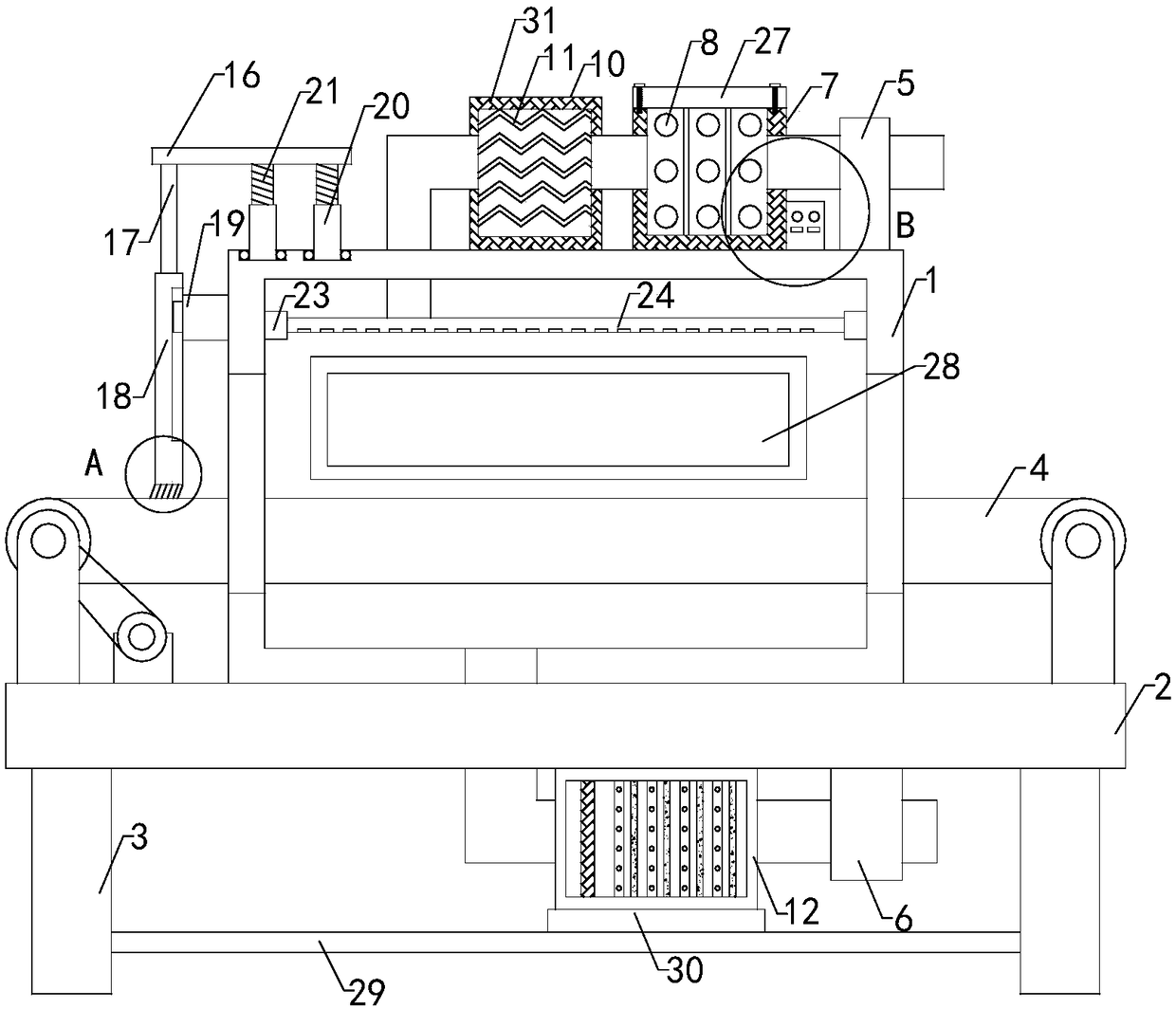

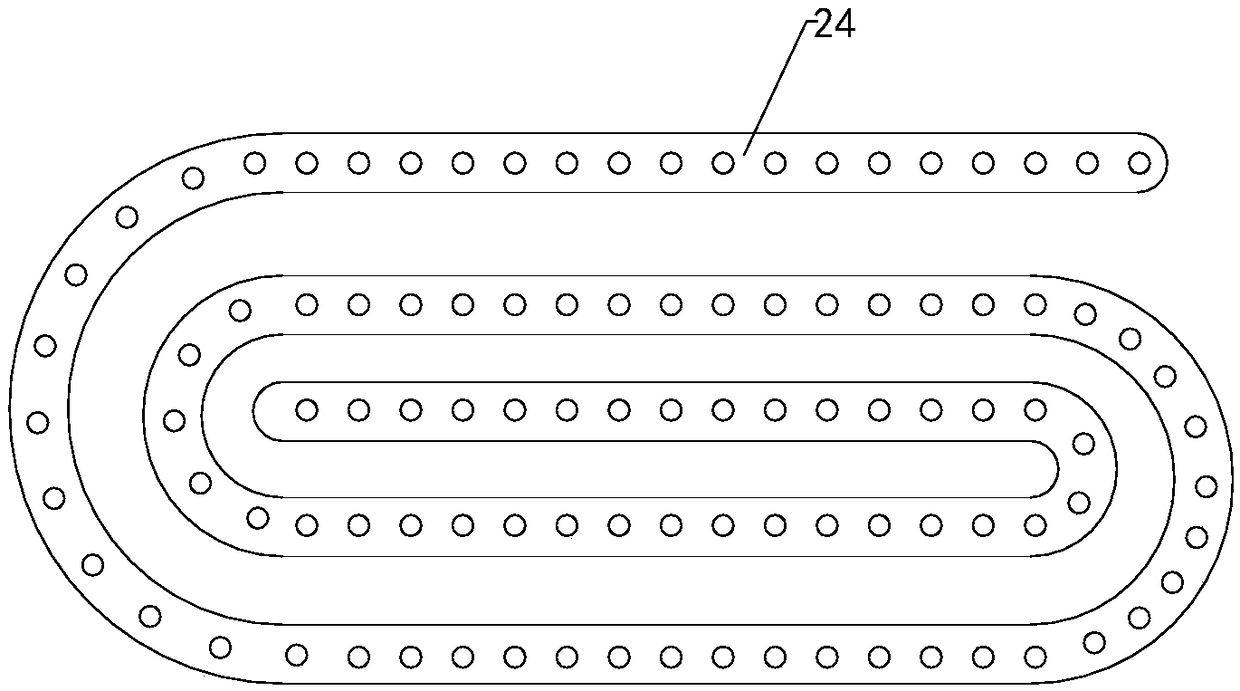

Roller type drying and sintering or roasting device

InactiveCN106679366AAutomatic separationEven heat absorptionRotary drum furnacesDrying gas arrangementsEngineeringNet shape

The invention relates to a roller type drying and sintering or roasting device which comprises a kiln body and a drive device. A drying roller comprises a kiln body outer shell, a net-shaped outer sleeve and a net-shaped inner sleeve from outside to inside in the radial direction of the drying roller. The inner wall of the kiln body outer shell and the outer wall of the net-shaped outer sleeve are connected through a plurality of sliding drive shifting blocks evenly distributed in the circumferential direction, and rotary drive is carried out. A powder chamber is formed by a space between the kiln body outer shell and the net-shaped outer sleeve. The net-shaped outer sleeve and the net-shaped inner sleeve are connected through a plurality of net-shaped partitions spirally extending in the length direction of the kiln body. A space between the net-shaped outer sleeve and the net-shaped inner sleeve is divided by the partitions into a plurality of drying or roasting (sintering) material chambers distributed in the circumferential direction. An inner sleeve air chamber is formed by a space in the inner sleeve. The device has the beneficial effects that material drying is even, thorough and fast; the manmade pellet (spherical block) damage rate is low; the device investment is reduced; the productivity is greatly improved; and energy saving and emission reduction are realized.

Owner:唐竹胜

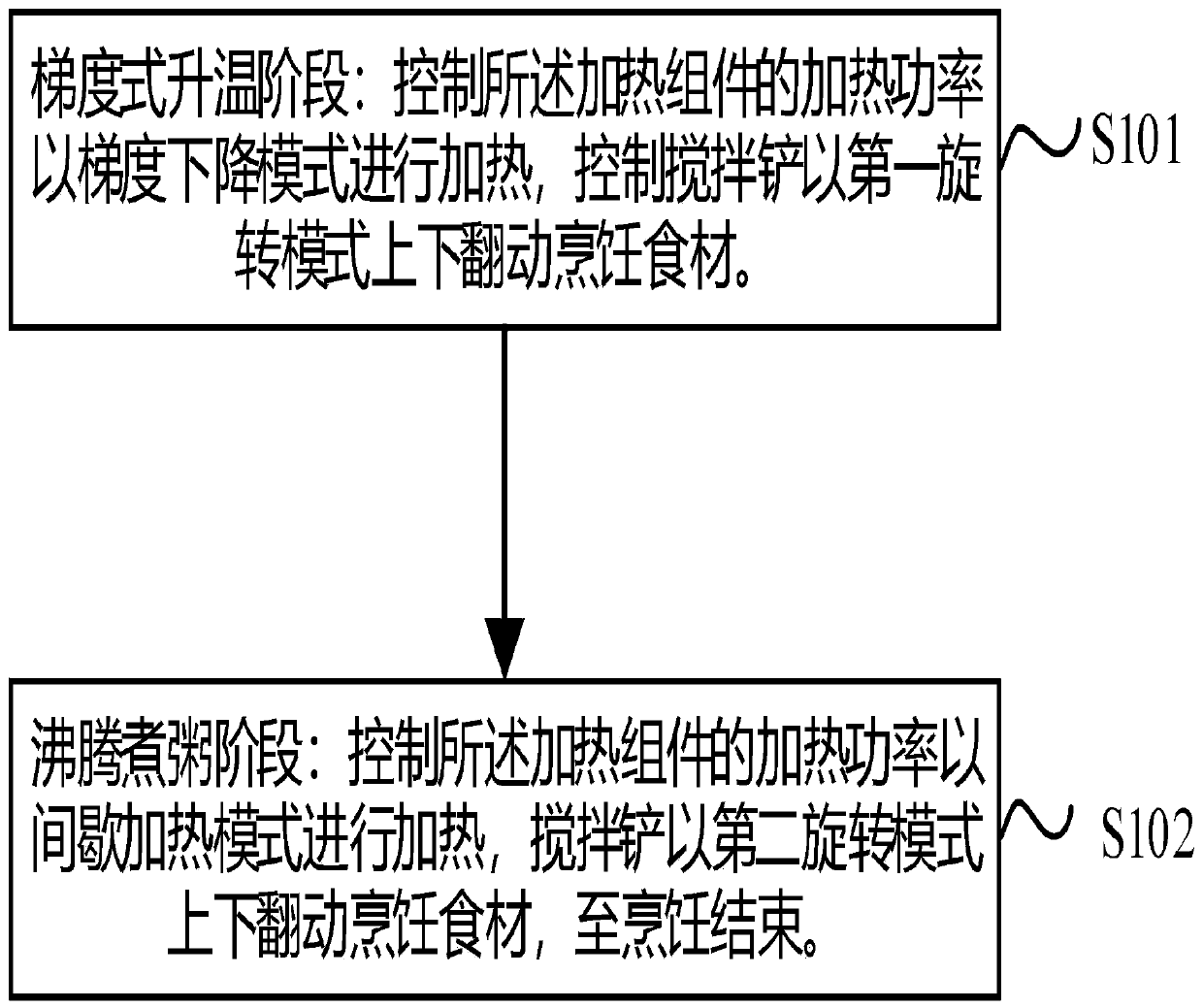

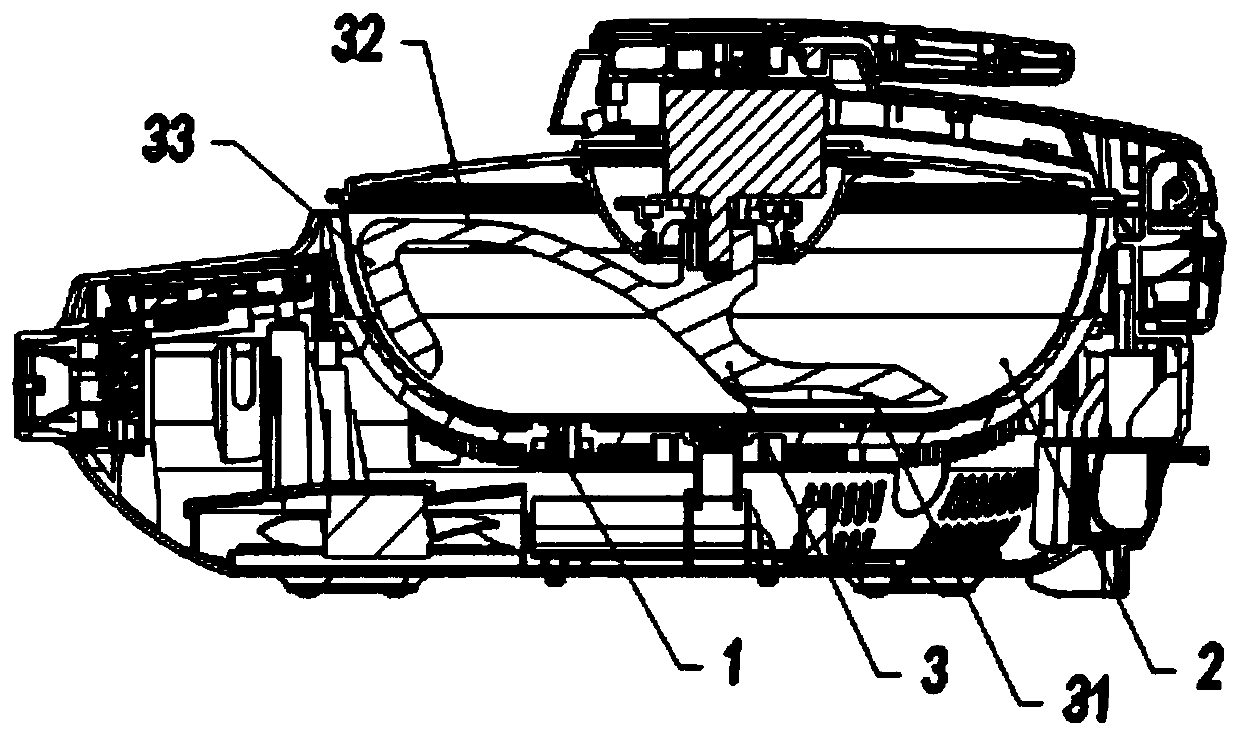

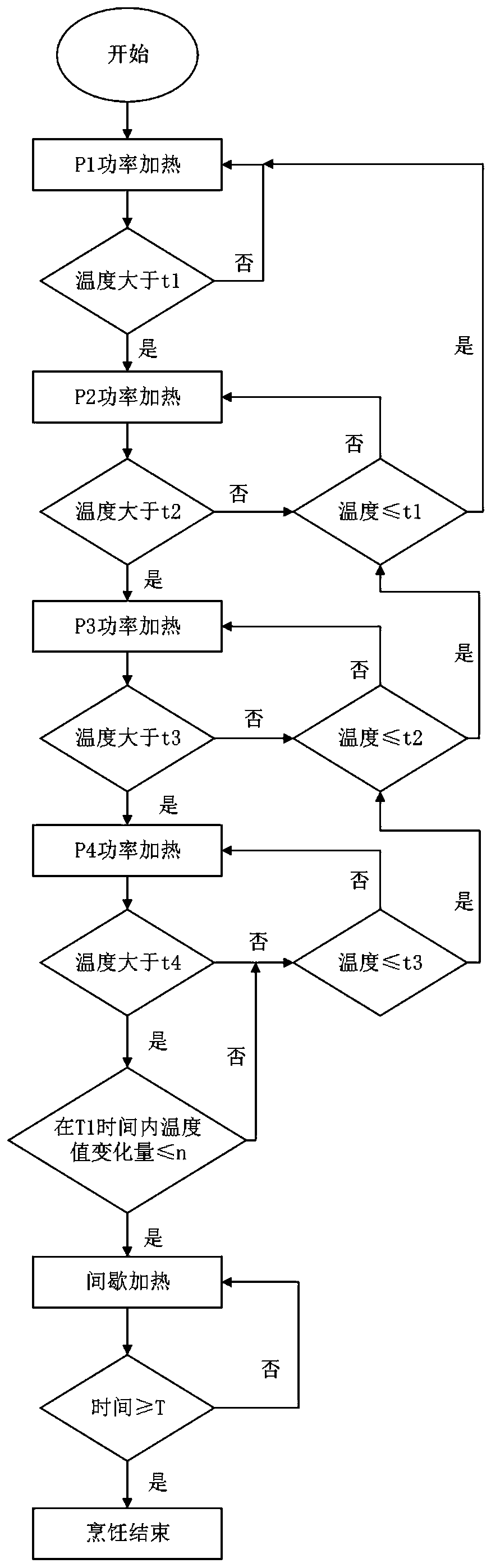

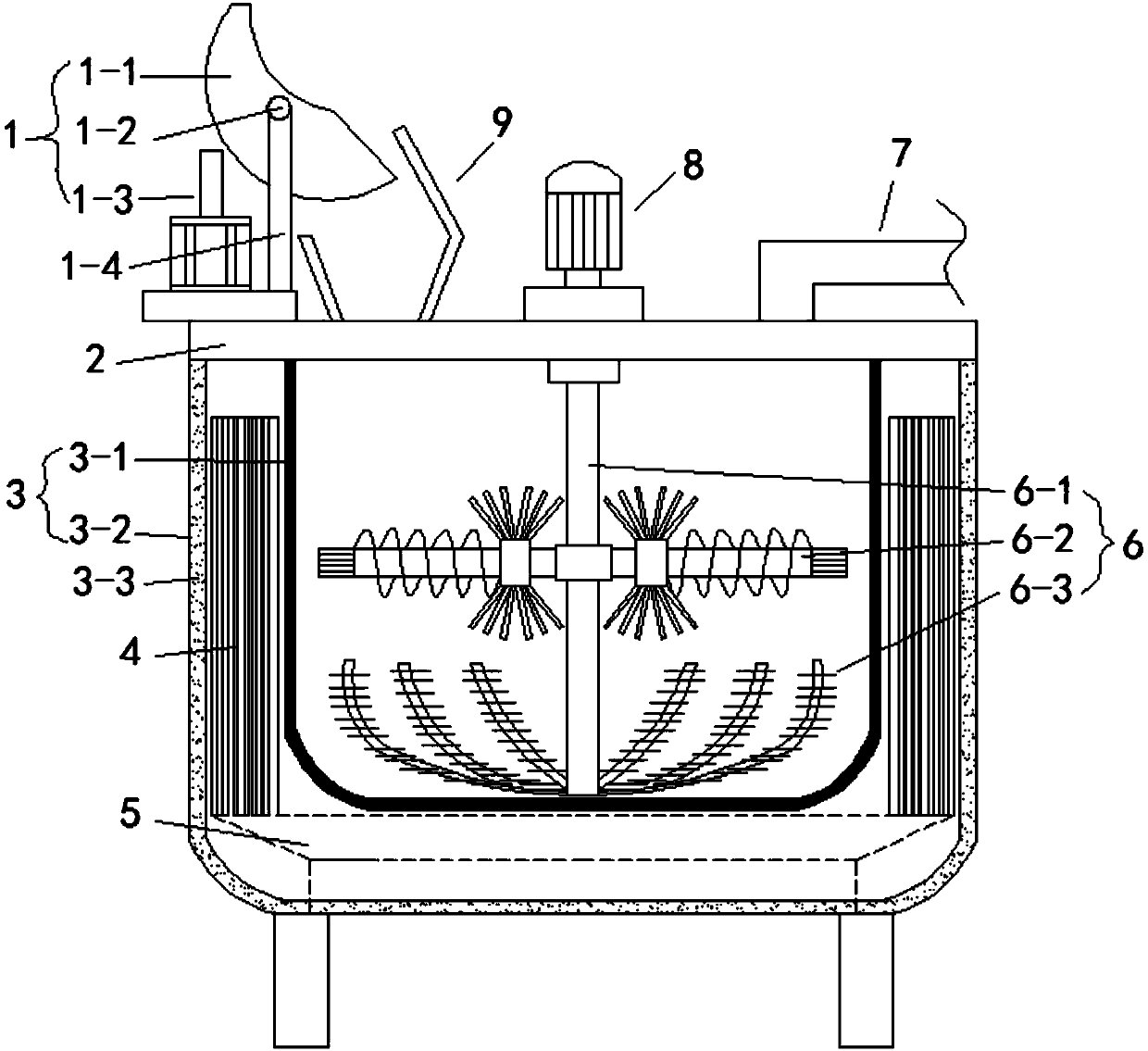

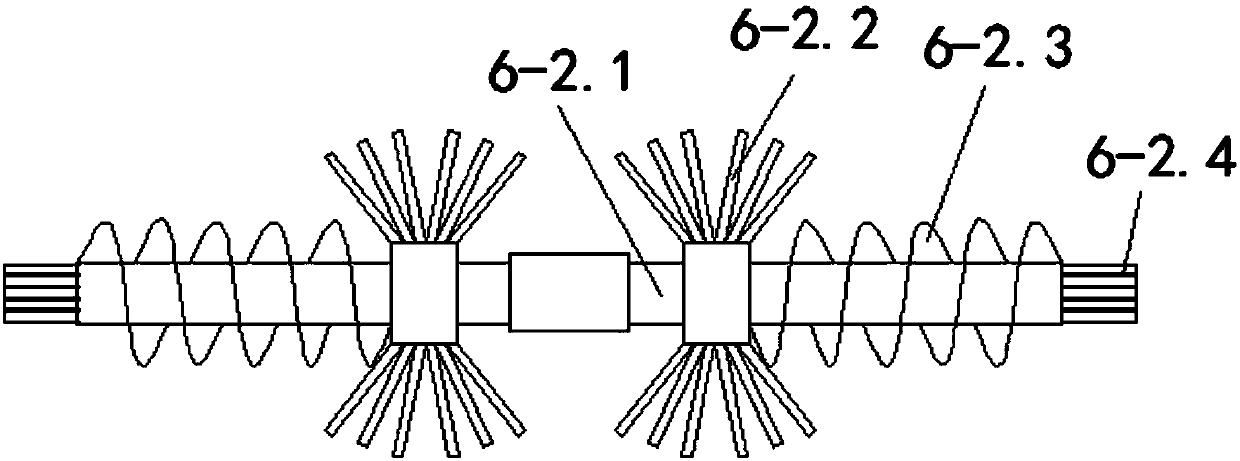

Stir-fry machine and porridge cooking control method thereof

ActiveCN111084537AFull heat absorptionBreak up fullyBoiling over preventionWarming devicesProcess engineeringFood material

The invention discloses a stir-fry machine and a porridge cooking control method thereof. The stir-fry machine comprises a heating assembly, a cooking cavity and a stirring shovel extending into the cooking cavity, wherein the stirring shovel is used for turning over cooking food materials that are placed in the cooking cavity up and down. The porridge cooking control method comprises the steps: agradient type temperature rising stage: controlling the heating power of the heating assembly to heat in a gradient descending mode, and controlling the stirring shovel to turn over the cooking foodmaterials in a first rotating mode; and a boiling porridge cooking stage: controlling the heating power of the heating assembly to heat in an intermittent heating mode, and turning over the cooking food materials up and down by the stirring shovel in a second rotating mode until the cooking is finished. According to the invention, in the stirring process, the food is gelatinized, the viscosity ismoderate, the taste of a user is good, and the pot overflowing phenomenon in the porridge cooking process can be avoided by combining segmented and stepped heating with stirring.

