Patents

Literature

49results about How to "Save transmission space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

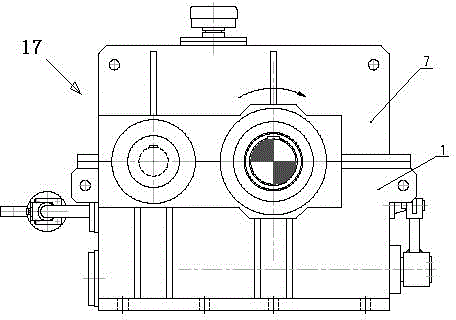

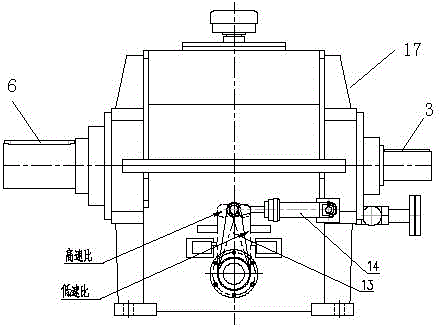

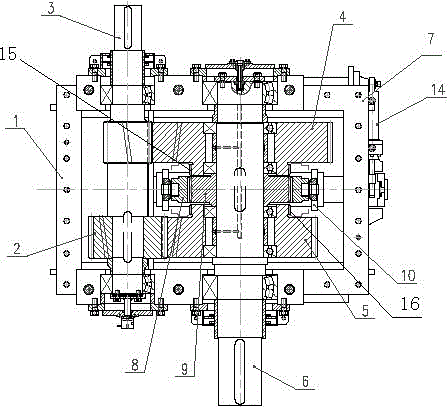

Special driving compound gear box of cold-rolling stainless steel sheet recoiling machine set

InactiveCN104358842AImprove efficiencyCompact structureGearboxesToothed gearingsGear wheelClassical mechanics

The invention relates to a special driving compound gear box of a cold-rolling stainless steel sheet recoiling machine set. The special driving compound gear box comprises a box body (17), an input gear shaft (3) and an output shaft (6), and is characterized in that a shaft gear on the gear shaft (3) is engaged with a first shift gear (4); a gear (2) is mounted at the lower end of the gear shaft (3), the gear (2) is engaged with a second shift gear (5), an external spline gear (9) is mounted on the output shaft (6), and an internal spline gear (8) is mounted on the external spline gear (9); a shift deflector rod (13) and a driving device (14) for driving the shift deflector rod (13) to rotate are mounted outside the box body (17), a selector fork (11) is mounted inside the box body, the shift deflector rod (13) is connected with the selector fork (11) through a spindle (12). The special driving compound gear box is compact in structure, small in transmission space and high in using efficiency.

Owner:NANJING KINGDOM HEAVY DUTY GEAR BOX

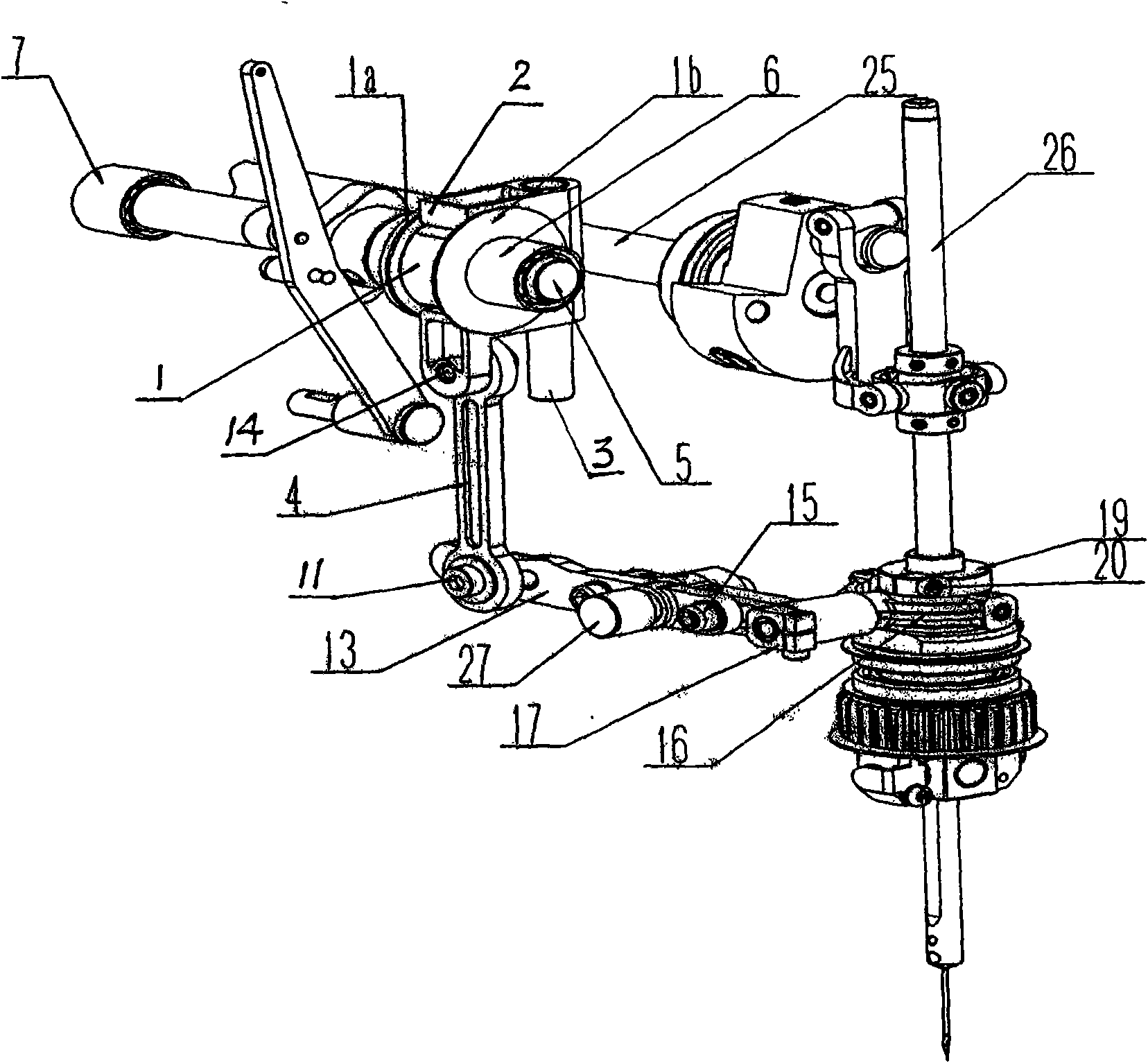

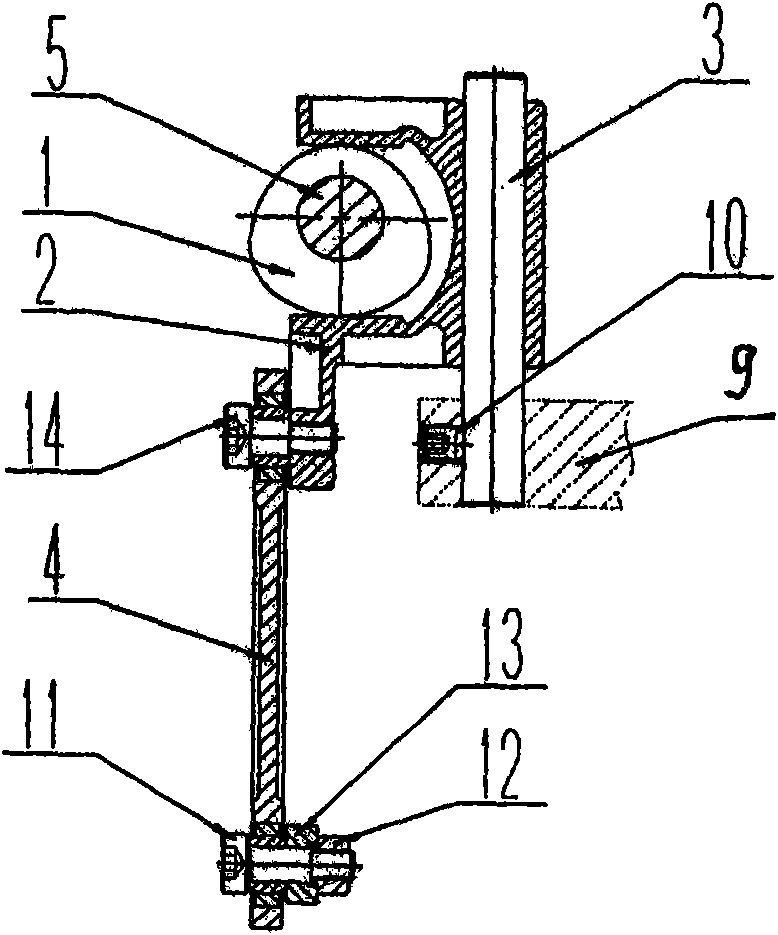

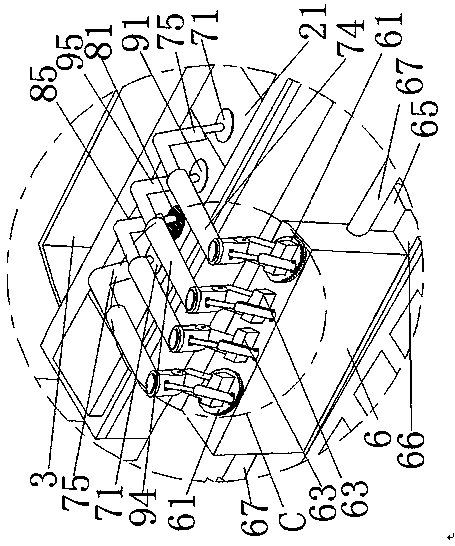

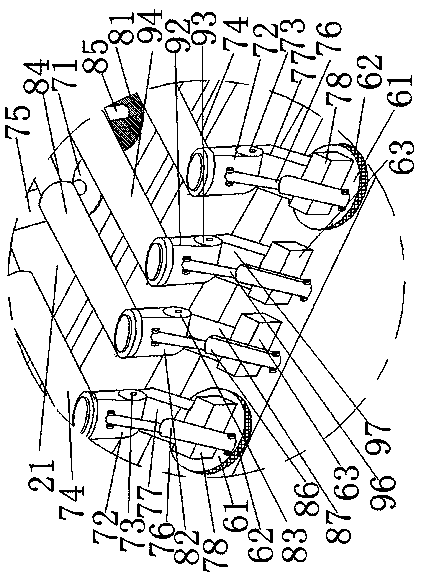

Buttonhole sewing machine

A buttonhole sewing machine comprises a frame, an upper frame, a boss rod, a needle bar for arranging an internal needle, a movable feed table with an x-y horizontal coordinate system and a curved needle below the feed table, the boss rod drives the needle bar, the needle bar moves up and down for punching and forms a buttonhole seam with the curved needle, a needle vibrating cam is arranged on the front end part of the upper frame and drives a fork reciprocating lever to move up and down, the fork reciprocating lever is articulated with a feed bar mechanism by a connecting rod, the rear end of the feed bar mechanism is articulated with a shifting rod, a shifting fork on the shifting rod is articulated with a needle vibrating slide block to cause the needle vibrating slide block to move up and down, and a trapezoid flume on the needle vibrating slide block promotes the needle bar to horizontally move, thus realizing needle vibrating motion. The needle vibrating mechanism has compact structure, reduces driving space, transmission links and accumulated clearance errors and has more stable transmission.

Owner:浙江胜佳特种缝制设备有限公司

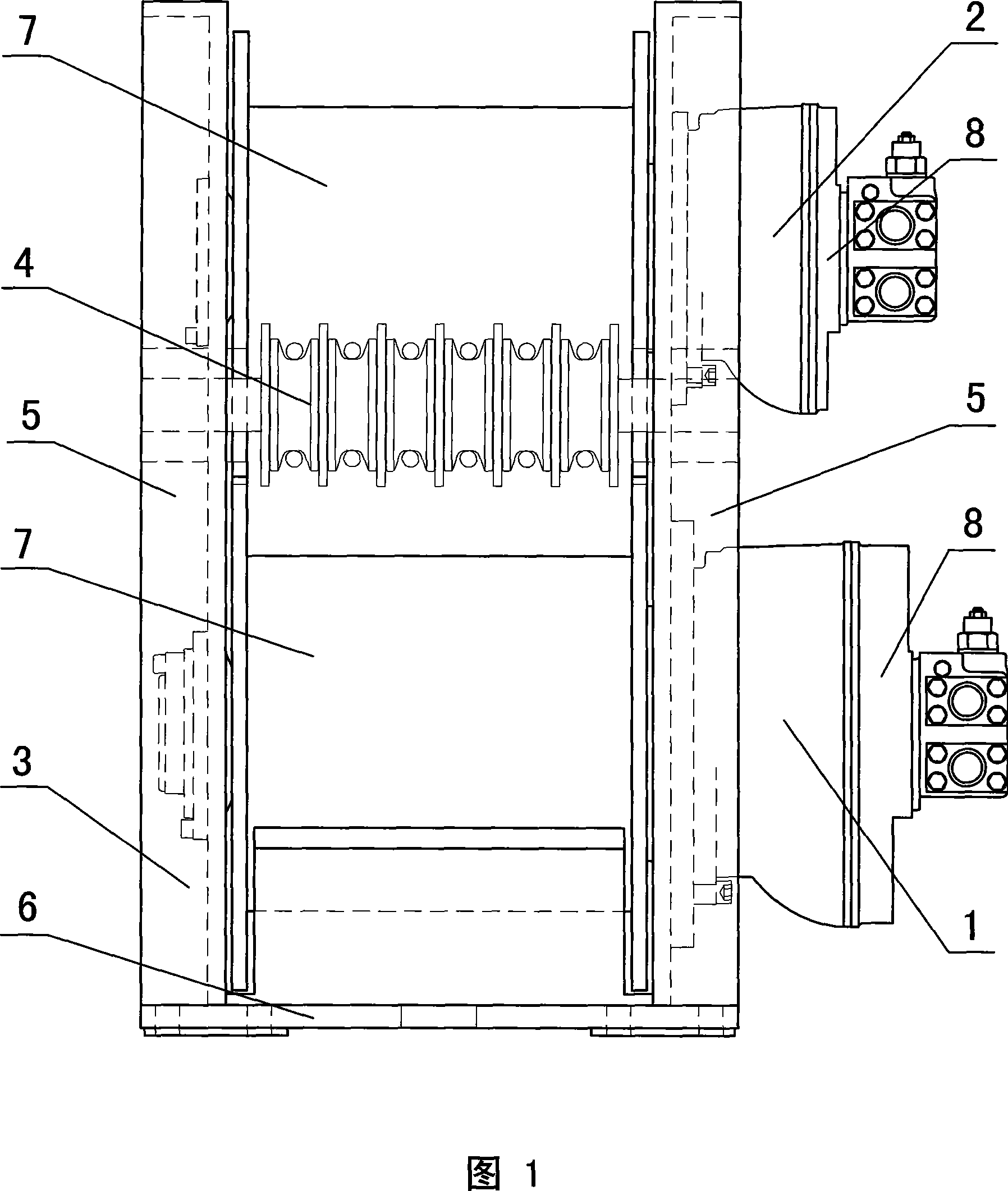

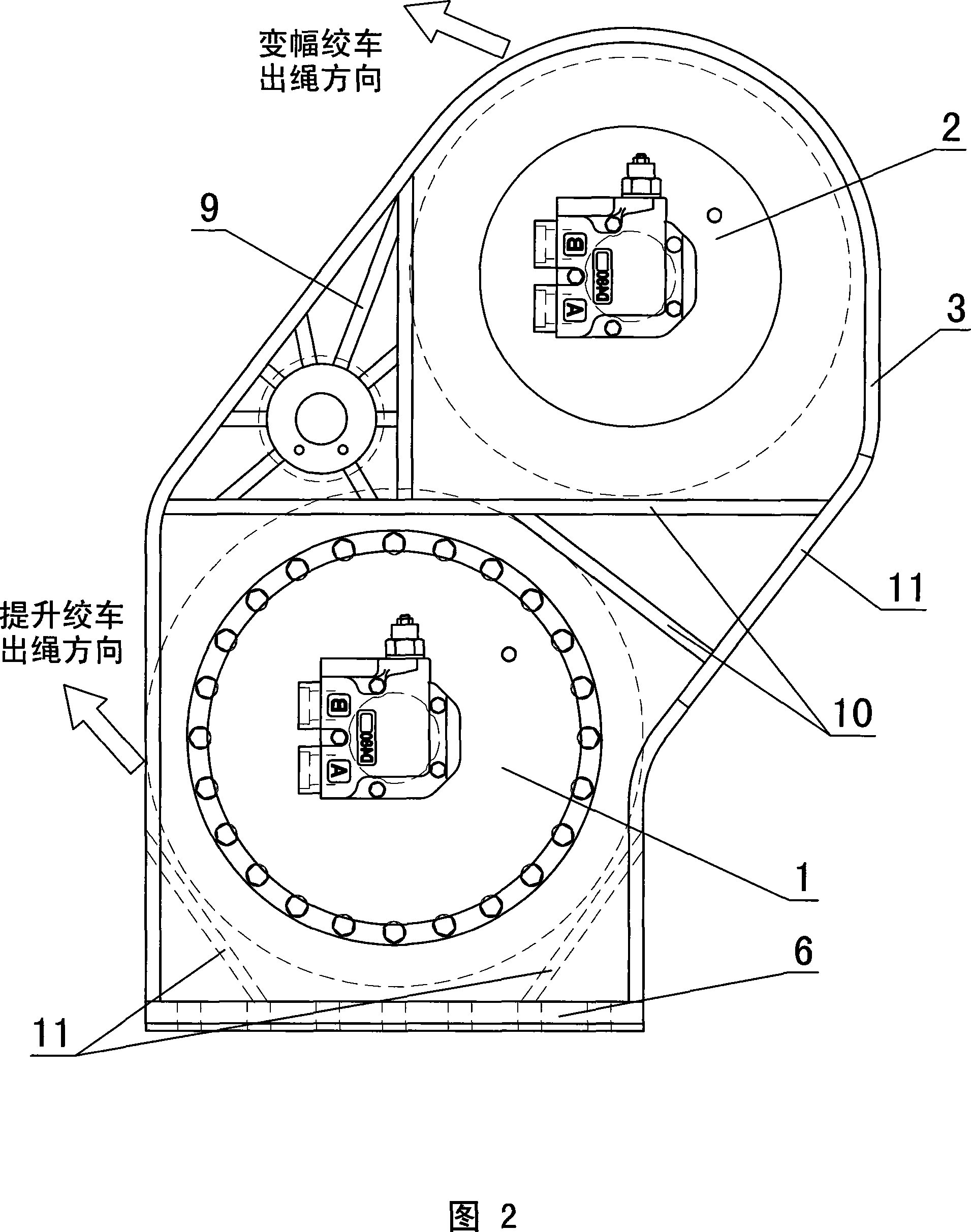

Combination type hydraulic pressure reel cart

The invention discloses a combined hydraulic winch which consists of a hoist winch, an amplitude winch and an amplitude fixed block group; wherein, the amplitude winch is arranged above the hoist winch which is arranged at the lower part of the combined hydraulic winch; the hoist winch, the amplitude winch and the amplitude fixed block group are arranged on the same frame. The invention reduces transmission space effectively and greatly lessens occupied space, which has the advantages of being small and flexible in the whole body, easy in installation, small in volume, light in weight, low in manufacturing cost and high in practical value.

Owner:INI HYDRAULIC

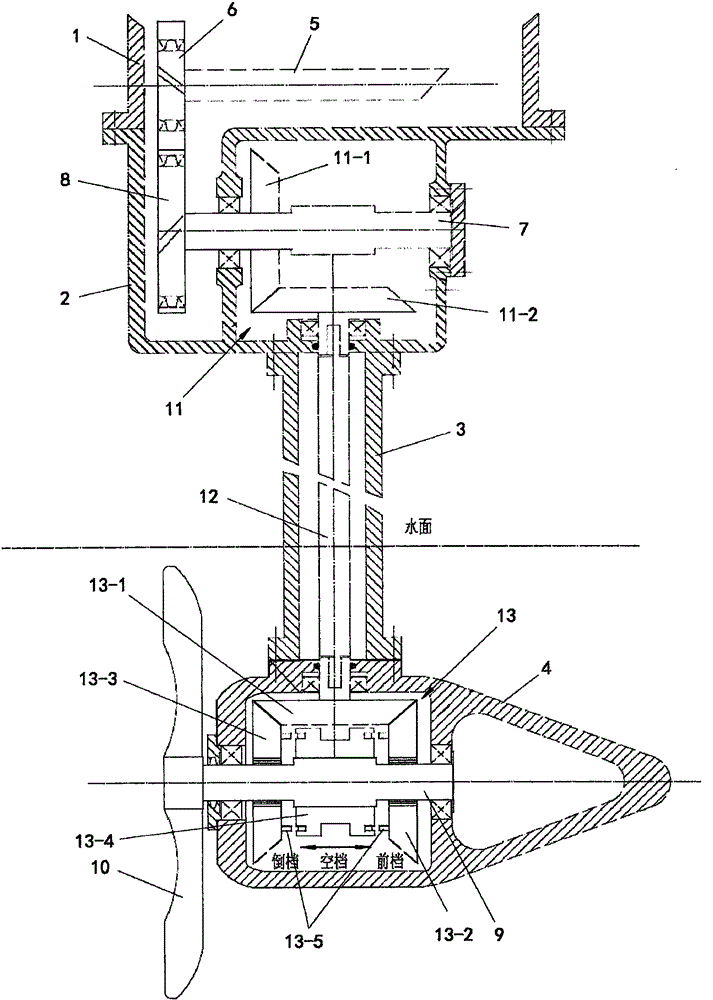

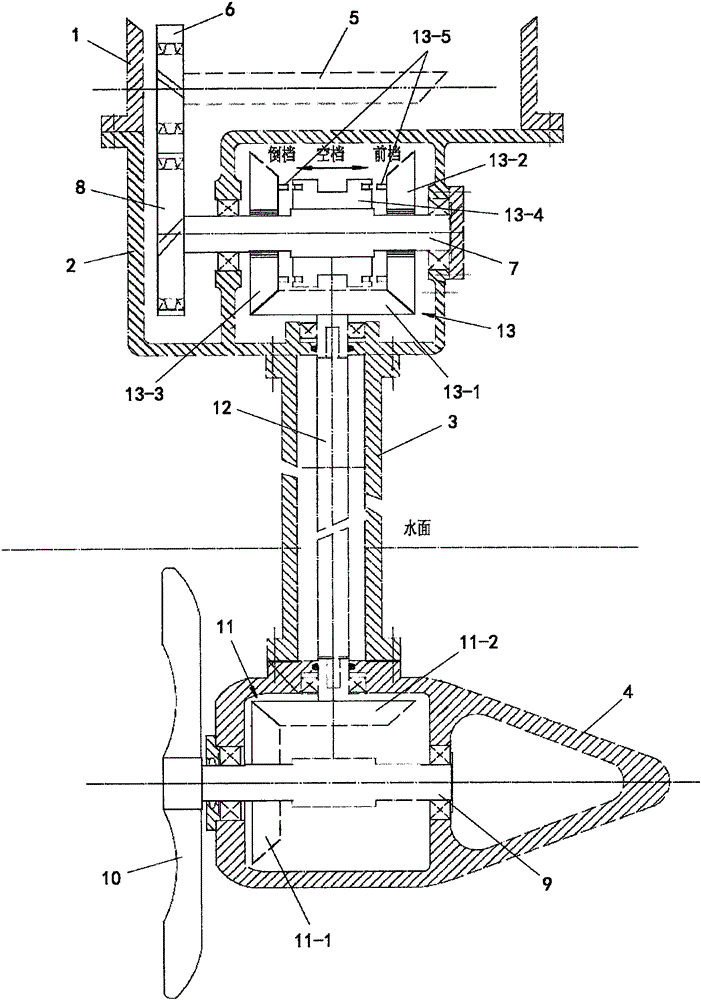

Outboard engine power transmission mechanism

InactiveCN106467162ASave transmission spaceImprove reliabilityPropulsion power plantsOutboard propulsion unitsDrive shaftPropeller

The invention discloses an outboard engine power transmission mechanism comprising a crankshaft lower case, a waterborne reduction box, an intermediate case, and an underwater reduction box; an engine crankshaft is arranged in the crankshaft lower case, and connected with a crankshaft output wheel; the waterborne reduction box is provided with a waterborne reduction box transmission shaft through a bearing, wherein the waterborne reduction box transmission shaft is connected with a waterborne reduction box power input wheel; the underwater reduction box is provided with an oar shaft through a bearing, wherein one end of the oar shaft is connected with a propeller; a transmission shift mechanism is arranged between the waterborne reduction box transmission shaft and the oar shaft, and comprises a transmission end, an intermediate transmission shaft, and a shift end; the transmission end and the shift end are respectively connected with the waterborne reduction box transmission shaft and the oar shaft, or respectively connected with the oar shaft and the waterborne reduction box transmission shaft. Compared with the prior art, the advantages are that the outboard engine power transmission mechanism reduces a transmission space, improves transmission reliability, reduces structure volume, and reduces noise and seawater corrosion influences.

