Evaporation device used for heat pipe radiator

A heat pipe radiator and evaporating device technology, used in evaporators/condensers, lighting and heating equipment, refrigerators, etc., can solve the problems of waste of condensed water, inability to continuously participate in cooling, short paths, etc., and achieve uniform heat distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

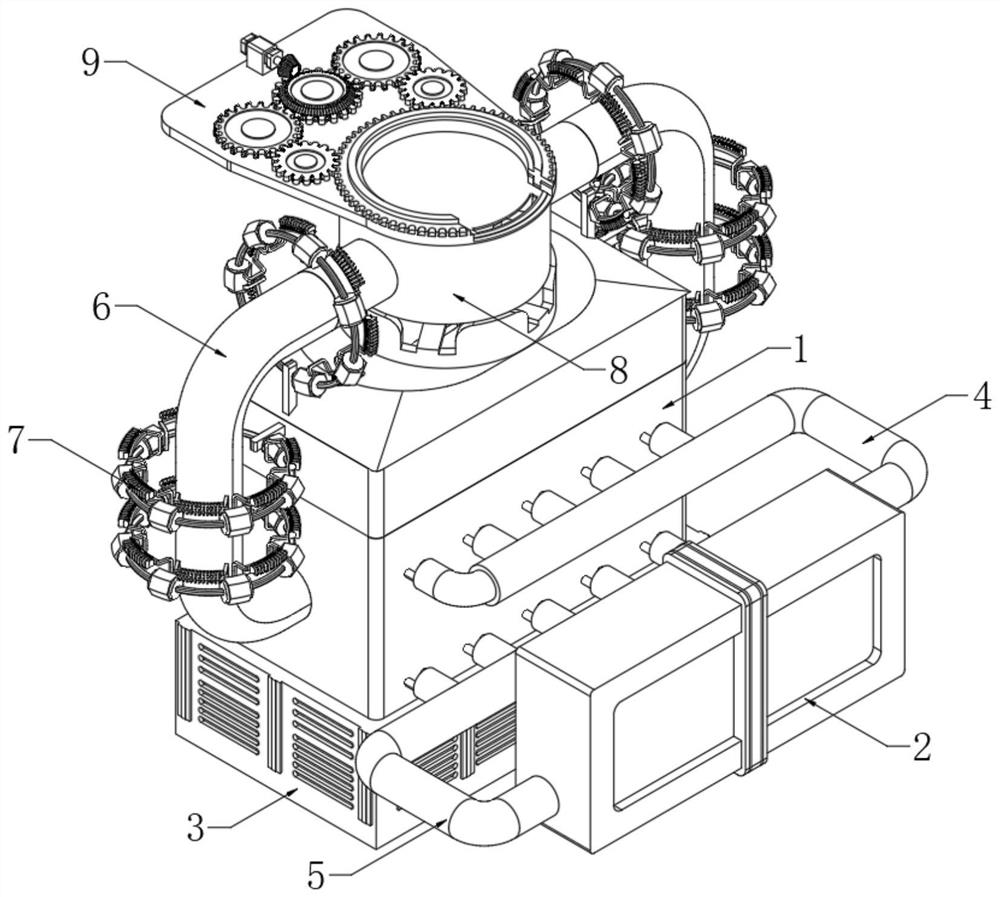

[0037] see Figure 1-6 , an evaporation device for a heat pipe radiator, comprising a cooling box 1, a condensate storage tank 3 is fixedly connected to the lower end of the cooling box 1, a driving water pump is arranged inside one side of the condensing water storage box 3, and the output end of the driving water pump is fixedly connected There is a spray pipe 10, the upper end of the spray pipe 10 is evenly connected with a plurality of spray pipes on the front side, and the end of the spray pipe is provided with a plurality of spray heads; the spray pipe 10 runs through the condensed water storage tank 3 and extends to the outside of the heat dissipation tank 1 At the upper end, the spray conduit at the front end of the spray pipe 10 runs through the upper side wall of the heat dissipation box 1; the fan 11 is fixedly connected to the center of the upper side of the heat dissipation box 1, and the circulation pipe 6 is fixedly connected to both sides of the heat dissipation...

