Medicinal material drying device

A technology for drying devices and medicinal materials, applied in heating devices, drying solid materials, drying chambers/containers, etc., can solve the problems of uneven heating, scorched medicinal materials, etc., to ensure uniform heating, controllable rotation angle, and optimized drying. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

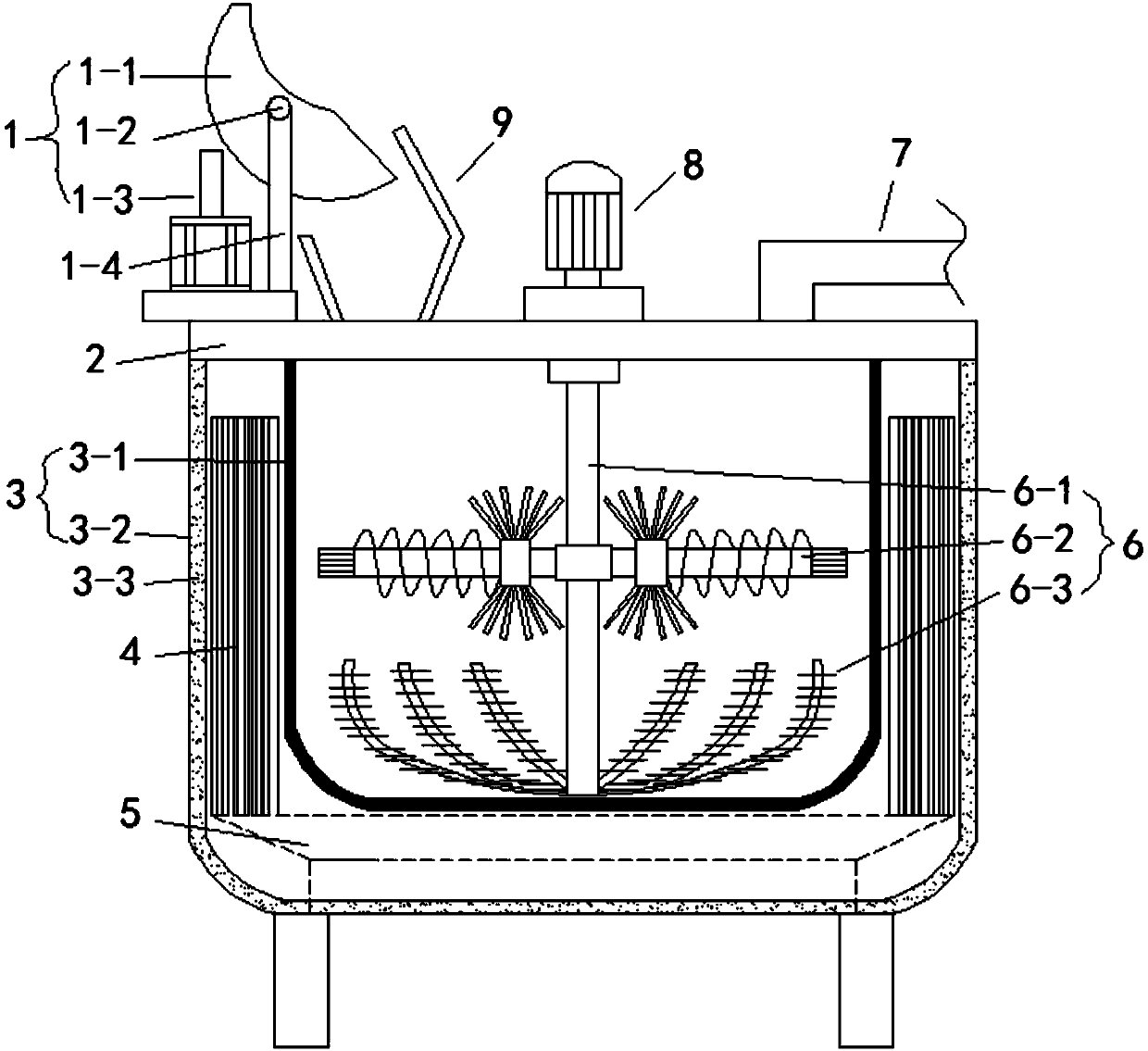

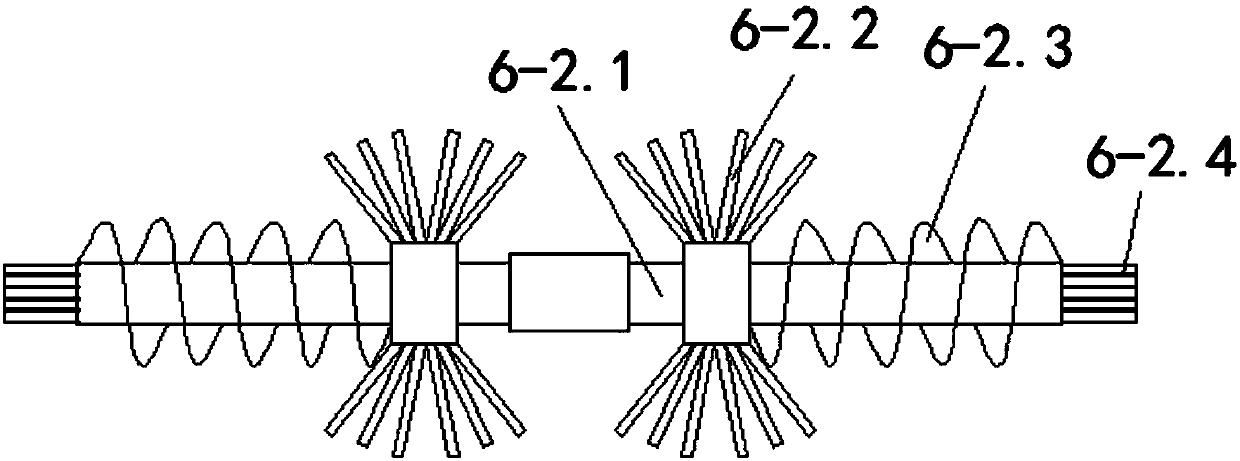

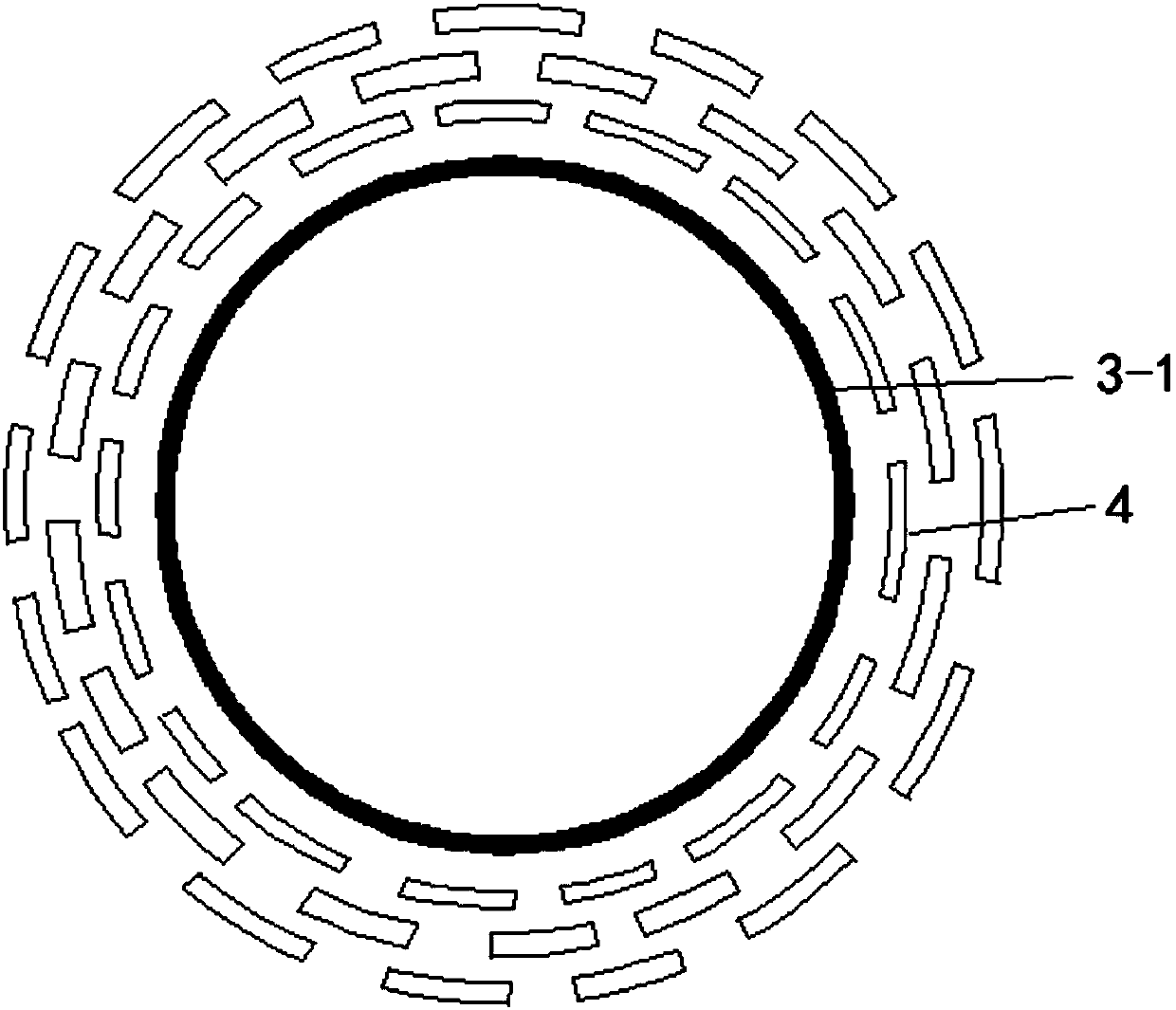

[0023] Such as Figure 1 to Figure 3 As shown, this embodiment provides a drying device for medicinal materials, including a drying tank body 3 and a tank cover 2 matched with the drying tank body 3, and the drying tank body 3 includes a thin-walled liner 3-1 And the double-layer shell 3-2, the double-layer shell 3-2 includes the inner shell