Owner:JOYOUNG CO LTD

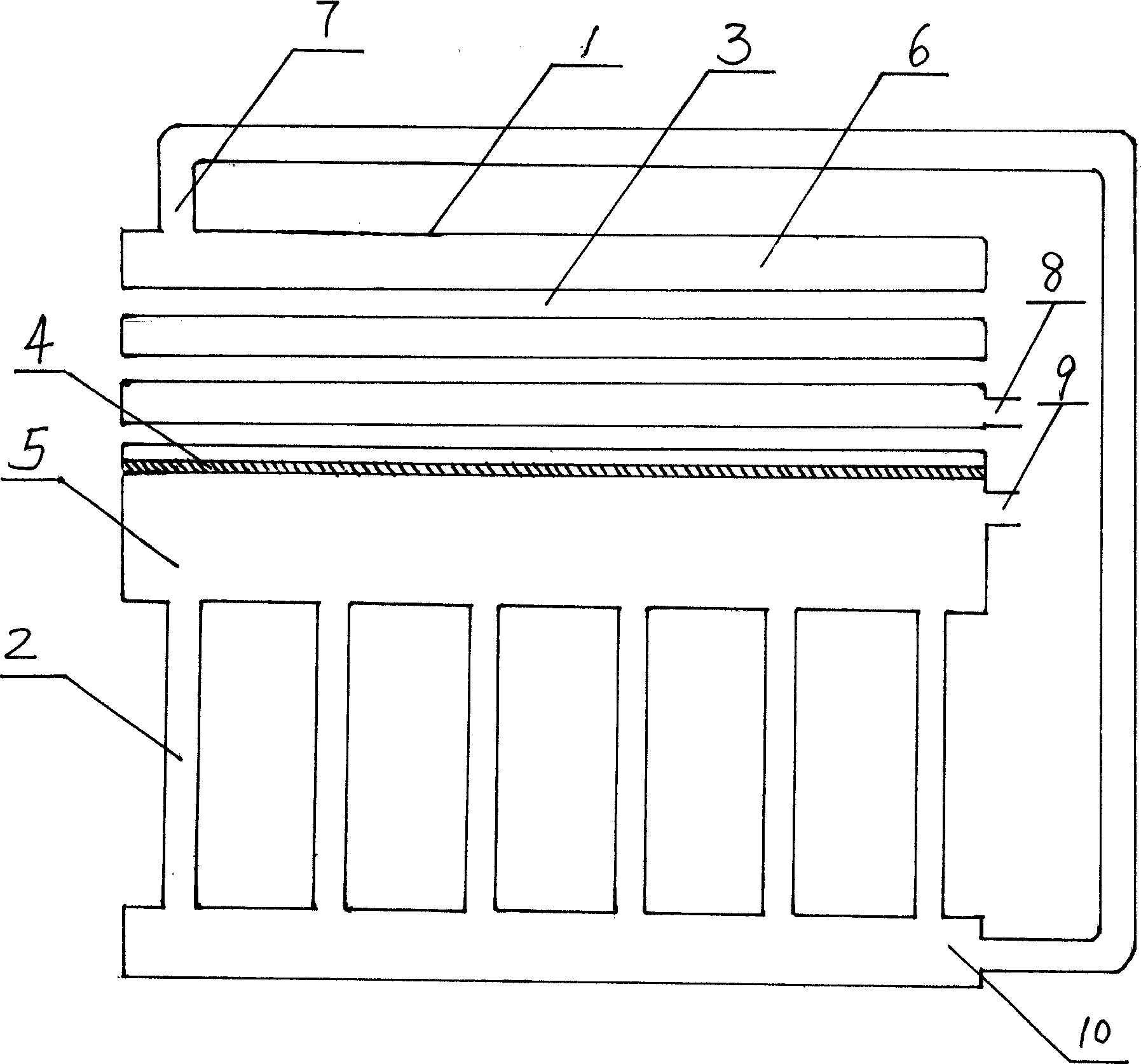

Water cooling plate for heat dissipation of high-power electrical heating element

InactiveCN103747654AIncrease disturbanceImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringWater cooling

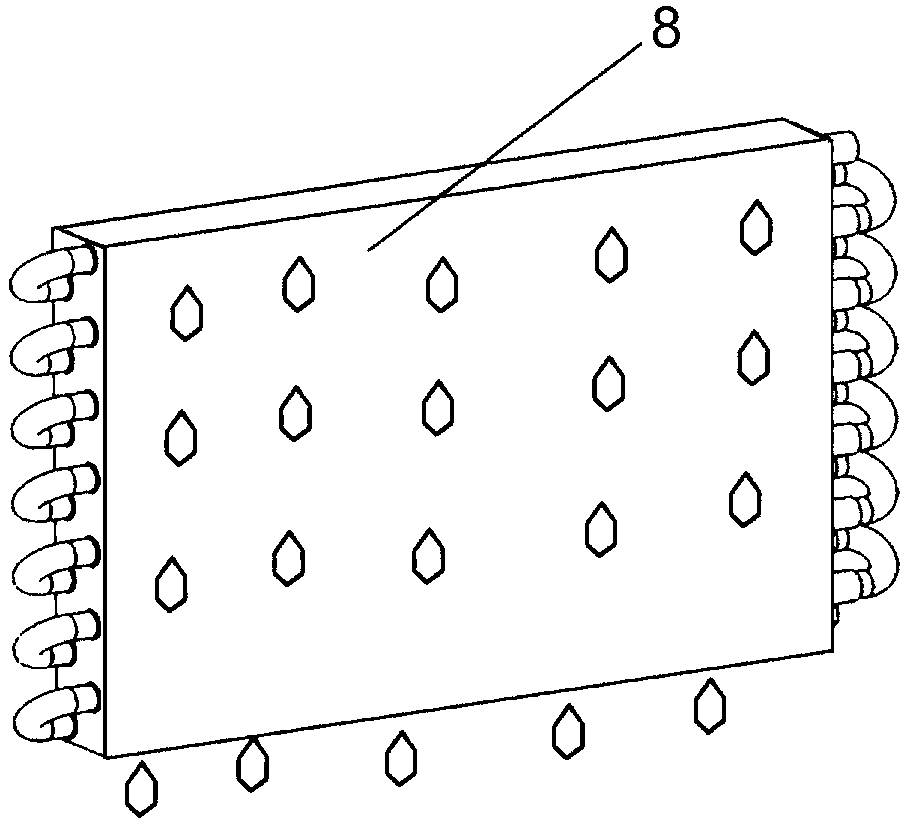

The invention provides a water cooling plate for heat dissipation of a high-power electrical heating element. The water cooling plate comprises an upper plate (6) with upper fins (8) and a lower plate (7) with lower fins (4); and the upper plate (6) with the upper fins (8) and the lower plate (7) with the lower fins (4) and a main flow channel are welded to form an integrated one, thereby forming a cooling medium flow channel. In addition, the upper plate and the lower plate respectively include upper plate slots (13) and lower plate slots (12), wherein the upper plate slots (13) and the lower plate slots (12) are formed by milling. And the upper fins (8) and the lower fins (4) are arranged in a staggered mode at certain angles in the flow channel. With the water cooling plate, the cooling liquid disturbance in the flow channel is enhanced. The heat dissipation efficiency is high; and the processing technology is relatively simply. And the water blocking can be controlled in a reasonable range.

Owner:周细文 +1

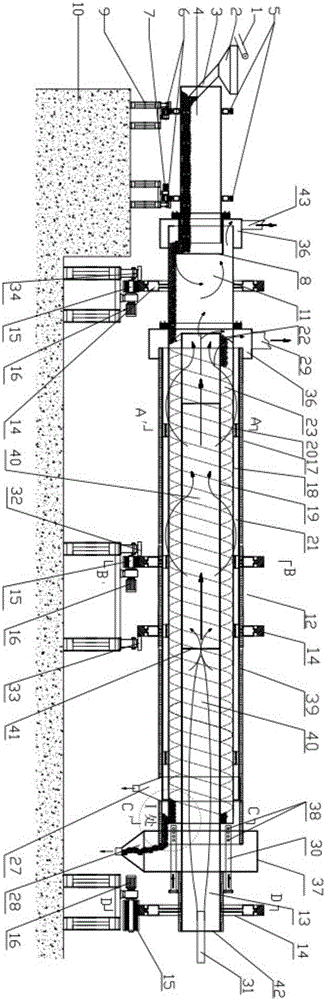

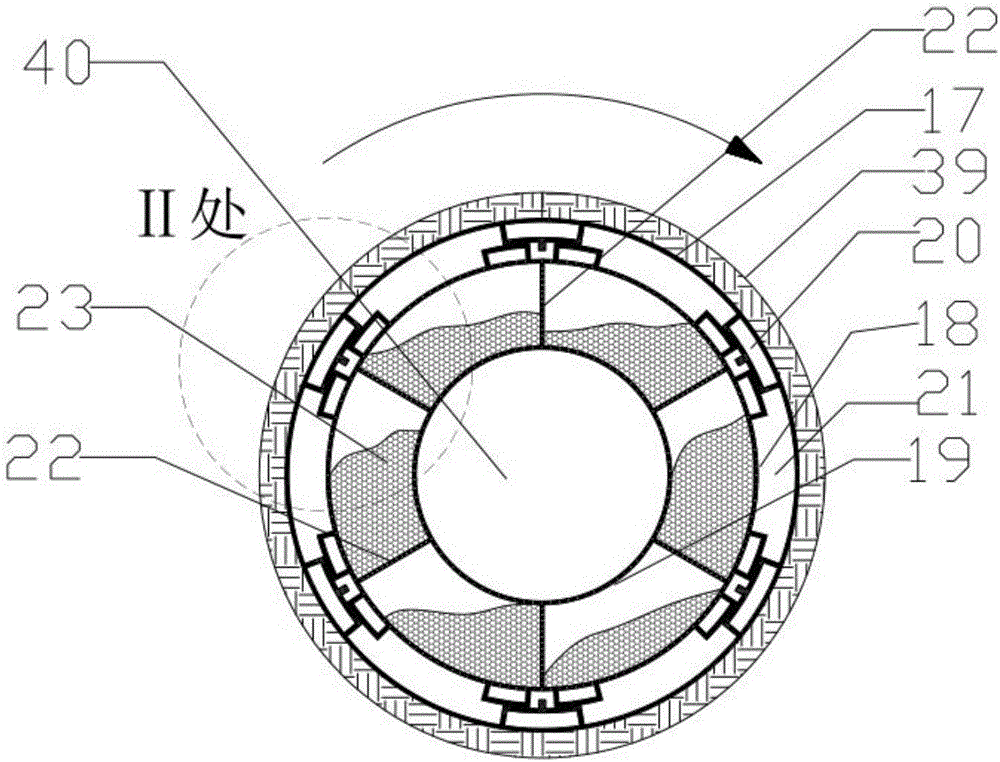

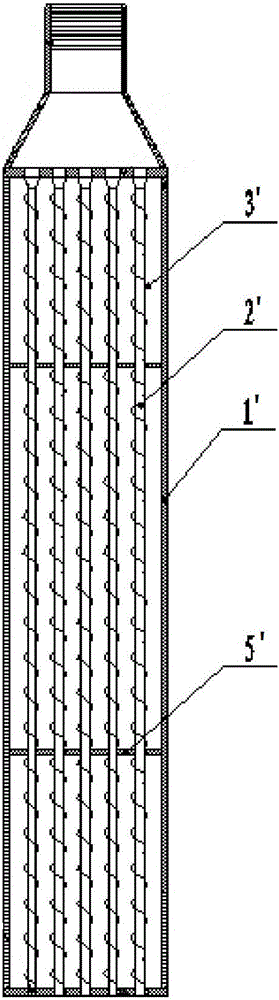

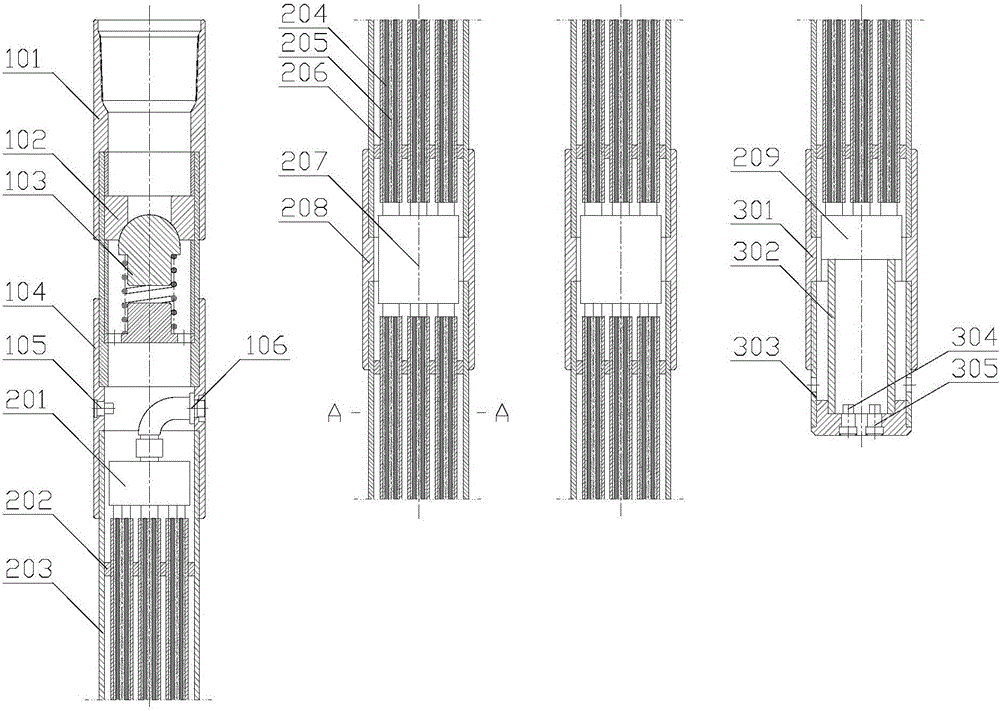

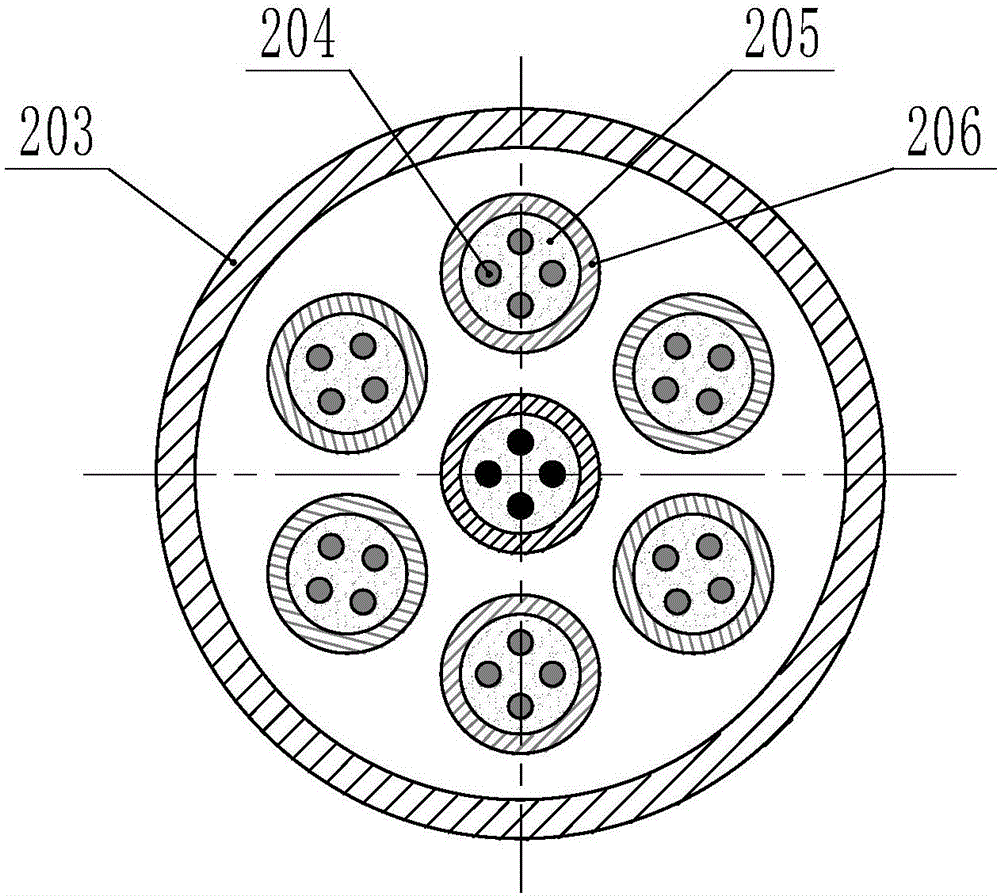

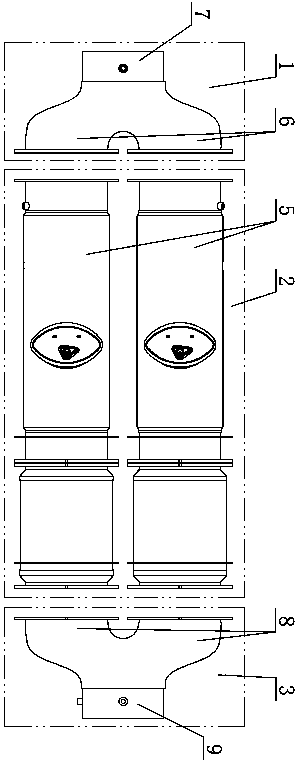

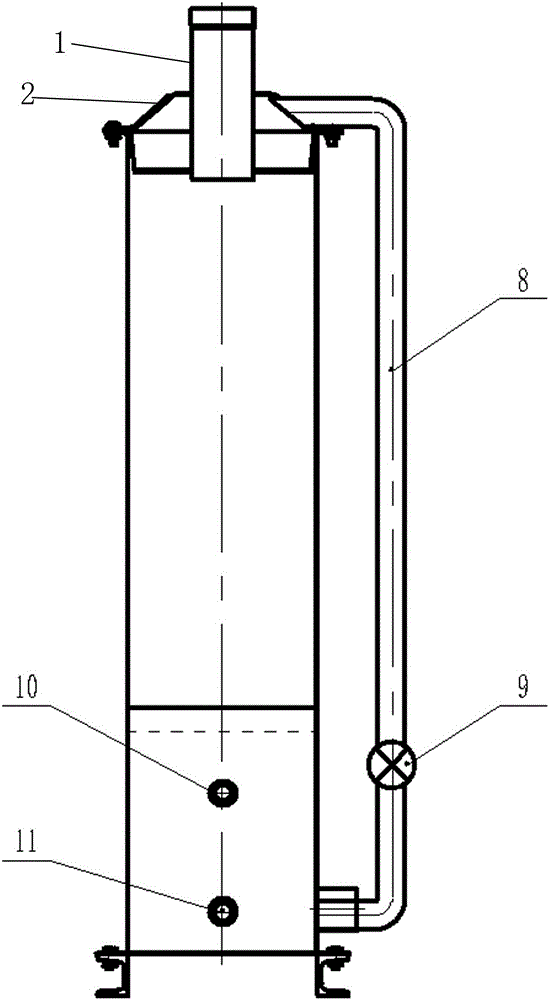

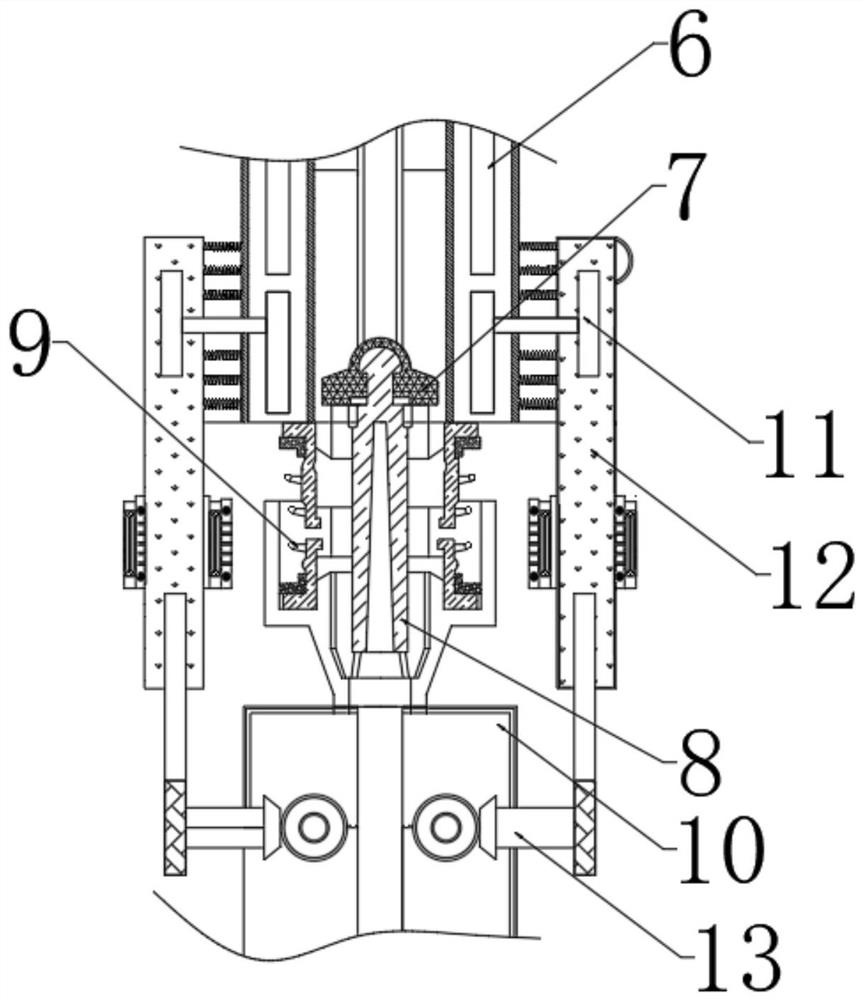

Electric heating type downhole steam generator

ActiveCN106016221AEasy to installExtended dwell timeSteam generation heating methodsFluid removalElectricityEngineering

The invention relates to the technical field of heavy oil thermal recovery in petroleum engineering, in particular to an electric heating type downhole steam generator. The generator comprises an inlet part, an electric heating part and an outlet part which are sequentially connected from top to bottom, wherein the electric heating part comprises at least one heating section; each heating section comprises a heating section casing and multiple heating tubes arranged inside the heating section casing; electric heating wires are arranged in all the heating tubes, and positions between the electric heating wires and the heating tubes are filled with insulating and temperature-resistant materials; space allowing water to flow through is formed among the heating tubes and between the heating tubes and the heating section casings; a water inlet is arranged at the inlet part; and a discharge port is arranged at the outlet part. High-temperature steam is produced downhole and directly injected into an oil layer, the heat loss is reduced, the energy utilization rate is greatly increased, and the generator has the outstanding advantages in deep well and extra-deep wells; and the electric heating wires are arranged in the heating tubes, so that the generator is convenient to mount, good in reliability and more beneficial to steam generation.