Owner:ZHEJIANG PIONEER MACHINERY & ELECTRON

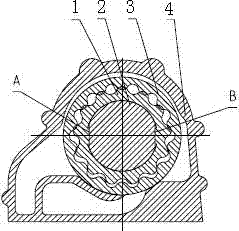

Driving device for oil pump

InactiveCN102777380AReduce manufacturing costSimplify the drivetrainRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure

The invention discloses a driving device for an oil pump. The driving device comprises an inner rotor (1), a crankshaft (2), an outer rotor (3) and an oil pump volute (4). The driving device is characterized in that the inner rotor (1) of the oil pump is arranged on the crankshaft (2) through a positioning surface A and a positioning surface B, the outer rotor (3) is sleeved on the inner rotor (1) in an embedded manner, the oil pump volute (4) is positioned on the outermost side, the positioning surface A and the positioning surface B are used for stopping relative rotation of the crankshaft (2) and the inner rotor (1), the inner rotor (1) of the oil pump can be directly driven to rotate by the crankshaft (2) so that high-pressure oil is delivered, and the maximum fit clearance between a joint surface A and a joint surface B of the crankshaft (2) and the inner rotor (1) is 0.1mm, for example, the fit clearance can range from 0.03mm to 0.1mm. By the aid of the driving device, a transmission system can be simplified, transmission space is saved, a gear and a central shaft of the oil pump are omitted, the production cost of an engine is saved, and the driving device is simple to mount and high in working efficiency.

Owner:NO 70 INST OF CHINA NORTH IND GRP

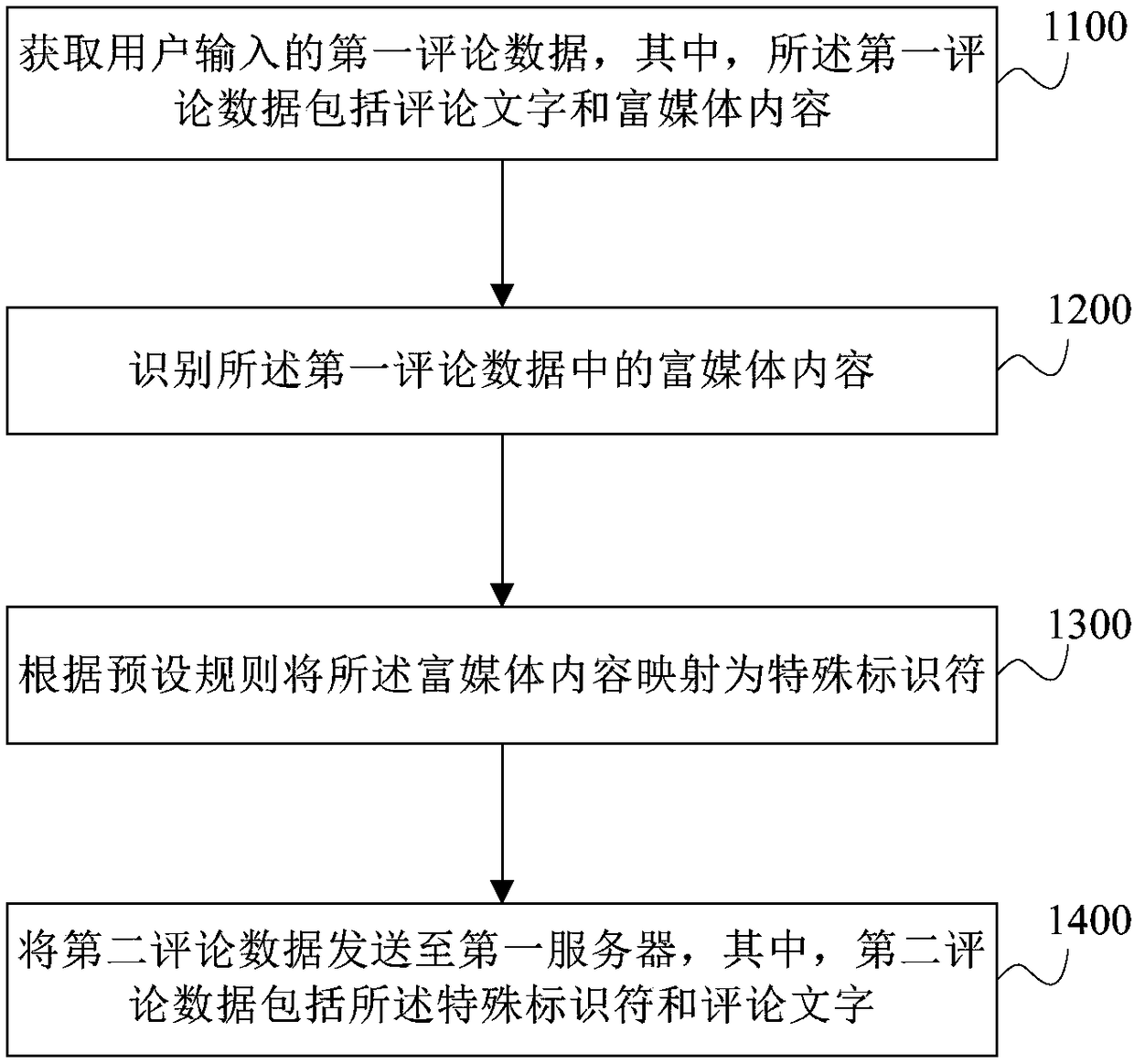

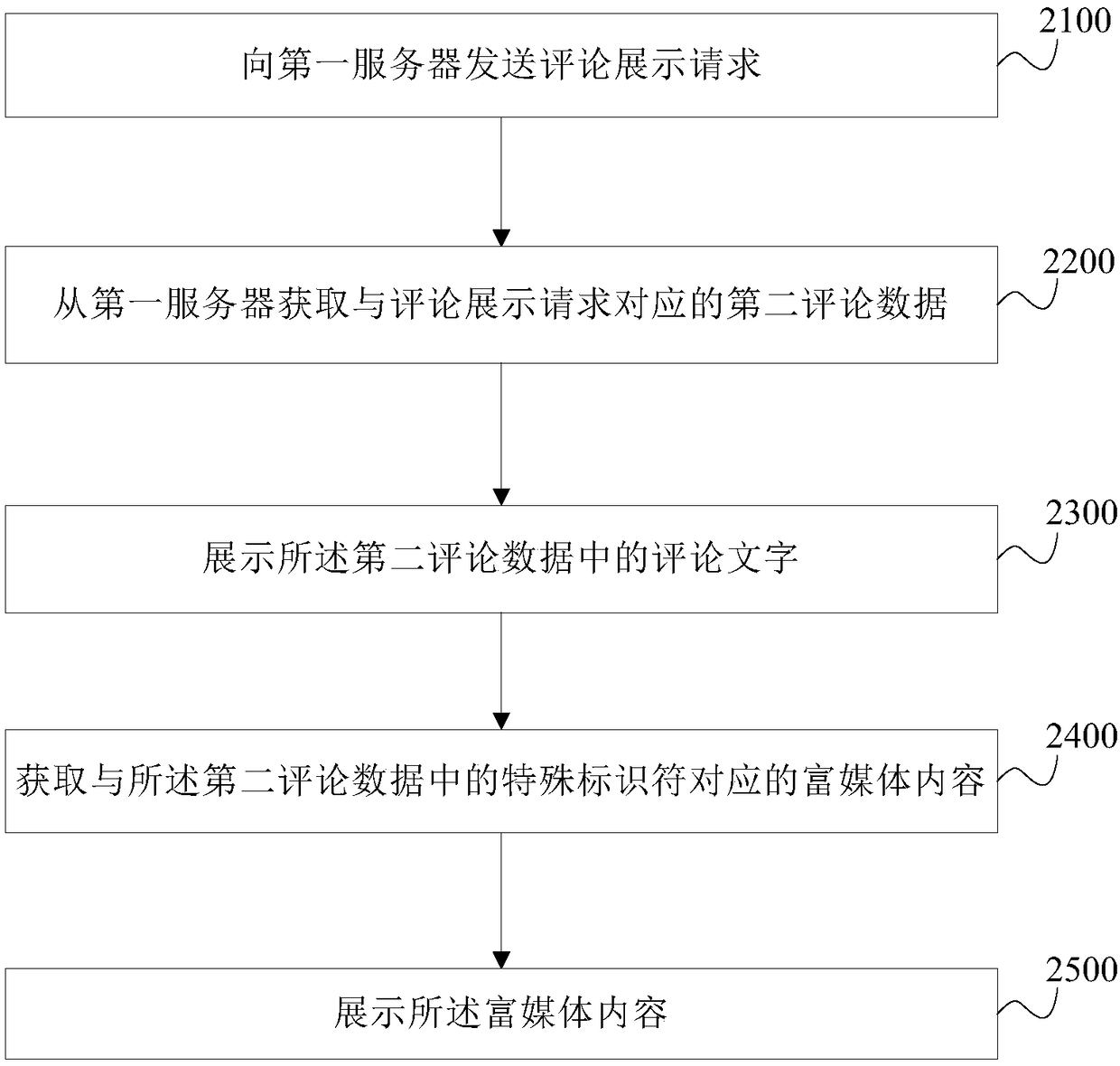

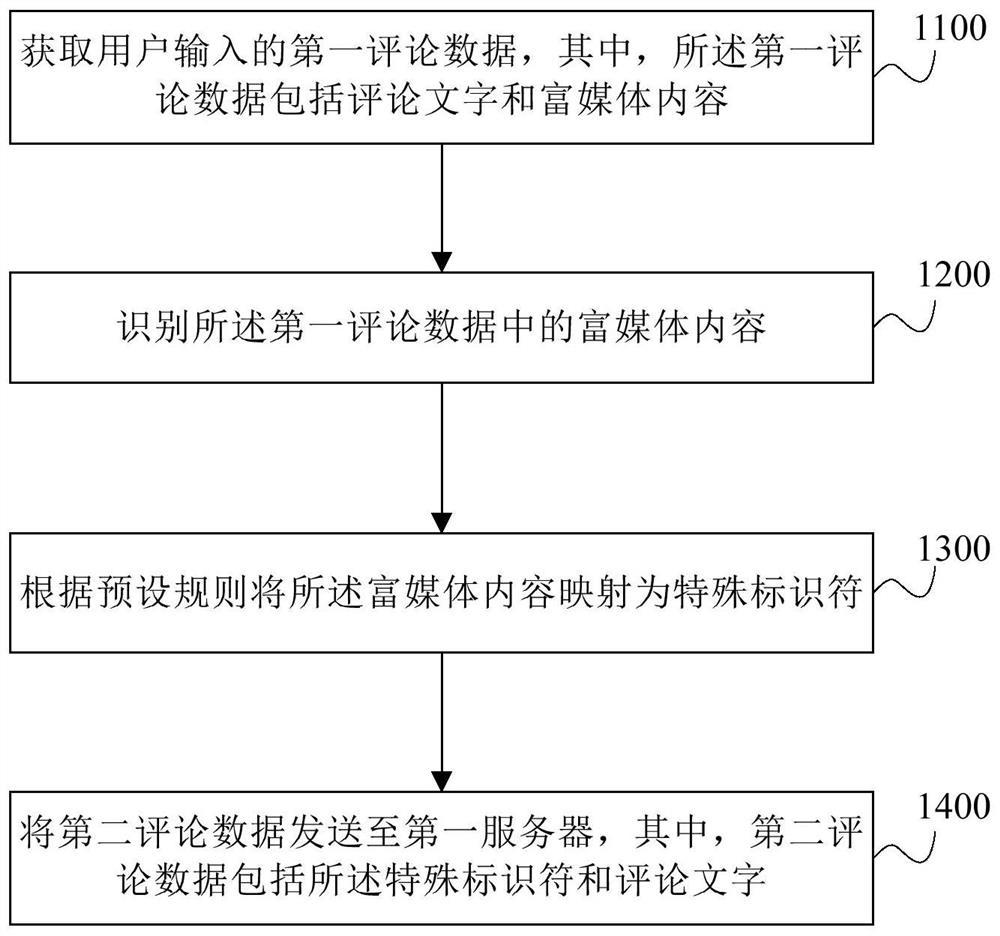

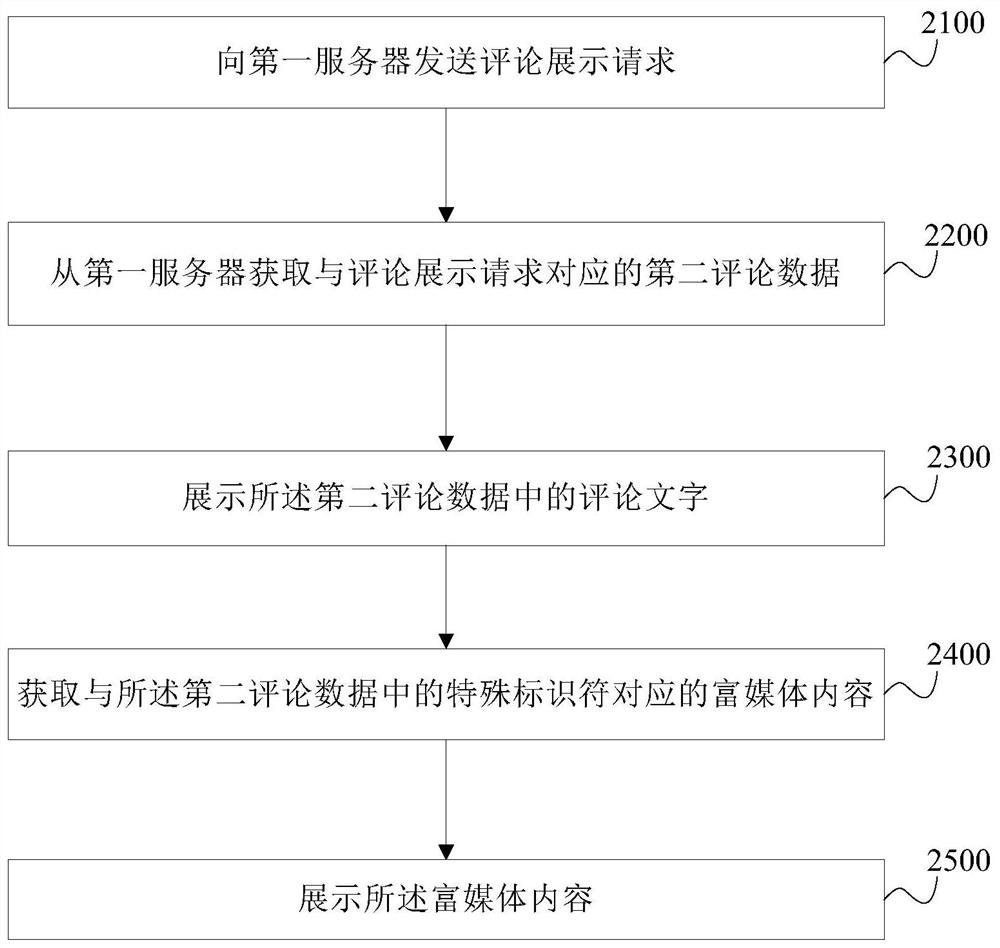

Comment interaction method and equipment, client device and electronic equipment

ActiveCN108449255ASave transmission spaceIncrease transfer rateData switching networksUser inputData transmission

The invention discloses a comment interaction method, comment interaction equipment, a client device and electronic equipment. The comment interaction method comprises the steps of acquiring first comment data input by a user, wherein the first comment data comprises a comment text and rich media content; recognizing the rich media content in the first comment data; mapping the rich media contentinto a special identifier according to a preset rule; and sending second comment data to a first server, wherein the second comment data comprises the special identifier and the comment text. According to the method, equipment and device provided by the invention, the data transmission space can be saved, and the data transmission speed can be enhanced.

Owner:ALIBABA (CHINA) CO LTD

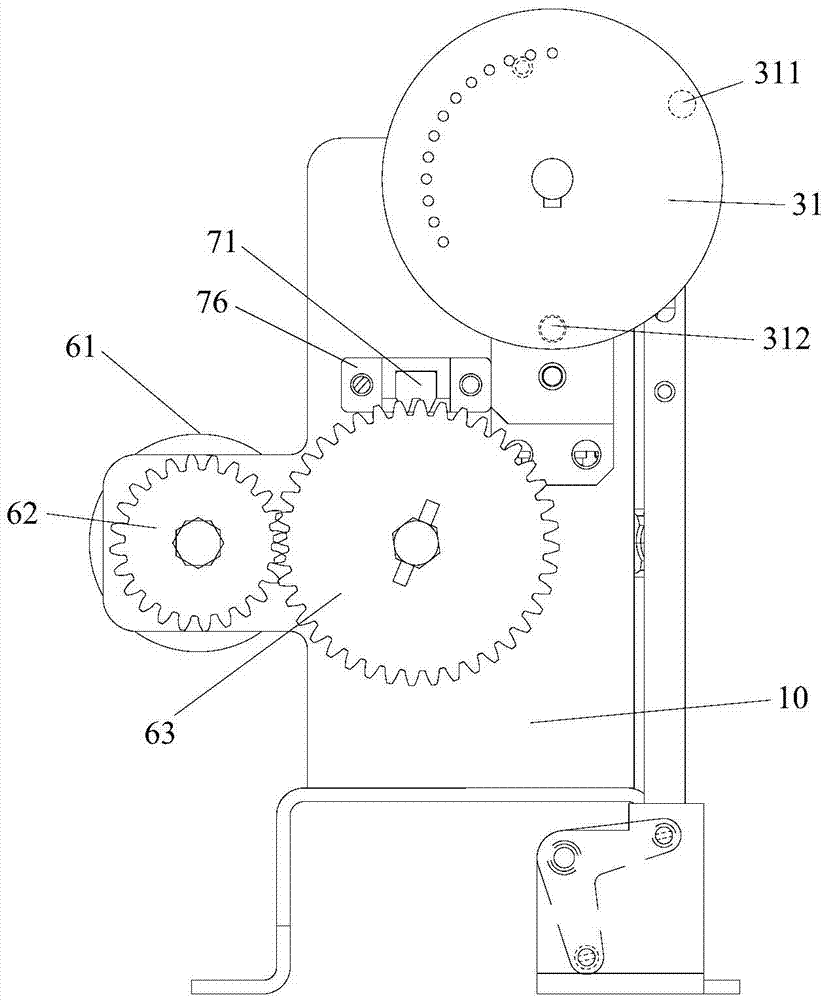

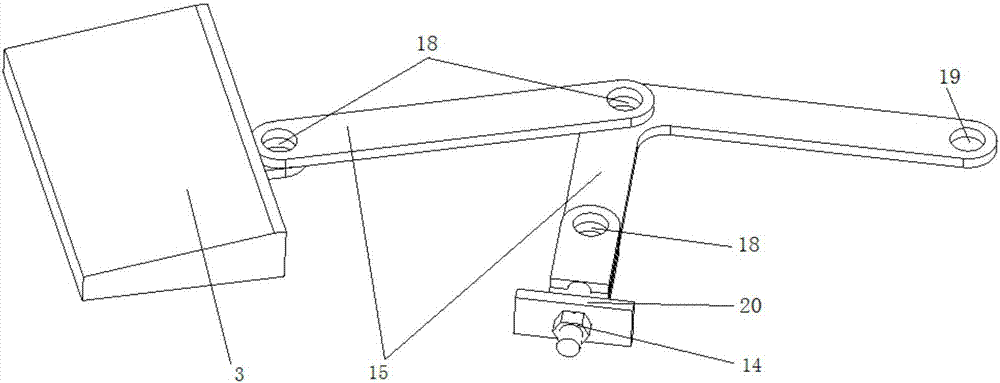

Operation device of isolation switch

ActiveCN105448552ASimple structureSave transmission spaceContact driving mechanismsContact operating partsEngineeringElectrical and Electronics engineering

