High-torque synchronous belt preparation method

A synchronous belt and high-torque technology, which is applied in the field of S3M high-torque synchronous belt production, can solve the problems of large transmission system structure, large belt pitch, and high cost, so as to avoid excessive force on local teeth, improve transmission torque, Effect of high modulus stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The best mode for carrying out the present invention will be described below with reference to the appropriate drawings.

[0025] Because it is widely used in the transmission system for high torque transmission, the belt teeth have better wear resistance and stronger shear force.

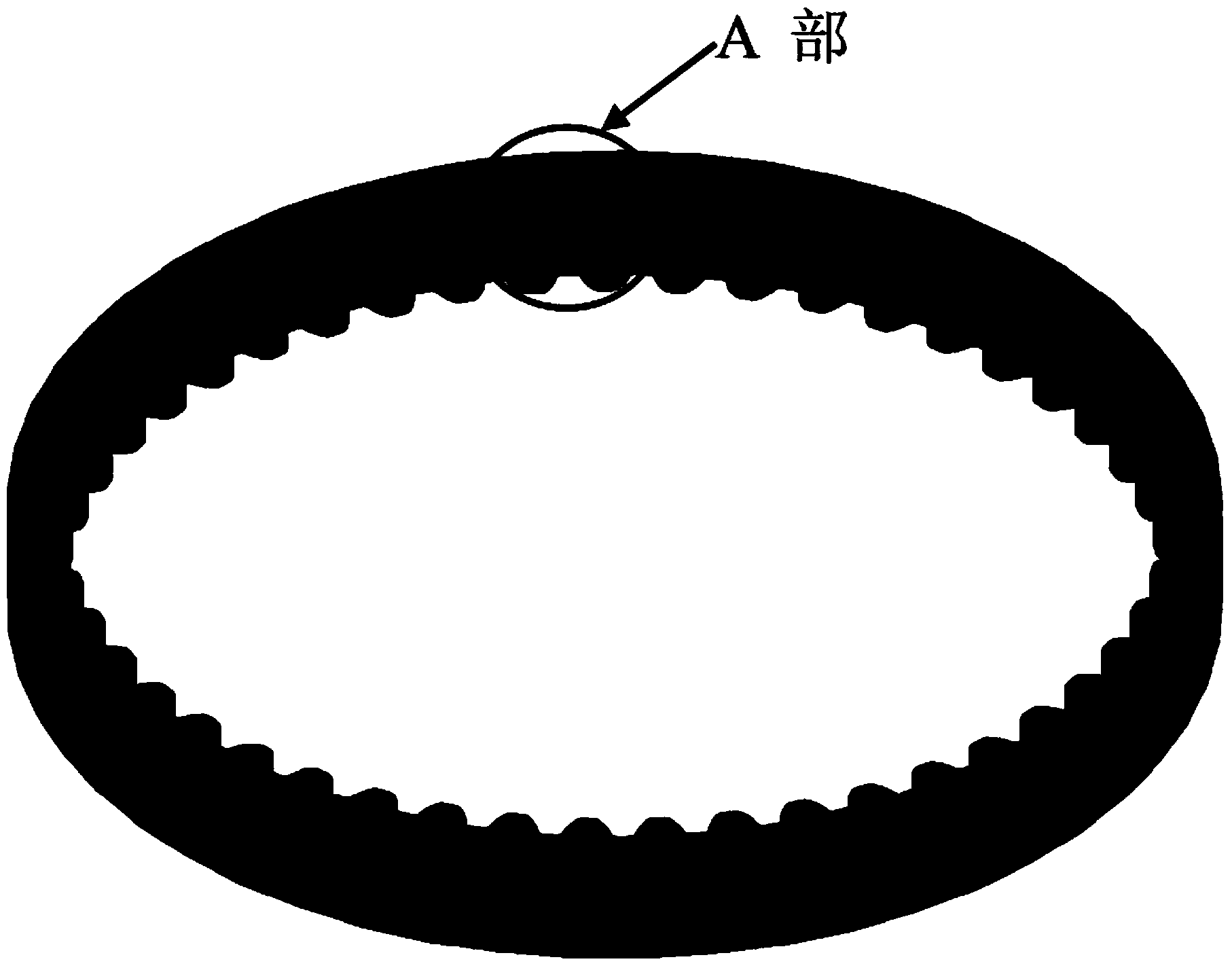

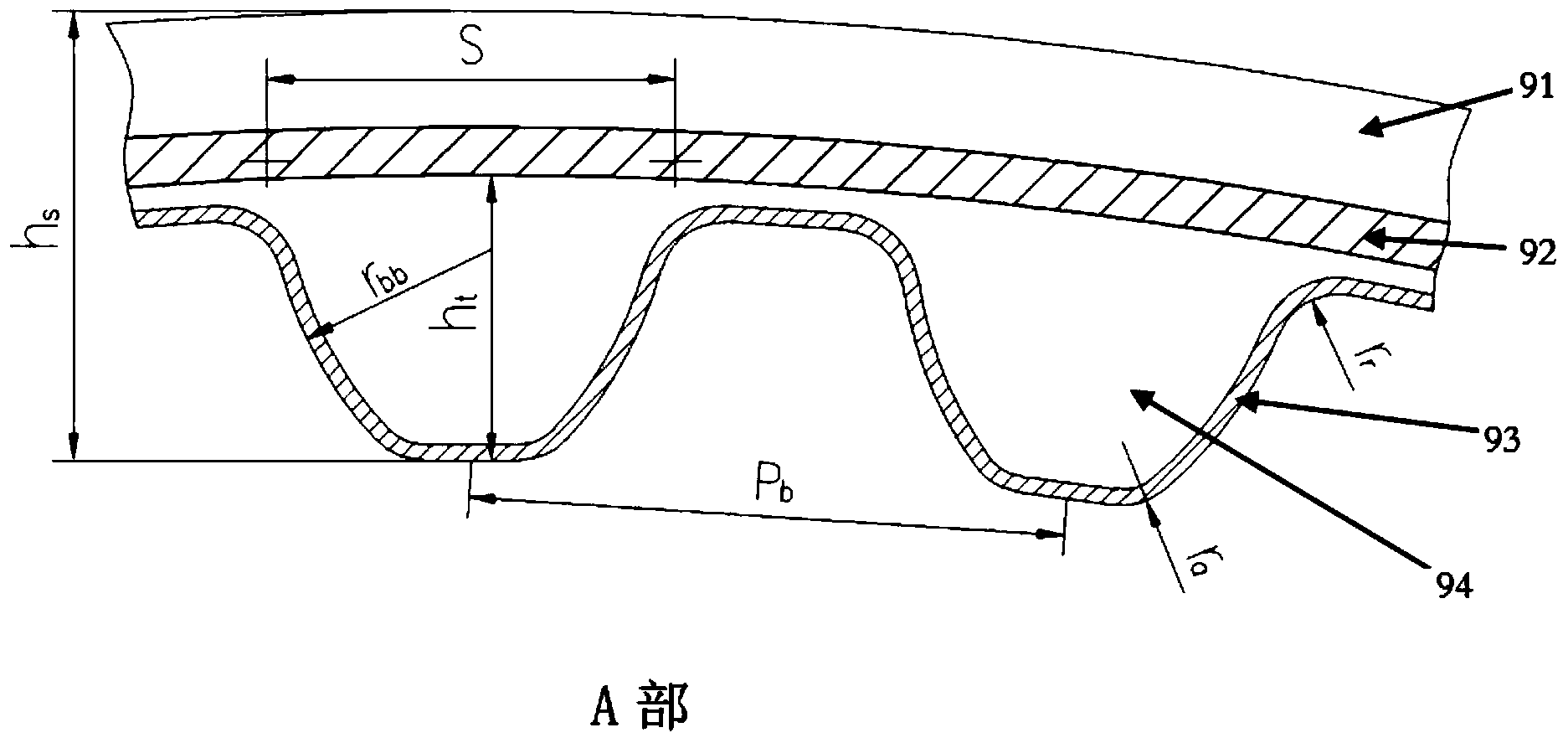

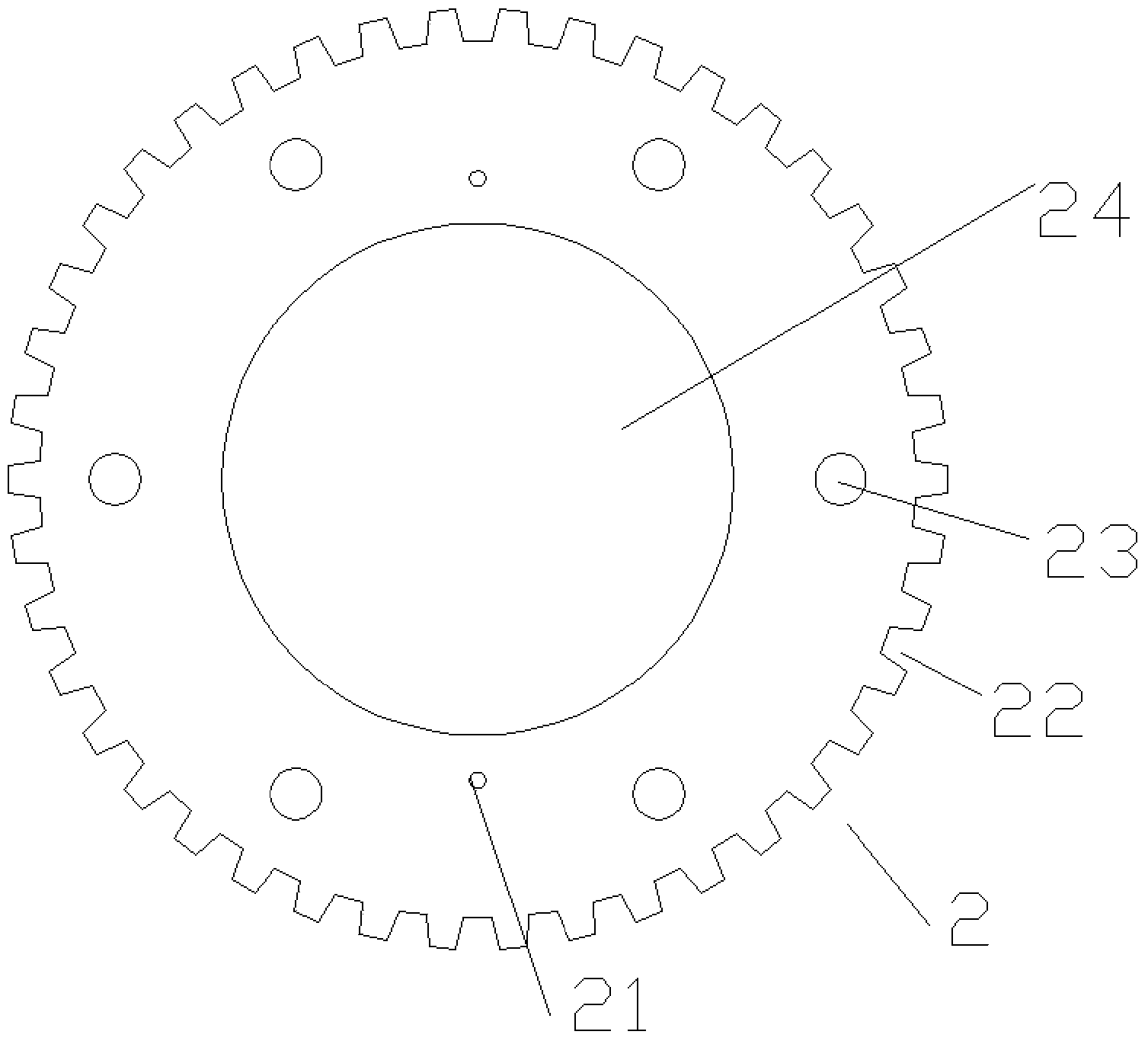

[0026] A synchronous belt of the present invention, especially a method for preparing a S3M high-torque synchronous belt, the synchronous belt has an endless belt body, and the endless belt body includes: equidistant along the inner peripheral surface of the annular belt body A plurality of teeth 94 are arranged; elastic nylon cloth 93 with wear resistance is coated on the surface of the teeth; a core rope 92 is laid inside the endless belt body along the circumferential direction of the endless belt body , and the back of the core rope 92 is covered with a rubber material with bending properties 91;

[0027] The method of the present invention includes the following steps: kneading the rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com