Owner:YANGTZE UNIVERSITY

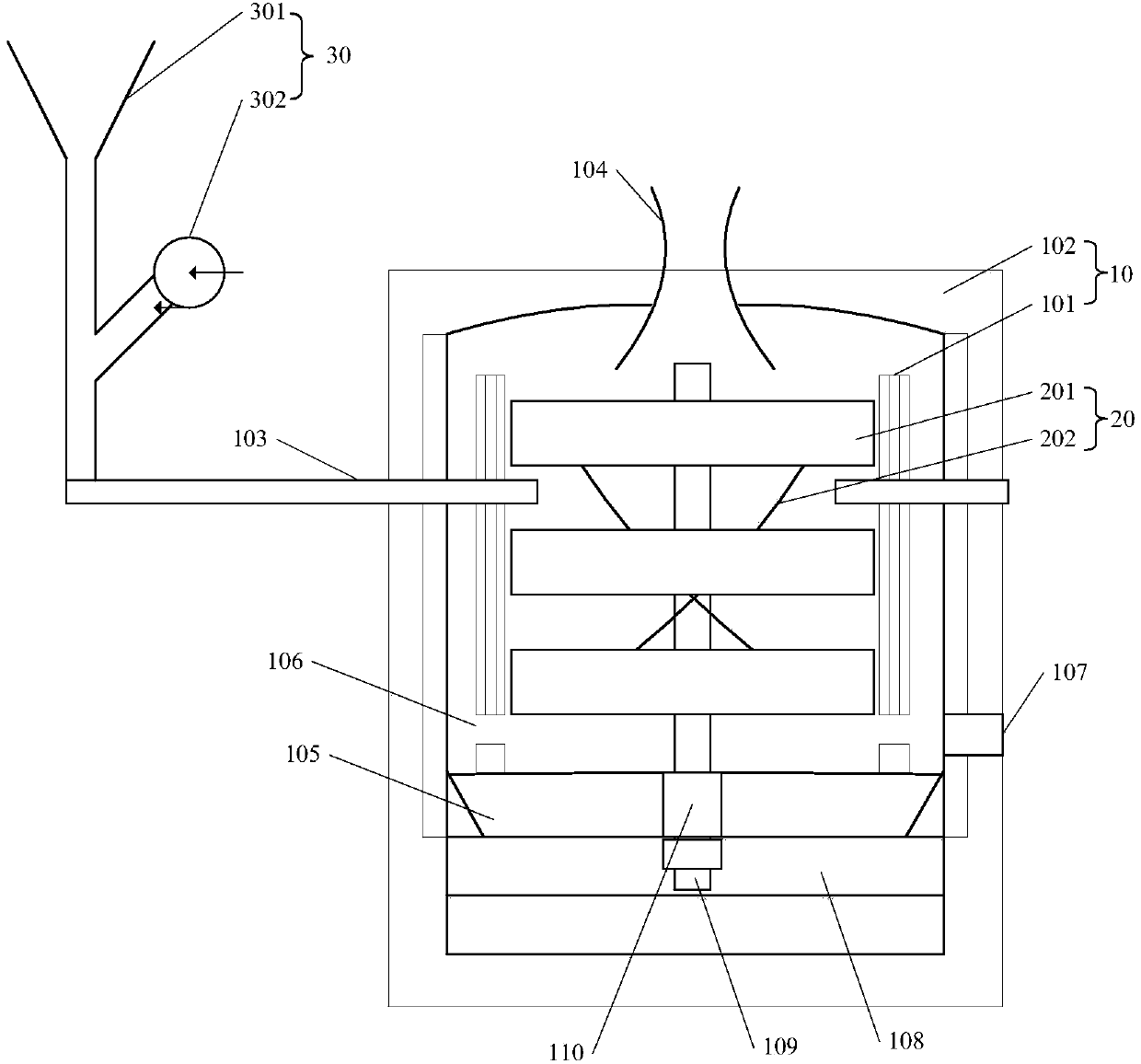

Heat energy controlling method for melting process of single crystal furnace

InactiveCN102618920AExtended service lifeFull heat absorptionAfter-treatment apparatusBy pulling from meltThermal energyConstant power

The invention relates to a heat energy controlling method for a melting process of a single crystal furnace. After a silicon material is put into the single crystal furnace, the method comprises the following steps for controlling: (A), heating to a low temperature according to the power of 40 to 45 kilowatts per hour, and keeping a constant power for 15 to 30 minutes; (B), heating to a medium temperature according to the power of 65 to 75 kilowatts per hour, and keeping a constant power for 15 to 30 minutes; (C), heating to a high temperature according to the power of 75 to 85 kilowatts per hour, and keeping a constant power; D, when 3 to 5 percent of silicon material is not melted in the furnace, cooling to a medium temperature according to the power of 65 to 75 kilowatts per hour, and keeping a constant power for 30 to 60 minutes, so that the silicon material is completely melted; and E, seeding. By adopting the method, the power value is gradually improved for gradual heating of the single crystal furnace, the silicon material can be promoted to fully absorb heat, and a small part of silicon material is melted by using waste heat, so that energy consumption is reduced; and experimental results show that the service life of a graphite heat field is remarkably prolonged and can be prolonged from average 40 times of use to 70 times of use in the furnace.

Owner:ZHEJIANG HUAYOU ELECTRONICS

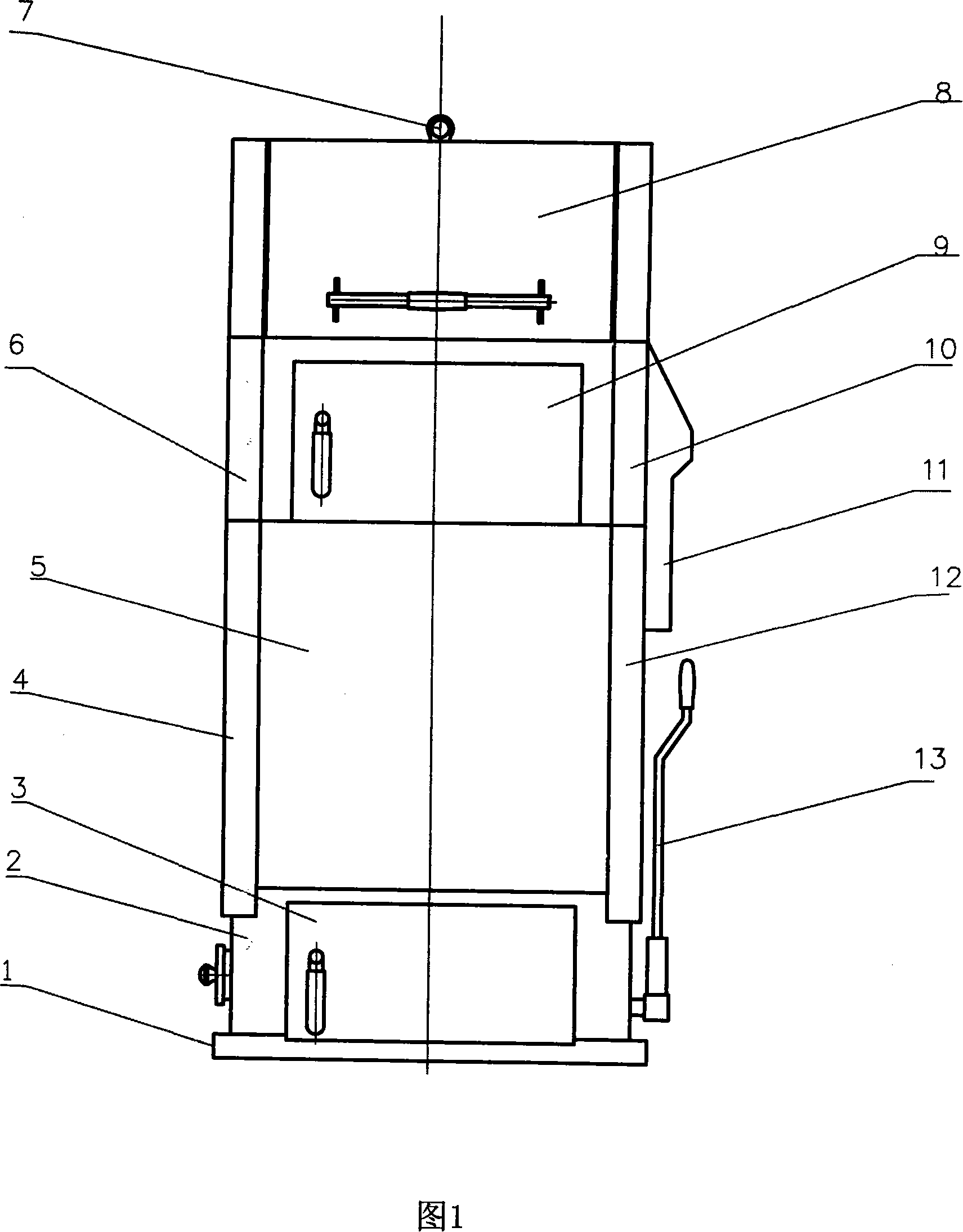

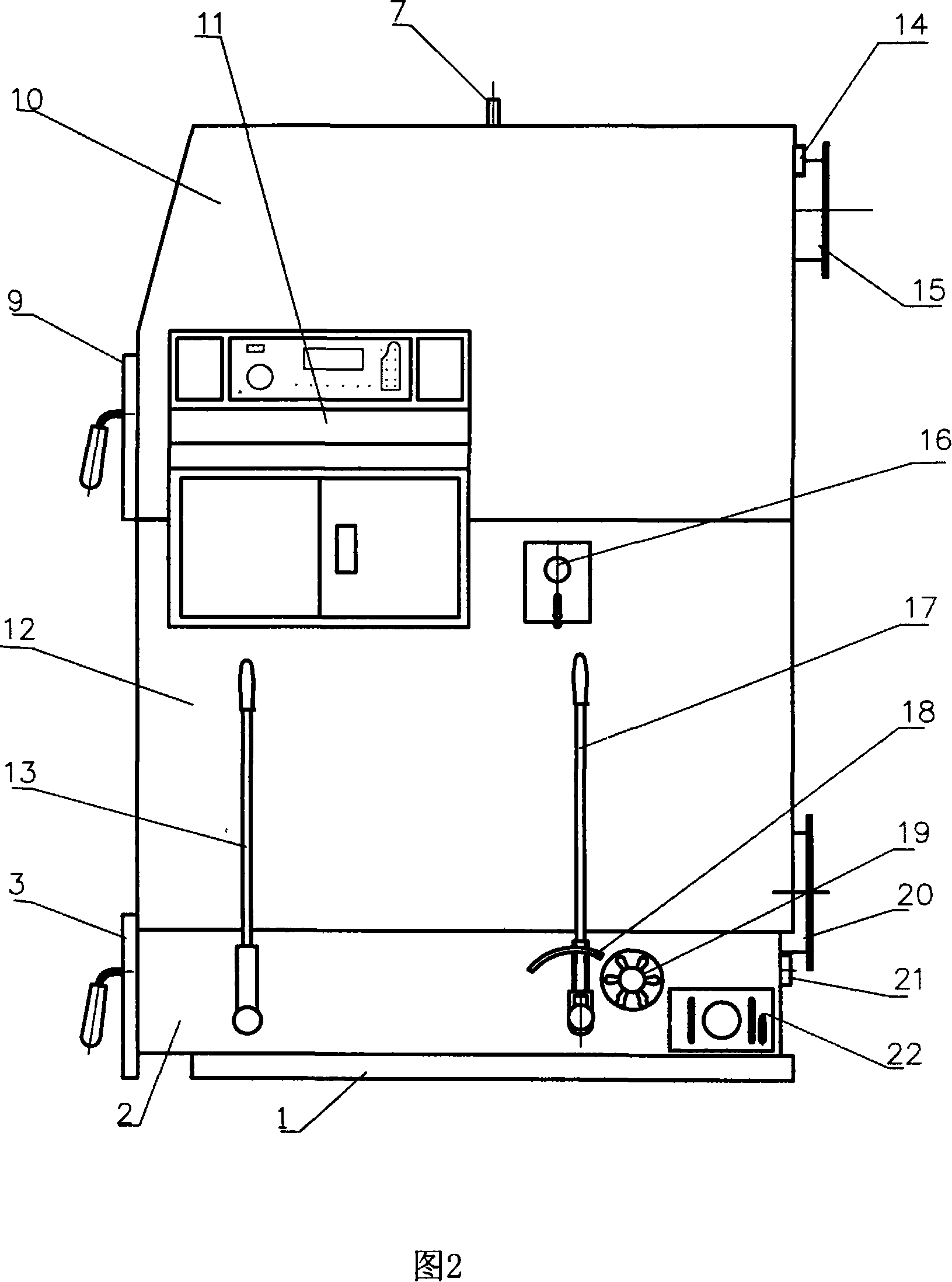

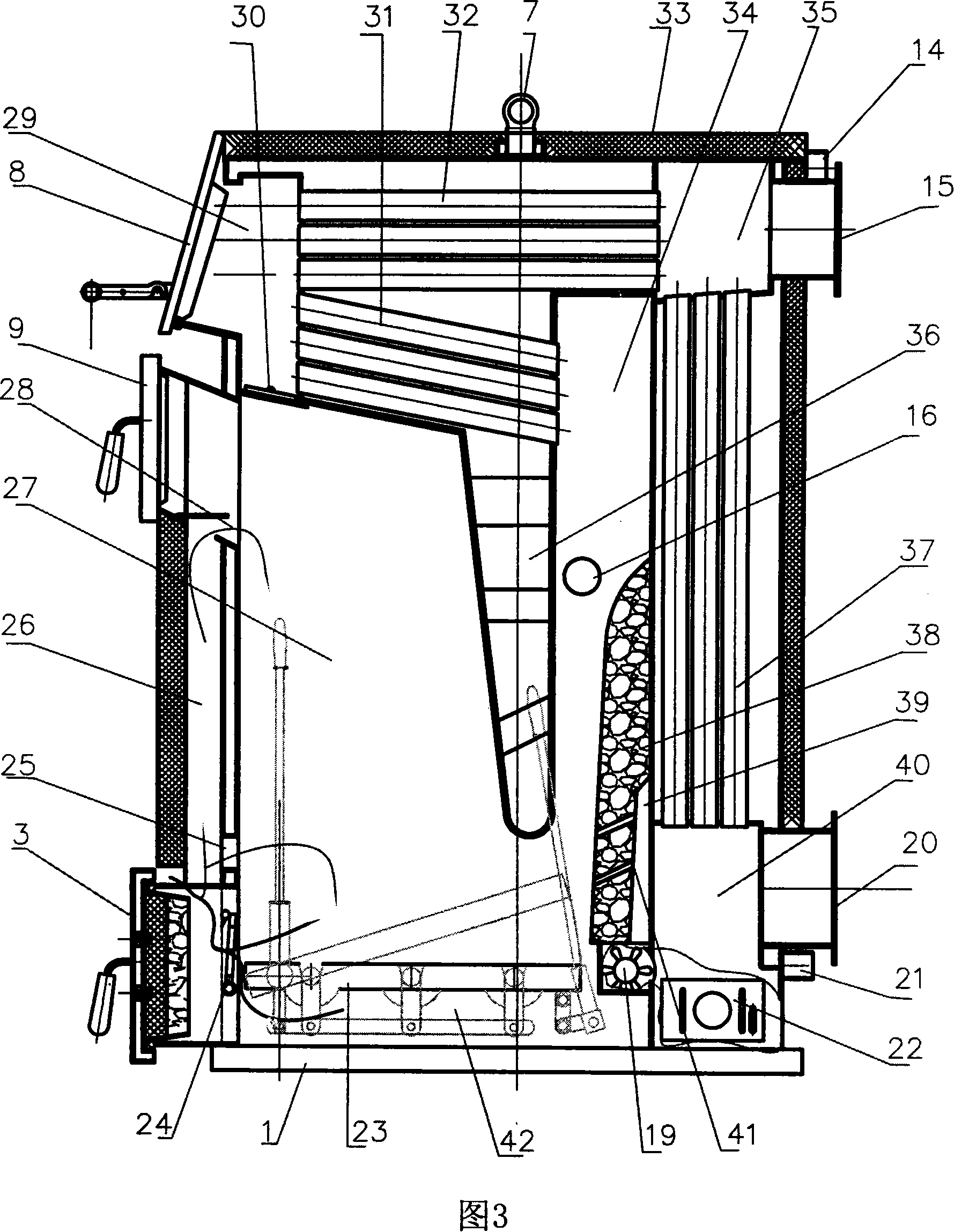

Biomass gasification automatic-control boiler

InactiveCN101122417AReduce the overall heightReduce generationSolid bar grateSolid fuel combustionAutomatic controlCombustion chamber

The invention discloses a biomass gasification automatic control boiler. A furnace is arranged above an ash removal grate. A secondary combustion chamber is arranged above the back of the ash removal grate. The middle is equipped with a fireproof plate with a sandwich structure. A flue gas channel is arranged between the lower end of the fireproof plate and the ash removal grate. Sandwich water jackets, which are mutually communicated, are arranged on the periphery and the top of the furnace, the fireproof plate and the secondary combustion chamber. A primary air is supplied into the furnace from a plurality of directions of the furnace. A secondary air is supplied into the secondary combustion chamber through a secondary air channel and a ventilating hole on a spoiler. An upper settling chamber is arranged above the furnace, which is communicated with the secondary combustion chamber through a fire tube. In addition, a settling and flue conversion chamber and a lower settling chamber, which are communicated through a fire tube is arranged above the furnace. The ash removal grate is a lifting grate, which can rotate around an anterior location pin and is used to adjust the height of the opening arranged between the lower end of the fireproof plate and the ash removal grate. A microcomputer control device can automatically control the operation of the boiler according to the set requirements. Using biomass fuels and coals, the invention has the advantages of high efficiency and low emission, which accords with the requirements of environmental protection and energy saving.