Owner:北京朝阳杰优能新能源有限公司

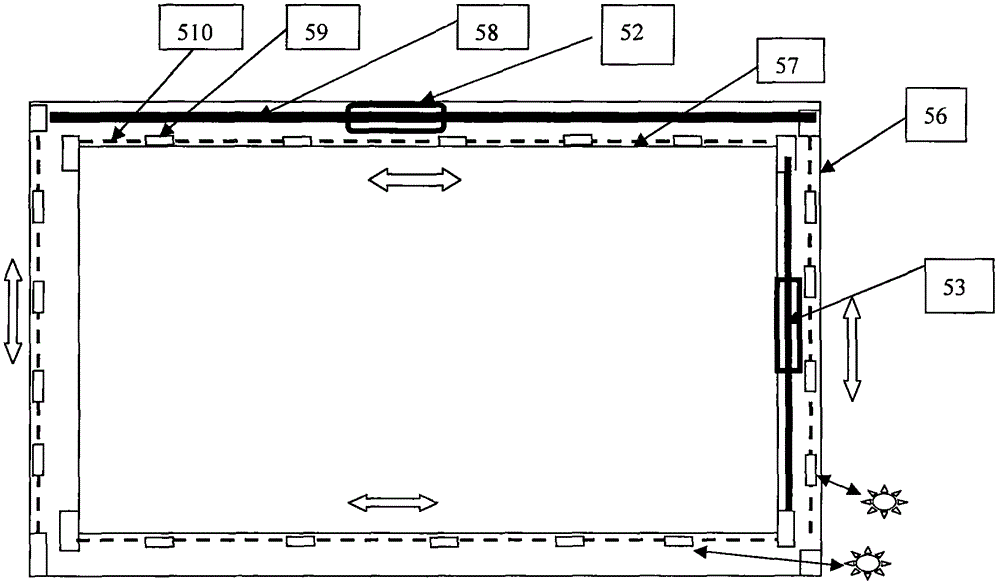

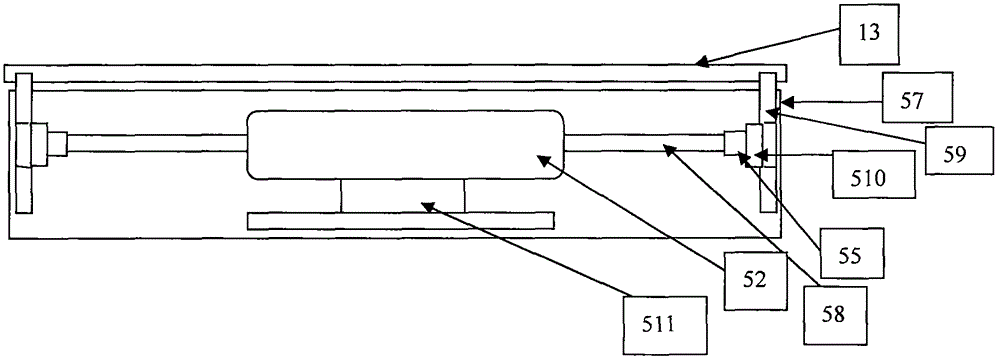

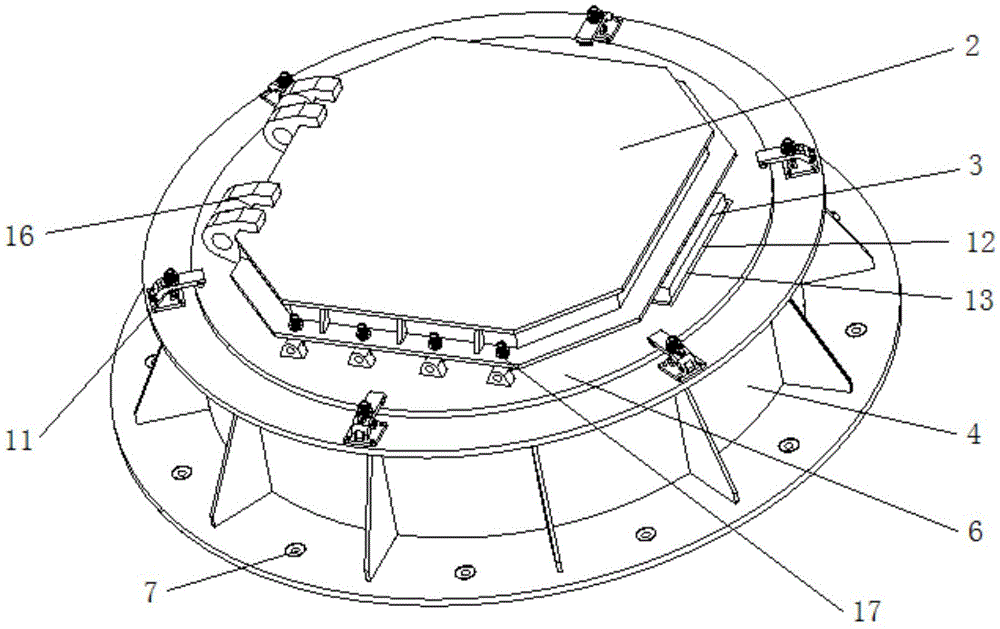

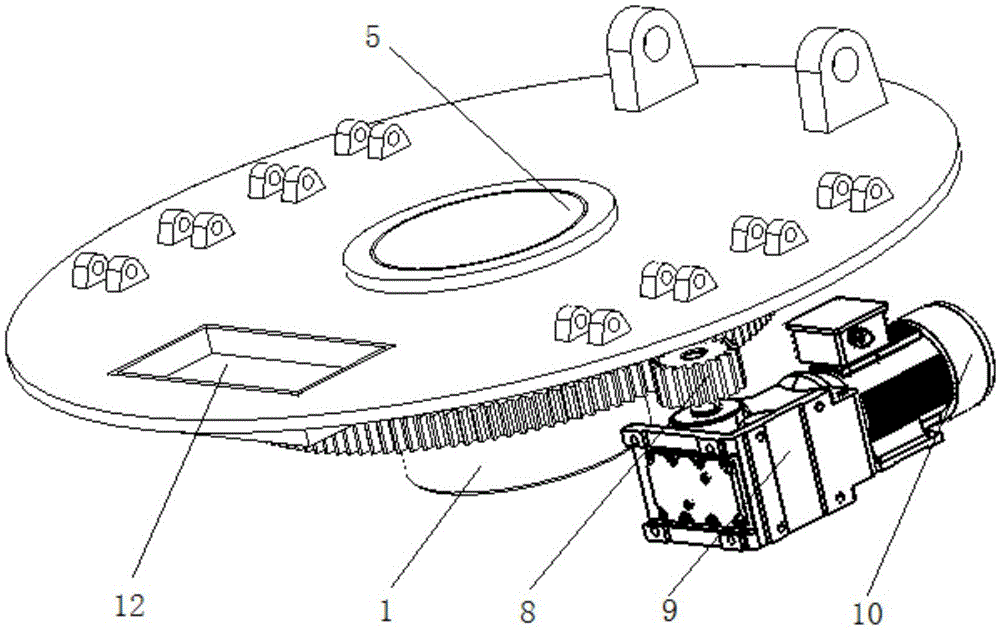

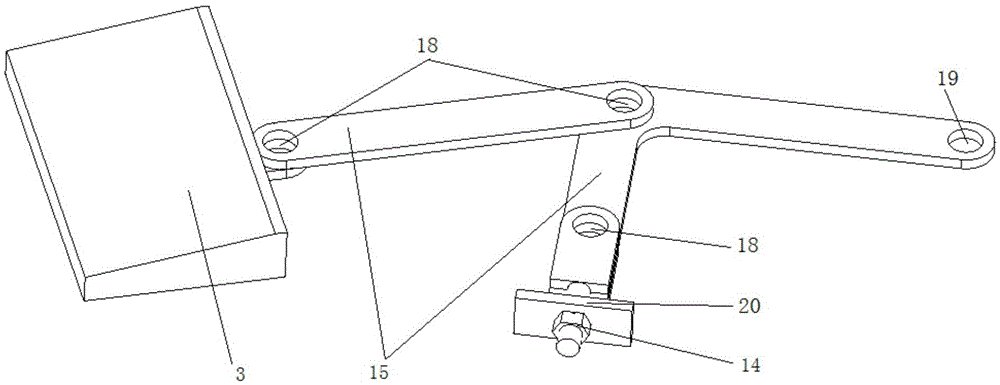

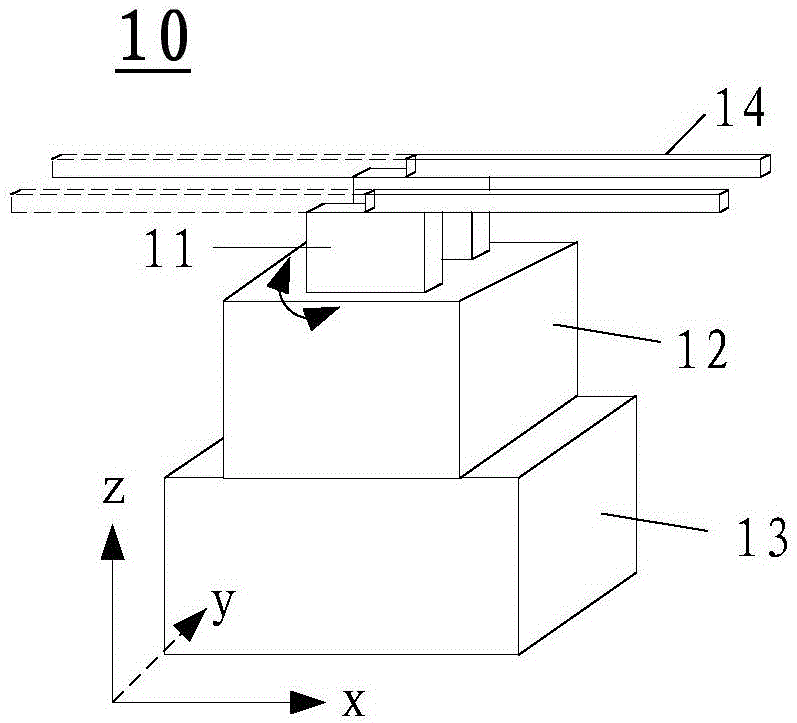

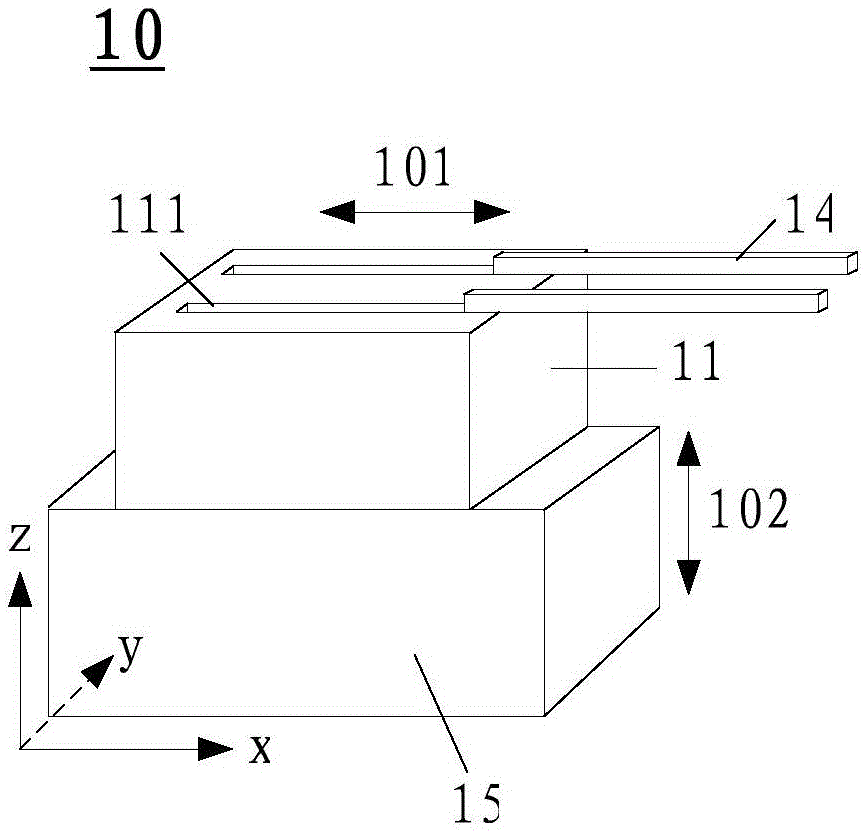

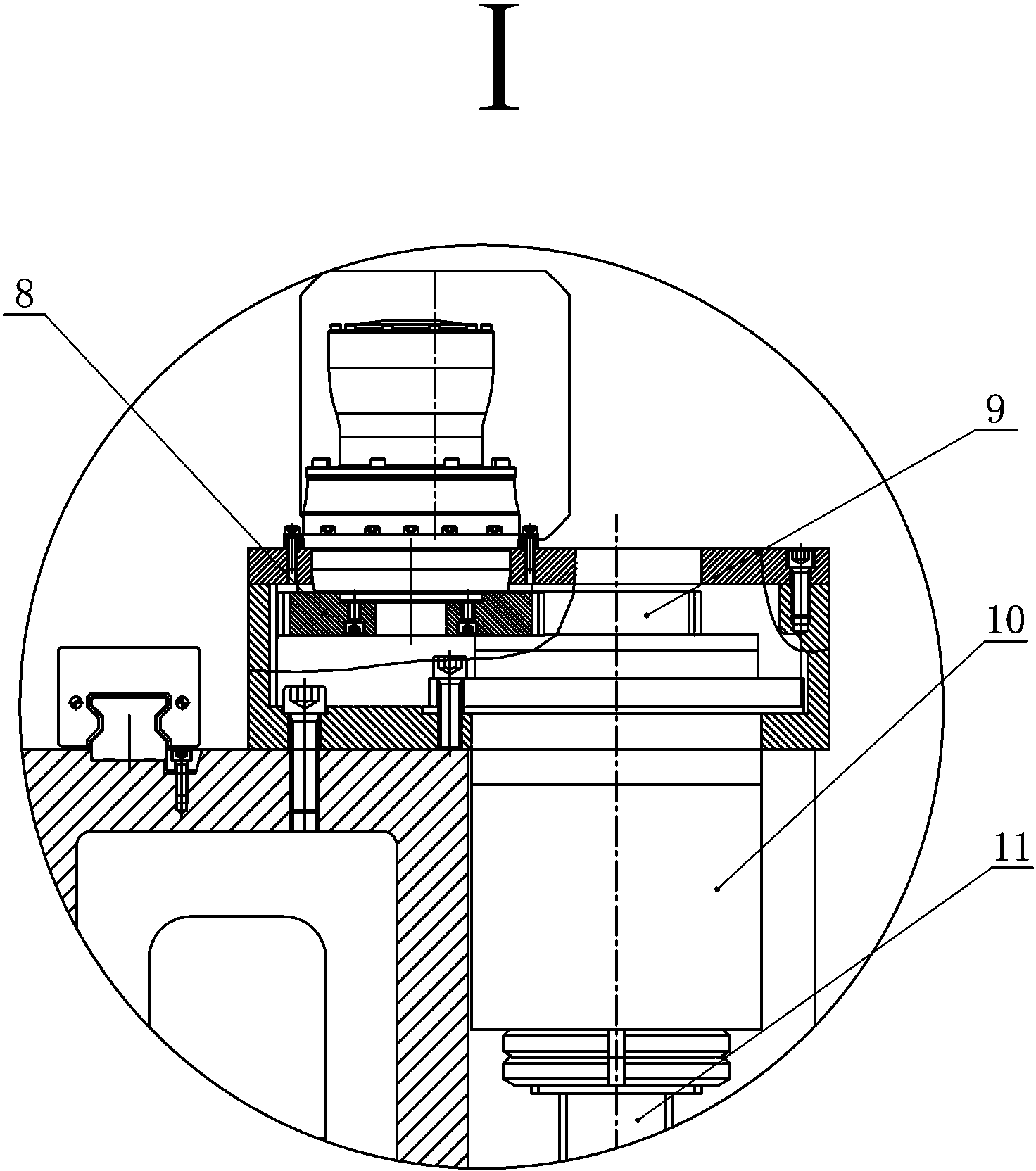

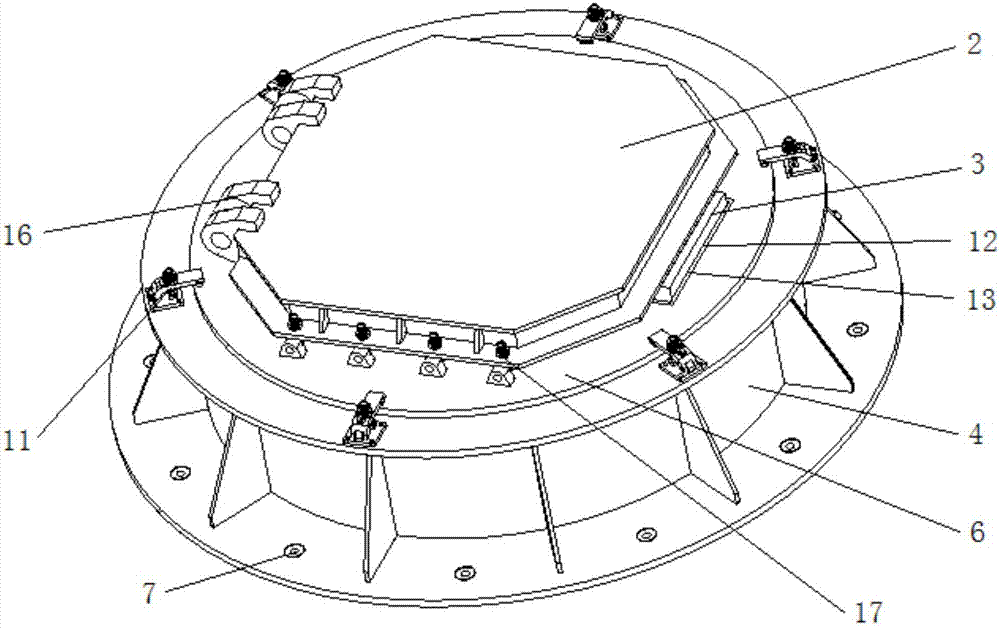

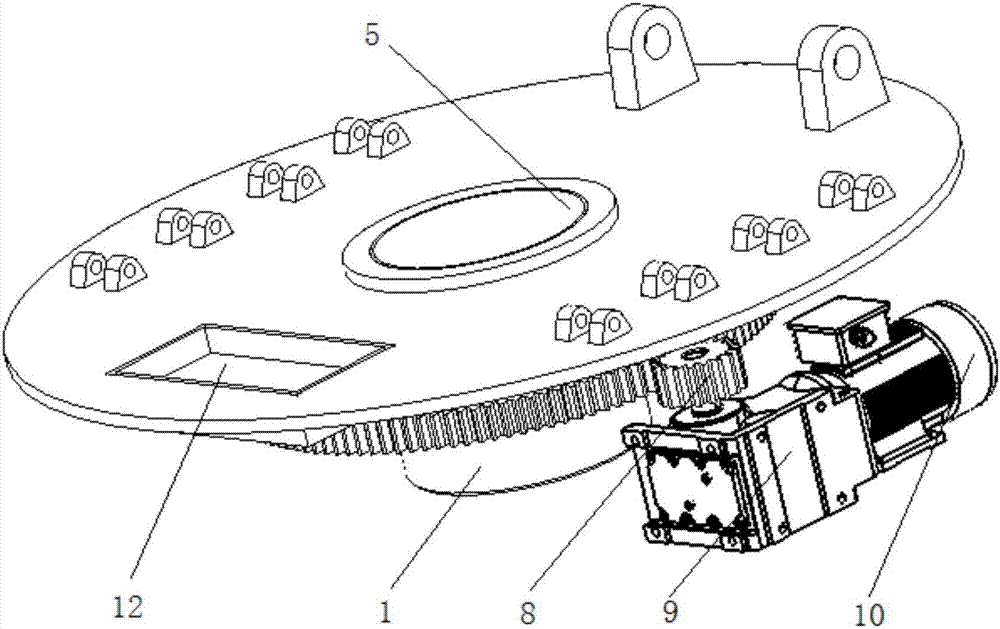

Test work platform with both revolving and angle adjusting functions

The invention discloses a test work platform with both revolving and angle adjusting functions. The test work platform comprises a motor, a work platform body, a revolving platform and a base, wherein the work platform body is connected with the revolving platform and used for holding an object to be tested; the revolving platform is located above the base; a hole is formed in the upper surface of the base; a main gear shaft is connected with the revolving platform through the hole, further connected with a motor and used for driving the revolving platform to revolve under the driving of the motor; an inclined wedge is arranged between the work platform body and the revolving platform and used for moving along the surface of the revolving platform, so that the work platform body is inclined, and the inclination angle of the work platform body is adjusted. The test work platform has the revolving and angle adjusting functions. The object to be tested does not need to be transferred back and forth among work platforms with different functions for tests with various parameters and does not need to be positioned, leveled, fixed or the like again. Especially for a large product or workpiece, the waste of manpower, material resources and time is avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

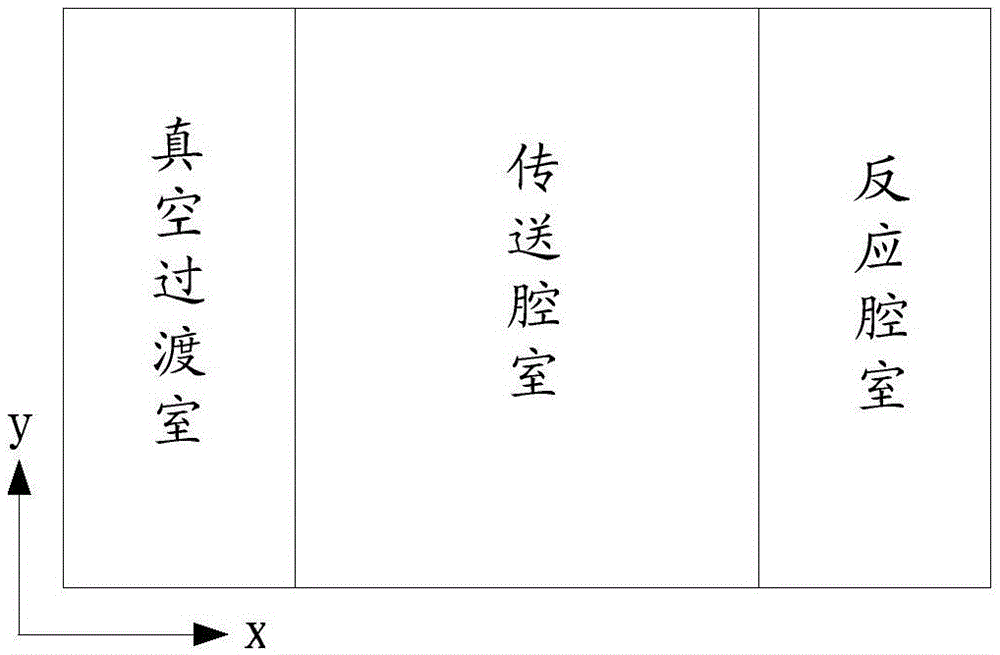

Mechanical arm

ActiveCN105151776AReduced risk of breakageIncrease the marriage rateSemiconductor/solid-state device manufacturingCharge manipulationEngineeringManipulator

The invention provides a mechanical arm, and relates to the field of automation. The mechanical arm solves the problems that when a conventional mechanical arm takes and places boards, the conventional mechanical arm needs to rotate, so that the occupied space is large, and the rate of qualified products is reduced. The mechanical arm is mounted between a first chamber and a second chamber of vacuum reaction equipment, and used for moving the boards in the first chamber to the second chamber. The mechanical arm comprises a first supporting structure, arms and a vertically-moving mechanism, wherein railways in the first direction of a horizontal plane are formed in the first supporting structure; the first chamber and the second chamber are respectively positioned at two opposite ends of the railways; the arms are mounted on the first mounting structure and used for bearing the boards; the arms can move along the railways; the first supporting structure and the arms are mounted on the vertically-moving mechanism, and the first supporting structure and the arms can be driven by the vertically-moving mechanism to move in the vertical direction.

