Multistage parallel SCR system

A SCR system, parallel technology, applied in exhaust gas treatment, mechanical equipment, engine components, etc., can solve the problems of poor gas flow velocity distribution uniformity, high nitrogen oxide conversion efficiency, low nitrogen oxide conversion efficiency, etc., to achieve uniform speed The effect of easy control, high uniformity of flow velocity distribution, and reduced risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

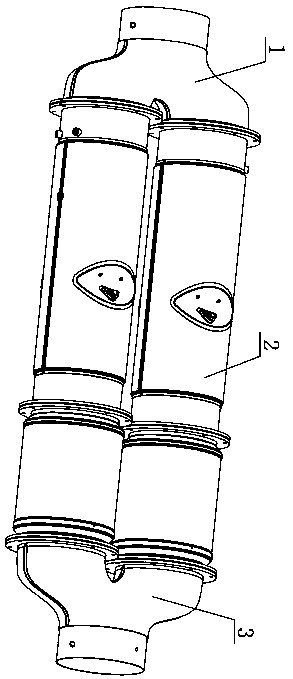

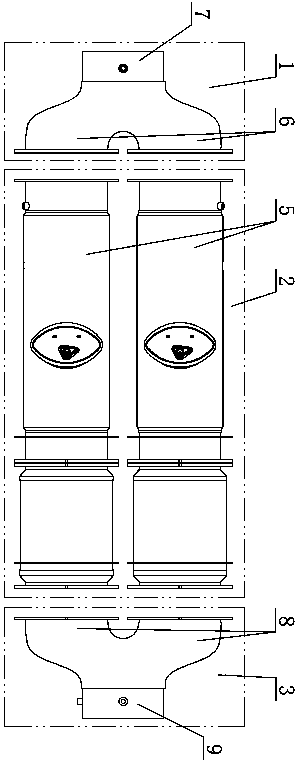

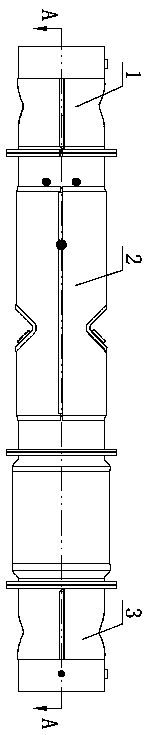

[0043] Such as figure 1 , figure 2 , image 3 As shown, the present invention is provided with an air intake unit 1, a reaction unit 2, and an air outlet unit 3 in series from left to right. The air intake unit 1, the reaction unit 2, and the air outlet unit 3 are respectively connected by flanges, which are convenient for disassembly and maintenance. . Such as figure 2 As shown, according to the displacement of the marine diesel engine, several reaction passages 5 are arranged in the reaction unit 2, and several branch pipes 6 are arranged corresponding to several reaction passages 5 on the air intake unit 1, and several branch pipes 6 are integrally formed, and Simultaneously connected to the same air inlet 7 of the air intake unit 1; the air outlet unit 3 is provided with several confluence branch pipes 8 corresponding to several ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com