Owner:SHANDONG DUOLE HEATING EQUIP

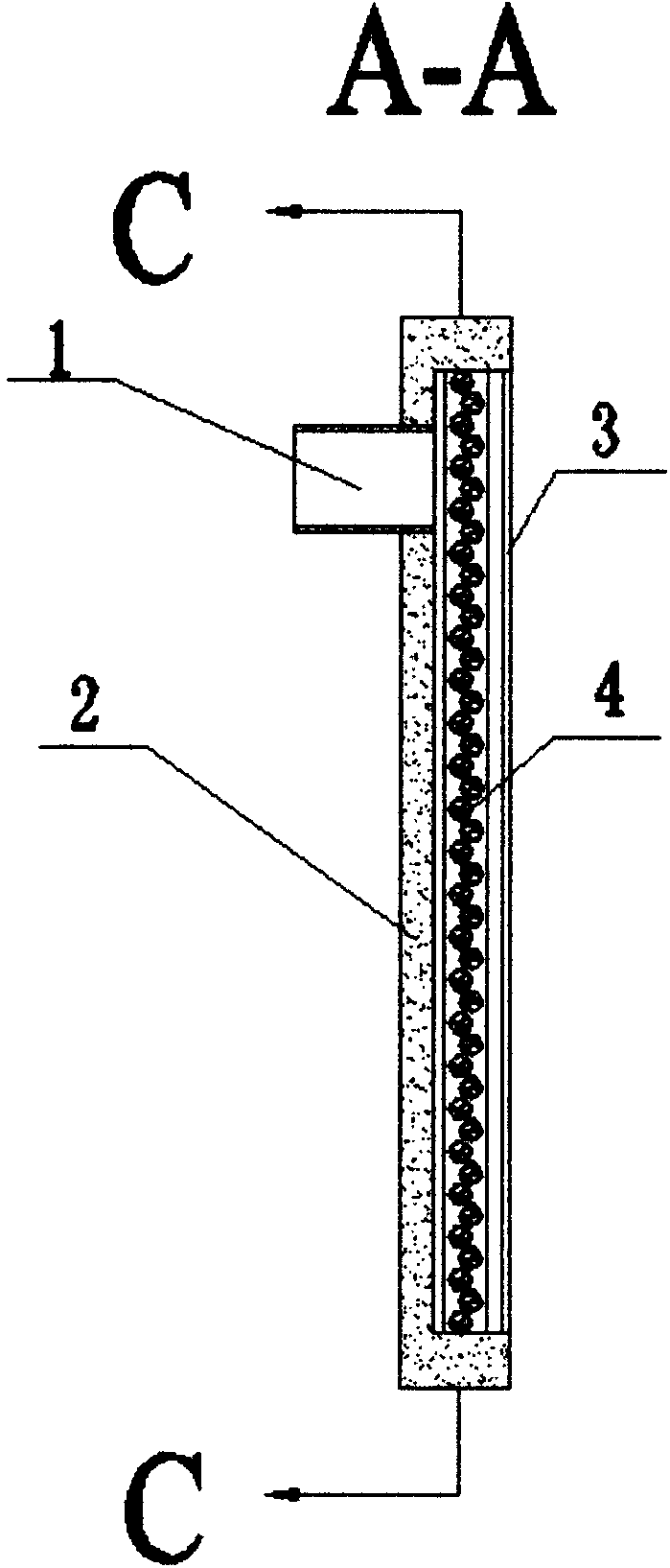

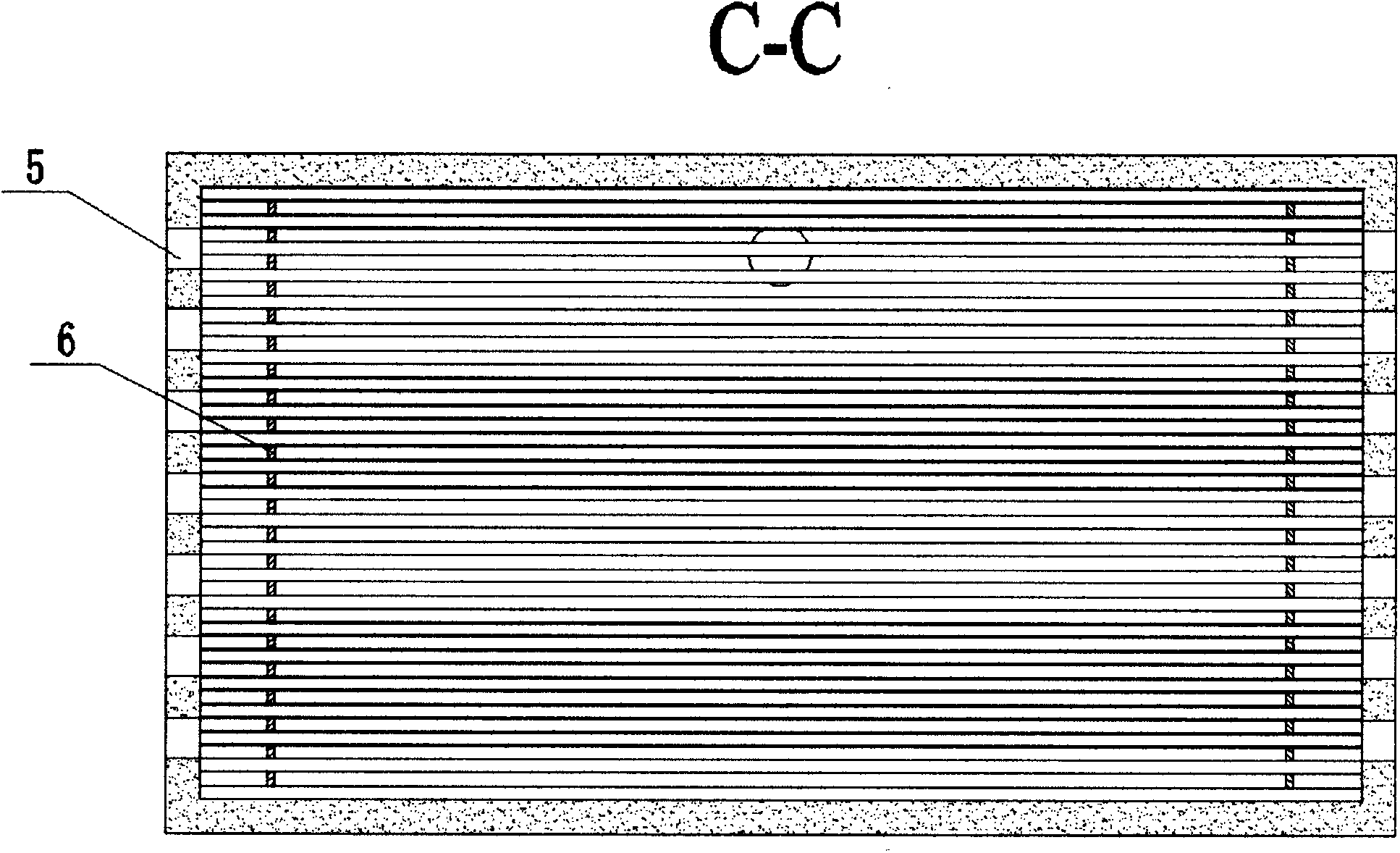

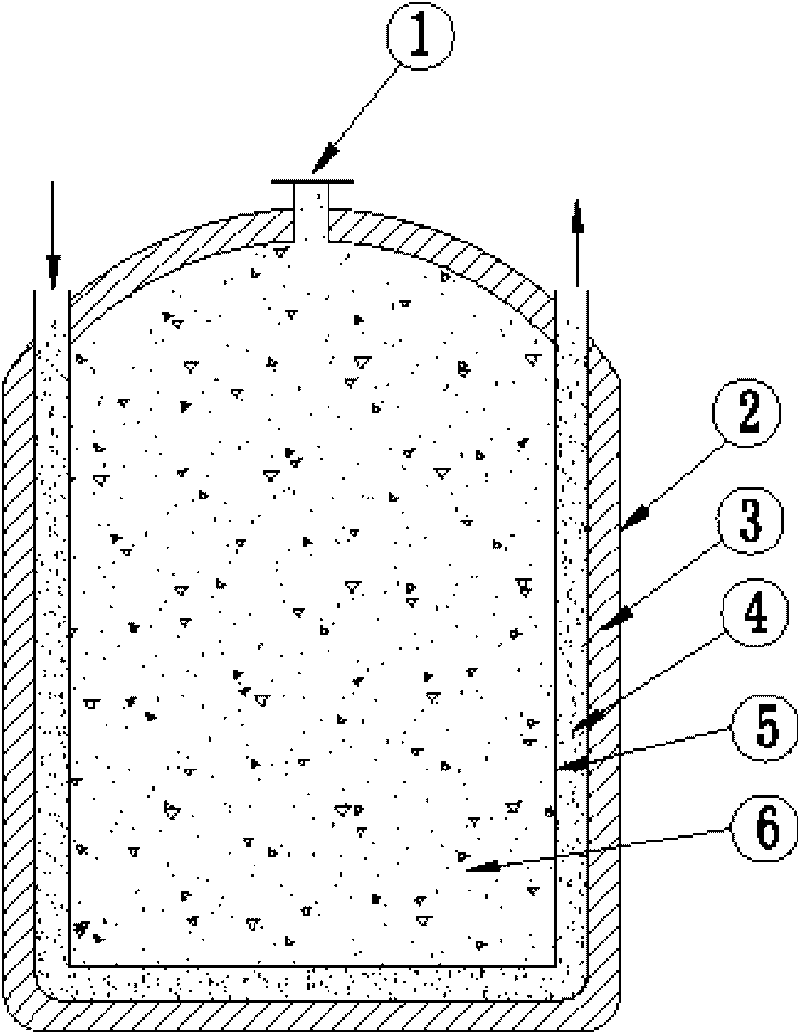

Solar heat storage heating device

InactiveCN103528123AClosely arrangedRaise the room temperatureLighting and heating apparatusCentral heating systemEngineeringPhase change

The invention discloses a solar heat storage heating device. A heat absorbing body of the device comprises a plurality of metal tubes which are closely arranged, phase-change heat storage media are filled inside the metal tubes, selective absorbing coatings are coated on the outer surfaces of the metal tubes, and solar energy can be absorbed and stored. A fan is connected to the outside of the solar heat storage heating device, so that air can flow into the solar heat storage heating device from air inlets, is heated by the heat storage body and flows into an indoor environment, and the indoor environment can be heated. The solar heat storage heating device has the advantages that the device is additionally provided with the fan, so that the air is forced to flow through the heat storage body to absorb heat, and the temperature of the indoor environment can be quickly increased; pipelines of the heat storage body are closely arranged, and the internal phase-change heat storage media can sufficiently absorb heat from tube walls, so that the heat storage efficiency can be improved.