Owner:BOE TECH GRP CO LTD +1

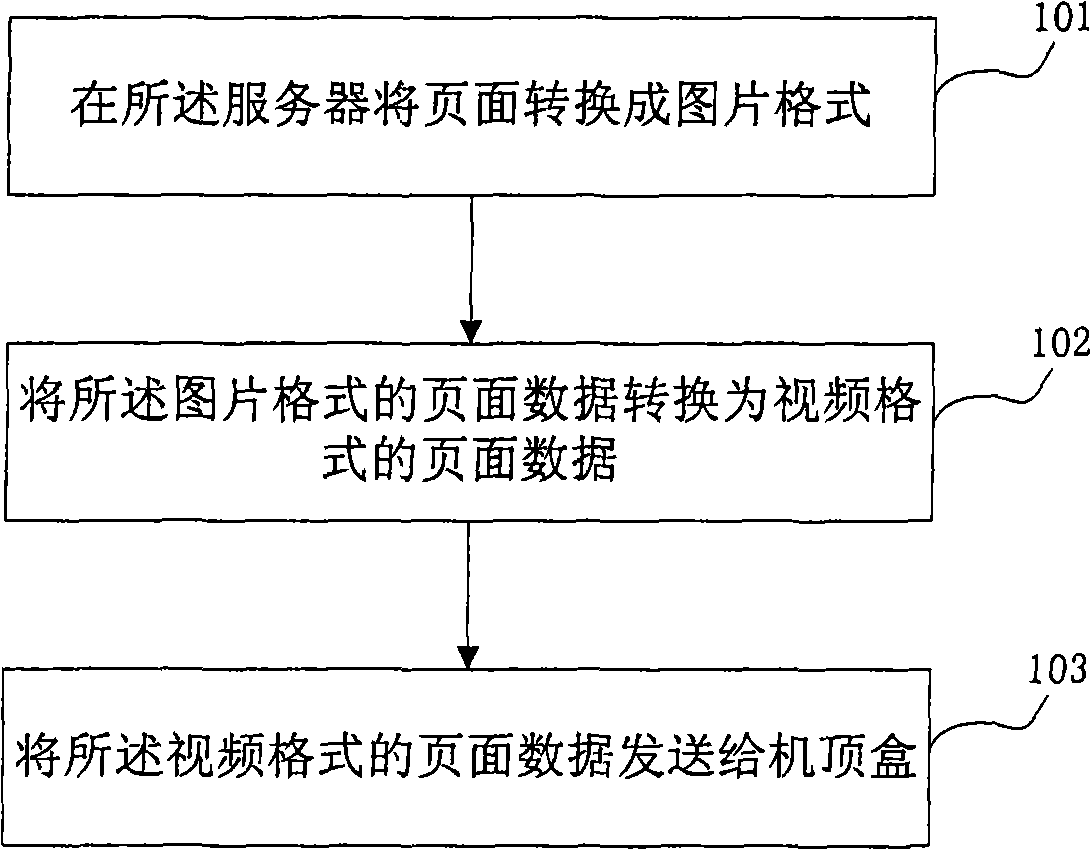

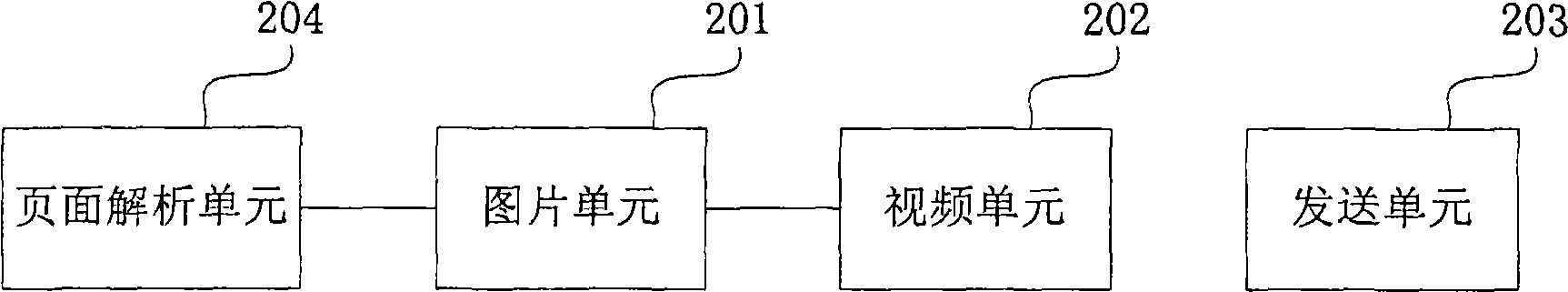

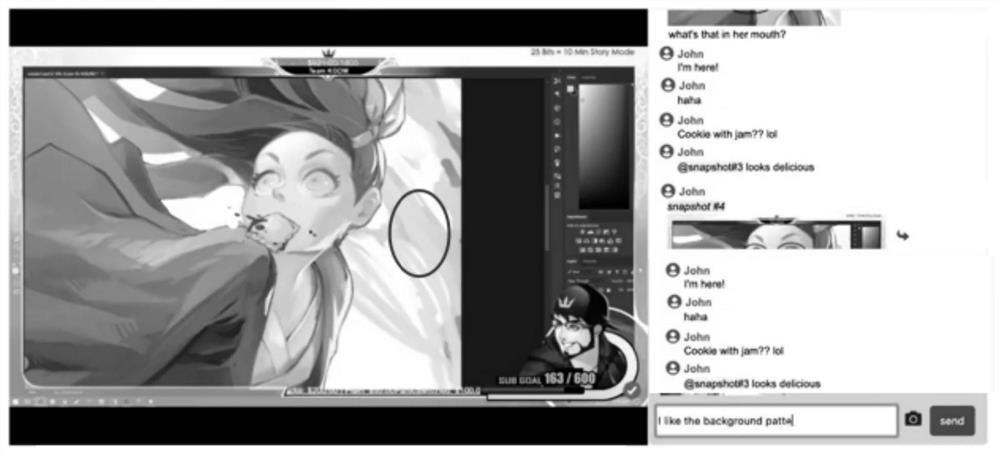

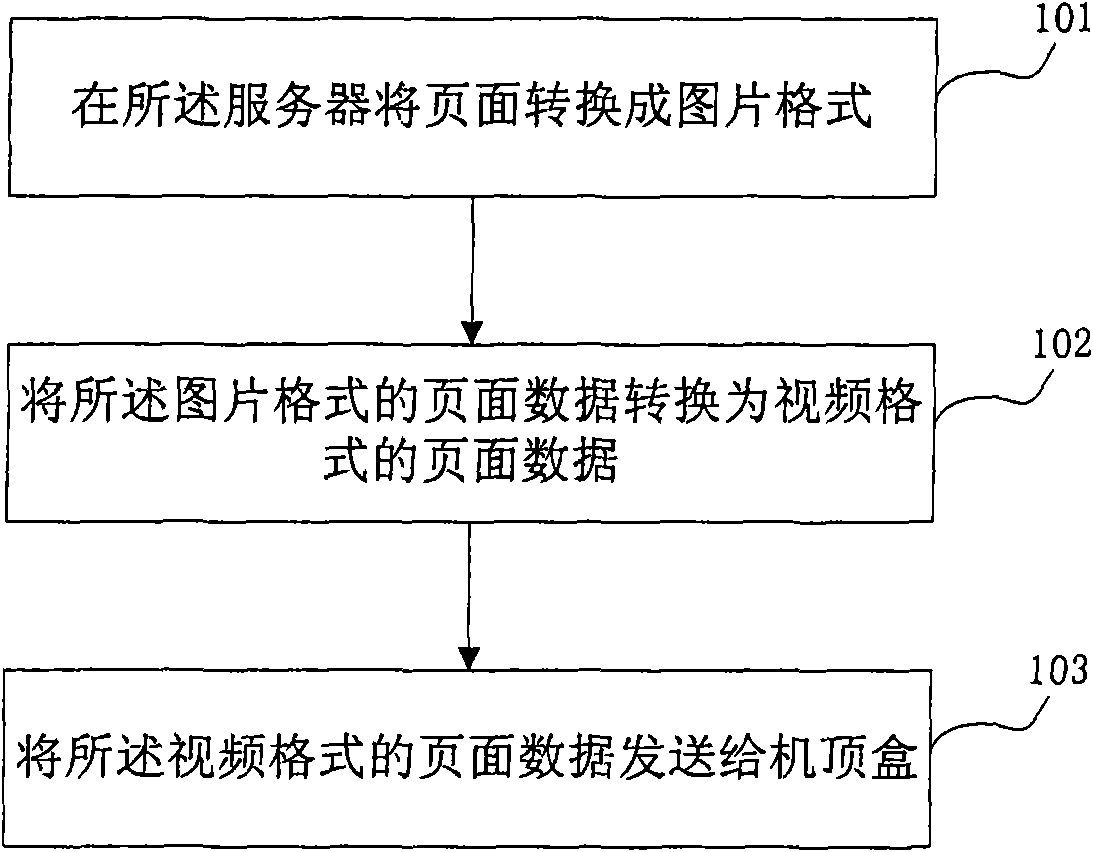

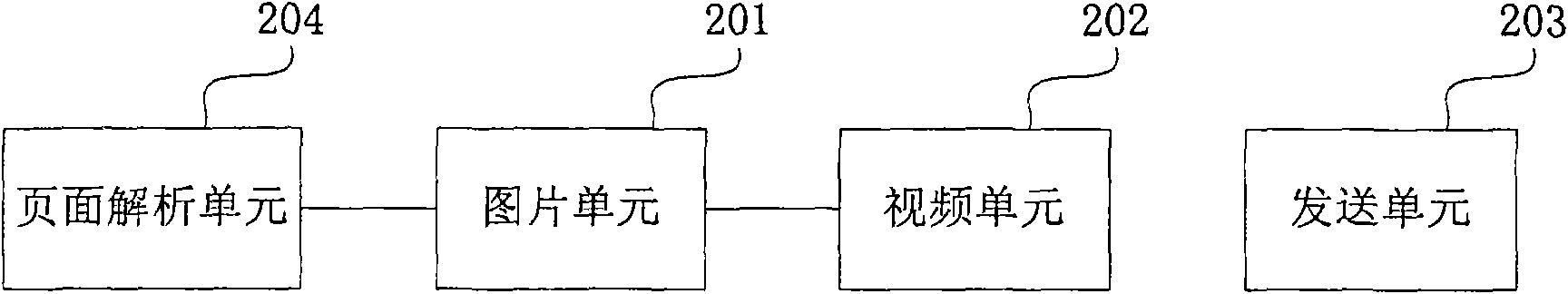

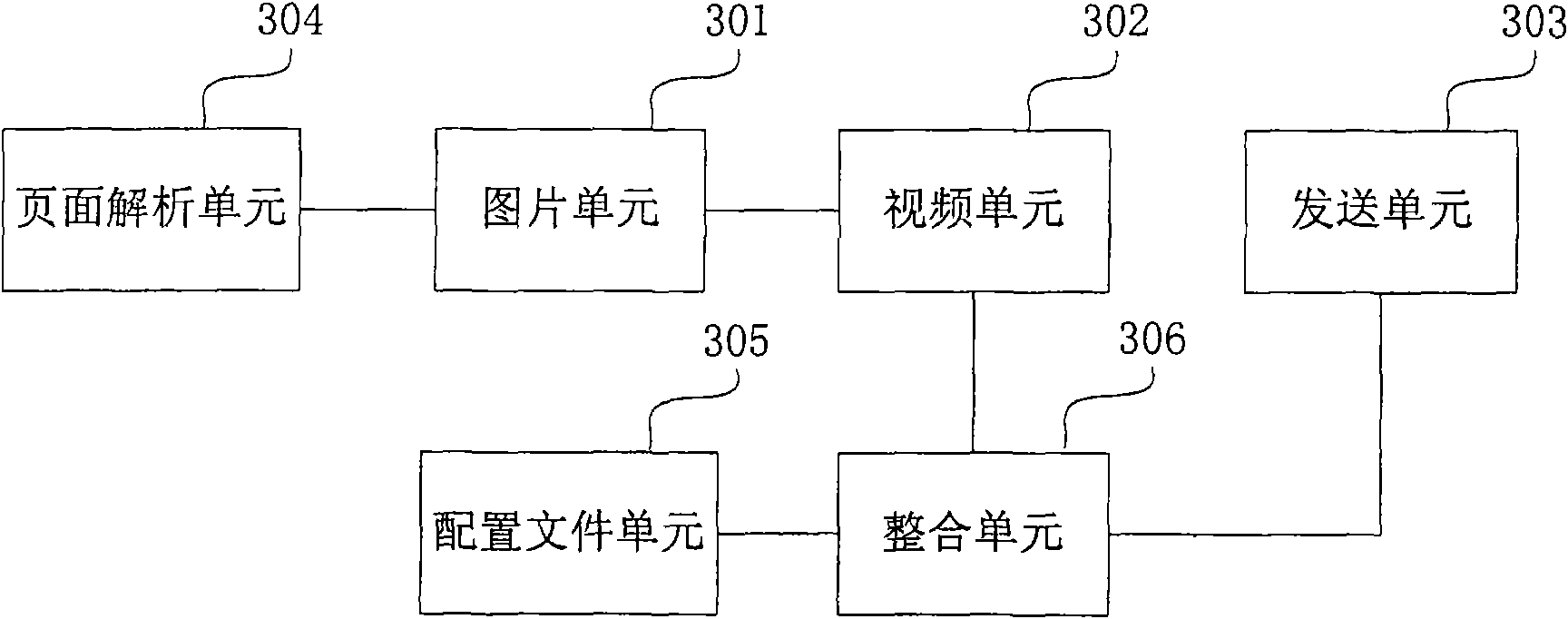

Method for browsing pages in digital television and system thereof

ActiveCN101534419ANot easy to make mistakesBit downTelevision system detailsColor television detailsWeb pageDigital television

The invention relates to the field of digital television, aiming to solve the problems in the prior art that a set-top box is slow in analyzing web pages and mistakes are prone to take place and providing a method for browsing pages in digital television and a system thereof. In the method, a server converts the web pages into picture format, converts web page data in picture format into web page data in video format and sends the web page data in video format to the set-top box. The method and the system of the invention have the advantage of improving speed of the set-top box in browsing web pages.

Owner:北京兴国融合通讯科技有限公司

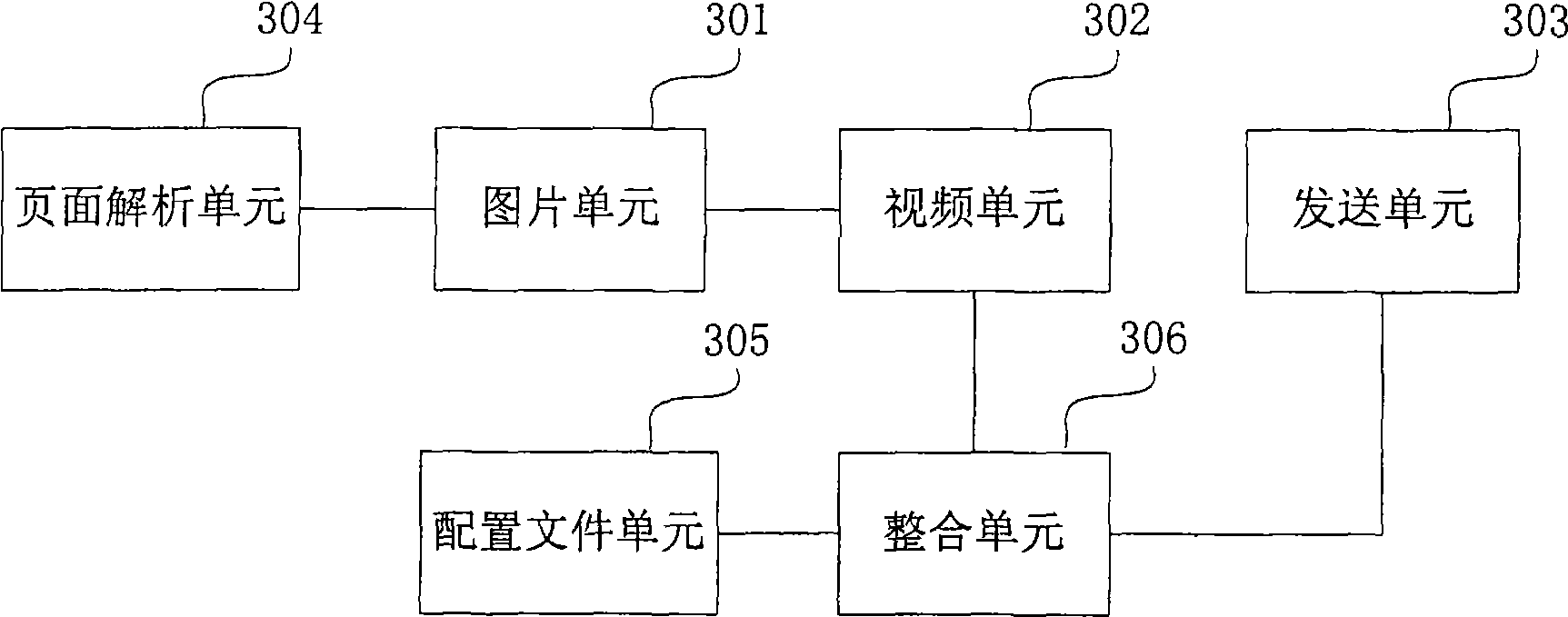

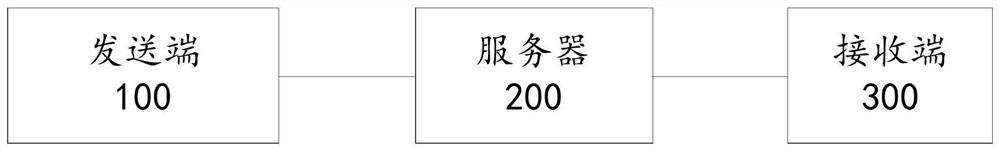

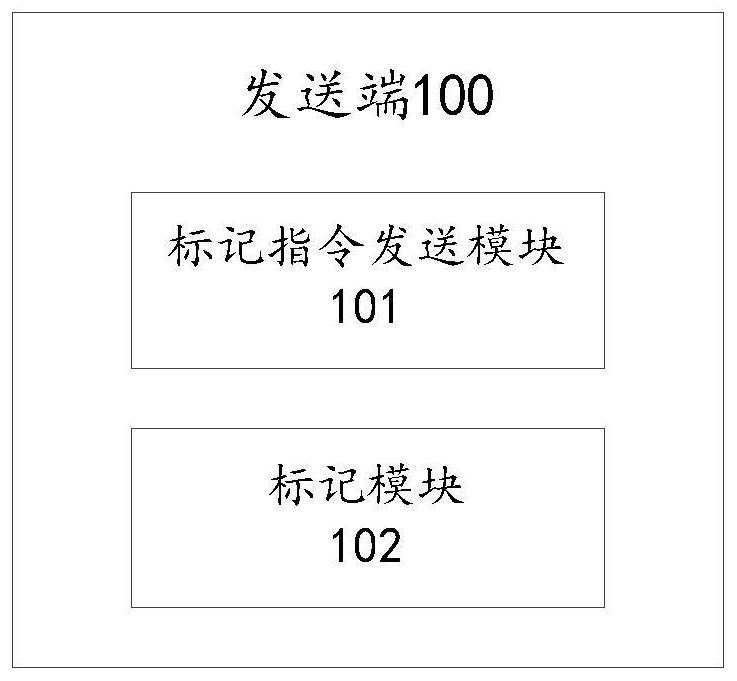

Video interaction system and method and receiving end

ActiveCN112601129ASave transmission spaceImprove the efficiency of viewing tag informationSelective content distributionInteraction systemsVideo processing

The embodiment of the invention relates to the technical field of video processing, in particular to a video interaction system and method and a receiving end, timestamp information and marking information of a to-be-marked video frame are recorded, the marking information and the timestamp information are associated to generate a marking file, and the marking file and a video are associated during playing, and when the video is played, the mark information at different timestamps can be presented, the efficiency of checking the mark information by a user is greatly improved, and meanwhile, asthe receiving end and the sending end only need to transmit the mark file and do not need to carry specific video content, the transmission space of the file is greatly reduced, and the transmissionefficiency is improved.

Owner:深圳市房多多网络科技有限公司

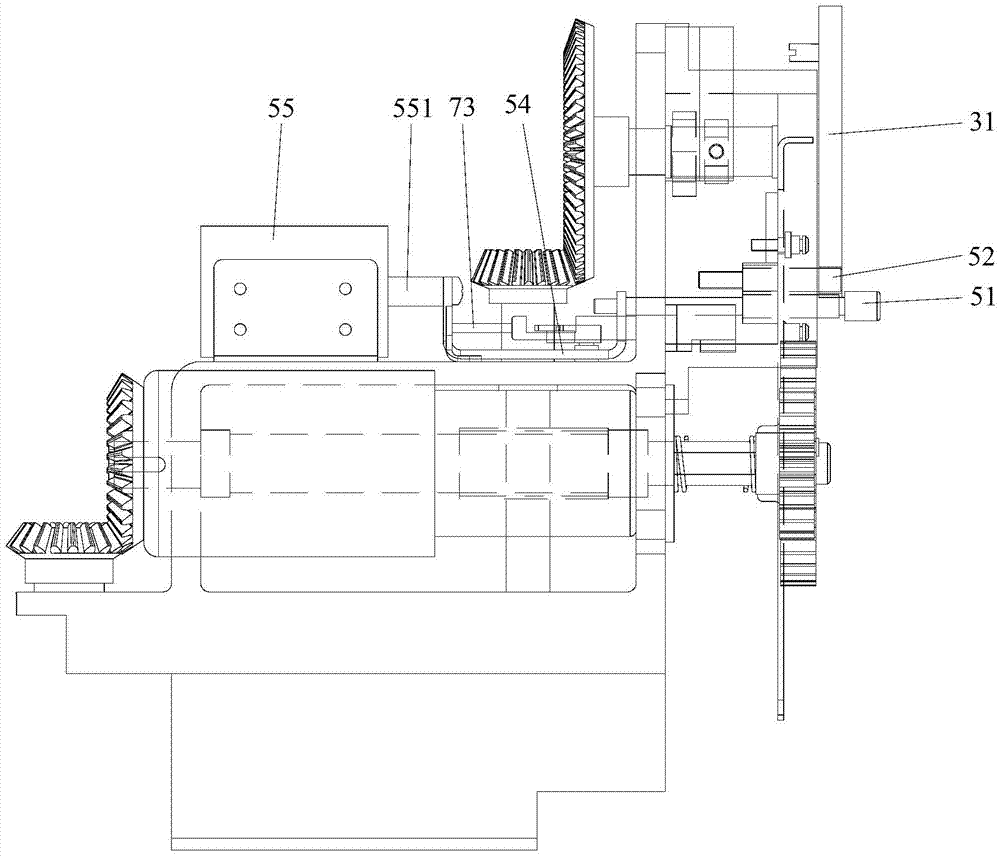

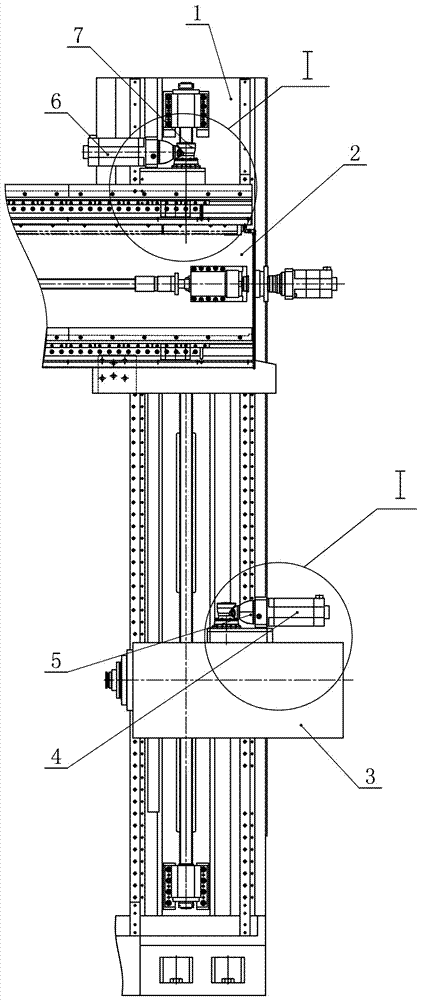

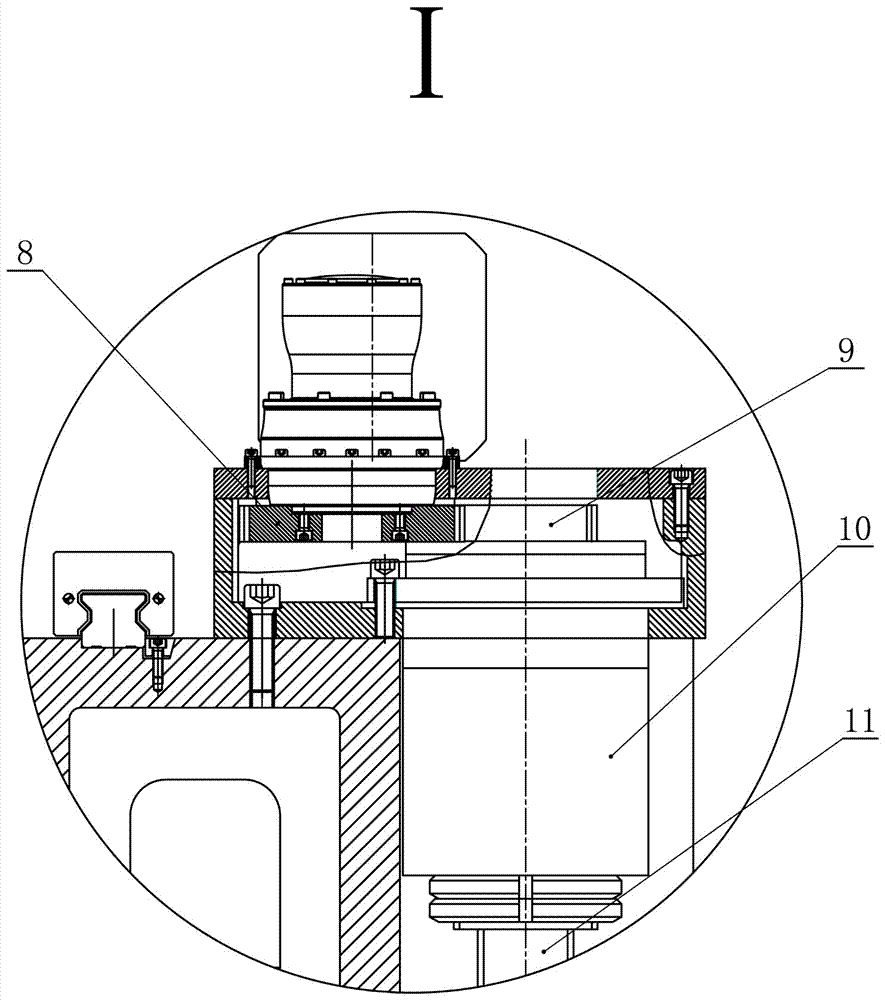

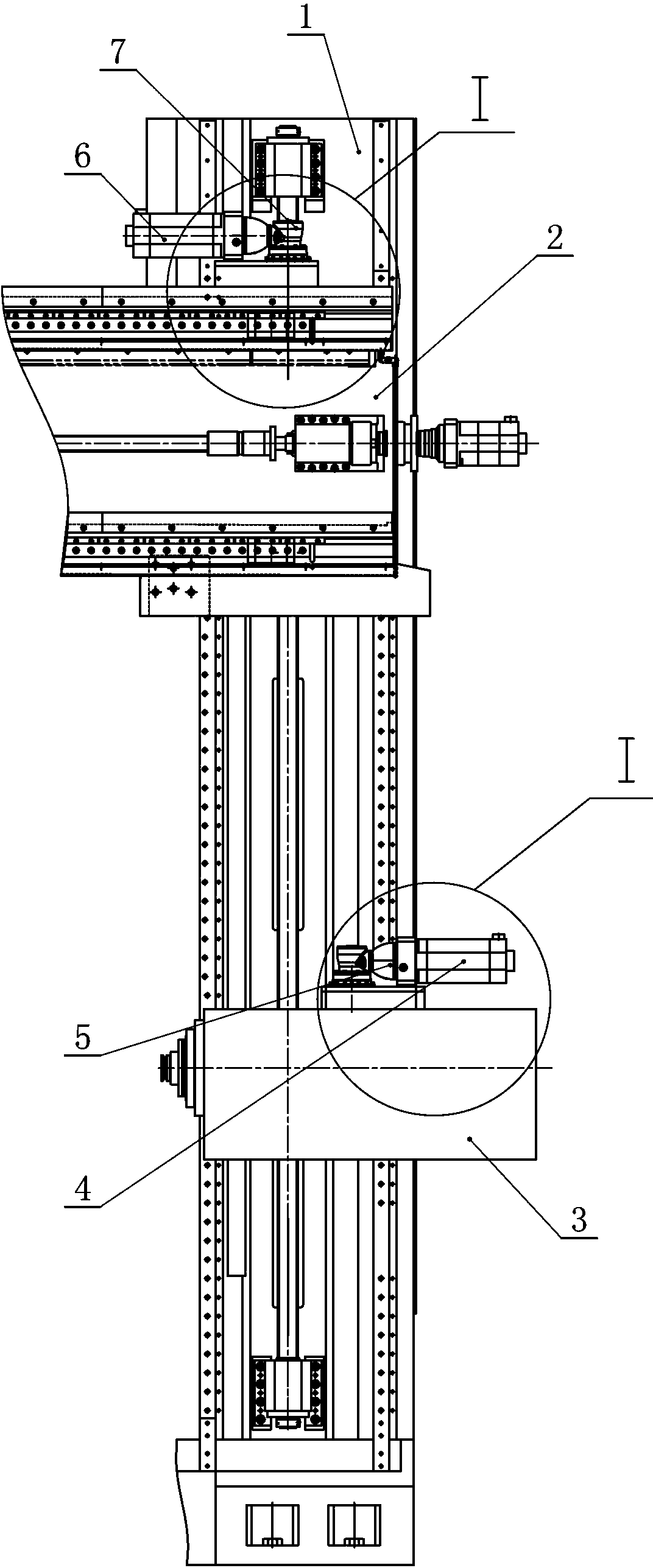

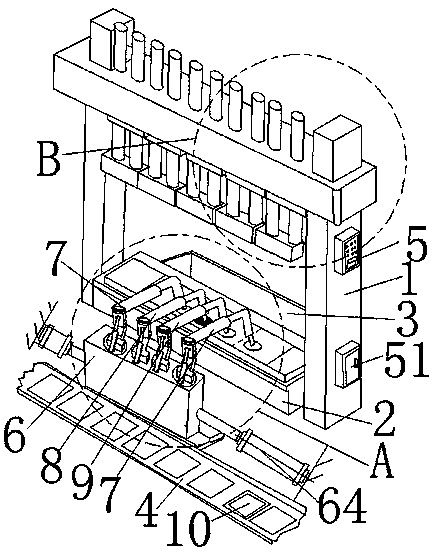

The beam and the double-sided horizontal boring and milling head lift share the guide rail and ball screw structure

ActiveCN104029071BPrevent jumpingAvoid noiseFeeding apparatusLarge fixed membersCommon railBall screw

A guide rail and ball screw structure for lifting of both cross beam and horizontal boring and milling heads at two sides comprises a vertical pillar, wherein the left side and the right side of the front surface of the vertical pillar are fixedly connected with linear rails respectively, the front surface of each linear rail sliding block is fixedly connected with the cross beam, the vertical pillar is fixedly connected with a ball screw, the upper portion and the lower portion of the ball screw are connected with a first nut and a second nut respectively in a threaded mode, the front surface of the first nut is fixedly connected with the cross beam, the first nut is connected with a driven gear in a sleeved mode, the driven gear is meshed with a driving gear, the driving gear is fixedly connected with a first planetary gear reducer, the first planetary gear reducer is connected with a first servo motor, the front surface of the second nut is fixedly connected with a lateral horizontal boring head, the inner layer of the second nut is connected with another driven gear in a sleeved mode, the driven gear is meshed with another driving gear, the driving gear is fixedly connected with a second planetary gear reducer, and the second planetary gear reducer is fixedly connected with a second servo motor.

