Water and fire direct heat exchange household heating stove

A heating furnace and direct technology, applied in the field of boilers, can solve the problems of easy scale formation, complex structure, low heat exchange efficiency, etc., and achieve the effects of improving utilization efficiency, high efficiency, and direct and rapid heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

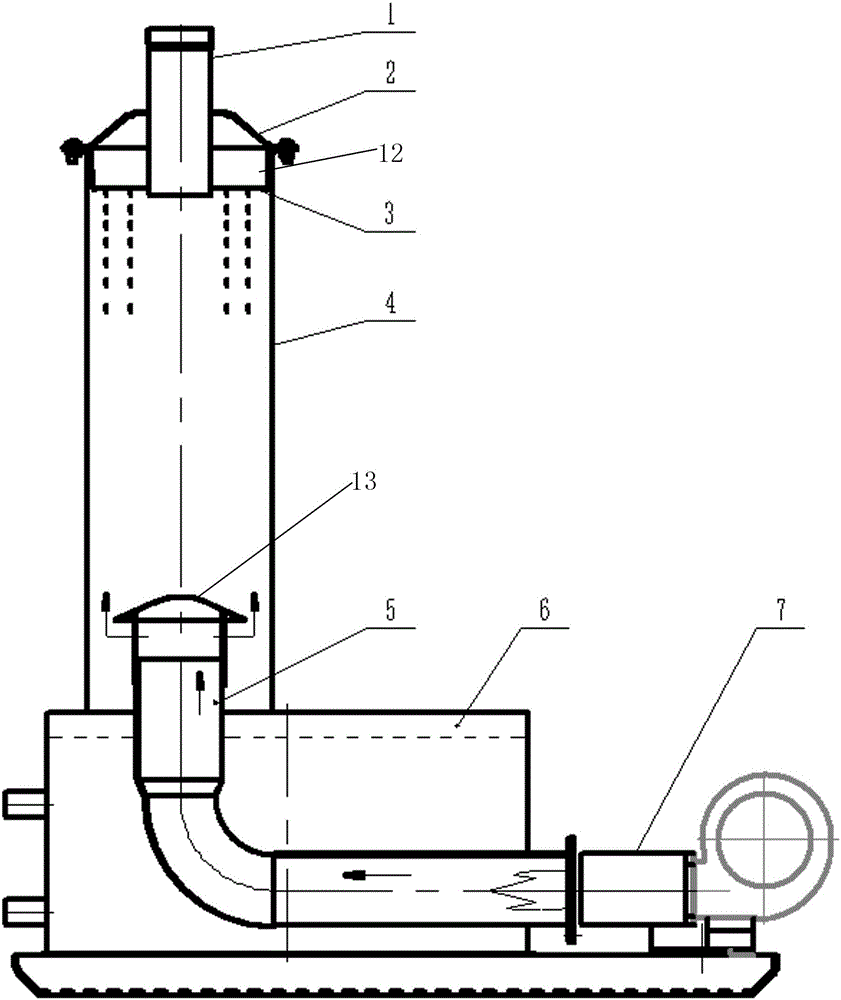

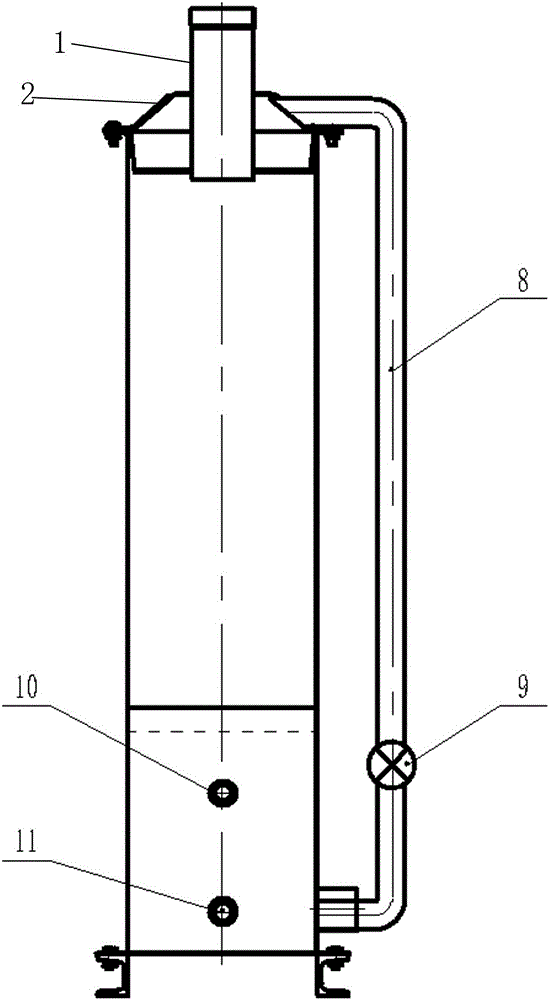

[0012] A water-fire direct heat exchange household heating furnace, comprising a water tank 6 provided with a water outlet 10 and a water return port 11, a burner 7, and a heat exchange cylinder 4 arranged on the top of the water tank 6 and having an opening at the top; the burner 7 is connected to There is a fire outlet pipe 5 extending into the inside of the heat exchange cylinder 4; the heat exchange cylinder 4 is provided with a water tank 12 with a smoke exhaust port and a spray port 3 near the top port of the heat exchange cylinder 4, and the bottom of the heat exchange cylinder 4 is connected to the The water tanks 6 are connected (can be realized through water leakage holes); the water tank 6 leads water to the top of the water tank 12 through the circulation pipe 8 connected with the water pump 9 in series.

[0013] The fire outlet pipe 5 is sealed from the outside and passes through the water tank 6 and then extends into the heat exchange cylinder 4 through the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com