Owner:ZHENJIANG XINMENGXI ENERGY TECH

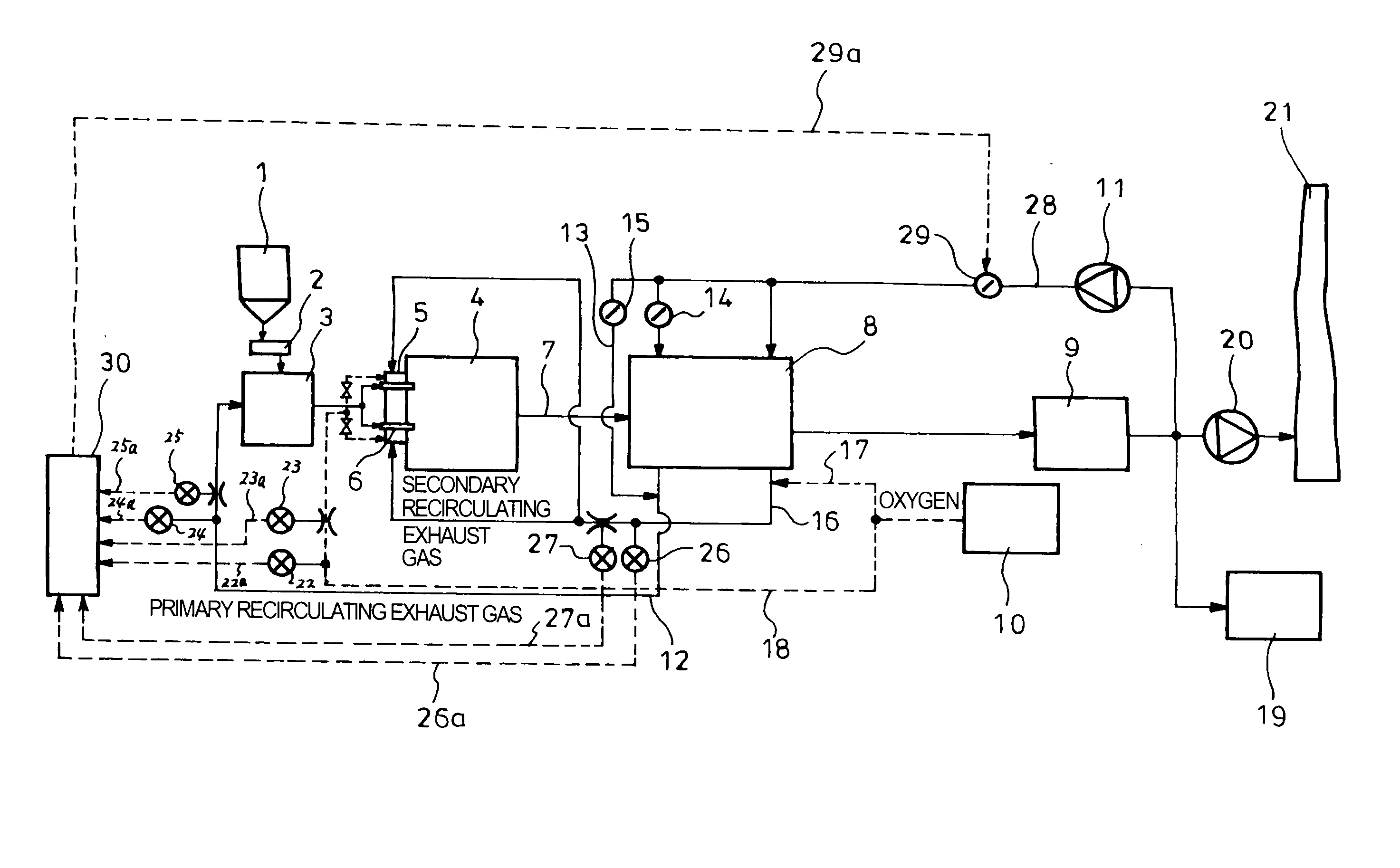

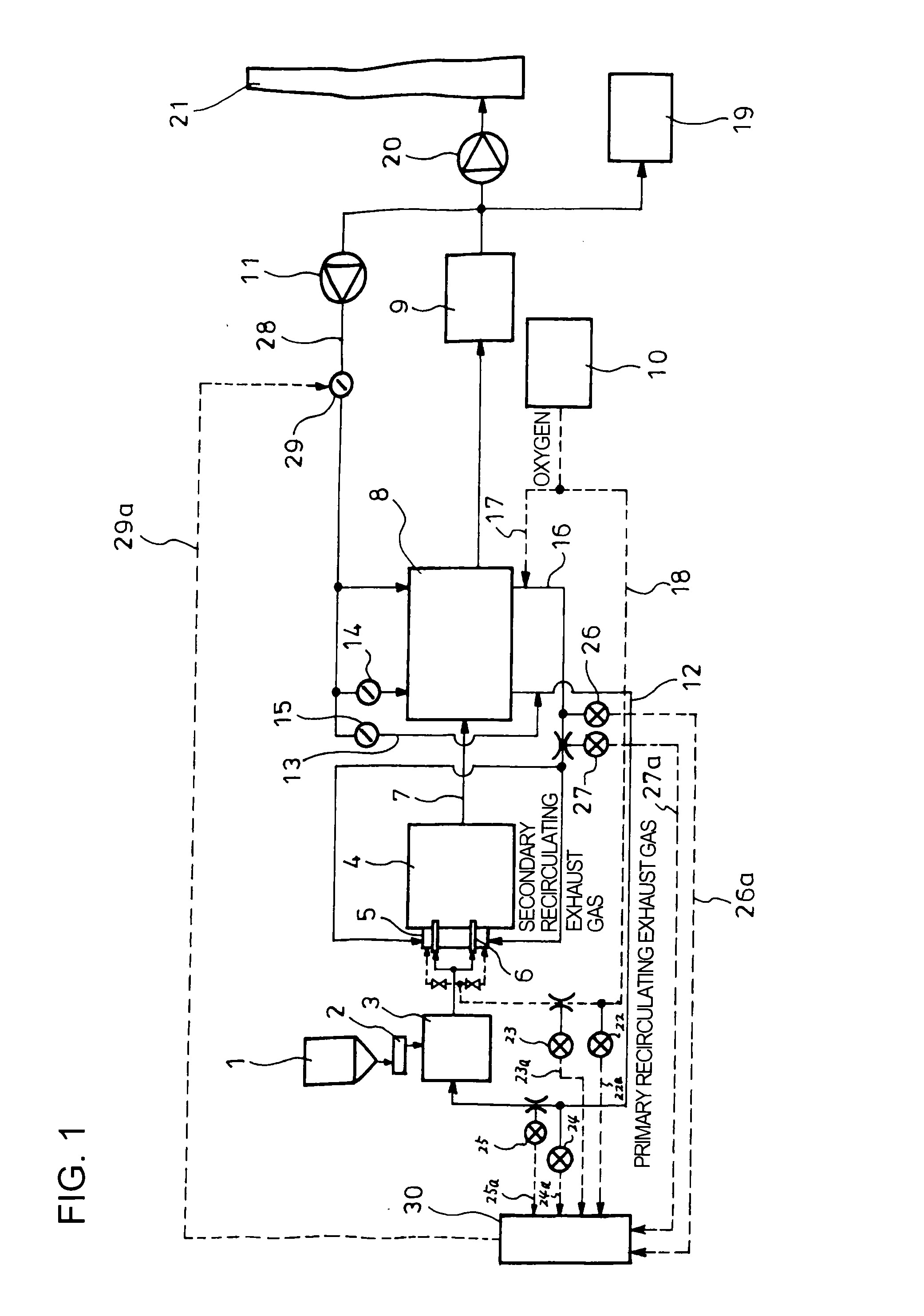

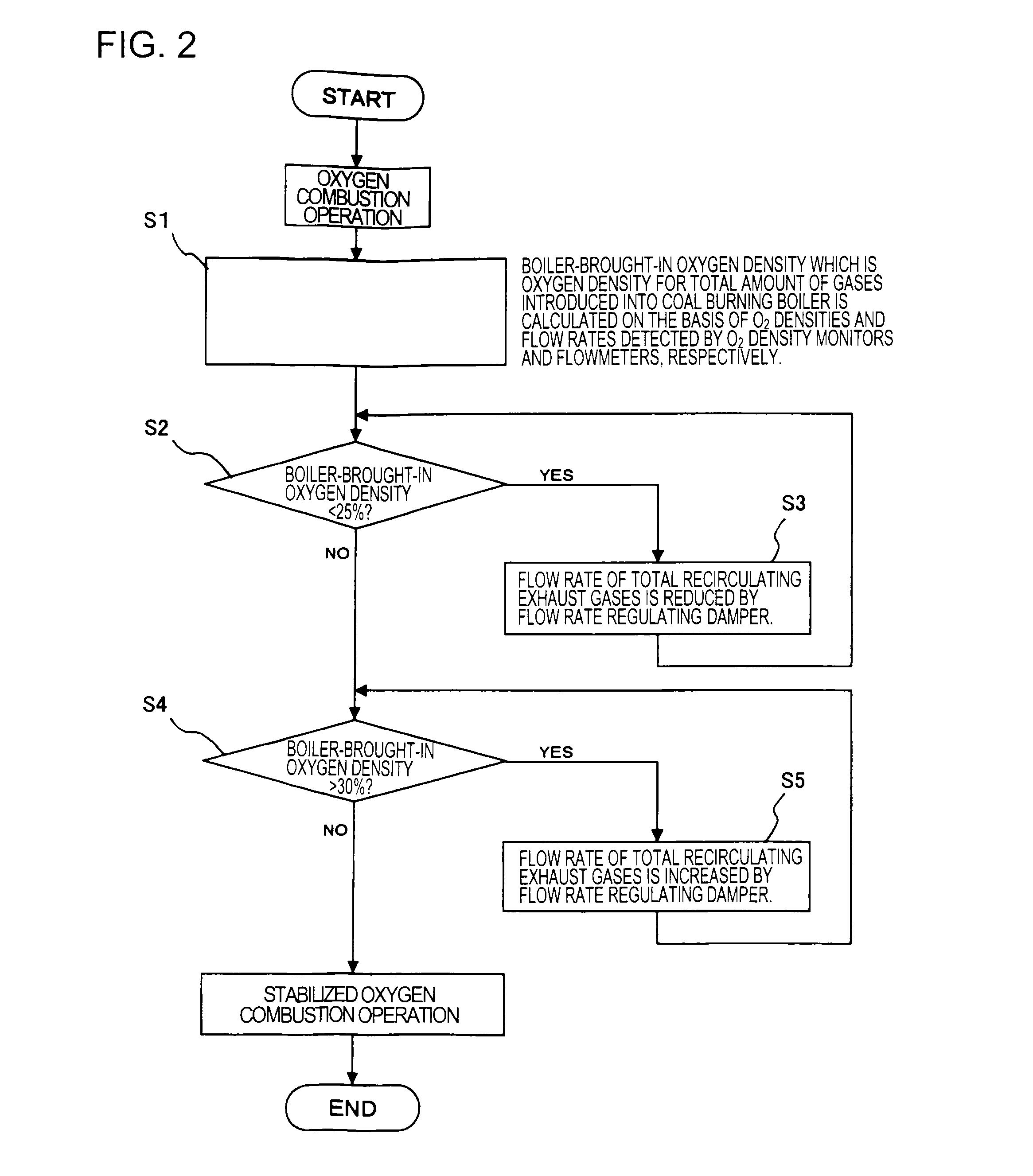

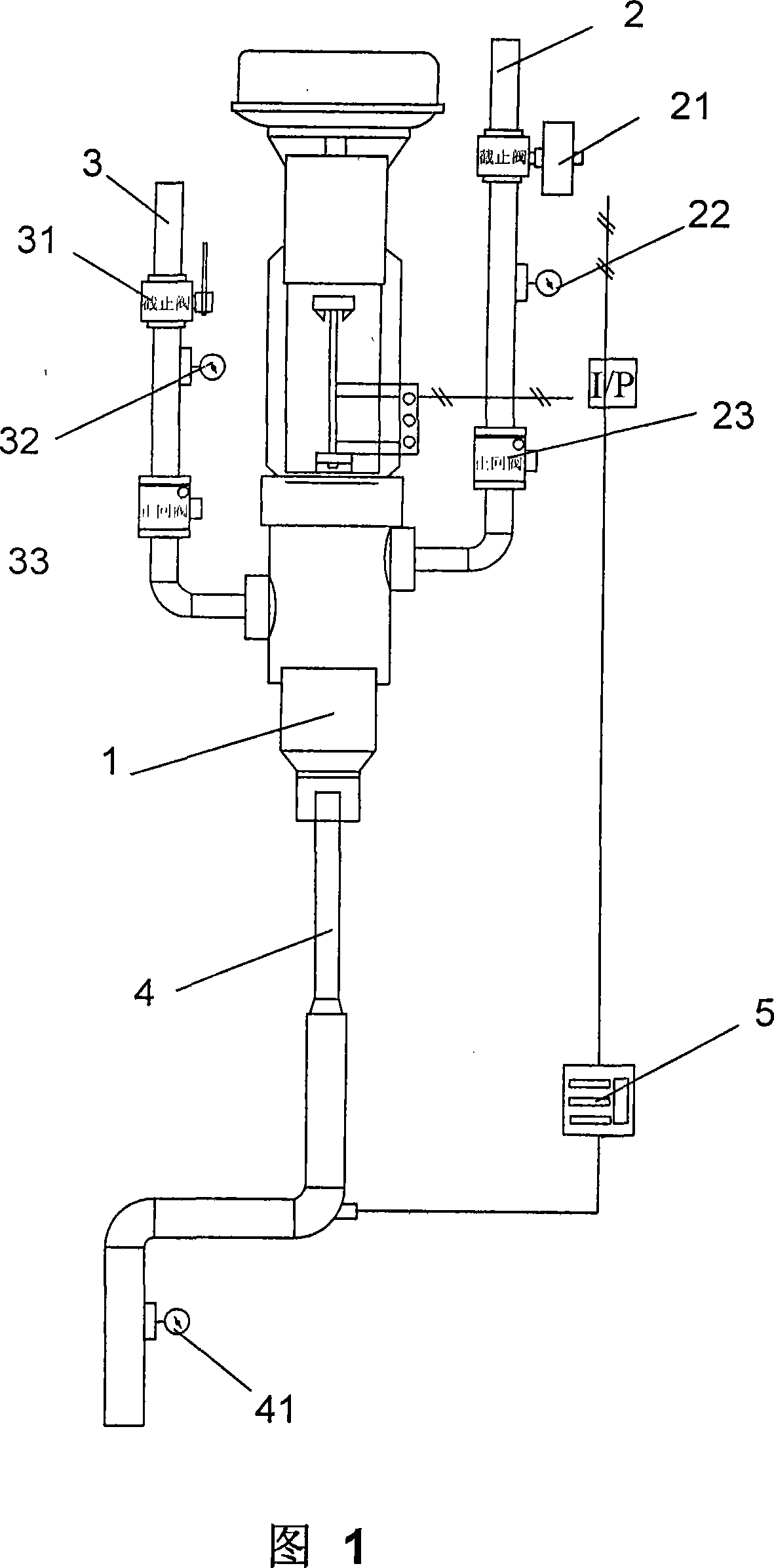

Method and apparatus of controlling combustion in oxyfuel combustion boiler

InactiveUS20110104624A1Sufficient furnace heat absorptionPrevention of lowering of flame temperatureFuel supply regulationAir supply regulationProcess engineeringProduct gas

A method and an apparatus of controlling combustion in an oxyfuel combustion boiler are provided which ensure a sufficient furnace heat absorption through prevention of lowering of flame temperature, enabling oxyfuel combustion operations to be performed in a stable manner. A boiler-brought-in oxygen density which is an oxygen density for a total amount of gases introduced into a coal burning boiler is calculated and a flow rate of total recirculating gases is controlled such that the boiler-brought-in oxygen density falls within a predetermined range.

Owner:IHI CORP +1

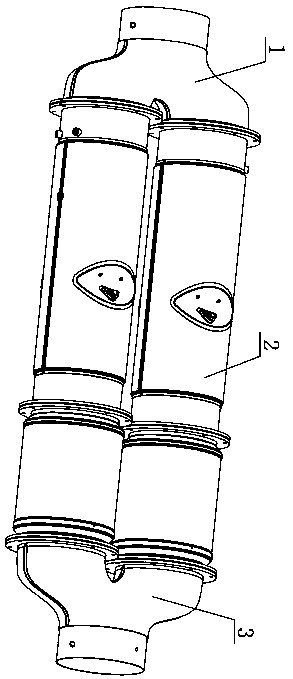

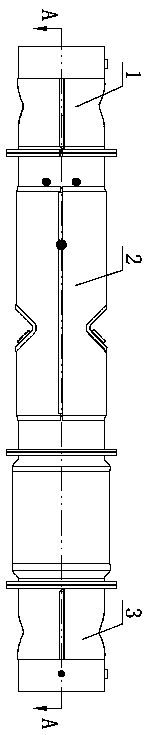

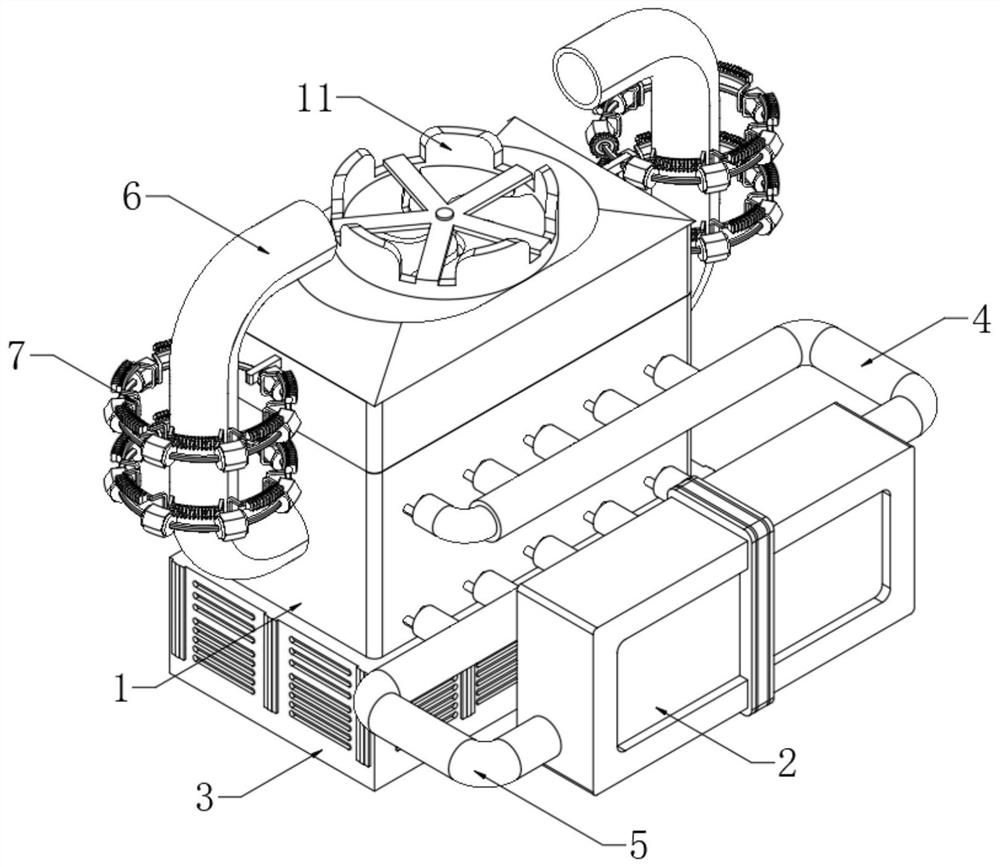

Multistage parallel SCR system

PendingCN110848004ASpeed uniformity is easy to controlReduced risk of crystallizationInternal combustion piston enginesExhaust apparatusNitrogen oxidesNitric oxide

The invention discloses a multistage parallel SCR system. The multistage parallel SCR system comprises a gas inlet unit, a reaction unit and a gas outlet unit which are sequentially connected in series, wherein a plurality of reaction channels are arranged in the reaction unit; a plurality of distribution branch tubes, which correspond to the reaction channels, are arranged on the gas inlet unit;the distribution branch tubes communicate to the same gas inlet of the gas inlet unit; a plurality of confluence branch tubes, which correspond to the reaction channels, are arranged on the gas outletunit; and the confluence branch tubes communicate to the same gas outlet of the gas outlet unit. Large-flow tail gas flow is distributed into the reaction channels through the distribution branch tubes of the gas inlet unit, so that tail gas flow in single reaction channel is correspondingly reduced, and therefore, the barrel body cross section dimension of single reaction channel can be correspondingly reduced, speed uniformity of tail gas flow is controlled easier, other-flow-speed distribution uniformity is high, urea crystallization risk is reduced, performance of a post-treatment systemis ensured, and conversion efficiency of nitric oxides is improved.

Owner:无锡亿利环保科技有限公司

Process for corn starch sugar by enzyme method

ActiveCN101117647AStrong shear forceFully cookedFermentationGlucose productionFlocculationIon exchange

The present invention provides a process of corn starch sugar producing by an enzymatic technique. The process step mainly includes hydrolysis liquefaction, flash braise, saccharification, bleaching, ion exchange and enrichment of amylum material under the action of enzyme preparation; wherein the hydrolysis liquefaction uses a water heater as the braising and boiling reactor, and the water heater has an adjustable clearance for material entering into. In the process of the hydrolysis liquefaction, the pressure difference of the feeding amylum material and the discharged amylum material on the water heater can be controlled between 0.15-0.30MPa, and 0.20-0.25MPa are optimal; the single braising and boiling temperature is controlled between 110-130 DEG C, and 110-125 DEG C are optimal. The water heater adopted by the present invention can ensure a curtain pressure difference of the feeding material and the discharged material, can bring strong cut force, and can ensure zymolyte molecules sizes of the liquefaction liquid to be regular and proportioned. The present invention adopts high temperature braising and boiling, which can make the protein denaturation more rapid, more complete, and the flocculation better, and can facilitate the protein removing.

Owner:COFCO RONGS BIOTECH

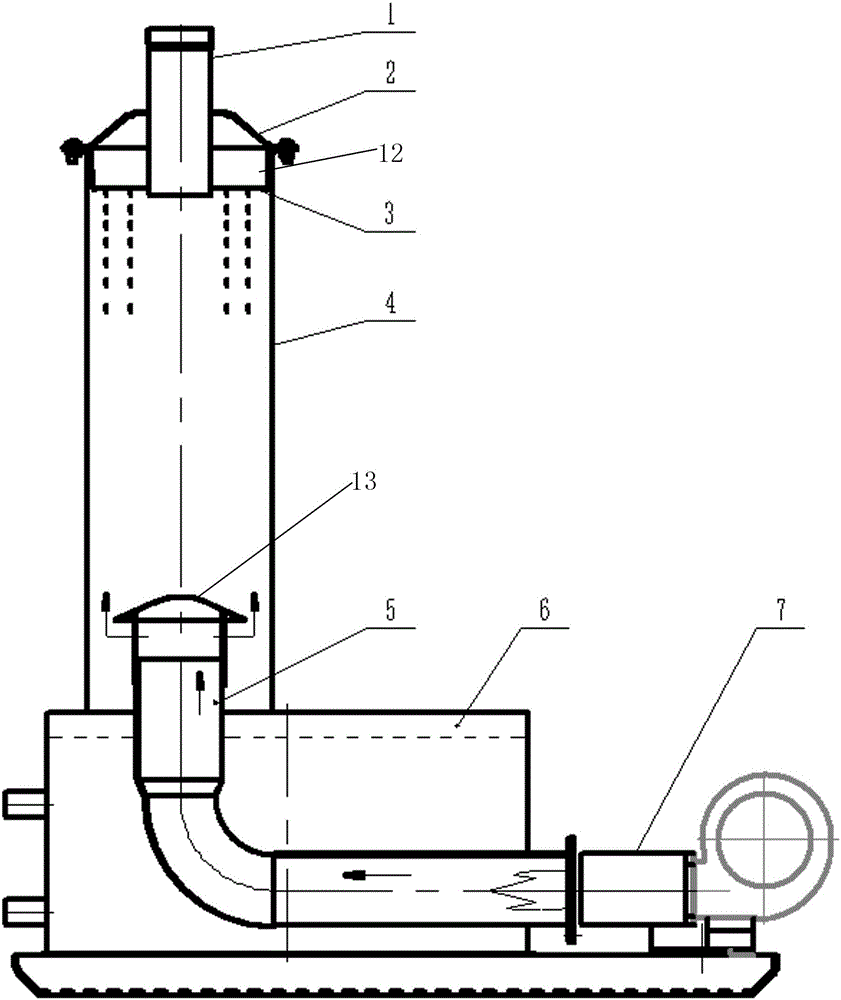

Water and fire direct heat exchange household heating stove

InactiveCN105115153AImprove utilization efficiencyFull heat absorptionWater heatersCombustorEngineering

The invention relates to a boiler, in particular to a water and fire direct heat exchange household heating stove. The technical problems that a traditional boiler is complex in structure, water scale can be generated easily, and heat exchange efficiency is not high are solved. The water and fire direct heat exchange household heating stove comprises a water tank provided with a water outlet and a water returning port, a combustor and a heat exchange cylinder arranged on the top of the water tank, wherein the top end of the heat exchange cylinder is provided with an opening. The combustor is connected with a fire outlet pipe stretching into the heat exchange cylinder. The position, close to the top end opening, of the heat exchange cylinder is provided with a water channel provided with a smoke exhaust port and a spraying port, and the bottom of the heat exchange cylinder is communicated with the water tank. The water tank guides water to the position above the water channel through a circulating pipe connected with a water pump in series. According to the water and fire direct heat exchange household heating stove, the metal intermediate medium heat exchange technology is directly replaced with water and fire direct heat exchange, and therefore the structure is simpler and more reasonable, heat exchange is more direct and faster, and efficiency is higher.