Owner:SHANDONG WEIDA HEAVY INDS

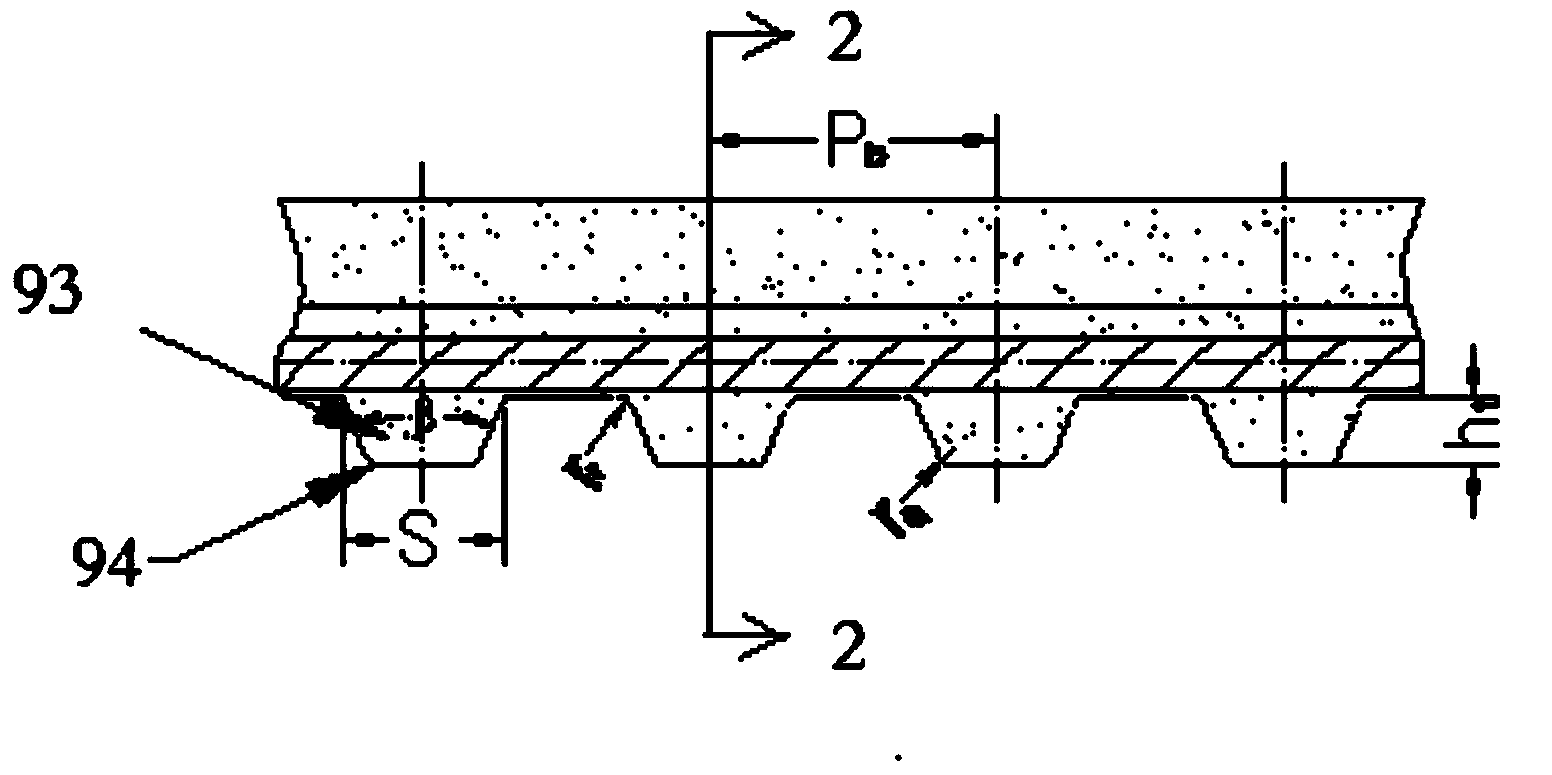

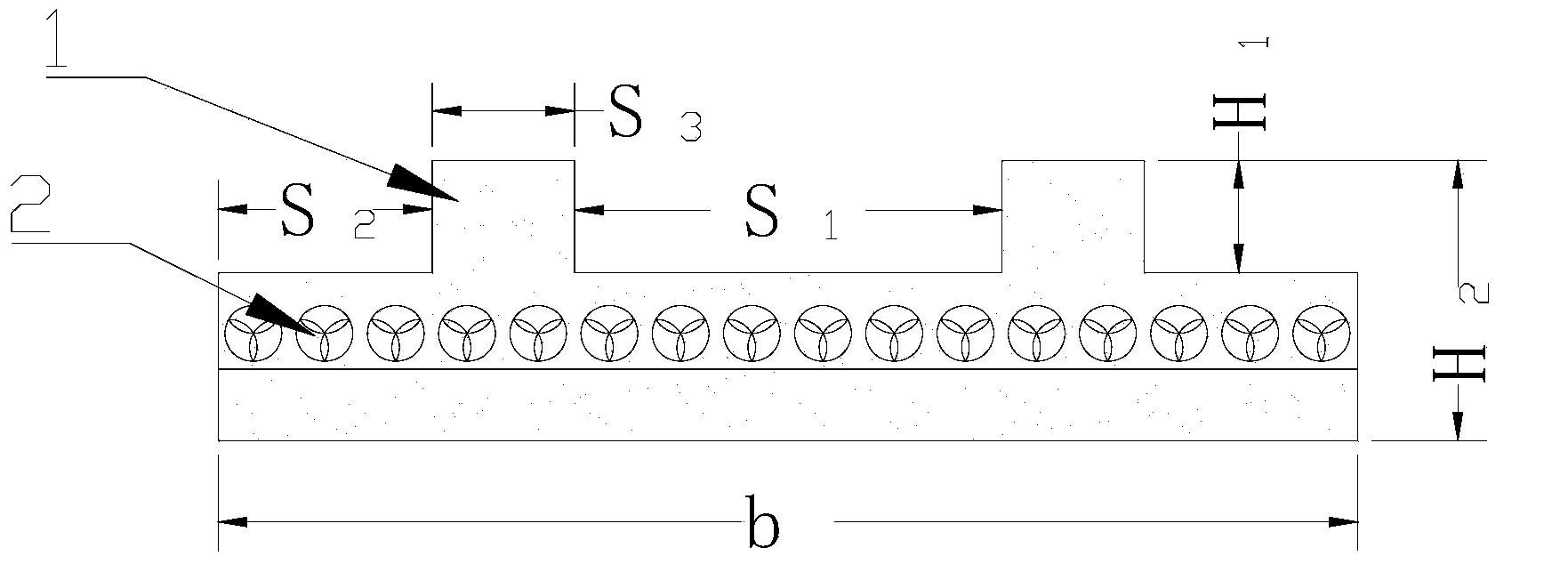

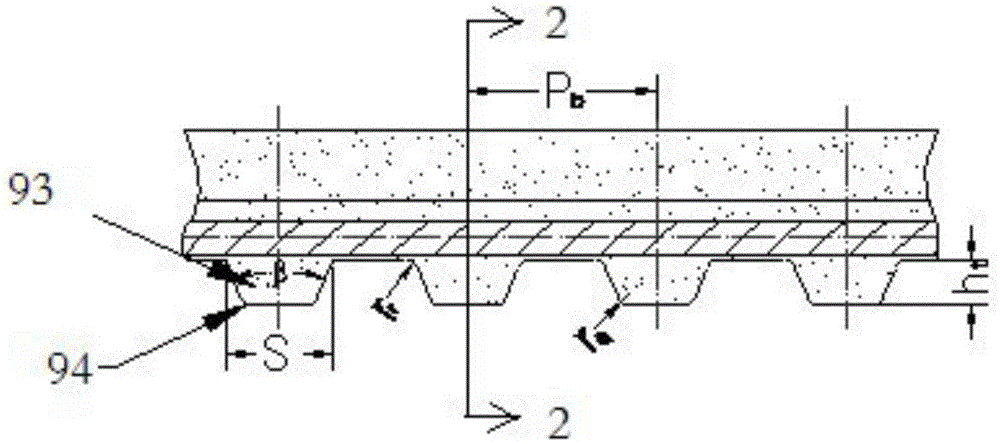

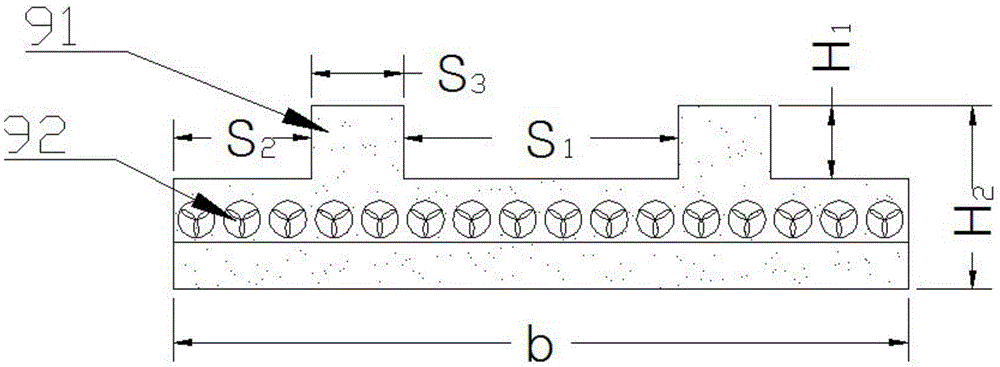

U-type transmission belt and preparation method thereof

Disclosed are a U-type transmission belt and a preparation method thereof. The U-type transmission belt sequentially comprises an outer U-type groove chloroprene rubber layer, a glass fiber layer, a toothed chloroprene rubber layer and an elastic nylon fabric layer. The grooves formed at back of the chloroprene rubber belt are U-type grooves.

