Polylactic acid microsphere and preparation method and application thereof

A technology of polylactic acid microspheres and polylactic acid, which is applied in the fields of polymer materials and biomedical engineering, can solve the problems of human body or environmental hazards, without mentioning the removal of organic solvents, and achieve good fluidity, sieving and grading and labeling particles The effect of accurate diameter and strong shearing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Weigh 60g of PDLGA with a viscosity of 50ml / g, add it to 100ml of dichloromethane, and make a polylactic acid solution with a concentration of 60g / ml;

[0044] (2) Add 6 g of sodium carboxymethyl starch to the above polylactic acid solution, and at a speed of 300 rpm, use mechanical stirring to uniformly disperse the sodium carboxymethyl starch in the polylactic acid solution in solid form to obtain a polylactic acid suspension;

[0045] (3) Under stirring at 200rpm, add 5ml of mineral oil to the polylactic acid suspension obtained in step (2) to obtain a layered mixed solution;

[0046] (4) Under stirring at 200 rpm, add 1000 ml of mineral oil to the mixed solution obtained in step (3), after stirring overnight, collect the solid by filtration, wash, and freeze-dry to obtain microspheres.

[0047] Determination of microsphere properties

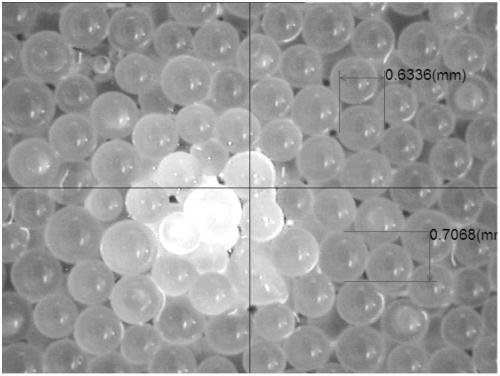

[0048] a. Morphological observation

[0049] Soak the microspheres in saline, observe and take pictures under an ordinary opti...

Embodiment 2

[0059] (1) Weigh 20g of PDLGA with a viscosity of 40ml / g, add it to 100ml of dichloromethane, and make a polylactic acid solution with a concentration of 20g / ml;

[0060] (2) Add 6 g of sodium carboxymethyl starch to the above polylactic acid solution, and at a speed of 300 rpm, use mechanical stirring to uniformly disperse the sodium carboxymethyl starch in the polylactic acid solution in solid form to obtain a polylactic acid suspension;

[0061] (3) Under stirring at 200rpm, add 5ml of mineral oil to the polylactic acid suspension obtained in step (2) to obtain a layered mixed solution;

[0062] (4) Under stirring at 200 rpm, add 1000 ml of mineral oil to the mixed solution obtained in step (3), after stirring overnight, collect the solid by filtration, wash, and freeze-dry to obtain microspheres.

[0063] Determination of microsphere properties

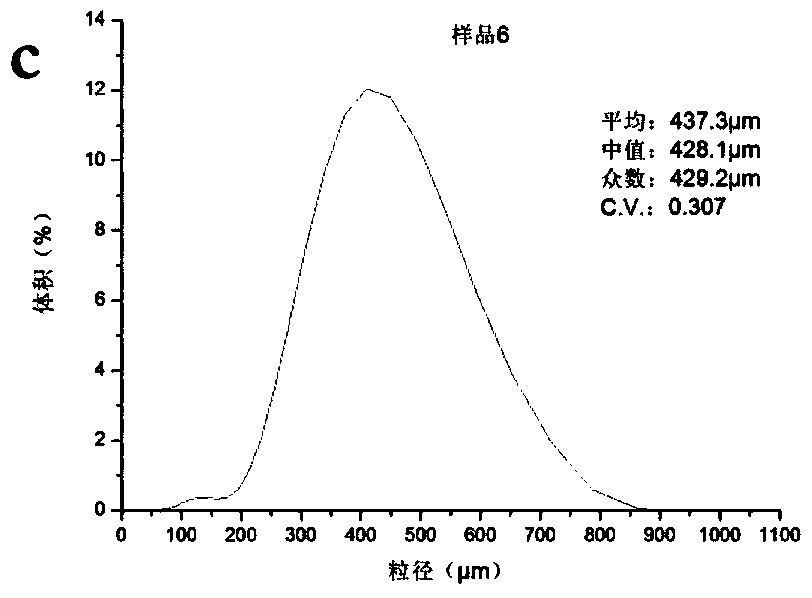

[0064] According to the same measuring method as in Example 1, it is observed that the microspheres of this embodiment are regu...

Embodiment 3

[0066] (1) Weigh 30g of PDLGA with a viscosity of 40ml / g, add it to 100ml of dichloromethane, and make a polylactic acid solution with a concentration of 30g / ml;

[0067] (2) Add 6 g of sodium carboxymethyl starch to the above polylactic acid solution, and at a speed of 300 rpm, use mechanical stirring to uniformly disperse the sodium carboxymethyl starch in the polylactic acid solution in solid form to obtain a polylactic acid suspension;

[0068] (3) Under stirring at a rotating speed of 180rpm, add 5ml of mineral oil to the polylactic acid suspension obtained in step (2) to obtain a layered mixed solution;

[0069] (4) Under stirring at a rotating speed of 180rpm, add 1000ml of mineral oil to the mixed solution obtained in step (3), after stirring overnight, collect the solid by filtration, wash, and freeze-dry to obtain microspheres.

[0070] Determination of microsphere properties

[0071] According to the same measuring method as in Example 1, it is observed that the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com