Owner:刘工勤

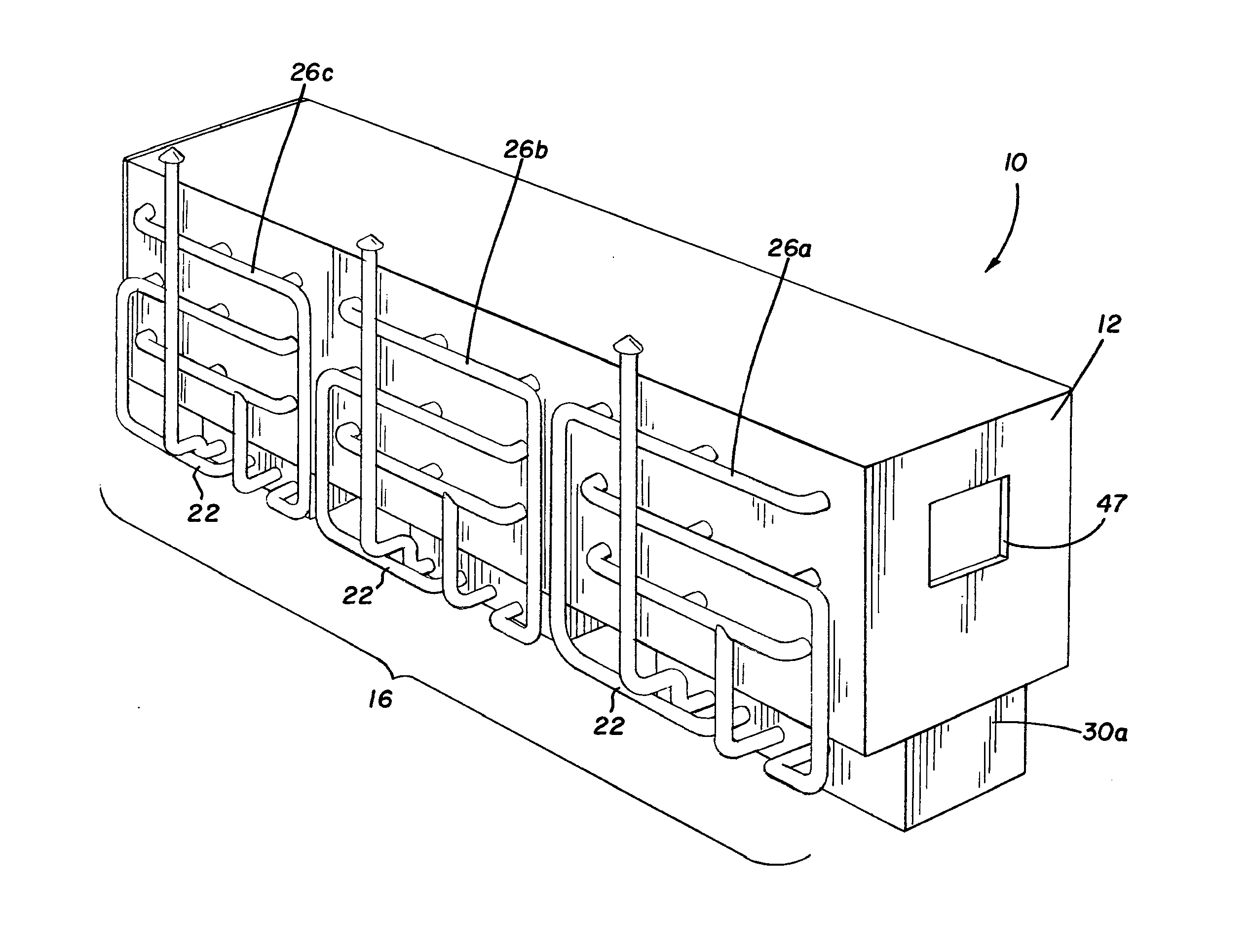

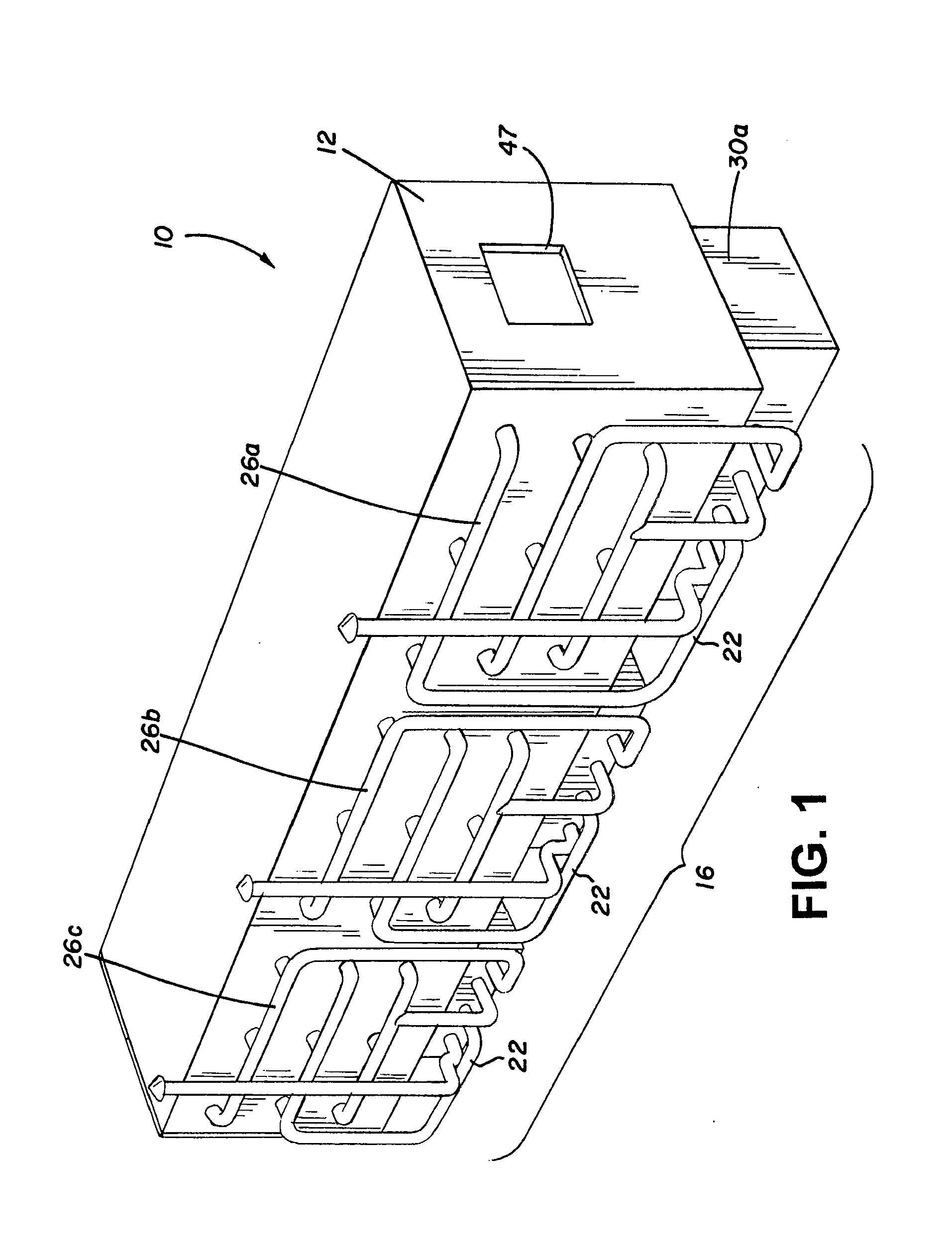

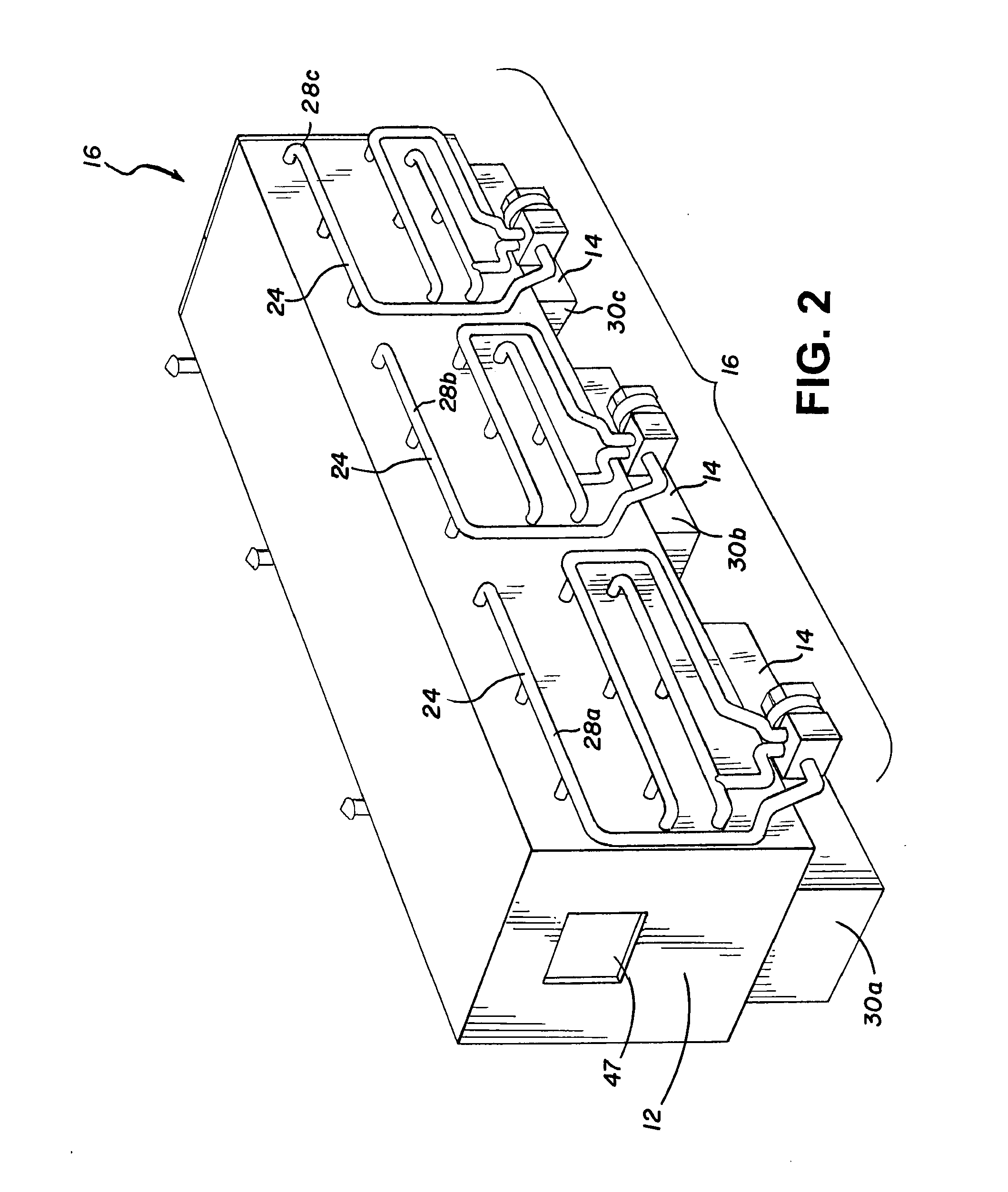

Thermal processes of reducing foodborne pathogens in bagged food products

InactiveUS20140023757A1Reduce and eliminate foodborne pathogenReducing foodborne pathogenFood preservationAvicultureControl systemProcess engineering

A heating assembly designed for reducing foodborne pathogens in bagged food products comprises a heat insulated treatment chamber, multiple high temperature natural gas fired furnaces, multiple insulated ductworks further comprising multiple sets of intake ducts and multiple sets of exhaust ducts, a cooling system that allows air to be controlled and supplied into the treatment chamber, multiple temperature sensor probes placed in the treatment chamber, the natural gas fired furnaces, and the bagged food products, a digital control system, and a computer program that monitors the temperature of each probe. A specially designed racking system with multiple levels allows multiple dry bags containing the food products to be stacked in a manner that rapidly and uniformly heat the food products.

Owner:HONEYVILLE

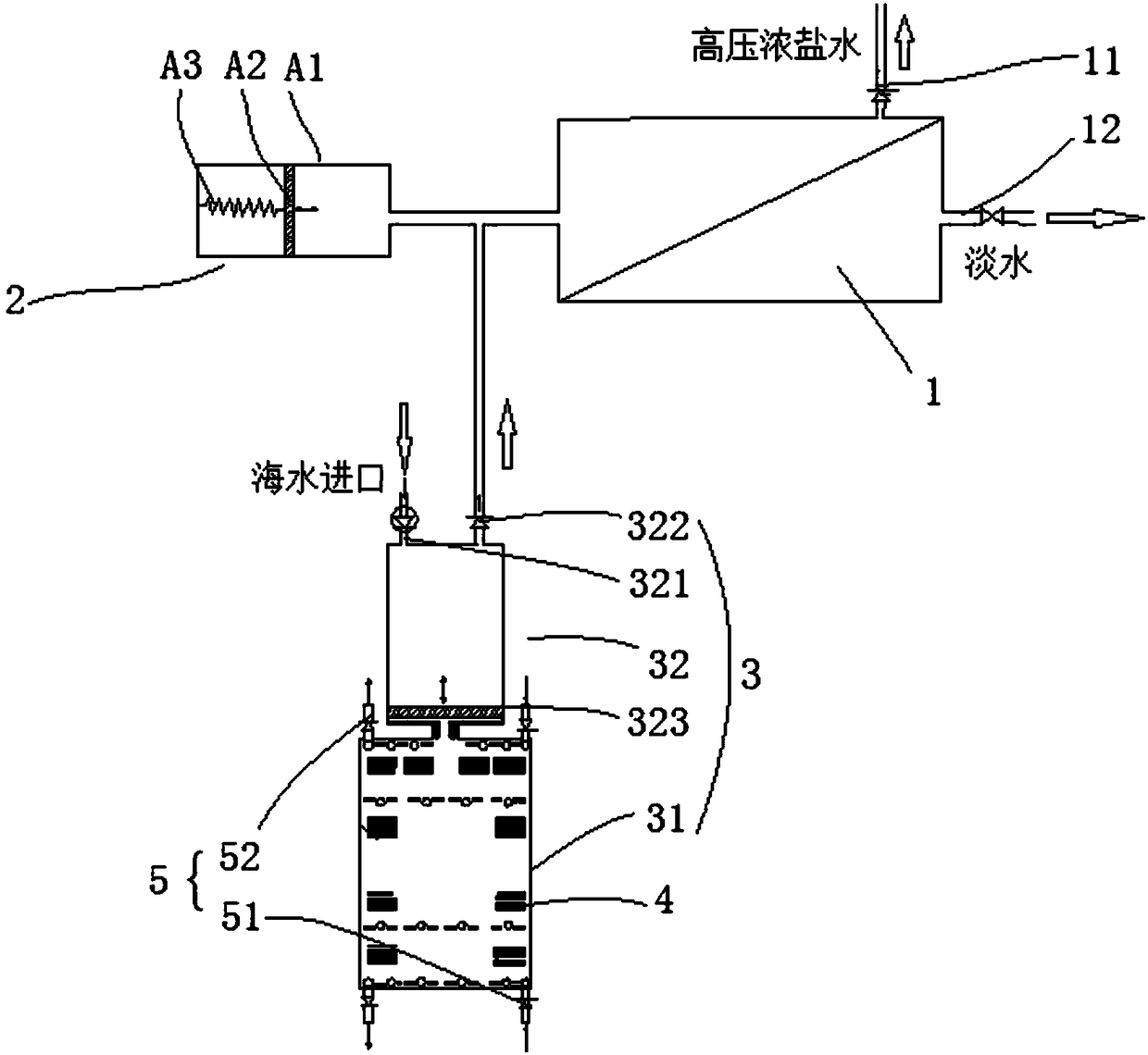

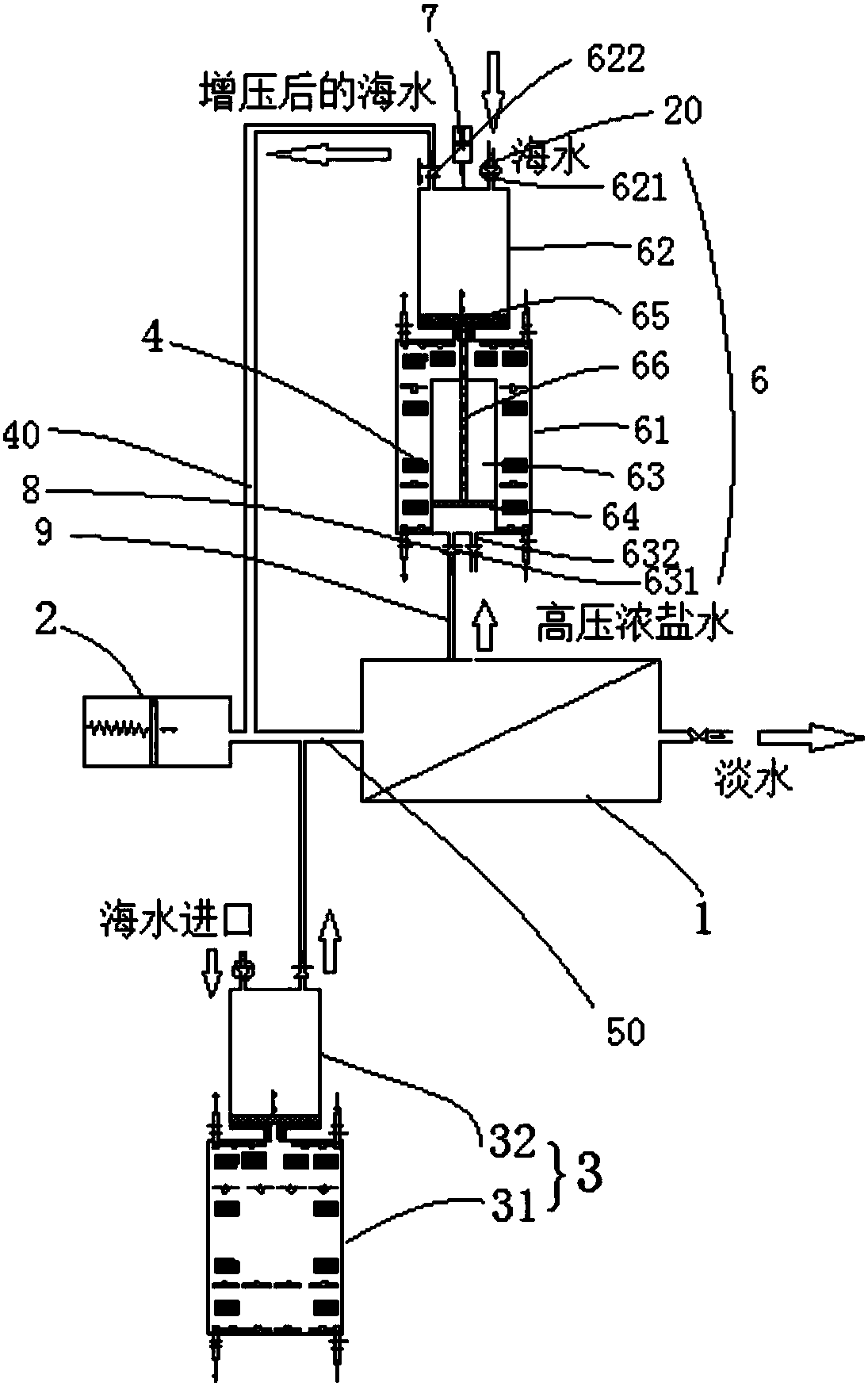

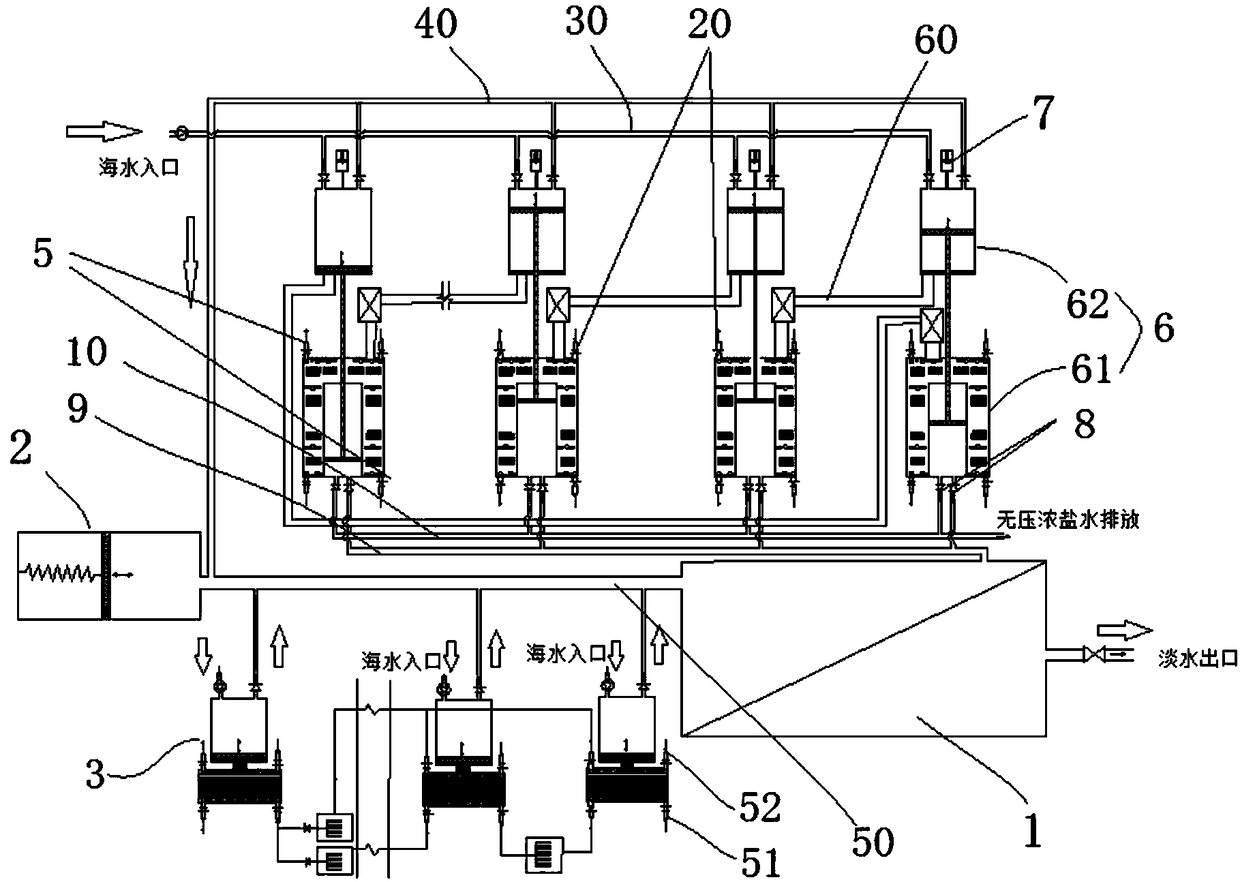

Seawater desalination device and composite system utilizing temperature difference drive

PendingCN108285192AReduce energy consumption costsStable pressureGeneral water supply conservationSeawater treatmentSaline waterSeawater reverse osmosis

The invention discloses a seawater desalination device and composite system utilizing temperature difference drive. The device comprises a reverse osmosis membrane system, a first pressure maintainingsystem and a drive system, the drive system comprises a first phase-change cylinder and a first drive cylinder, and the first phase-change cylinder is provided with a phase change working medium anda temperature regulating system; the first drive cylinder is provided with a first seawater inlet and a first seawater outlet, the interior of a cylinder body is provided with a drive piston, and thefirst seawater outlet and the first pressure maintaining system are separately connected with a water inlet of the reverse osmosis membrane system; and temperature of the first phase-change cylinder is adjusted to make a phase change working medium have phase change, and the phase change working medium drives the drive piston to enter seawater raw water, and after pressurizing is performed, seawater desalination is performed. According to the device provided by the invention, the multi-stage drive system and an energy recovery system are added in the composite system, the energy recovery system absorbs and utilizes residual pressure of reverse osmosis concentrated brine and partial heat of the concentrated brine by combining temperature difference drive, supplements seawater to the reverseosmosis membrane system, and better solves the problem of high energy consumption costs in seawater reverse osmosis desalination.

Owner:天津融渌众乐科技有限公司

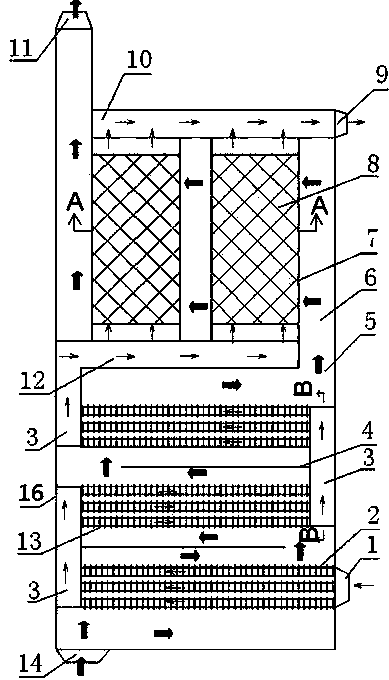

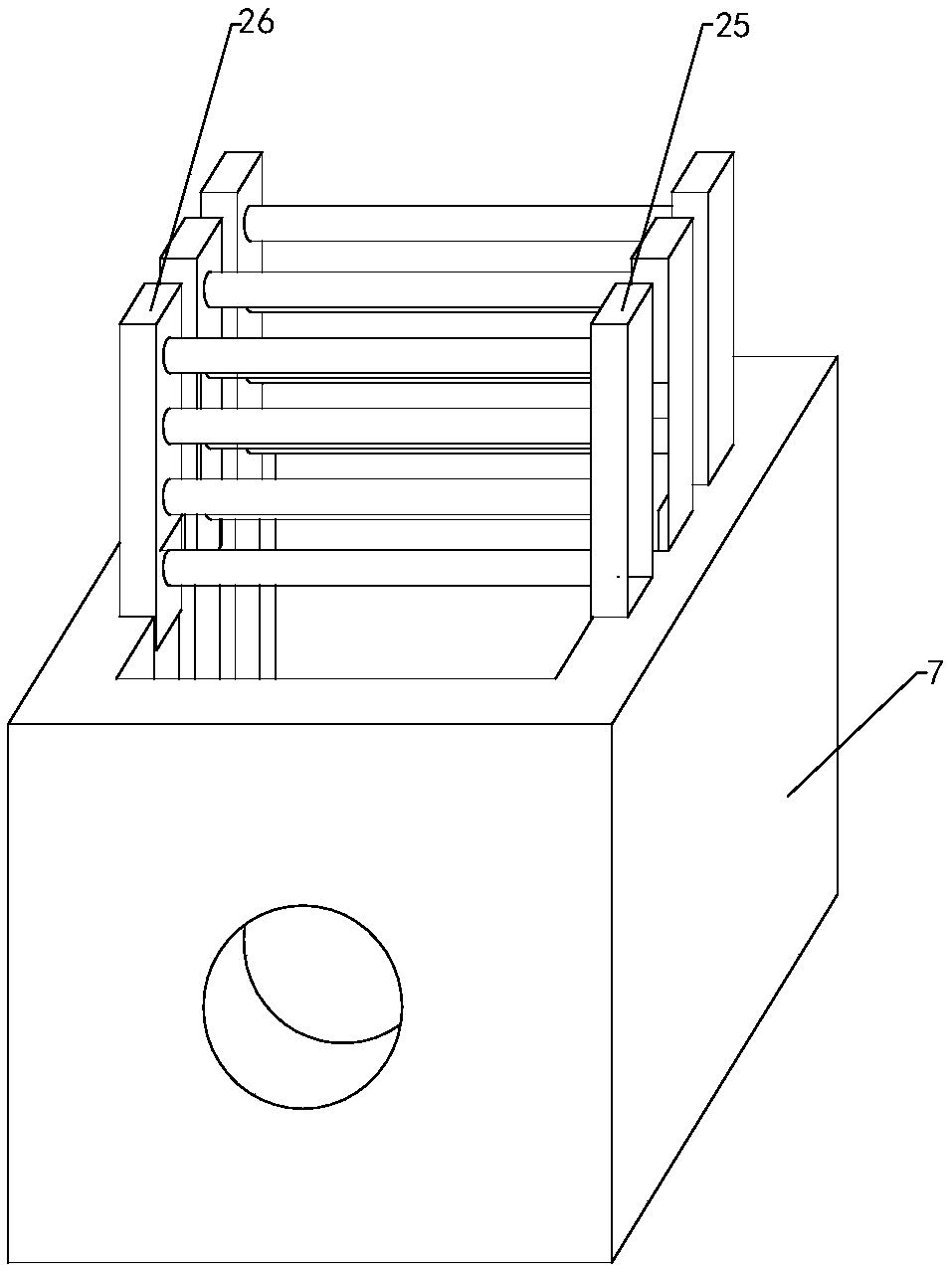

Tube type and heat storage type combined heat exchanger based on high-low-temperature segmented heat exchange

InactiveCN103712491AImprove heat transfer effectHighly corrosiveHeat storage plantsStationary tubular conduit assembliesFlue gasEngineering

The invention discloses a tube type and heat storage type combined heat exchanger based on a high-low-temperature segmented heat exchange. The heat exchanger comprises a tube type heat exchanger body and a heat storage heat exchange body, wherein the tube type heat exchanger body enables flue gas flowing outside a tube to flow along an S-type path through a partition board, air flowing in the tube also flows along the S-type path and opposite to the direction of the flue gas so that violent heat exchange between the flue gas in the tube type heat exchanger body and the air can be achieved, the utilization rate of heat is improved, and the flue gas flows away from the tube type heat exchanger body when the temperature of the flue gas is higher than a dew point temperature; the heat storage type heat exchanger body comprises four heat storage cylinders which are provided with heat storage bodies and made of ceramic, heat exchange between flue gas flowing outside the cylinders and air flowing in the cylinders enables the temperature of the flue gas to be lower than the dew point temperature, corrosion is caused, ceramics has strong corrosion resistance so that the heat exchanger can have anti-corrosion performance, and the ceramics has good heat storage capacity so that fluctuation of air flow temperature can be effectively prevented and stability of the air flow temperature can be effectively improved.

