Water cooling plate for heat dissipation of high-power electrical heating element

A technology for heating elements and water-cooling plates, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of unfavorable water-cooled plate heat exchange efficiency, difficulty in reducing fin spacing, and difficulty in increasing fin thickness, etc. The effect of heat dissipation efficiency, increased disturbance, and strong heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

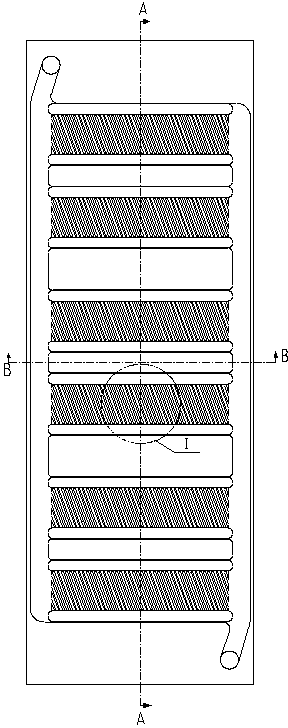

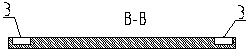

[0037] The new fin arrangement form high-power heat dissipation water-cooled plate, including the upper plate 6 with fins and the lower plate 7 with fins, is a heat dissipation substrate welded together by vacuum brazing, and the surface of the substrate is provided with threaded holes 10 for installing IGBTs , a water pipe joint 5 is also installed, and the threaded hole is inlaid with a wire thread sleeve to meet the torque requirements for installation.

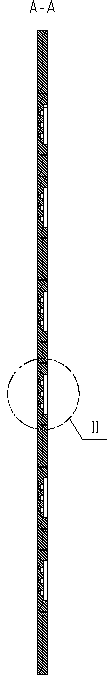

[0038] The upper and lower plate fins are formed by milling grooves on the upper and lower plates. First, the height h of the fins of the upper and lower plates is given 1 , h 2 with spacing. (also both the milling groove depth and groove spacing), when machining the upper plate fin area, the tool feed direction and the upper plate form a certain angle (θ 1 , θ 2 ), the processing is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com