Embodiment 2

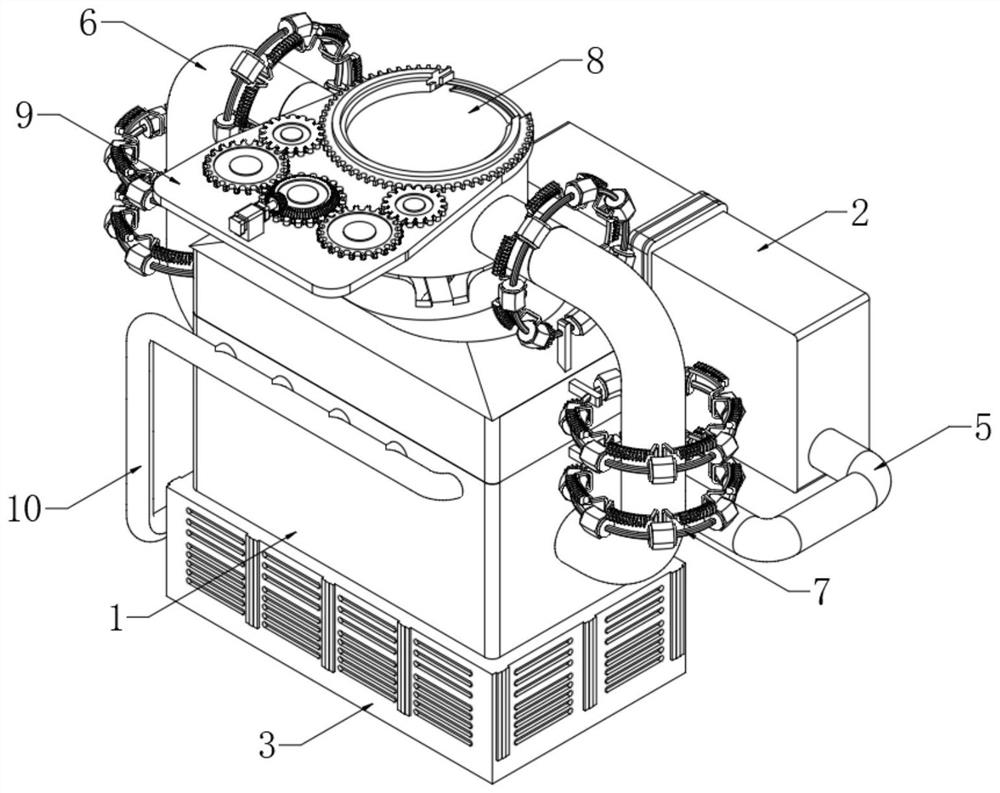

[0041] Such as Figure 6-8 As shown, the differences based on Embodiment 1 are:

[0042] The cooling assembly 7 includes a mounting ring 701, the center of the mounting ring 701 is fixedly connected to the wall of the cooling box 1 through a mounting rod 706, and a plurality of positioning columns 702 are uniformly arranged on the mounting ring 701;

[0043] The outside of the positioning column 702 is rotatably connected with an overturning column 703, and one side of the overturning column 703 is rotatably connected with two U-shaped bars 707, and a connecting frame 704 is fixedly connected between the U-shaped bars 707 on two adjacent overturning columns 703, and the connecting frame The outer side of 704 is fixedly connected with a heat sink group 705;

[0044] One side near the mounting rod 706 is provided with a turning motor 708, and the mounting ring 701 is provided with an installation arc, and one end of the turning motor 708 is fixedly connected with the installati...

Embodiment 3

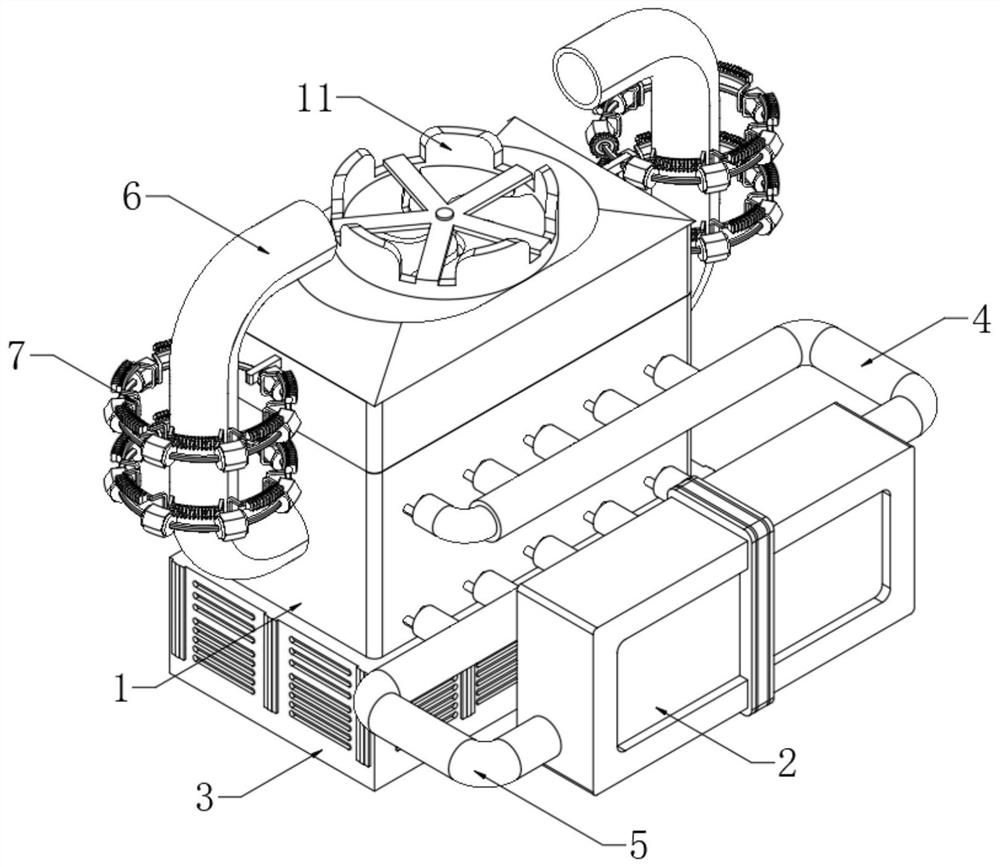

[0048] Such as Figure 9-12 , based on Embodiment 1-2, the difference is:

[0049] An exhaust pipe 8 is fixedly connected to the center of the upper end of the circulation pipe 6, and an intermittent exhaust assembly 9 is arranged on the upper side of the exhaust pipe 8. The intermittent exhaust assembly 9 includes a mounting plate 901, and the mounting plate 901 is fixedly connected to the upper end of the exhaust pipe 8;

[0050] The front end of the mounting plate 901 is fixedly connected with a connection plate 908, and the connection plate 908 is fixedly connected to the upper side of the exhaust pipe 8; the front side of the connection plate 908 is provided with an exhaust hole 909, and the upper side of the connection plate 908 is provided with a ring rail, which slides in the ring rail A gear ring 907 is connected; the lower side of the gear ring 907 is fixedly connected with a sealing ring 911, the surface of the sealing ring 911 is provided with a rubber layer, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com