A kind of preparation method of U-shaped transmission belt

A transmission belt and U-shaped technology, which is applied in the field of transmission belts, can solve the problems of large cumulative tolerance, distorted pictures, and lack of access to users, and achieve the effects of good bending, reduced transmission space, and improved transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The best mode for carrying out the present invention will be described below with reference to the appropriate drawings.

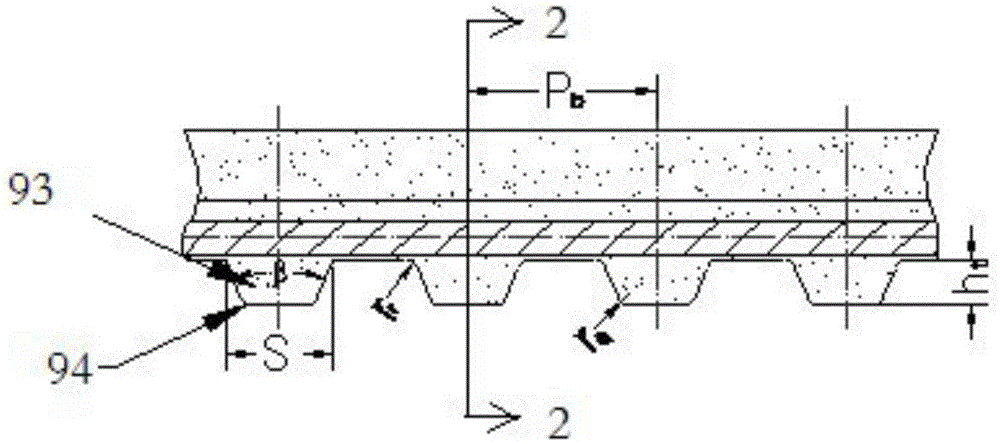

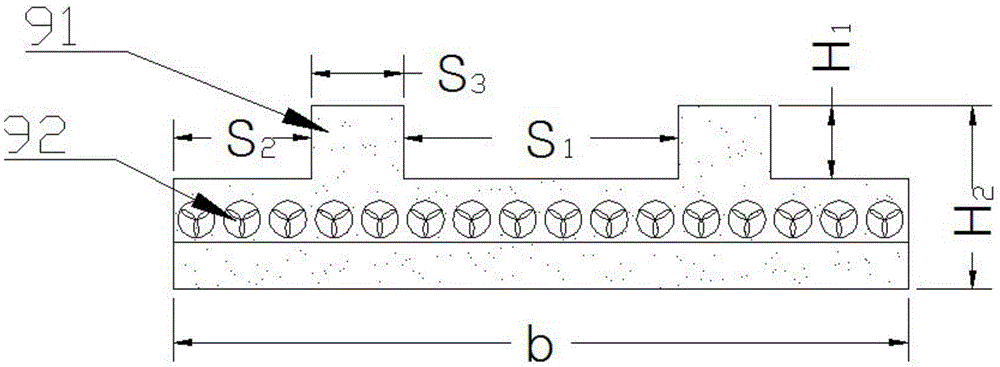

[0027] A transmission belt of the present invention is a U-shaped transmission belt, which successively comprises an outer layer of U-shaped groove neoprene, a glass fiber layer, a neoprene tooth layer and an elastic nylon cloth layer, and the groove of the neoprene belt back is The type is U-shaped groove.

[0028] The width S1 of the bottom of the U-shaped middle groove is 3.0mm, the width and height of the bottom of the grooves on both sides are S2 is 1.5mm, the width S3 of the top is 1.0mm, and the tooth height H1 is 0.8mm.

[0029] The width b of the U-shaped transmission belt is 8±0.40mm.

[0030] The thickness H2 of the U-shaped transmission belt is 2±0.15mm.

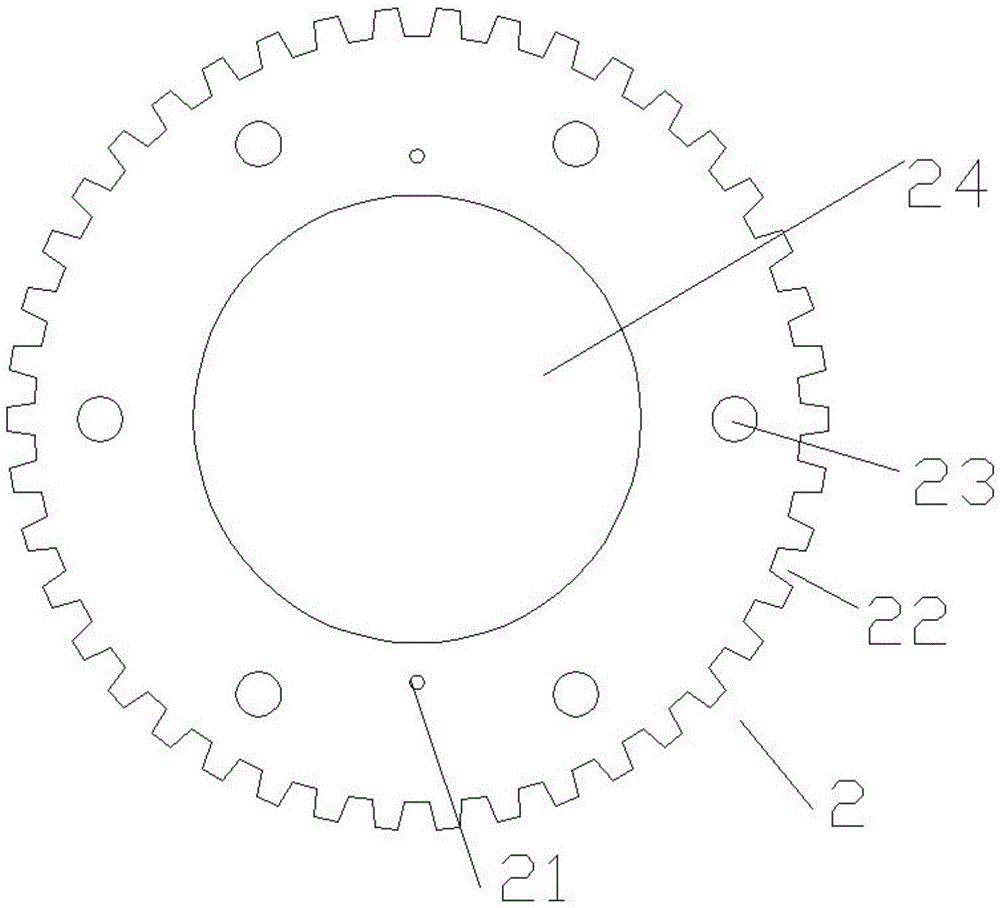

[0031] The inner tooth shape of the U-shaped transmission belt is trapezoidal teeth. The pitch Pb of the trapezoidal tooth is 2.016mm, the root transition radius rr is 0.13mm, the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com