Owner:CHONGQING UNIV

Biomass fuel boiler with rotatable fire grate

InactiveCN107741025APrevent fallingHeating up fastSolid fuel combustionWater heatersSlagMechanical engineering

The invention discloses a biomass fuel boiler with a rotatable fire grate. The biomass fuel boiler comprises a furnace body, wherein the furnace body comprises a first furnace body and a second furnace body which are arranged in a sleeved mode; the rotatable fire grate, wherein the rotatable fire grate is vertically arranged in the first furnace body in a rotating mode through a rotating shaft, the rotatable fire grate comprises multiple fuel trays, and the fuel trays are sequentially arranged in the axial direction of the rotating shaft at intervals; a pair of fins, wherein the pair of fins are spirally and symmetrically arranged on two sides of the rotating shaft, and sequentially penetrate through the multiple fuel trays; and pneumatic biomass powder feeding pipes, wherein one ends of the pneumatic biomass powder feeding pipes penetrate through the furnace body and extend to be opposite to the fins. A biomass particle feeding hole is formed in the top part of the furnace body; a mode water cooling wall is arranged on the side wall of the furnace body; a slag collecting tank is detachably arranged at the bottom part of the rotatable fire grate; multiple circulating ports are annularly and uniformly arranged on the side wall, close to the first furnace body, of the bottom of the second furnace body at intervals; and the biomass fuel boiler further comprises a smoke outlet anda base. According to the biomass fuel boiler, biomass powder and biomass particle fuel can be fully mixed and combusted, combustion is sufficient, the heat utilization rate is high, and energy-savingand environment-friendly effects are achieved.

Owner:江苏东方电力锅炉配件有限公司

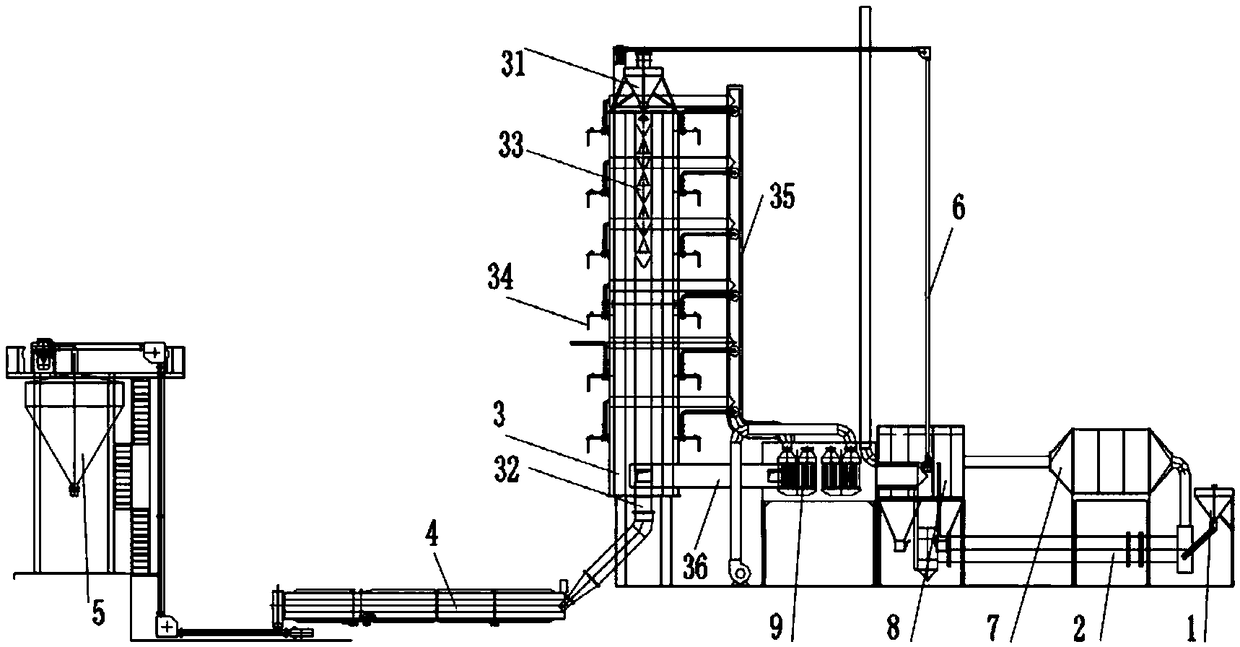

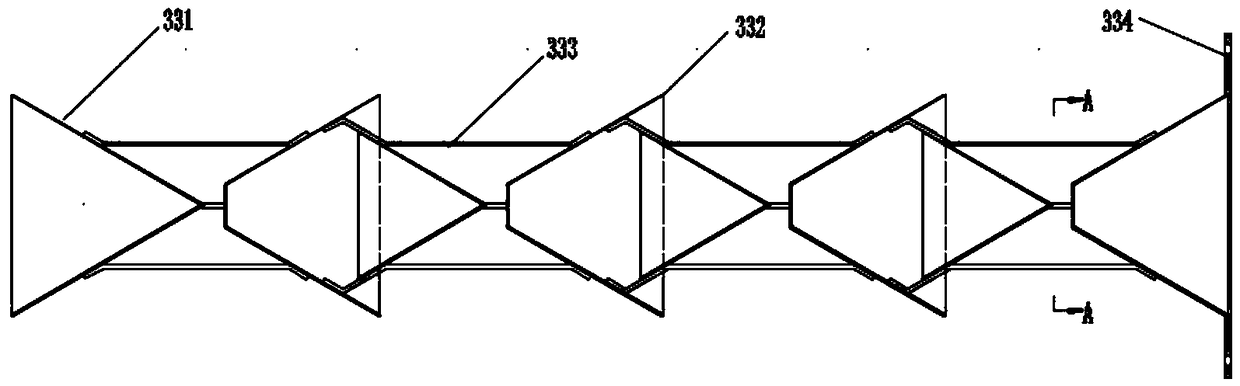

Microcrystalline heat insulation particles and continuous production apparatus thereof

PendingCN109180043AEfficient deliveryIncreased puffing endothermic timeGlass shaping apparatusVitrificationEngineering

The invention provides a continuous production apparatus of a microcrystalline heat insulation particle. The apparatus comprises a raw material bin, a preheating furnace, a kiln, a cooler and a finished product bin which are sequentially connected, a raw material is preheated by the preheating furnace and then is conveyed into the kiln through a tubular chain lifter, the kiln comprises a furnace body, a feeding bin is arranged at the upper end of the furnace body, a discharging port is arranged at the lower end of the furnace body, the furnace body comprises an expansion section and a vitrification section, a discharging device is arranged in the expansion section of the furnace body, the discharging device comprises at least one set of funnel and conical bucket, and the preheated sands are dispersed and gathered through the inner walls of the funnel and the cone; and the furnace body is symmetrically provided with a plurality of sets of burners. The perlite ore sands are dispersed andthen gathered in the furnace body, so the discharging time is delayed, and the expansion heat absorption time of the preheated sands is prolonged to ensure sufficient heat absorption and reach a expansion temperature; and the microcrystalline heat insulation particle wrapped with a smooth surface and having a cavity structure is produced through the apparatus, and the heat insulation particle hasthe advantages of no water absorption, high strength and excellent heat insulation performance.

Owner:湖南斯多孚节能科技有限公司

Engine-boiler integrated tube nest type combustion engine and device thereof for recovering three wastes

InactiveCN101975394AImprove combustion efficiencyFull heat absorptionFuel feedersCasings/liningsCoalEngineering

The invention discloses an engine-boiler integrated tube nest type combustion engine and a device thereof for recovering the three wastes. The combustion engine is composed of a hearth in a membrane type wall structure, an air supply chamber and a plenum chamber, wherein the air supply chamber is provided with an air inlet pipe; the plenum chamber is provided with a fuel gas inlet pipe; the inner wall of the air supply chamber is provided with a certain quantity of air pipes which are communicated to the heath in a membrane type wall structure; and the inner wall of the plenum chamber is provided with a certain quantity of gas pipes which are communicated to the hearth in a membrane type wall structure. The device for recovering the three wastes comprises a mixed combustion furnace, a separator and a waste heat boiler, wherein the lower part of the mixed combustion furnace is an ignition section, the middle part thereof is a boiling combustion section, and the upper part thereof is a cylinder; the upper end of the mixed combustion furnace is a coal slime inlet, the boiling combustion section main body of the mixed combustion furnace is the engine-boiler integrated tube nest type combustion engine, and the boiling section is internally provided with a boiling bed; and a solid waste inlet pipe and a refeed line are arranged at the outer sides of the heath at the boiling combustion section respectively, and a high-abrasive material layer is arranged at the inner side of the heath at the boiling combustion section. The invention has the characteristics of high heat efficiency, full combustion and stable operation.

Owner:郑州锅炉股份有限公司

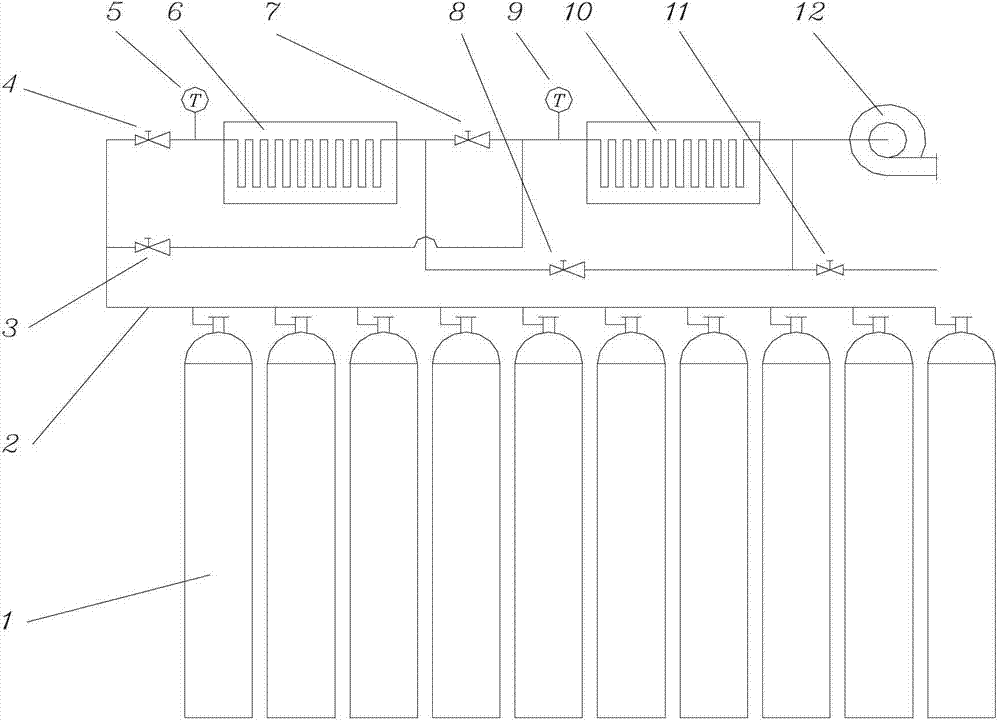

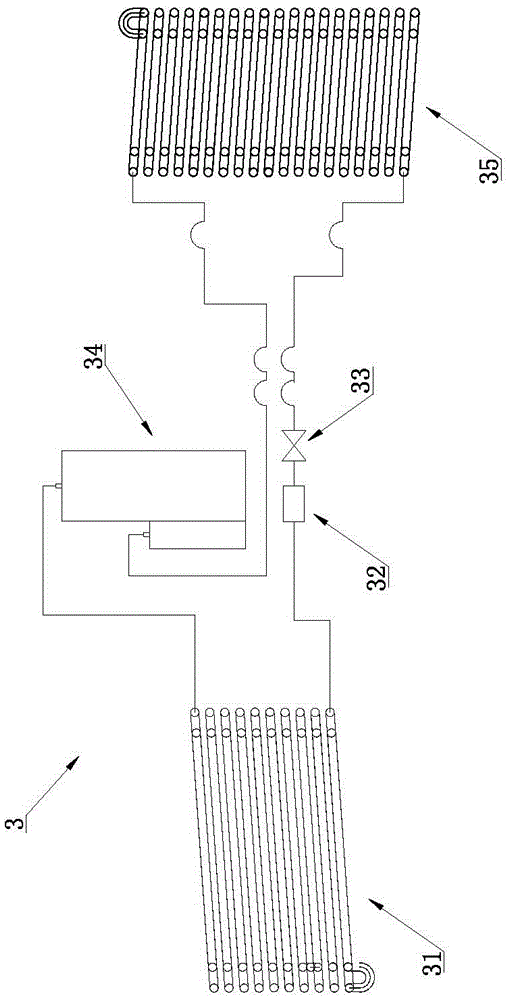

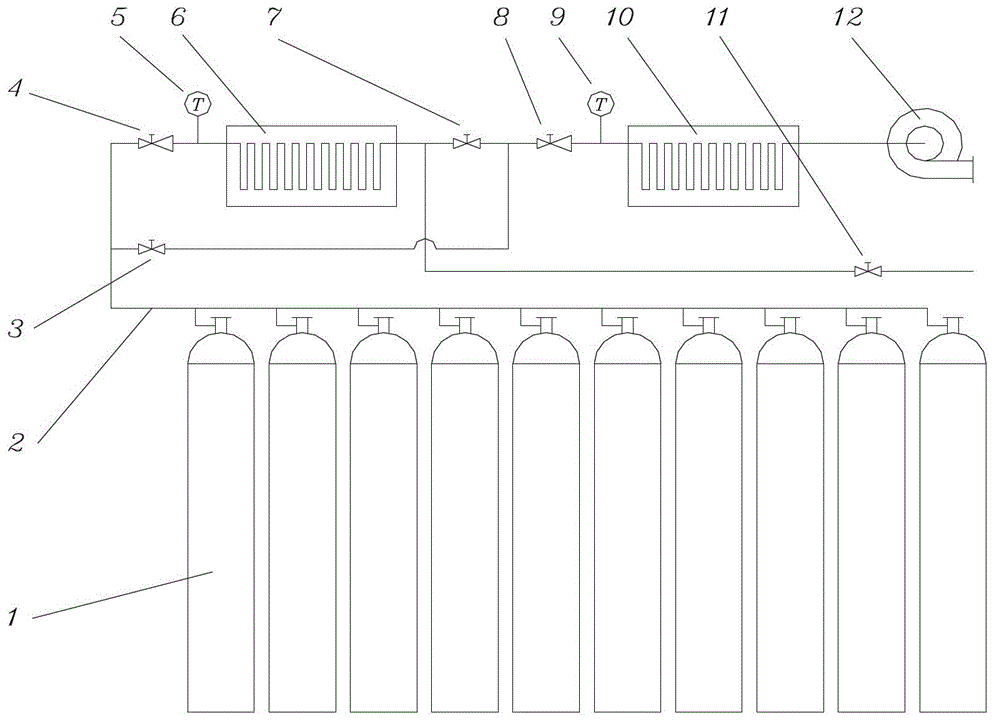

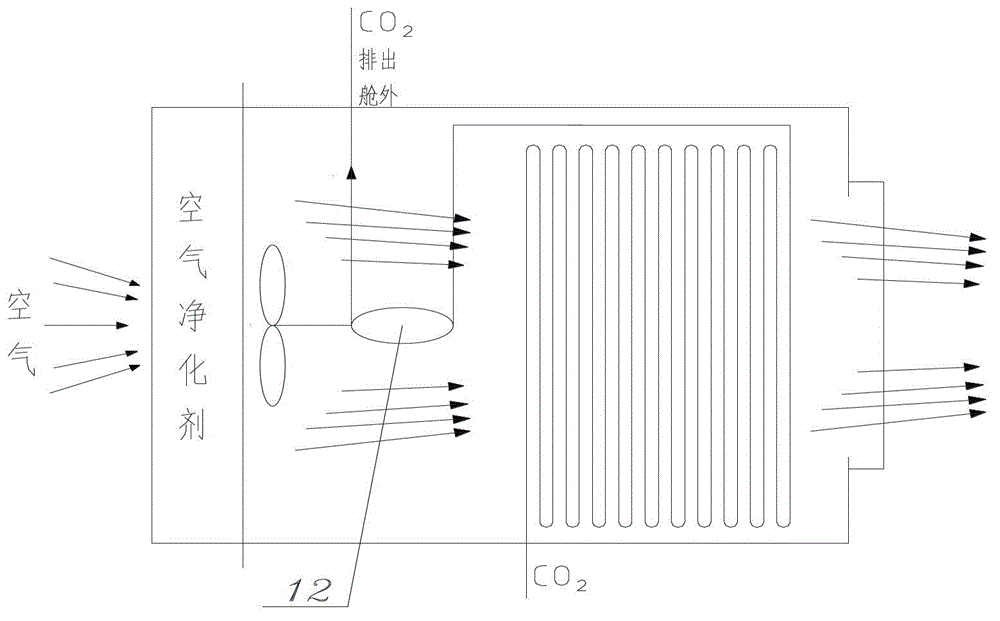

Refrigerating device and method of mining escape capsule

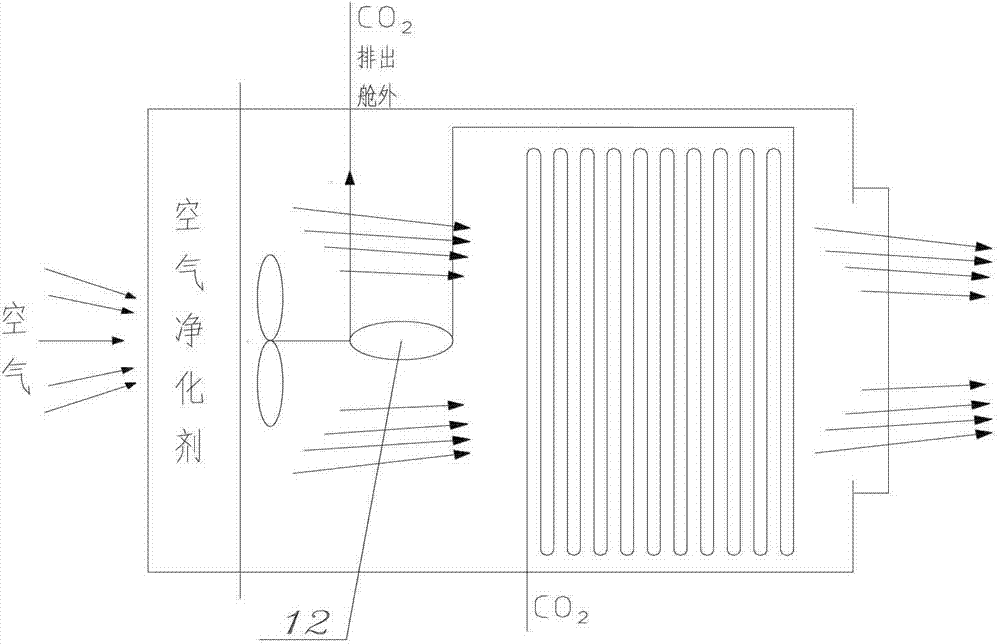

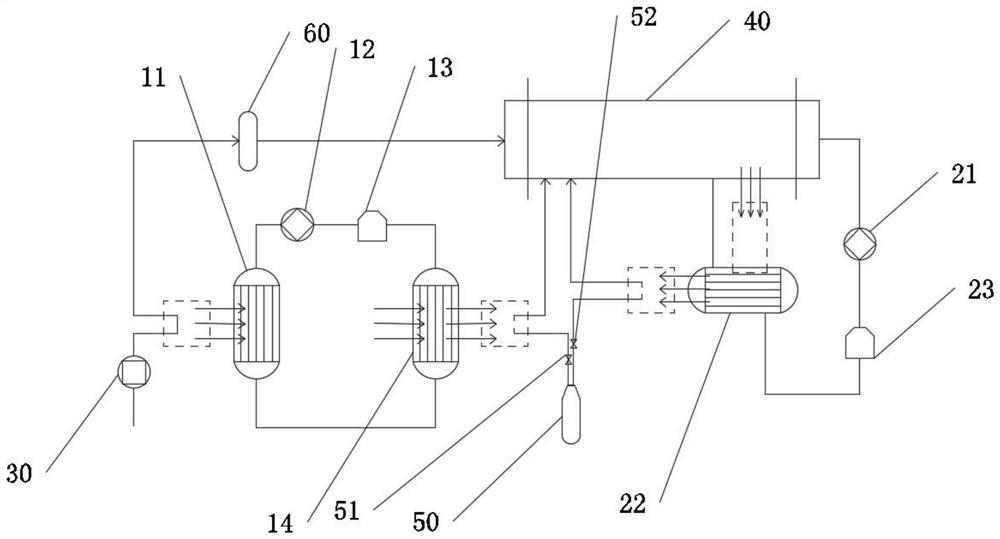

InactiveCN102889095AHigh trafficImprove cooling capacity utilizationTunnel/mines ventillationSafety equipmentsCarbon dioxide cylinderEngineering

The invention discloses a refrigerating device and a method of a mining escape capsule, belonging to the field of safe rescue and environment control in a sealing space. The refrigerating device comprises a carbon dioxide steel bottle, a pipeline, a primary decompression throttling valve, a primary bypass valve, a primary thermometer, a primary capillary tube evaporator, a secondary decompression throttling valve, a secondary bypass valve, a secondary thermometer, a secondary capillary tube evaporator, an exhaust adjusting valve and a pneumatic air blower. According to the refrigerating method provided by the invention, conversion elements are connected and arranged on the primary capillary tube evaporator and the secondary capillary tube evaporator in series and in parallel, so that the use ratio of the refrigeration capacity of refrigerating fluid can be effectively increased, and the loss of the refrigeration capacity can be reduced; and furthermore, the primary thermometer and the secondary thermometer are arranged, so that the controllability of the device operation can be improved. The refrigerating device and the method provided by the invention have the advantages of safe and reliable properties, flexible and convenient adjustment, energy conversation, environmental protection, and high economical benefits and the like.