Owner:NINGBO GUL TZ RUBBER BELT

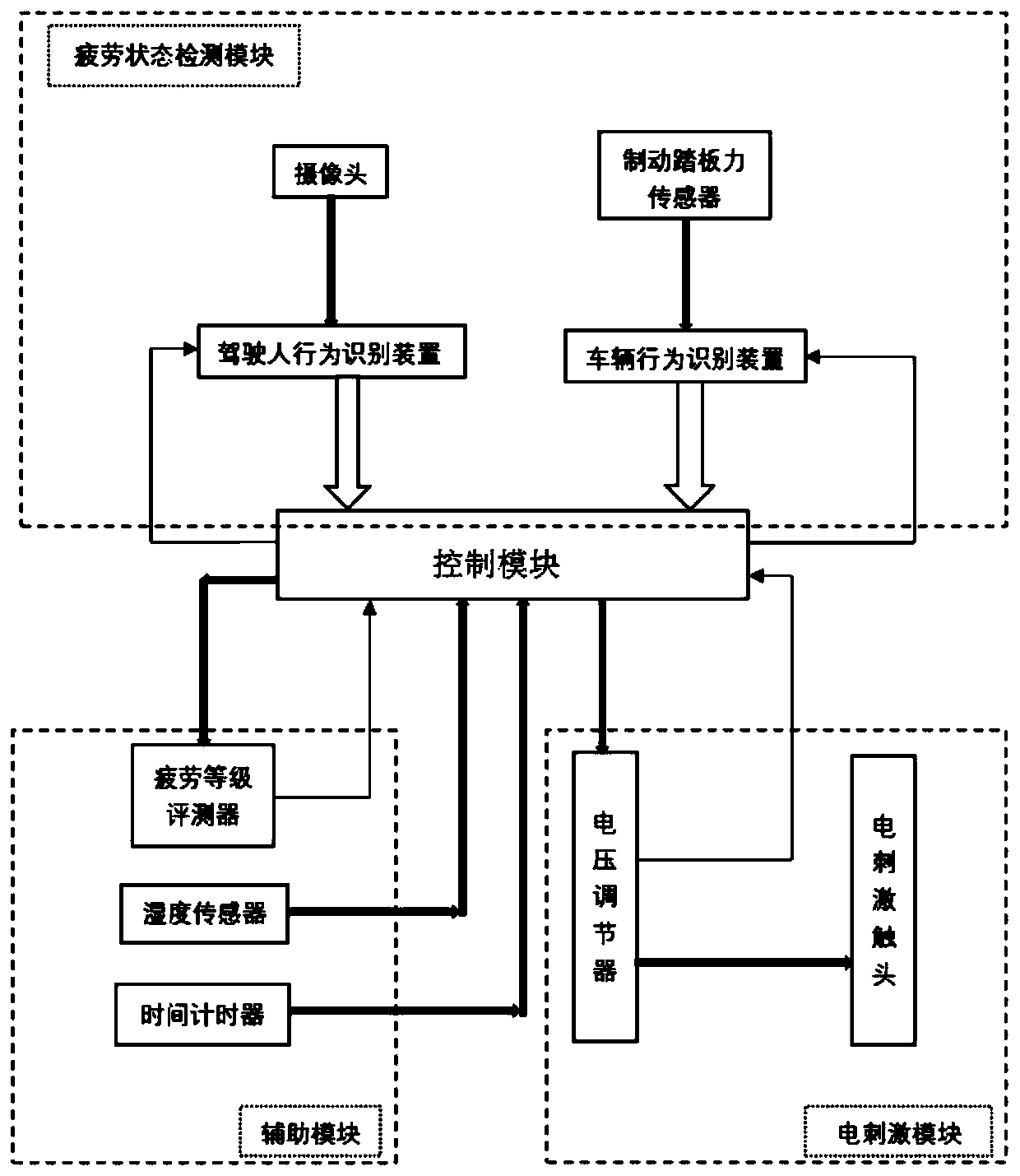

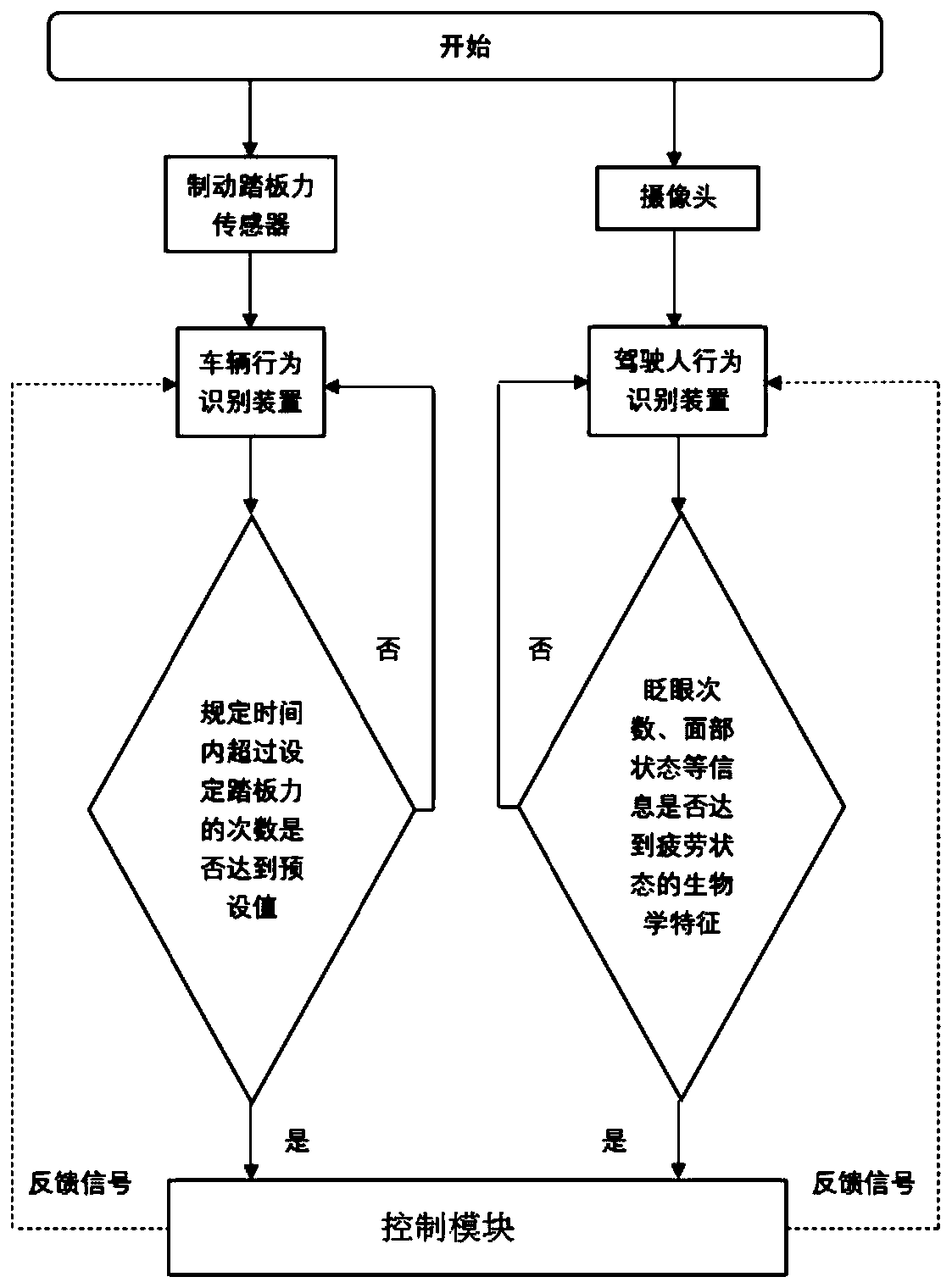

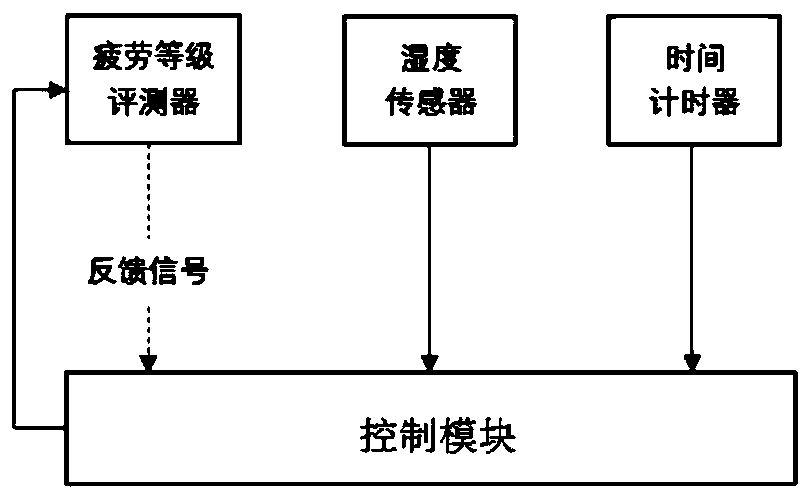

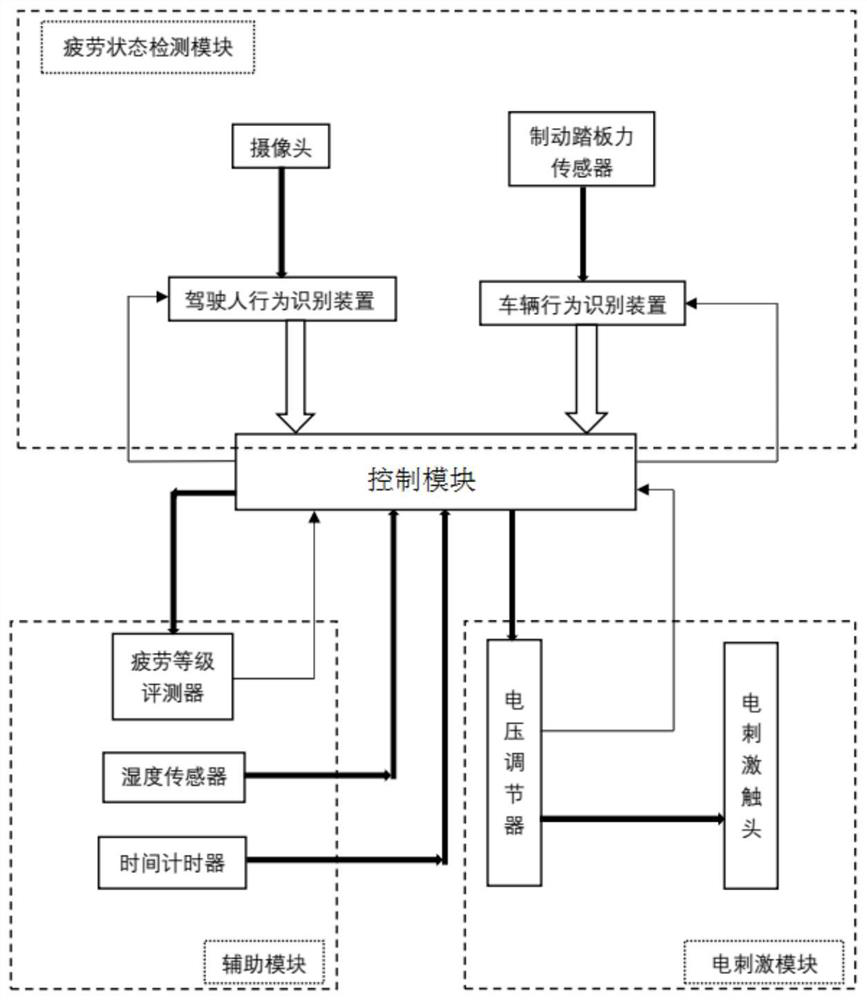

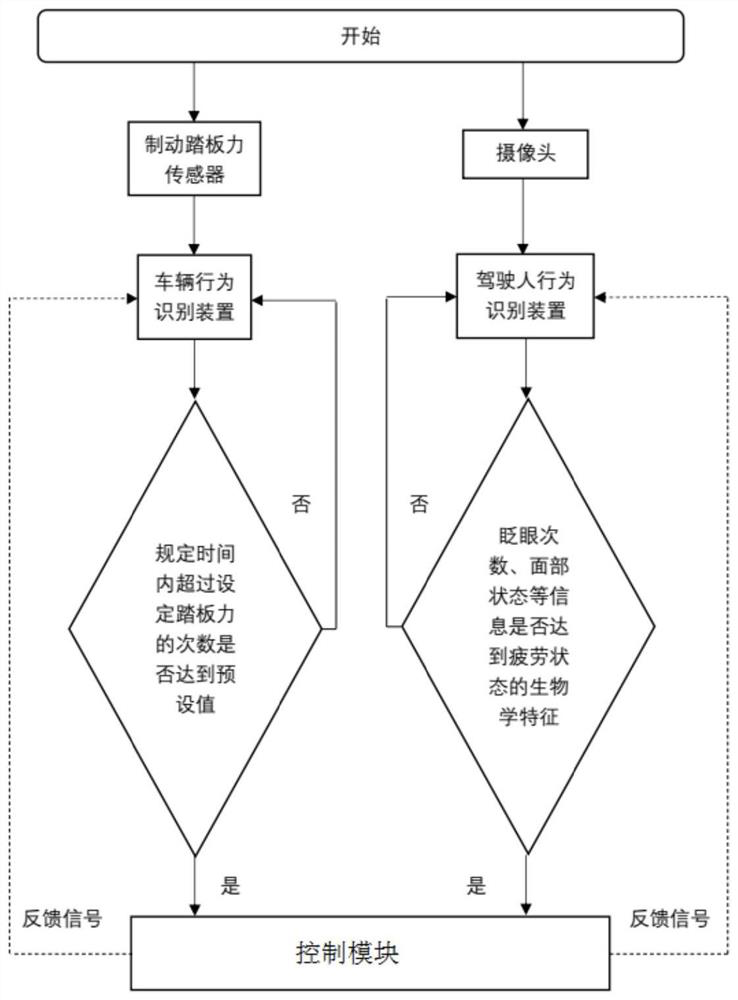

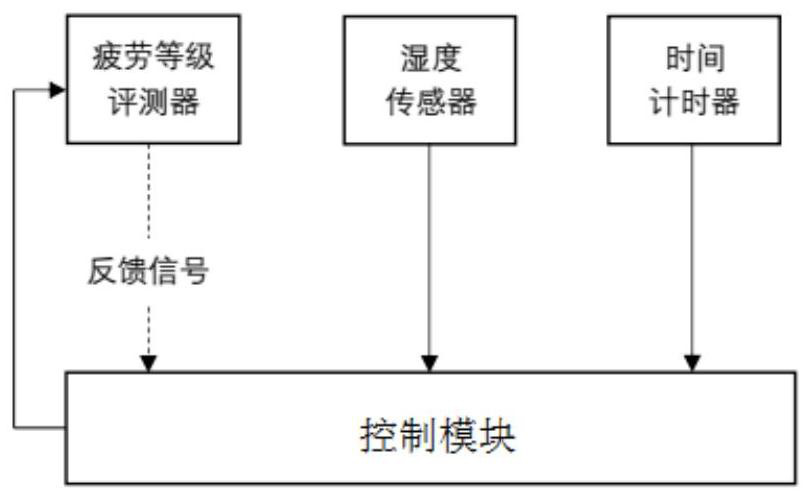

Electrical stimulation anti-fatigue system and control method

ActiveCN110712650AImprove fatigue detection accuracyRealize block production and installationSleep inducing/ending devicesControl devicesTouch receptorDriver/operator

The invention discloses an electrical stimulation anti-fatigue system and a control method. The method includes the following steps: adopting a fatigue state detection module to detect a driver fatigue state and feeding the detected driver fatigue state information back to a control module; adopting the control module for matching control signals according to the received driver fatigue state information, and transmitting the control signals to an electrical stimulation module; then adopting the electrical stimulation module arranged on a driver seat to generate stimulation current for electrical stimulation to a driver as per the received control signals; applying electric pulses to skin of the driver through the electrical stimulation module, so as to utilize current flowing through theelectrodes to stimulate a contact receptor in the skin for operation, besides, the driver under fatigue state is low in perception to outside signals, yet electrical stimulation can directly acts on human nerves, and is easier to be perceived by human brains, so that the driver is kept in a waking state, and the device is simple in structure and convenient to wear and has obvious stimulation effect.

Owner:CHANGAN UNIV

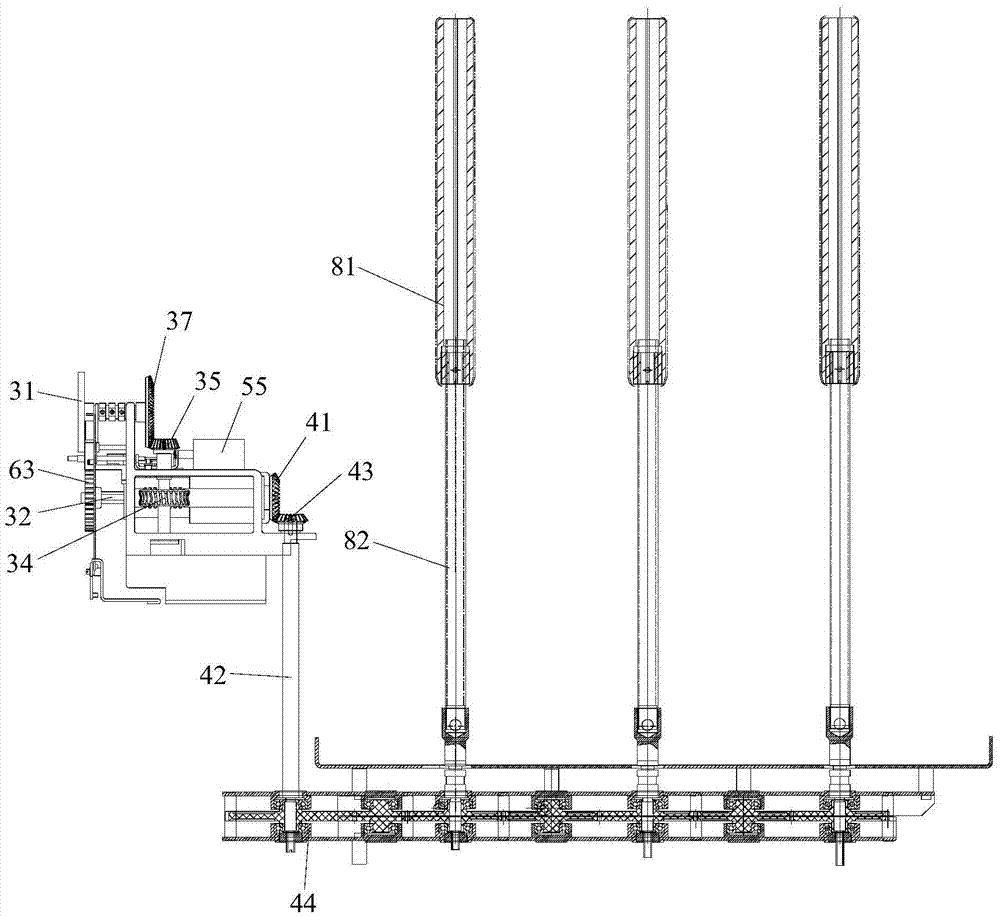

Capsule filling device

The invention relates to a capsule filling device used for automatically filling capsules with powder pill materials, and belongs to the field of pharmaceutical machinery. The capsule filling device comprises a machine plate, a metering device, a pre-compression device and a discharging device, wherein two metering supports are installed on the machine plate and are arranged in a spaced mode, a three-level telescopic shaft device is installed on each metering support, each three-level telescopic shaft device comprises a metering shaft, a compression shaft and a discharging shaft, each metering shaft is installed in the corresponding metering support in a sliding mode, each compression shaft is installed in the corresponding metering shaft in a sliding mode, the two ends of each compression shaft extend out of the corresponding metering shaft, each discharging shaft is installed in the corresponding compression shaft in a sliding mode, the two ends of each discharging shaft extend out of the corresponding compression shaft, the metering device is installed between the two metering shafts arranged above the machine plate, the pre-compression device is installed between the two compression shafts arranged above the machine plate, and the discharging device is installed between the two discharging shafts arranged above the machine plate. According to the capsule filling device, the capsule filling motion is simple, control is easy, production efficiency is high, the material scatter and leakage phenomenon is avoided, and the cost is reduced.

Owner:SHANDONG SMA PHARMATECH CO LTD

Guide rail and ball screw structure for lifting of both cross beam and horizontal boring and milling heads at two sides

ActiveCN104029071AReduce in quantitySave transmission spaceFeeding apparatusLarge fixed membersEngineeringBall screw

A guide rail and ball screw structure for lifting of both cross beam and horizontal boring and milling heads at two sides comprises a vertical pillar, wherein the left side and the right side of the front surface of the vertical pillar are fixedly connected with linear rails respectively, the front surface of each linear rail sliding block is fixedly connected with the cross beam, the vertical pillar is fixedly connected with a ball screw, the upper portion and the lower portion of the ball screw are connected with a first nut and a second nut respectively in a threaded mode, the front surface of the first nut is fixedly connected with the cross beam, the first nut is connected with a driven gear in a sleeved mode, the driven gear is meshed with a driving gear, the driving gear is fixedly connected with a first planetary gear reducer, the first planetary gear reducer is connected with a first servo motor, the front surface of the second nut is fixedly connected with a lateral horizontal boring head, the inner layer of the second nut is connected with another driven gear in a sleeved mode, the driven gear is meshed with another driving gear, the driving gear is fixedly connected with a second planetary gear reducer, and the second planetary gear reducer is fixedly connected with a second servo motor.

Owner:SHANDONG WEIDA HEAVY INDS

A test work platform with functions of rotation and angle adjustment

Owner:HUAZHONG UNIV OF SCI & TECH

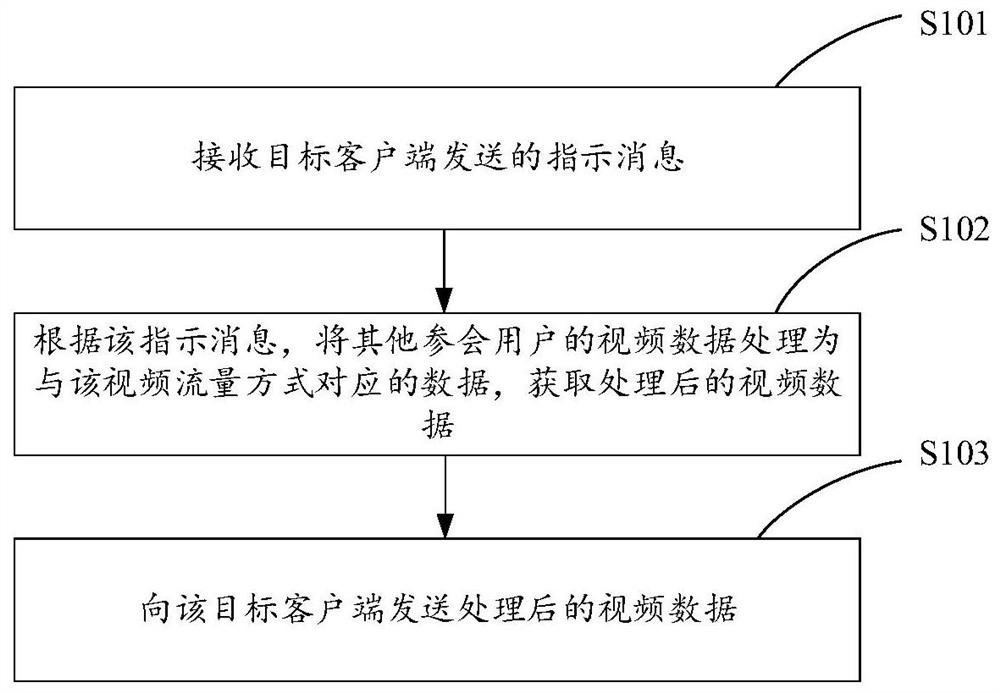

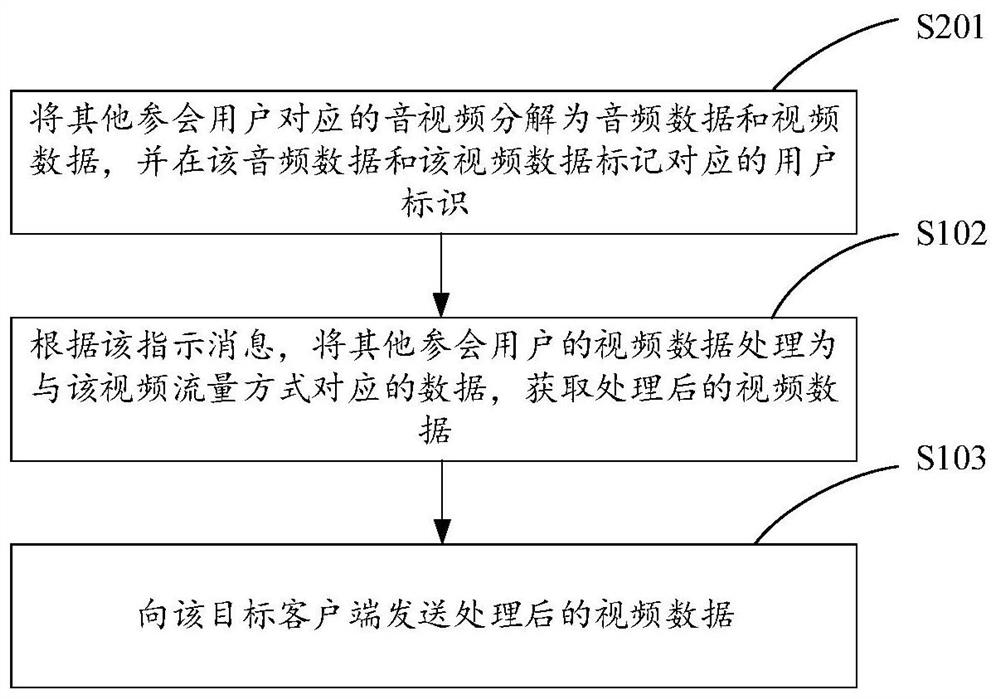

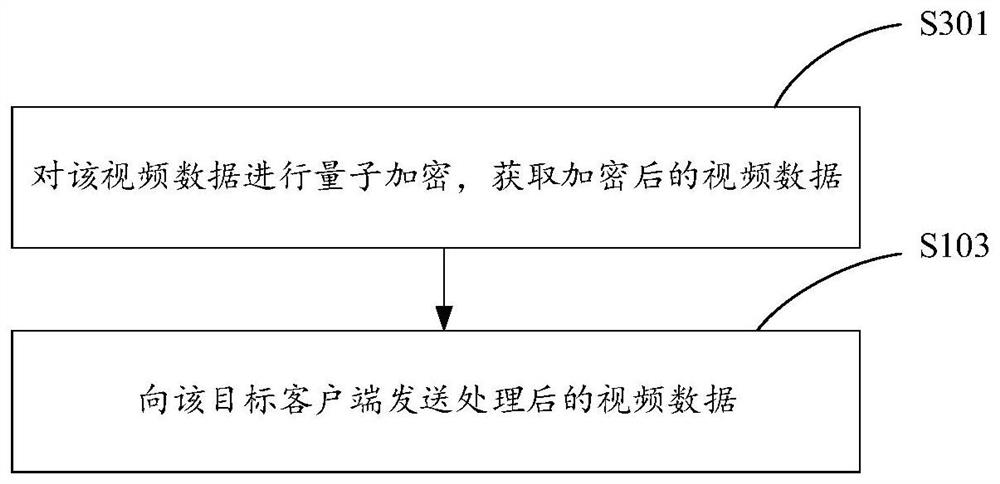

Video conference data processing method and device

ActiveCN111770301AData augmentationReduce occupancyTelevision conference systemsTwo-way working systemsData applicationClient

The invention provides a video conference data processing method and device, and relates to the technical field of video conferences. The method can comprise the steps that an indication message sentby a target client is received;, the indication message is used for indicating video flow modes, needing to be received, of other conference participating users, and; the video flow modes comprise thea small flow mode and the a large flow mode; according to the indication message, processing the video data of other participant users is processed into data corresponding to the video traffic mode,and obtaining the processed video data is obtained; and sending the processed video data is sent to the target client. By applying the method disclosed in the embodiment of the invention, the video data can occupy less transmission space in the transmission process, so thatand therefore the number of conference participating users in the video conference can be increased.

Owner:百家云集团有限公司

An electrical stimulation anti-fatigue system and control method

ActiveCN110712650BStay awakeSimple structureSleep inducing/ending devicesControl devicesTouch receptorDriver/operator

The invention discloses an electrical stimulation anti-fatigue system and a control method. A fatigue state detection module is used to detect the driver's fatigue state, and the detected driver's fatigue state information is fed back to the control module. The state information matches the control signal, and transmits the control signal to the electrical stimulation module, and then uses the electrical stimulation module set on the driver's seat to generate a stimulating current to stimulate the driver according to the received control signal. Electric pulses are applied to the driver's skin, so that the current flowing through the electrodes can be used to stimulate the tactile receptors in the skin to work. At the same time, because the driver's ability to perceive external signals is reduced in a fatigued state, the electrical stimulation can directly act on the skin. The human nerves and the brain are easier to perceive, so as to achieve the purpose of keeping the driver awake. The device has a simple structure, is easy to wear, and has an obvious stimulating effect.

Owner:CHANGAN UNIV

Review interaction method, device, client device and electronic device

ActiveCN108449255BSave transmission spaceIncrease transfer rateData switching networksData packMediaFLO

Disclosed are a comment interaction method, equipment, client device and electronic equipment. The comment interaction method includes: acquiring the first comment data input by the user, wherein the first comment data includes comment text and rich media content; identifying the rich media content in the first comment data; mapping the rich media content to a special identifier; and sending the second comment data to the first server, wherein the second comment data includes the special identifier and comment text. According to the present disclosure, the data transmission space can be saved and the data transmission rate can be improved.