and the outer shell, the inner shell and the outer shell form the heat preservation chamber 3-3, the heat preservation chamber 3-3 is filled with glass fiber, and the thin-walled liner The outer side wall of 3-1 and the inner side wall of the inner shell form a heating cavity, and a horizontal heating plate 5 is arranged at the bottom of the heating cavity. There are three layers of heating fins 4 distributed, a stirring assembly 6 for stirring the medicinal materials is arranged in the thin-walled inner tank 3-1, and the tank cover 2 is provided with inlets respectively connected with the inside of the thin-walled inner tank 3-1. The hop...

Embodiment 2

[0026] Such as figure 1 As shown, the present embodiment is further optimized on the basis of embodiment 1, specifically:

[0027] The intermittent feeding assembly 1 includes a rotating shaft 1-2, a storage basket 1-1 with an arc-shaped bottom, and a driving component 1-3 that drives the storage basket 1-1 to swing around the rotating shaft 1-2, and the rotating shaft 1-2 passes through a bearing frame 1-4 is erected on the tank cover 2, the storage basket 1-1 is erected on the bearing frame 1-4 through the rotating shaft 1-2, the driving part 1-3 is a cylinder, and the piston rod of the cylinder drives the storage basket 1-1 around the rotation shaft 1-2 swings to intermittently feed material to the feed hopper 9, the limit plate is connected to the feed hopper 9, and the rotation angle of the storage basket 1-1 is limited by the cylinder piston rod and the limit plate, so that the medicinal materials fall into the feed accurately In the hopper 9, the structure of this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com