Owner:中船(天津)环境工程技术有限公司

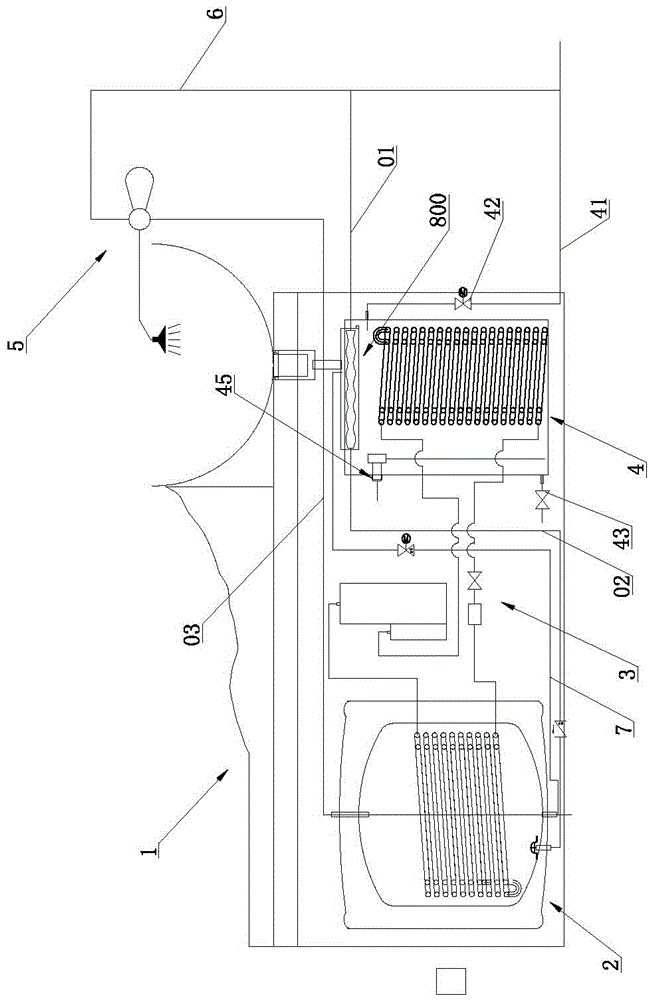

Thermal management system of hydrogen fuel cell

InactiveCN114597440AGuaranteed reliabilityAvoid uncontrollabilityFuel cell heat exchangeTransportation hydrogen technologyHeat flowHydrogen fuel cell

The invention discloses a hydrogen fuel cell thermal management system, which comprises a gas inlet cooling heat exchanger, a first refrigerant pump, a first refrigerant liquid storage tank and a fuel heat exchanger, and is characterized in that a cathode gas flow path and a first refrigerant heat absorption flow path are formed in the gas inlet cooling heat exchanger; a fuel flow path and a first refrigerant heat release flow path are formed in the fuel heat exchanger, and the first refrigerant liquid storage tank, the first refrigerant pump, the air inlet cooling heat exchanger and the fuel heat exchanger are sequentially communicated to form a first refrigerant circulation loop. According to the invention, the technical problems that the cooling structure of the fuel cell is relatively complex and the system energy efficiency is not high are effectively solved.

Owner:苏州欣富辉精密机械科技有限公司

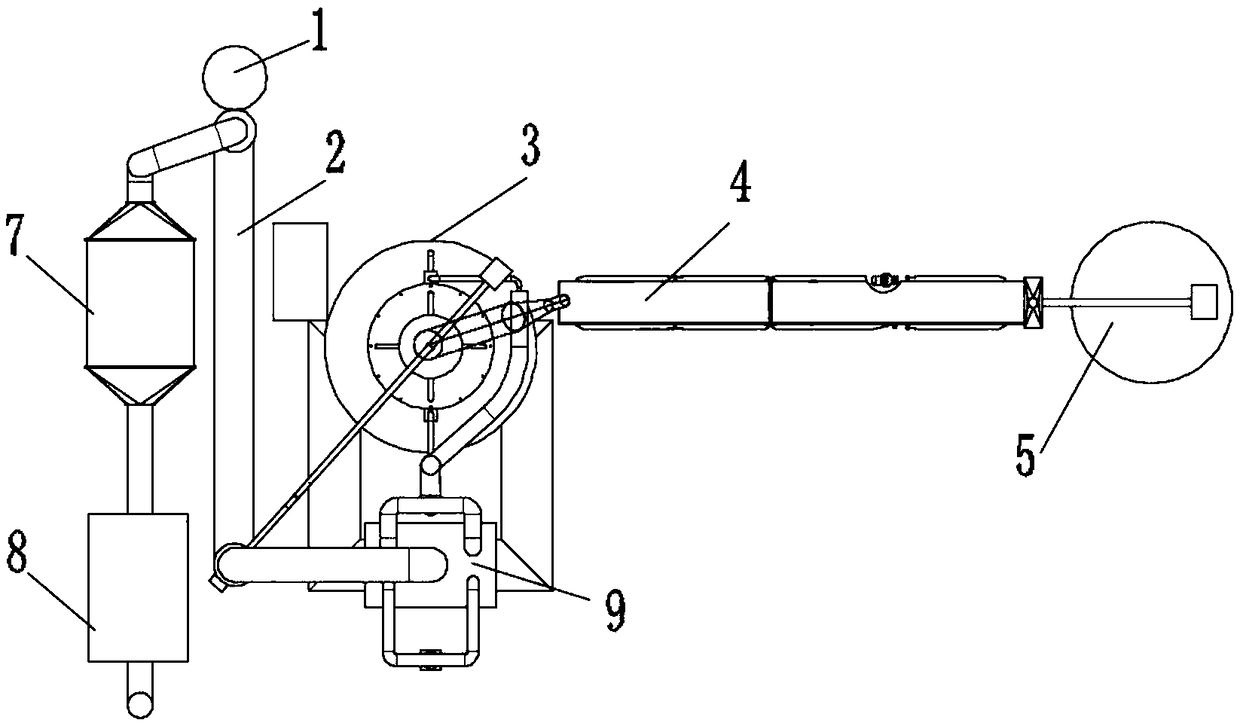

Evaporation device used for heat pipe radiator

ActiveCN113758062AEven heat distributionTimely deliveryEvaporators/condensersCondensed waterEngineering

The invention discloses an evaporation device used for a heat pipe radiator, and belongs to the technical field of radiators. The evaporation device used for the heat pipe radiator comprises a heat dissipation box, the lower end of the heat dissipation box is fixedly connected with a condensate water storage box, a driving water pump is arranged in one side of the condensate water storage box, the output end of the driving water pump is fixedly connected with a spraying pipe, the front side of the upper end of the spraying pipe is evenly connected with multiple spraying guide pipes, and multiple spraying heads are arranged at the tail ends of the spraying guide pipes; the spraying pipe penetrates through the condensate water storage box and extends to the upper end of the outer portion of the heat dissipation box, and the spraying guide pipes at the front end of the spraying pipe penetrate through the side wall of the upper end of the heat dissipation box; and a fan is fixedly connected to the center of the upper side of the heat dissipation box, and circulating pipes are fixedly connected to the two sides of the heat dissipation box. The evaporation device solves the problem that in the prior art, gaseous condensate water after heat absorption is discharged along with airflow and cannot continuously participate in the circulating cooling process.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

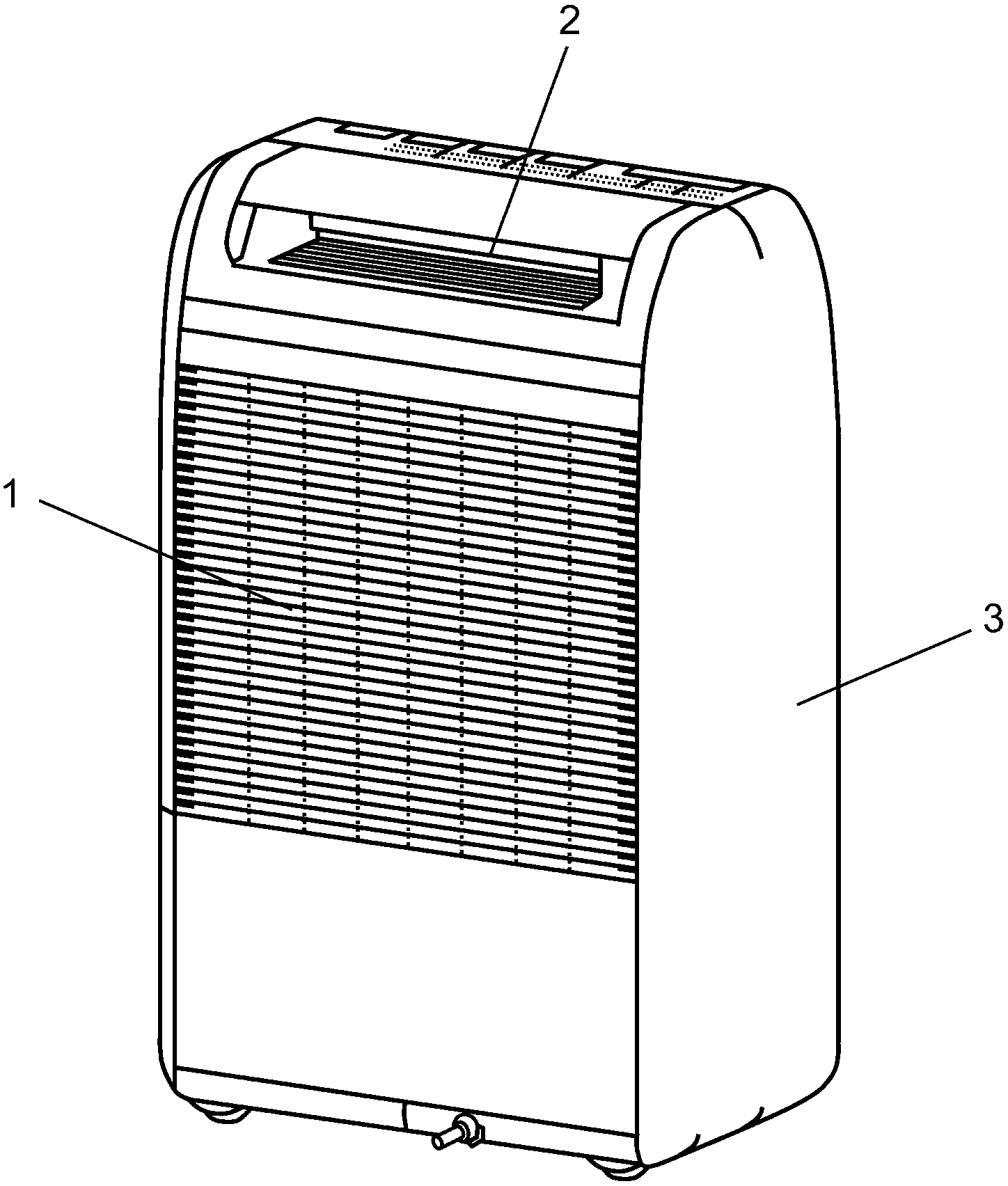

Dehumidifying device

A dehumidifying device comprises a body case provided with a first suction opening and a discharge opening, a refrigeration cycle mechanism arrajged a compressor, a heat dissipater, an expander and a heat absorber in the body case in turn; a fan for a first air flow path in which the sucked air is sent to the first discharge opening after being passed through the heat dissipater and the heat absorber in that order; a moisture releasing section of a dehumidifying rotor located in the first air flow path and provided between the heat dissipater and the heat absorber, a moisture absorbing section of the dehumidifying rotor located in the first air flow path and provided between the heat absorber and the discharge opening, and a heater located in the first air flow path and provided between the humidity discharging section and the heat absorber.

Owner:PANASONIC CORP

Tube-on-sheet heat exchanger type shampoo bed

ActiveCN106323040ACompact structureEasy to installStationary conduit assembliesHair cleaningLower gradeEngineering

The invention relates to the technical field of shampoo beds, in particular to a tube-on-sheet heat exchanger type shampoo bed. The tube-on-sheet heat exchanger type shampoo bed comprises a shampoo bed body, a hot water tank, a heating device for heating water in the hot water tank, a water mixing valve assembly communicated with the hot water tank and a cold water inlet pipe communicated with the water mixing valve assembly and further comprises a tube-on-sheet heat exchanger and a heat exchange water inlet pipe. The tube-on-sheet heat exchanger type shampoo bed can recover hygienic hot water waste heat immediately and low-grade fluid heat, saves energy and is environmentally friendly, the energy consumption caused by tap water heating is reduced, resources are saved, and the usage cost is reduced. The plate A and the plate B are combined to form the core body by adopting sheet pipe structures, the overall smoothness of a plate A sinking tank is good, sewage is smooth to flow, and the problem of remarkable reduction of the heat transfer coefficient due to dirt blockage and sedimentation is avoided. In addition, tap water is good in heat absorption effect in a medium channel, and the waste water and tap water heat exchange effect is good.

Owner:东莞市康源节能科技有限公司

Solar energy heat accumulating method by using soluble salt

InactiveCN101737970AEasy to manufactureDoes not affect normal workSolar heat devicesSolar thermal energy generationThermal energyNuclear engineering

The invention relates to a solar energy heat accumulating method by using soluble salt. The method is characterized in that: a closed heat accumulating container with the expected size can be produced and a great amount of heat energy can be stored in the container by using soluble salt as the heat accumulator; under the normal sunlight condition, a small part of high-temperature conducting medium flowing through a heat user is distributed in the heat accumulating container for favorable heat conduction with the soluble salt which absorbs heat; during interruption of sunlight, heat energy in the heat accumulating container is used, and low-temperature conducting medium soluble salt flows through the heat accumulating container to absorb heat inside the soluble salt which discharges heat. The whole heat accumulating container is made of a material with very good insulating effect and reduces only 3-5 DEG C of the heat accumulation temperature every 24 hours.

Owner:裴如锋

Medicinal material drying device

InactiveCN107642964AEvenly heatedAvoid scorchingDrying chambers/containersDrying machines with non-progressive movementsEngineeringMaterials processing

The invention discloses a medicinal material drying device and relates to the technical field of medicinal material processing equipment. The medicinal material drying device includes a drying tank body and a tank cover matched with the drying tank body. The drying tank body includes a thin-wall inner container and a double-layer casing. The outer side wall of the thin-wall inner container and theinner side wall of the double-layer casing define a heating cavity. A horizontal heating disc is arranged at the bottom of the heating cavity, a plurality of layers heating fins in cross distributionaround the thin-wall inner container are distributed circumferentially on the horizontal heating disc, a stirring assembly for stirring medicinal materials is disposed in the thin-wall inner container, a feeding hopper and a moisture removing pipe which are communicated with the inside of the thin-wall inner container are arranged on the tank cover, and an intermittent feeding assembly is arranged above the feeding hopper. The medicinal material drying device can heat the medicinal materials omni-directionally, the medicinal materials are continuously stirred in the heating process, so that the medicinal materials are heated evenly, and the drying efficiency is improved.

Owner:成都元始信息科技有限公司

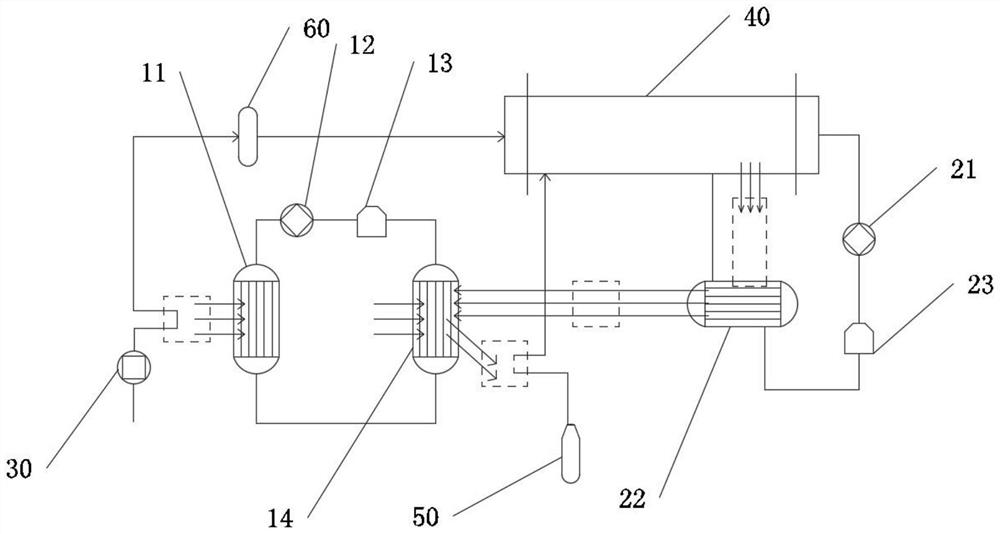

Mining escape capsule refrigerating system and method

InactiveCN102877879AHigh trafficImprove cooling capacity utilizationTunnel/mines ventillationMachines using refrigerant evaporationCarbon dioxide cylinderCapacity loss

The invention discloses a mining escape capsule refrigerating system and method, and belongs to the field of confined space safety rescue and environment control. The system comprises a carbon dioxide steel bottle, a pipeline, a primary bypass valve, a primary pressure reduction and throttling valve, a primary temperature meter, a primary capillary evaporator, a secondary communicated valve, a secondary pressure reduction and throttling valve, a secondary temperature meter, a secondary capillary evaporator, a gas exhaust regulating valve and a pneumatic fan. According to the invention, the primary capillary evaporator and the secondary capillary evaporator are adopted to be connected in series and in parallel to arrange and exchange elements, the refrigeration capacity utilization ratio of a refrigerant can be improved effectively, and the refrigeration capacity loss is reduced; and additionally, through the arrangement of the primary temperature meter and the secondary temperature meter, the controllability of system running and operation is improved; and the mining escape capsule refrigerating system provided by the invention has the advantages that performance is safe and stable, regulation is flexible and convenient, is energy-saving, environment-friendly and economic, and the like.

Owner:中船(天津)环境工程技术有限公司

Cylinder preheating type hot water boiler

InactiveCN1955610AIncrease temperatureThe heat absorber absorbs heatWater heatersCombustion chamberEngineering

A hot water boiler of preheated boiler cylinder is prepared as setting boiler cylinder with flue and heat absorber in combustion chamber independently and relatively, setting water outlet and inlet at top and bottom of boiler cylinder and setting water outlet and inlet at top and bottom of heat absorber in combustion chamber then connecting water outlet of boiler cylinder to water inlet of heat absorber in combustion chamber.

Owner:陈永春

Energy-saving and environment-friendly power generation equipment for desalinating seawater by utilizing seawater salinity difference energy

InactiveCN112636635AReduce stepsReduce economic costsGeneral water supply conservationSeawater treatmentOsmotic powerLiquid state

The invention relates to the technical field of seawater salinity difference energy, and discloses energy-saving and environment-friendly power generation equipment for desalinating seawater by utilizing seawater salinity difference energy. According to the energy-saving and environment-friendly power generation equipment capable of desalinating seawater by utilizing seawater salinity difference, a limiting piece plays a role in protecting the equipment, a rotating shaft meshed with a screw rod is gradually acted to move downwards and move into a power generation bin, and internal cooling liquid is changed from a blocky solid state into a liquid state under the action of an adaptive rail on a sliding groove and the starting action of an induction switch piece; seawater salinity difference energy is formed, and seawater is pumped into a reverse osmosis seat by utilizing the low pressure. In addition, a transmission shaft is pushed to operate in the downward moving process of the rotating shaft, the transmission shaft drives a low-pressure component to rotate synchronously, the low-pressure component and seawater in the reverse osmosis seat are desalted synchronously, and the low-pressure component and the reverse osmosis seat operate synchronously, so that the operation steps are saved, the working time is shortened, the working efficiency is improved, and the economic cost is saved.

Owner:杭州雅唐科技有限公司

Sprayed paint drying device

InactiveCN108722829AExtended stayImprove the heating effectGas treatmentDispersed particle filtrationBristleThreaded pipe

The invention relates to the technical field of drying accessory devices, in particular to a sprayed paint drying device. The temperature of air generated by a supply fan of the drying device can be controlled, drying effects are improved, exhaust gas discharged by an exhaust fan can be treated, environmental pollution is prevented, use reliability of the device is improved, dirt substances on thesurface of a conveying device can be conveniently cleaned, pollution of a sprayed workpiece is prevented, and practicability is improved. The drying device comprises a drying box, a bottom plate, twogroups of left supporting legs, two groups of right supporting legs, a conveying device, a heating box, three groups of first heating bars, three groups of second heating bars, three groups of thirdheating bars, a controller, a buffering box, a treatment box, a filtering screen, multi-group photocatalyst carriers, multi-group ultraviolet lamp pipes, an adjusting plate, two groups of lifting rods, a brush plate, a supporting block, two groups of threaded pipes and two groups of threaded rods, a sliding block is arranged at the left end of the supporting block, a sliding groove is longitudinally formed into the right end of the brush plate, a slider is slidably matched with the inside of the sliding groove, and bristles are arranged at the bottom end of the brush plate.

Owner:JIANGSU ZIQIANG COATING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com