Owner:ALIBABA (CHINA) CO LTD

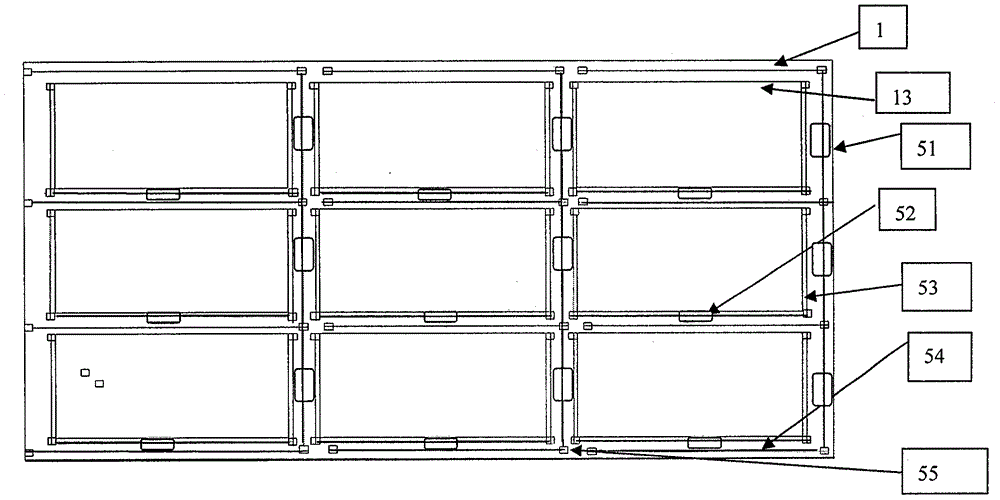

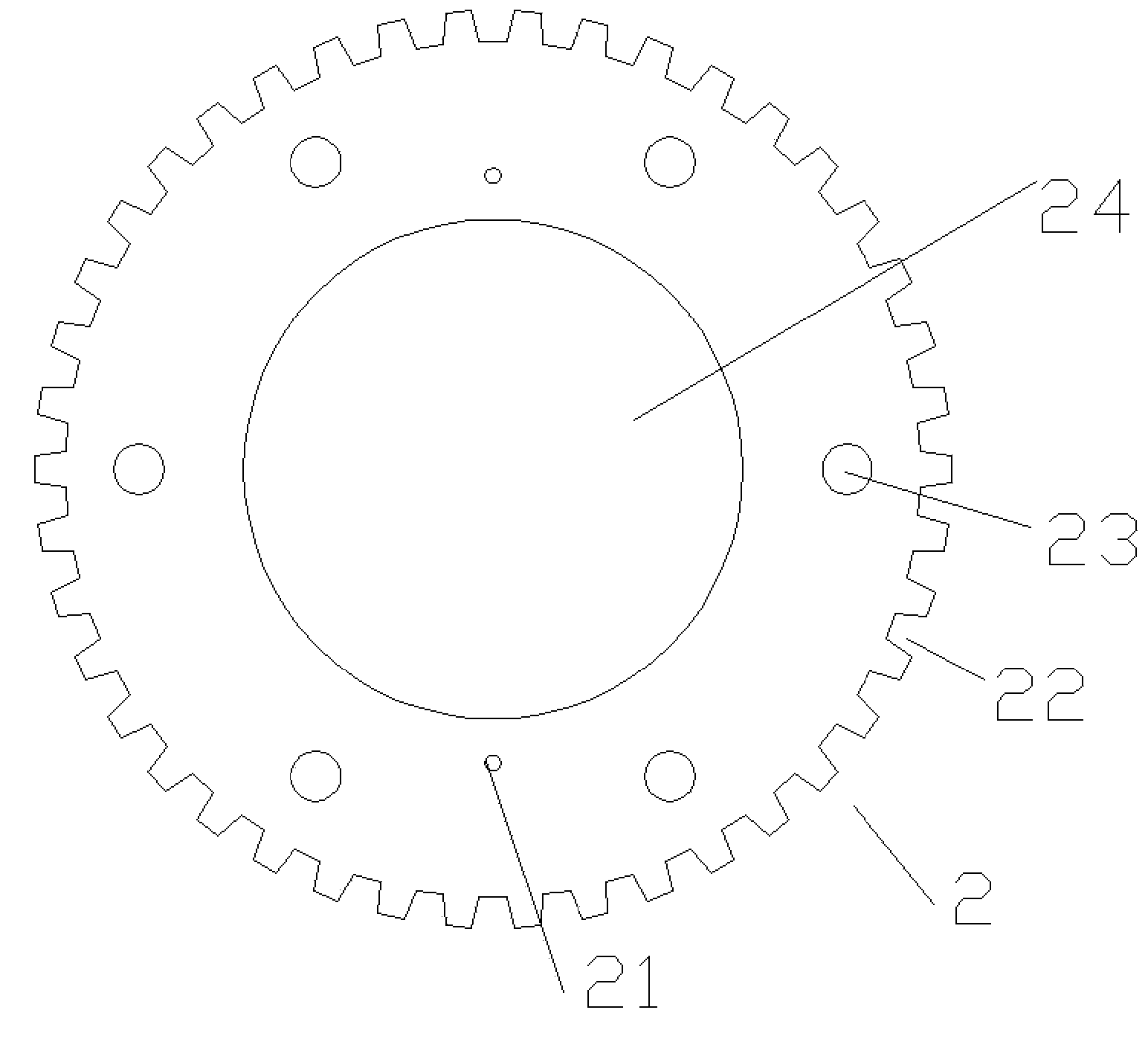

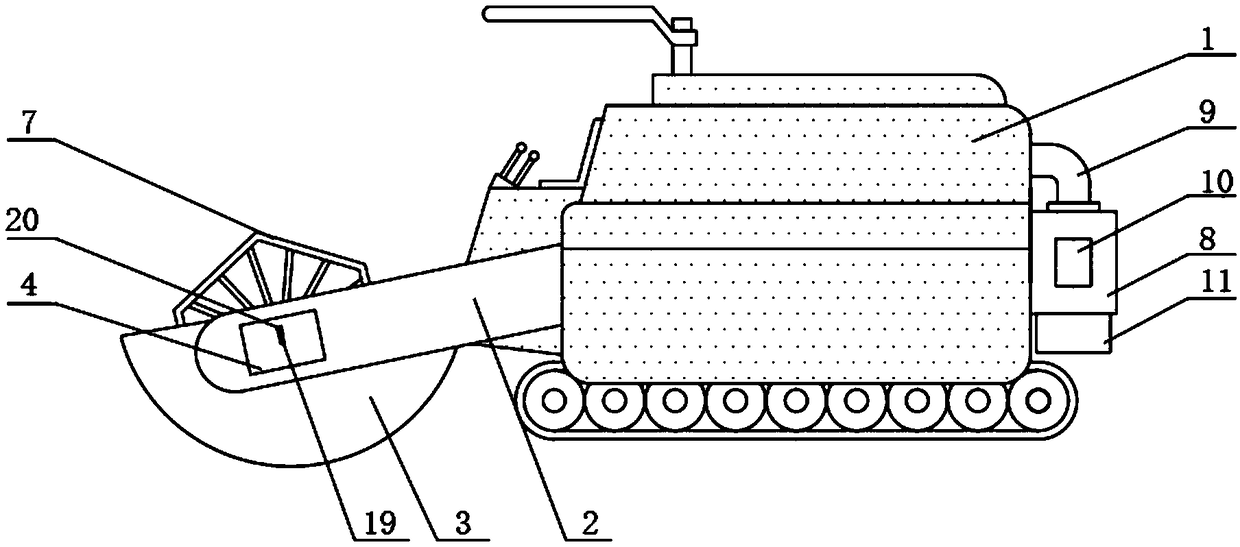

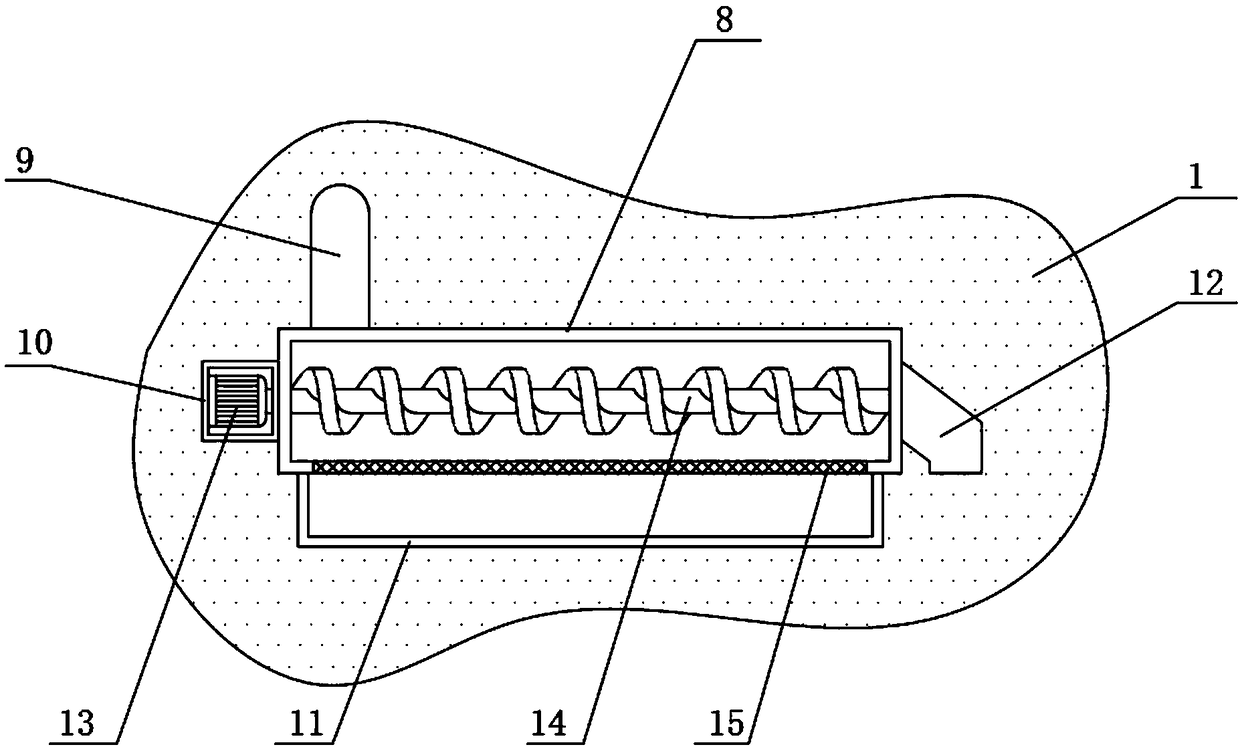

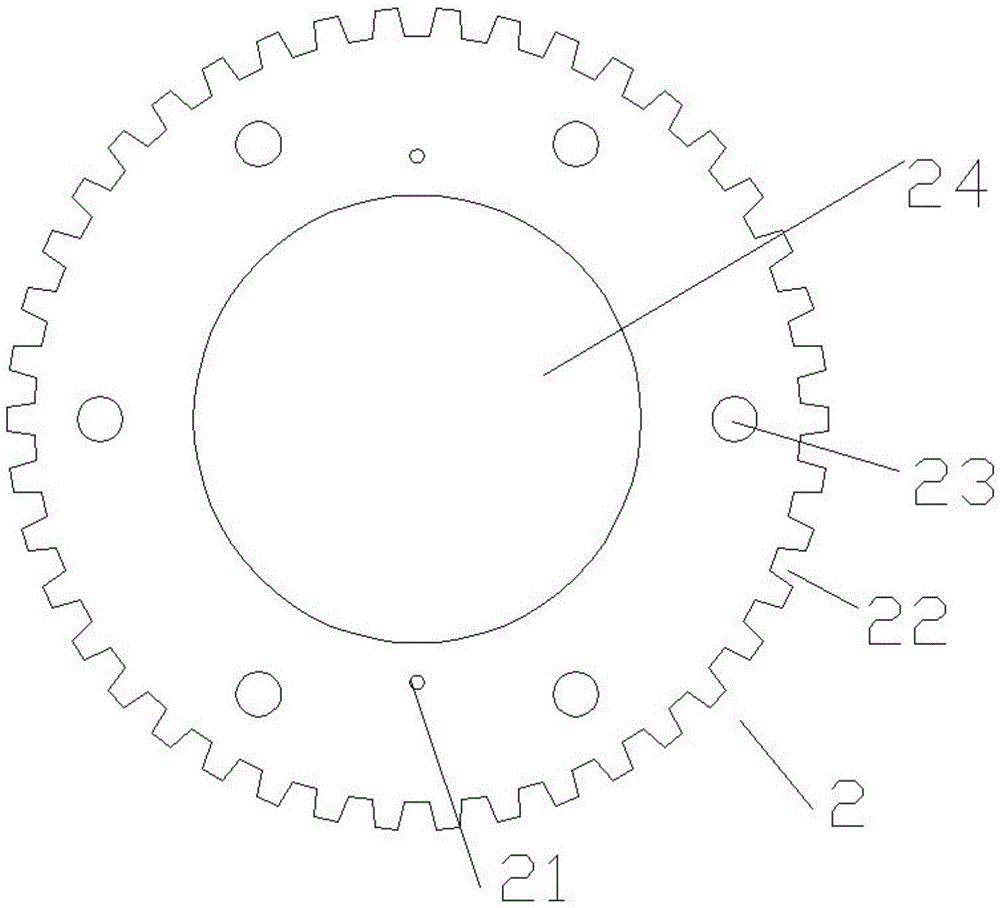

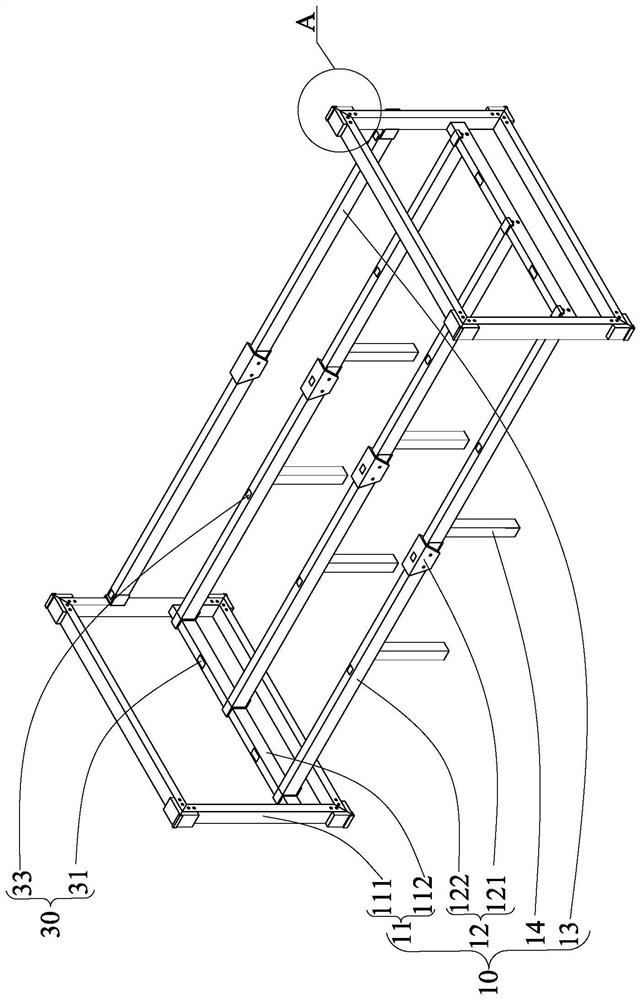

Whole-feed combined harvester capable of saving transmission space

The present invention relates to the technical fields of harvesters and discloses a whole-feed combined harvester capable of saving transmission space. The whole-feed combined harvester comprises a body, wherein two side beams are fixedly mounted on the left sides of the front and back of the body; a divider is fixedly mounted between the two side beams; a protection box is fixedly mounted on thefront of each side beam; and a transmission shaft is movably sleeved between the two side beams. The whole-feed combined harvester capable of saving transmission space is provided with a driven gear,a power motor, a driving gear, and an oil filling pipe; the power motor drives a reel body to rotate by means of the driving gear and through the driven gear, thereby saving the transmission space; and due to the use of the oil filling pipe, an operator is allowed to add lubricating oil conveniently, so that the abrasion between the driven gear and the driving gear is reduced and the effect of transmission is enhanced; therefore, the practicability of the harvester is improved.

Owner:郭永丹

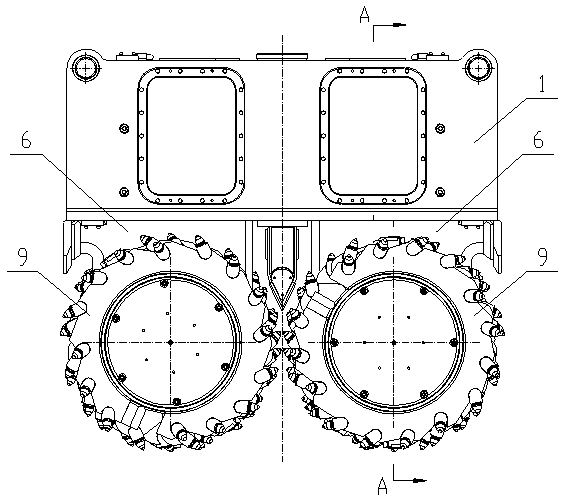

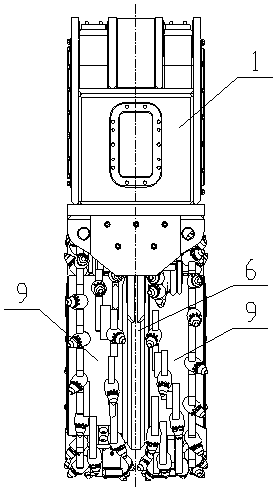

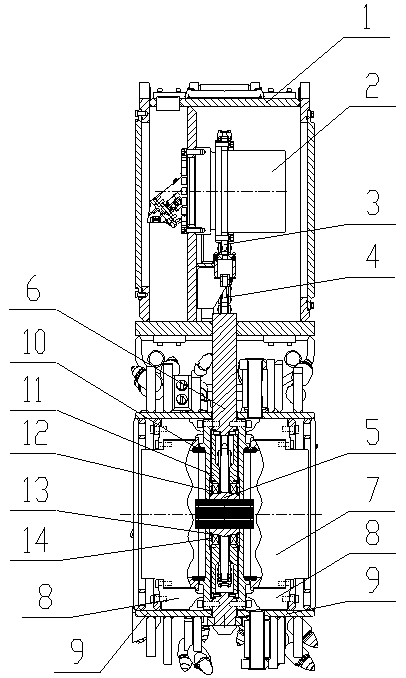

A double wheel groove milling machine transmission box

Owner:XUZHOU XUGONG FOUND CONSTR MACHINERY

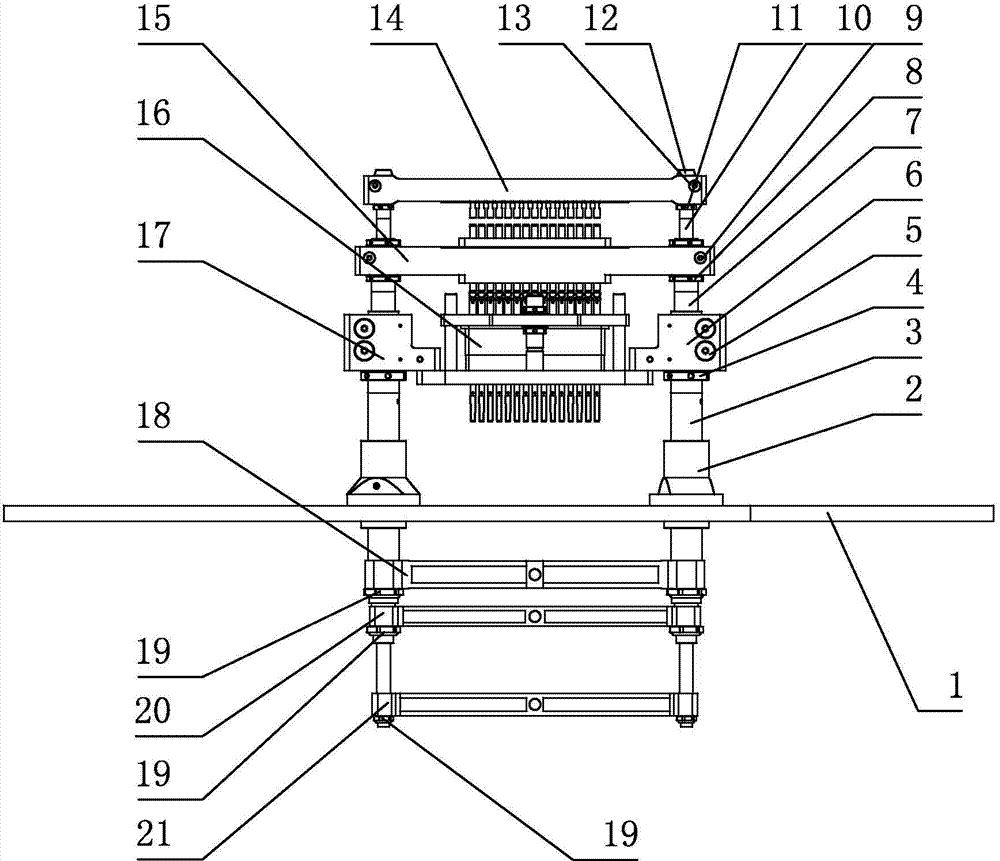

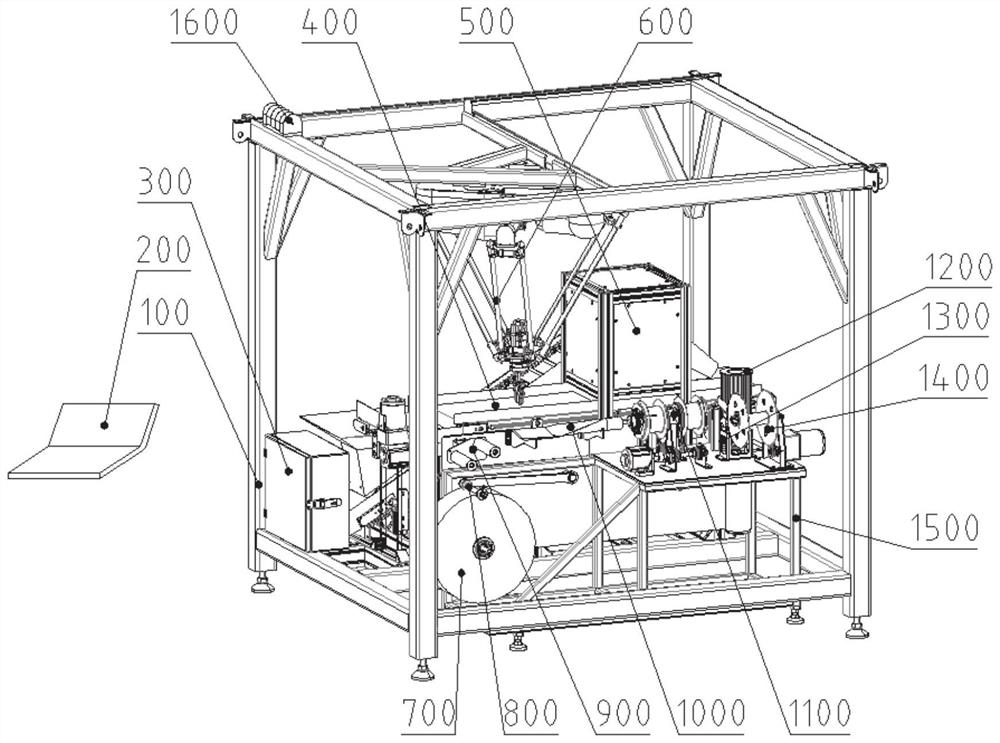

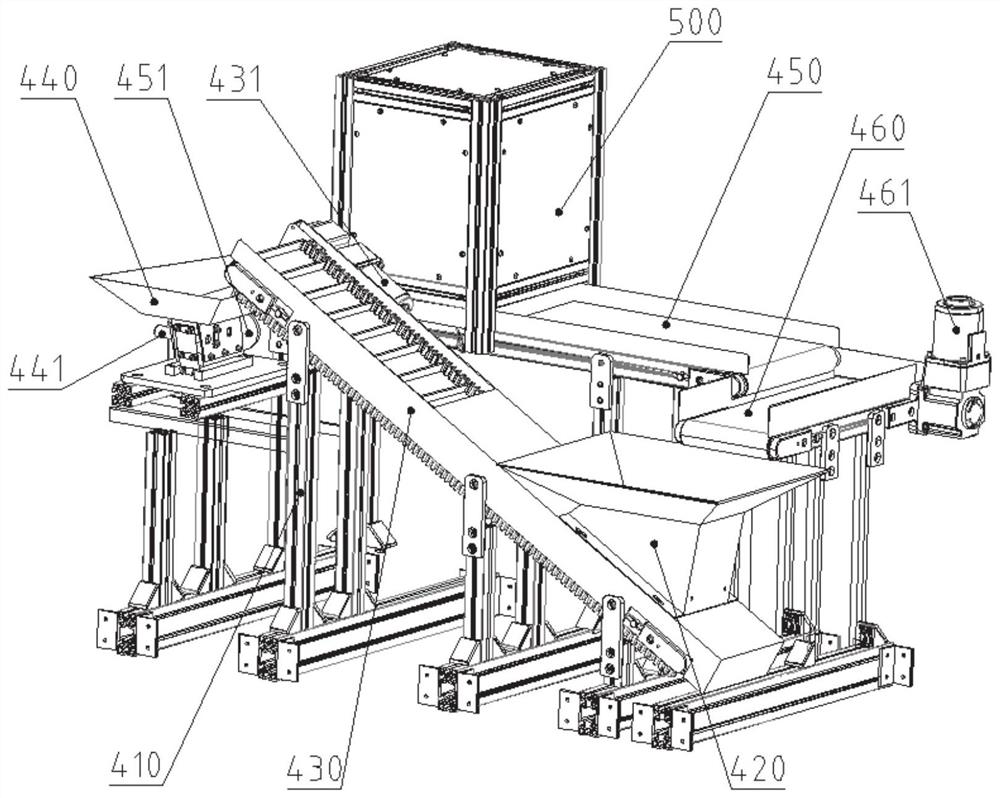

Stamping production line for small-volume auto parts and method for processing parts using the production line

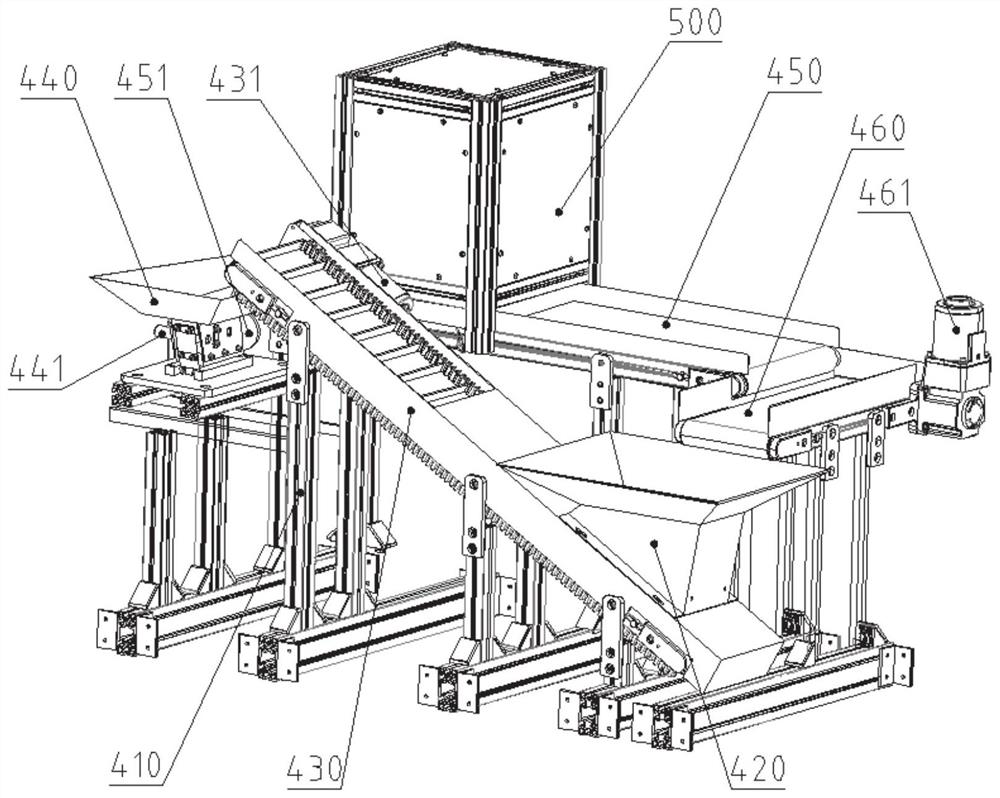

ActiveCN109647976BReduce labor costsSmall footprintMetal-working feeding devicesMetal working apparatusProduction lineStamping

The invention discloses a small-size automobile part stamping production line and a stamping method thereof. The small-size automobile part stamping production line comprises a stamping working system, a grabbing assembly, a debris containing assembly, a conveying assembly and a control system, wherein the stamping working system comprises a machine frame and a stamping working platform, a plurality of stamping tools which are suitable for different stamping procedures are transversely arranged on the stamping working platform, the grabbing assembly comprises a manipulator mounting seat whichis arranged on the front side or the rear side of the stamping working platform and can transversely move, two mechanical grippers, a plurality of longitudinal cleaning manipulators and a plurality oflongitudinal grabbing manipulators are arranged on the manipulator mounting seat, and the conveying assembly comprises a conveying belt which is transversely arranged on the side, away from the stamping working platform, of the manipulator mounting seat. According to the small-size automobile part stamping production line and the stamping method thereof, multi-station automobile part stamping machining is realized through multi-mechanism coordination operation, the automation degree is higher, the working efficiency and the operation accuracy are further improved, and the labor cost of enterprises can be greatly saved.

Owner:山东时风(集团)有限责任公司

A kind of preparation method of U-shaped transmission belt

Disclosed are a U-type transmission belt and a preparation method thereof. The U-type transmission belt sequentially comprises an outer U-type groove chloroprene rubber layer, a glass fiber layer, a toothed chloroprene rubber layer and an elastic nylon fabric layer. The grooves formed at back of the chloroprene rubber belt are U-type grooves.

