Method and apparatus of controlling combustion in oxyfuel combustion boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

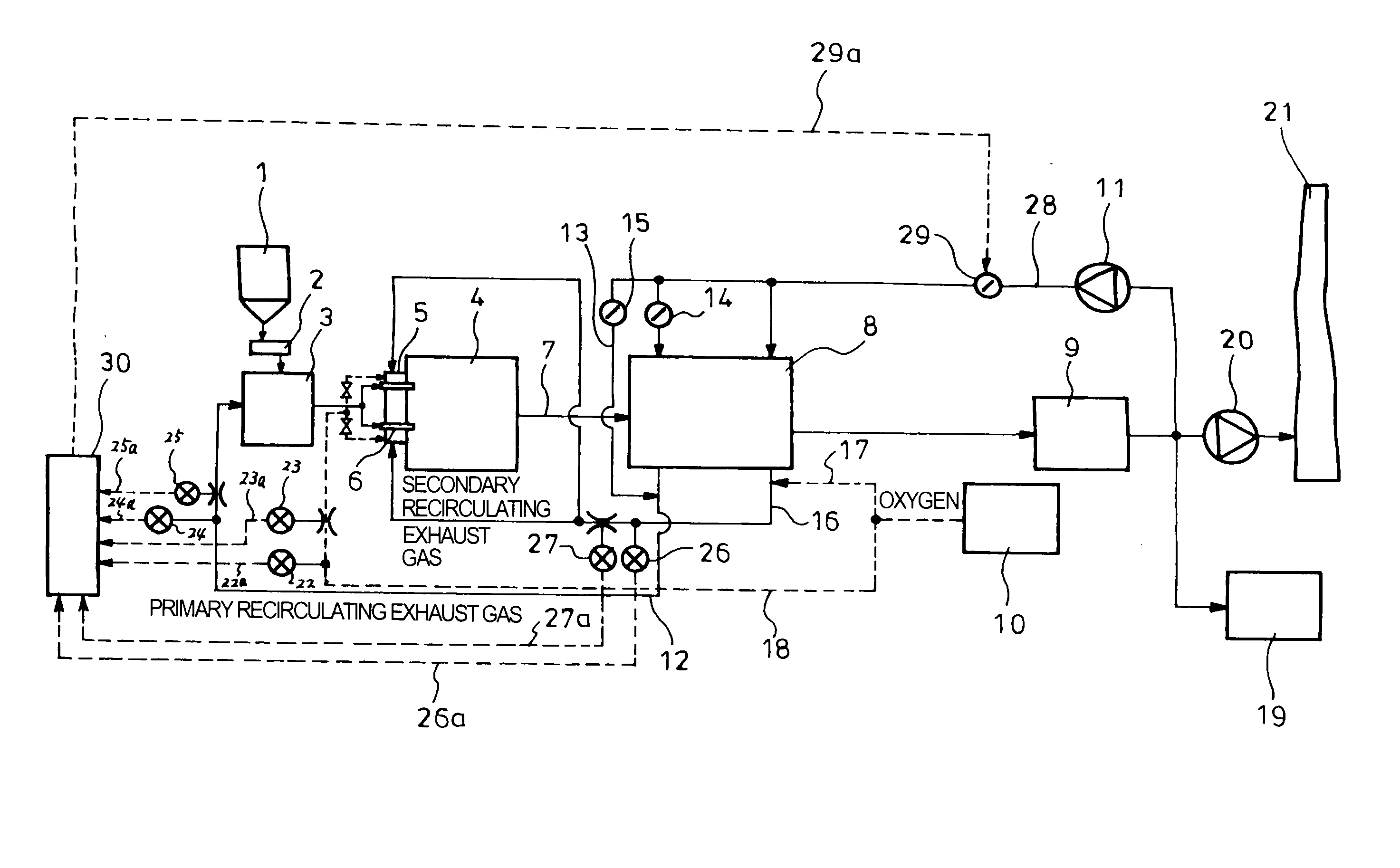

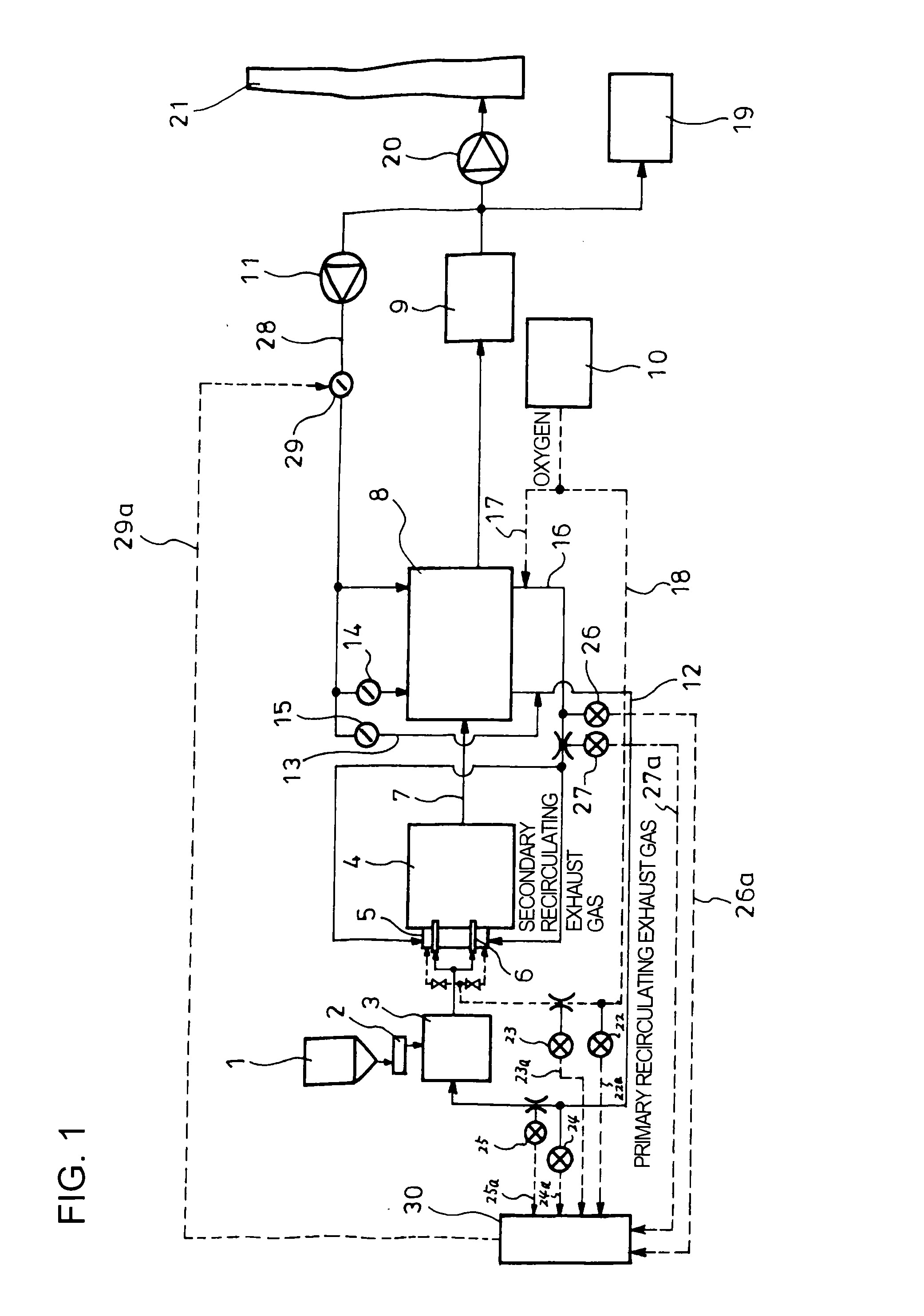

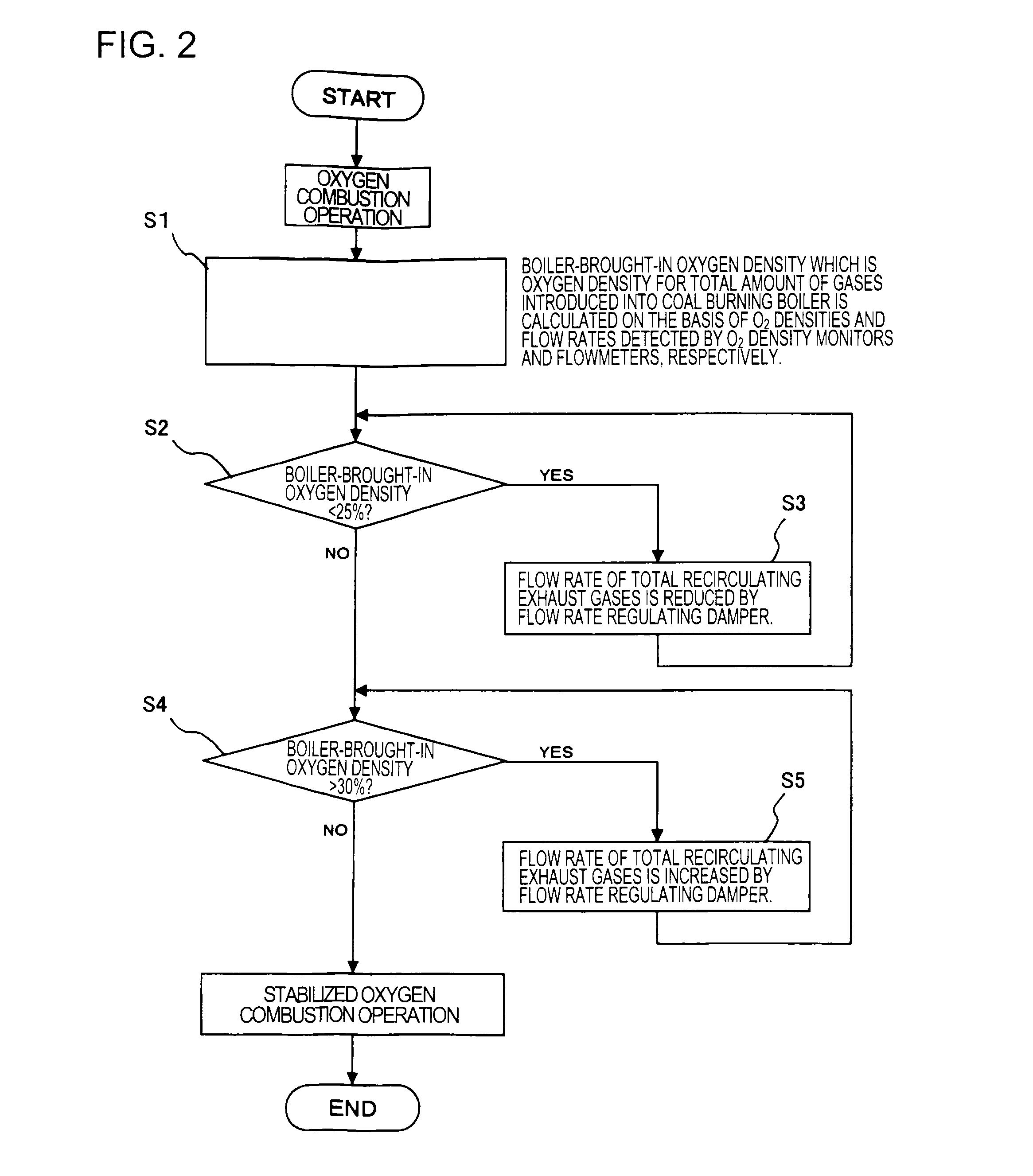

[0079]Embodiments of the invention will be described with reference to the accompanying drawings.

[0080]Referring to FIGS. 1 to 3 showing an embodiment of the invention, reference numeral 1 denotes a coal bunker for coal storage; 2, a coal feeder for feeding coal stored in the bunker 1; 3, a mill for pulverization and drying of the coal from the feeder 2; 4, a coal burning boiler; 5, a wind box fitted to the boiler 4; 6, a burner disposed in the wind box 5 for burning pulverized coal from the mill 3; 7, an exhaust gas line through which flows an exhaust gas emitted from the boiler 4; 8, an air preheater for heat exchange of the exhaust gas flowing through the exhaust gas line 7 with primary and secondary recirculating exhaust gases; 9, exhaust gas treating devices such as a desulfurizer and a dust collector for treatment of the exhaust gas passing through the air preheater 8; 10, an air separation unit for production of oxygen; 11, a forced draft fan (FDF) for forcedly sending the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com