Owner:NINGBO GUL TZ RUBBER BELT

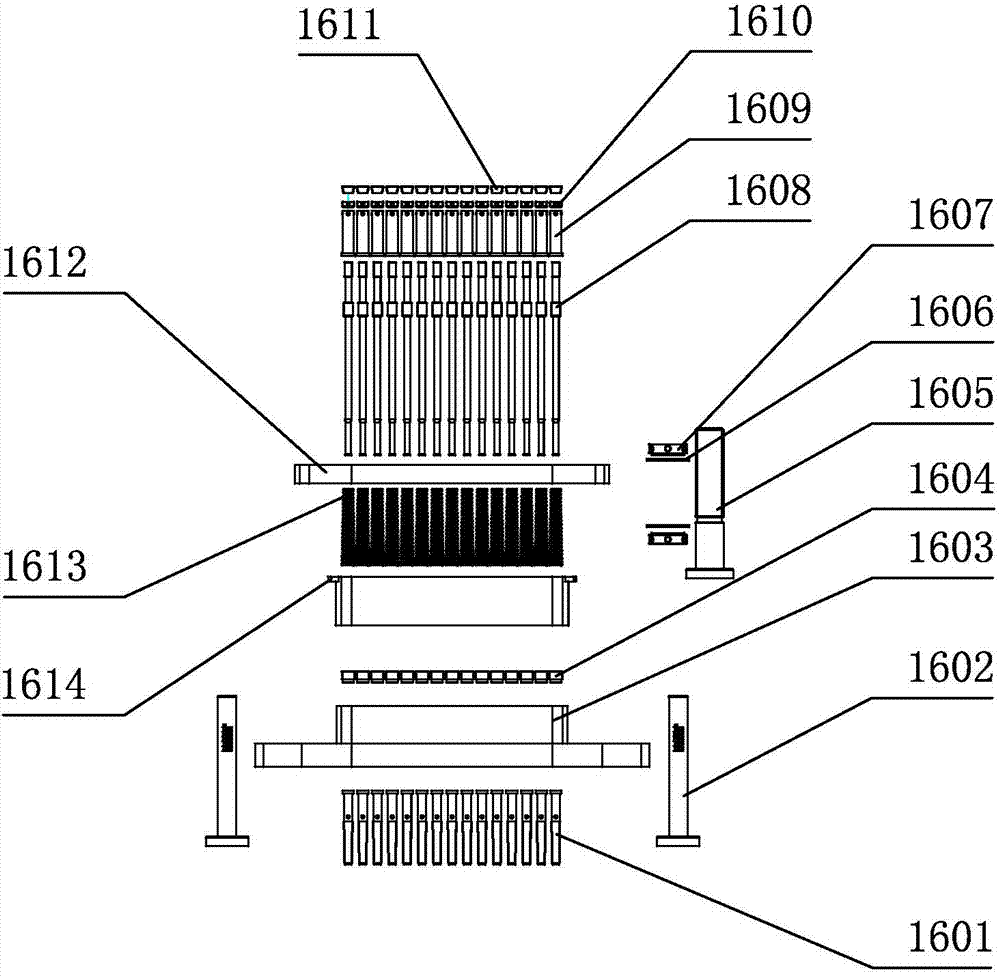

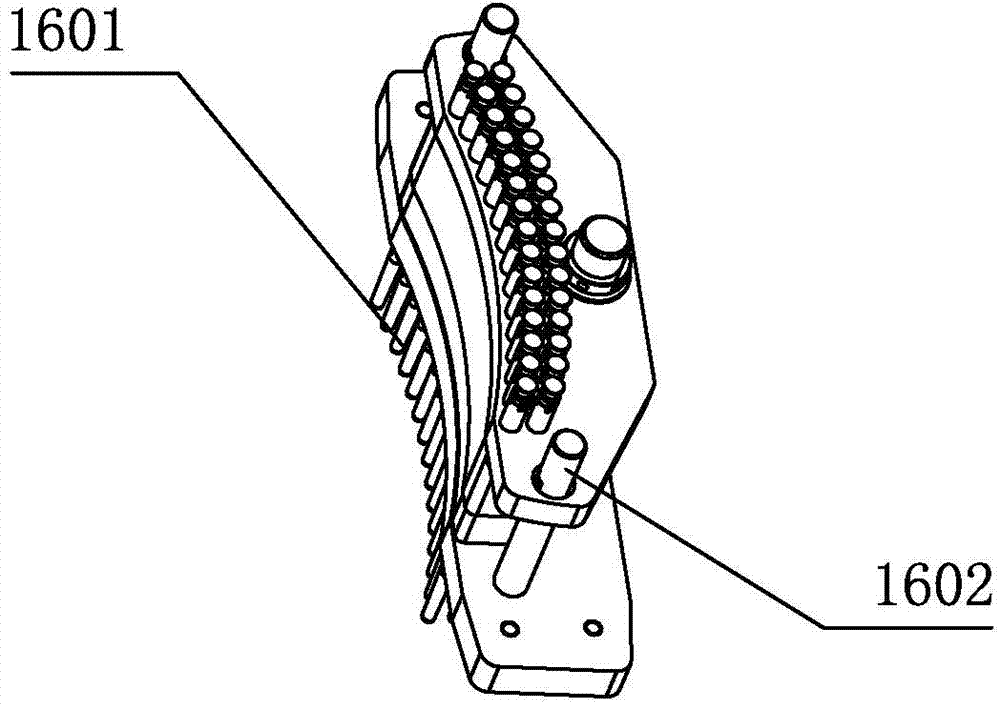

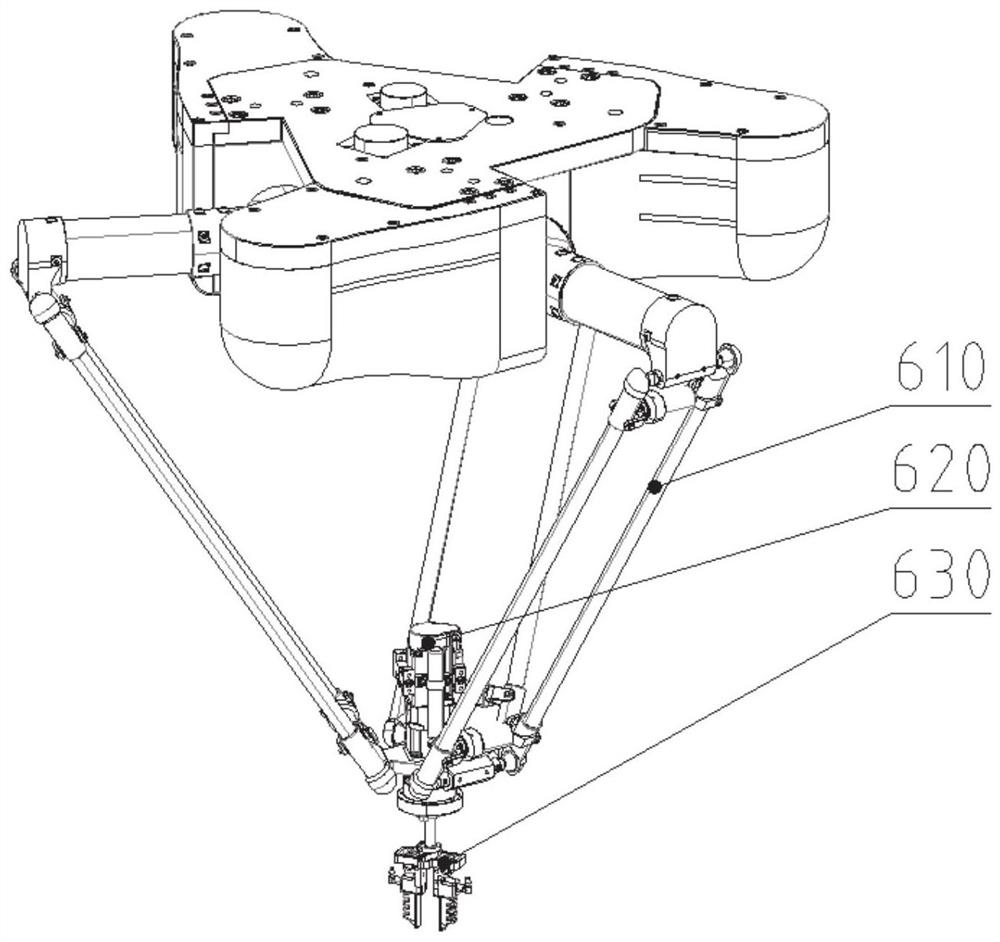

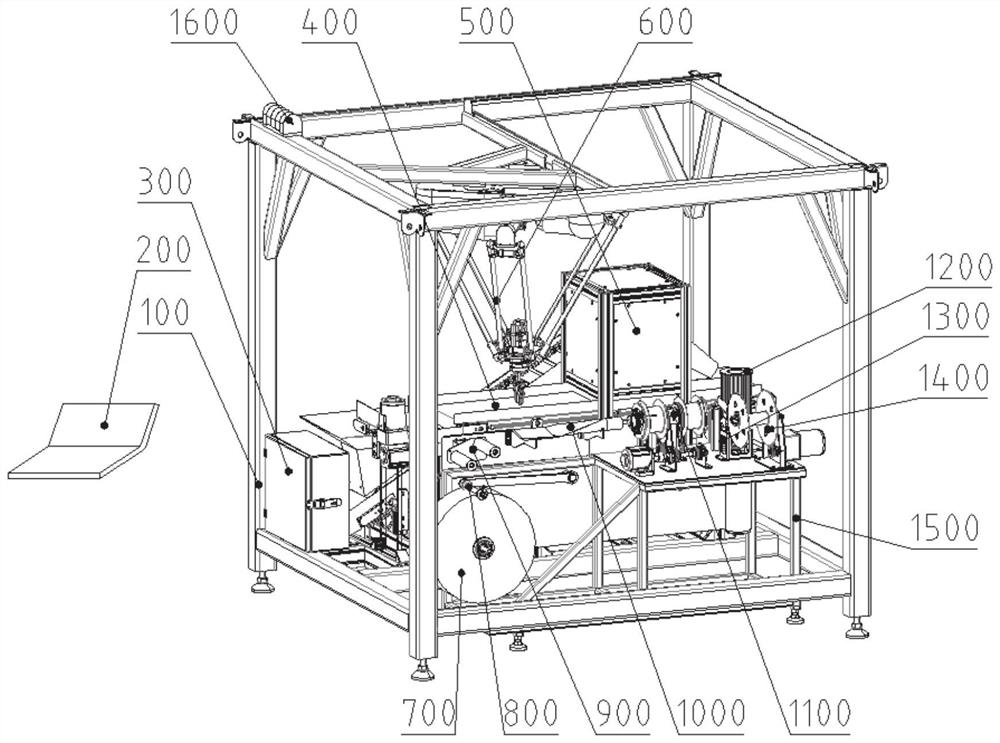

Intelligent precise seed rope braiding machine

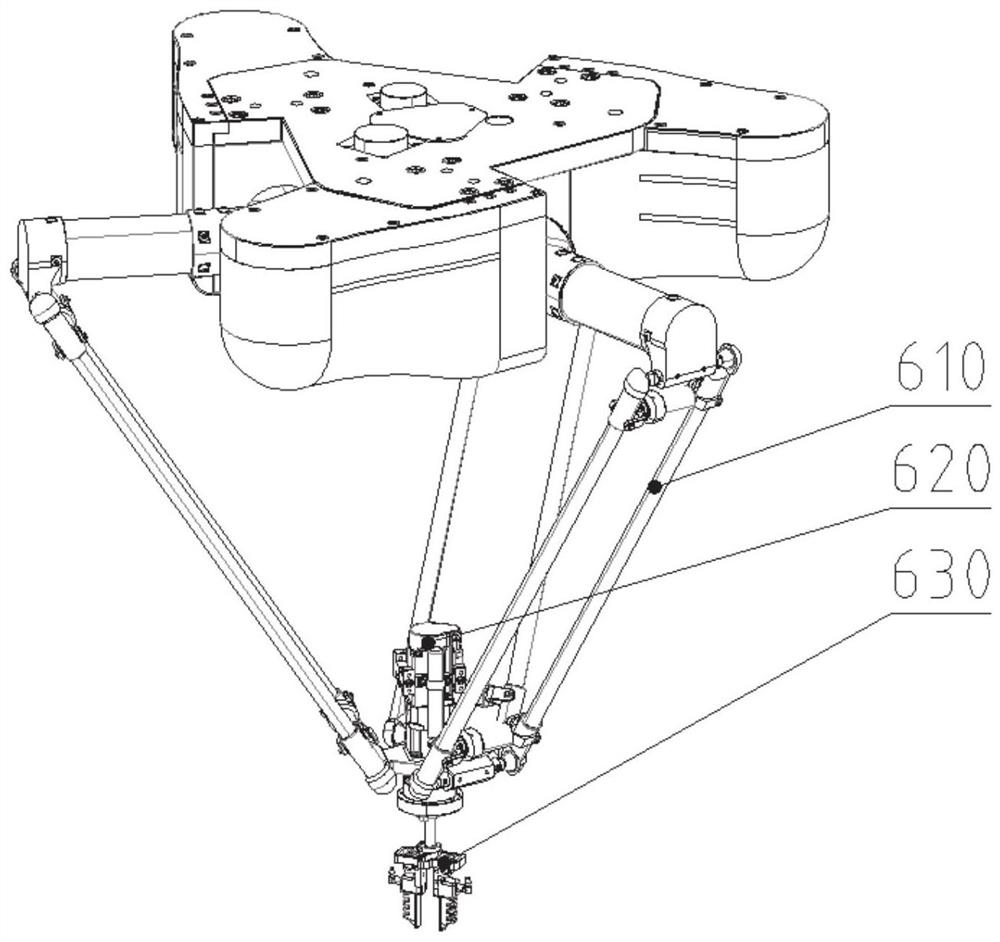

ActiveCN113151974AGuaranteed seeding accuracySimple and convenient operationBraidOther apparatusAgricultural engineeringWinding machine

The invention discloses an intelligent precise seed rope braiding machine which comprises a rack, a seed conveying mechanism, an image recognition mechanism, a seed taking mechanism and a seed rope braiding mechanism, wherein the seed conveying mechanism, the image recognition mechanism, the seed taking mechanism and the seed rope braiding mechanism are mounted on the rack and controlled by a control system; the seed conveying mechanism is used for screening and conveying seeds; the image recognition mechanism is mounted above the seed conveying mechanism and used for recognizing the position and shape characteristics of the screened seeds and feeding back a signal to the controller, and the controller sends an instruction to the seed taking mechanism according to the feedback signal; the seed taking mechanism is mounted at the top of the inner side of the rack and above the seed conveying mechanism, and is used for grabbing the screened seeds from the seed conveying mechanism according to the instruction and putting the grabbed seeds into a paper tape of a seed weaving mechanism in a directional and fixed-distance manner; the seed weaving mechanism is located on the other side of the rack and is parallel to the seed conveying mechanism, the seed weaving mechanism comprises a paper tape reel, a paper tape of the paper tape reel enters a paper tape leading-in mechanism after passing through a guide roller mechanism, and a winding mechanism winds a rope outside a paper bag in which the seeds are wrapped to form a seed rope.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Method for browsing pages in digital television and system thereof

ActiveCN101534419BNot easy to make mistakesBit downSelective content distributionWeb pageComputer science

The invention relates to the field of digital television, aiming to solve the problems in the prior art that a set-top box is slow in analyzing web pages and mistakes are prone to take place and providing a method for browsing pages in digital television and a system thereof. In the method, a server converts the web pages into picture format, converts web page data in picture format into web pagedata in video format and sends the web page data in video format to the set-top box. The method and the system of the invention have the advantage of improving speed of the set-top box in browsing web pages.

Owner:北京兴国融合通讯科技有限公司

An intelligent and precise seed rope weaving machine

ActiveCN113151974BAchieve crawlingRealize deliveryBraidOther apparatusWinding machineAgricultural science

The invention discloses an intelligent and precise seed rope weaving machine, comprising a frame, a seed conveying mechanism, an image recognition mechanism, a seed picking mechanism and a seed rope weaving mechanism, which are installed on the frame and controlled by a control system; the seed conveying mechanism completes the Screening and conveying of seeds; image recognition mechanism, installed above the seed conveying mechanism, used to identify the position and shape characteristics of the seeds after screening, and feedback the signal to the controller, and the controller sends the seed picking mechanism according to the feedback signal Instruction; Seed picking mechanism, installed on the top of the inner side of the frame, above the seed conveying mechanism, which grabs the screened seeds from the seed conveying mechanism according to the instructions, and puts them into the paper tape of the seed rope weaving mechanism at a fixed distance; The seed rope weaving mechanism is located on the other side of the frame and is arranged in parallel with the seed conveying mechanism. It includes a paper tape reel. The paper tape of the paper tape reel enters the paper tape introduction mechanism after passing through the guide roller mechanism. The winding mechanism is suitable for wrapping seeds. The rope is wrapped around the outside of the paper bag to form a seed rope.

Owner:SHANDONG ACADEMY OF AGRICULTURAL MACHINERY SCIENCES

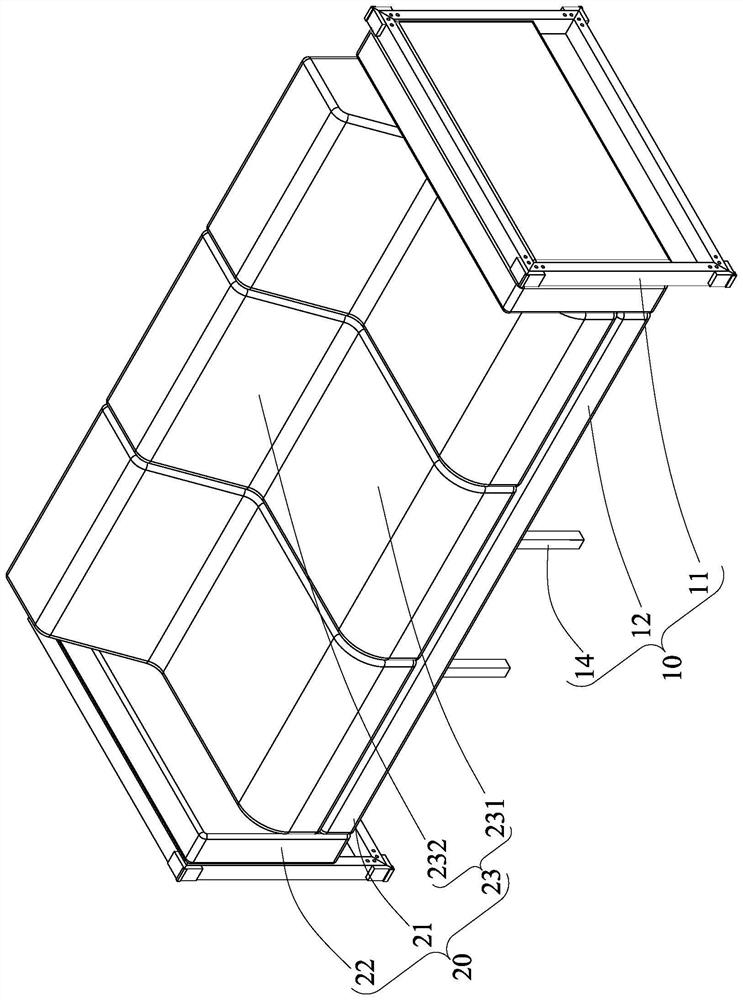

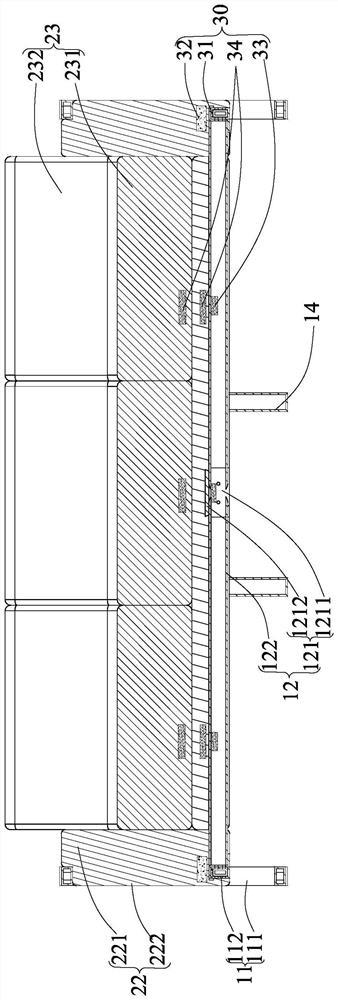

Sponge sofa with metal support

The invention discloses a sponge sofa with a metal bracket. The sponge sofa comprises a mounting frame and sofa units, the mounting frame comprises a handrail frame and a bottom folding frame. Each armrest frame comprises an armrest frame and an armrest connecting frame. Each bottom folding frame comprises a folding connecting base and a folding support. The folding connecting base comprises a clamping plate and a baffle. The folding support comprises a folding support body and a fixed connector. Each sofa unit comprises a sofa base, armrests and a sofa single seat. The sofa base comprises a sofa base main body and a base mounting groove. Each handrail comprises a handrail body, a limiting protrusion, a first mounting groove and a second mounting groove. The sponge sofa with the metal bracket is simple in structure, and the mounting frame and the sofa units can be fully disassembled and compressed, so that the occupied space during transmission is reduced, and the transmission space is saved.

Owner:GLORY HOME FURNISHING JIAXING

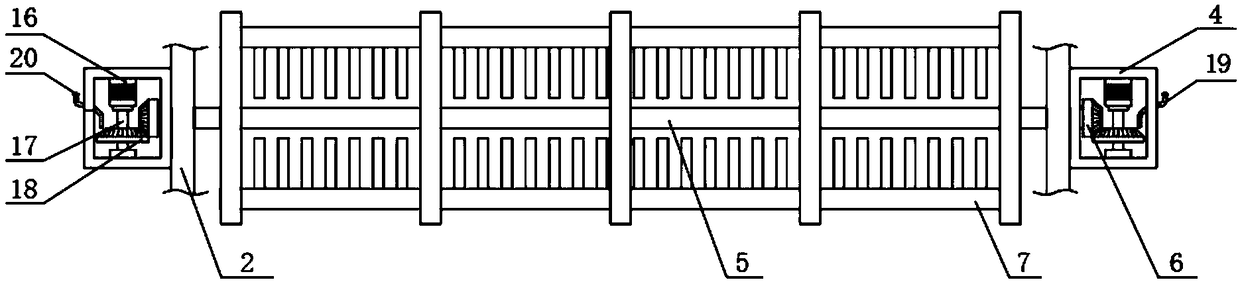

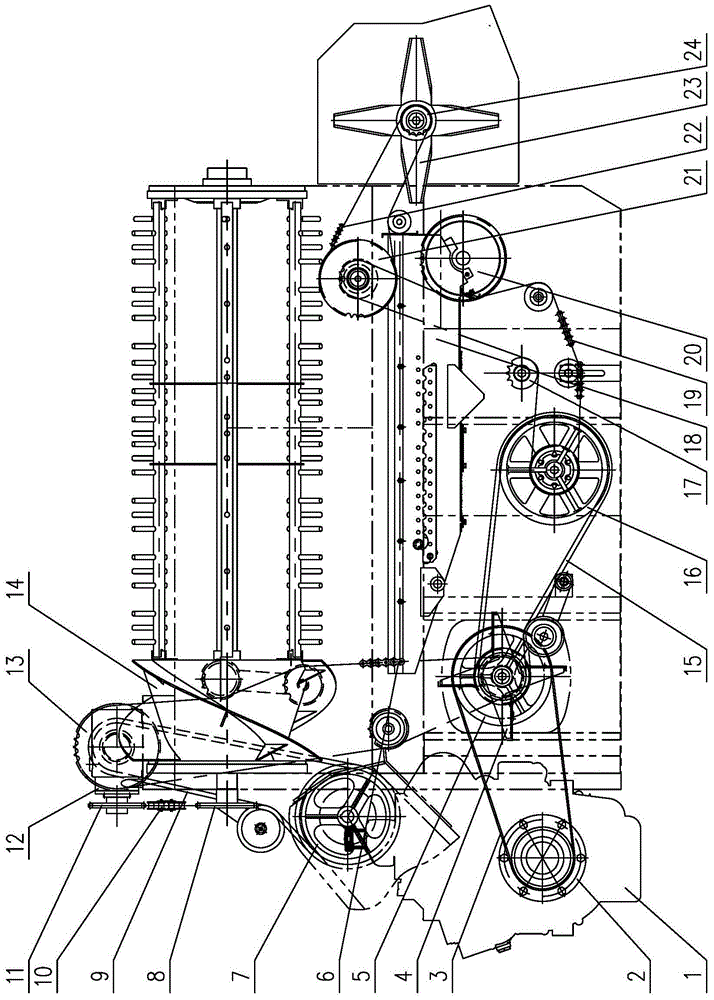

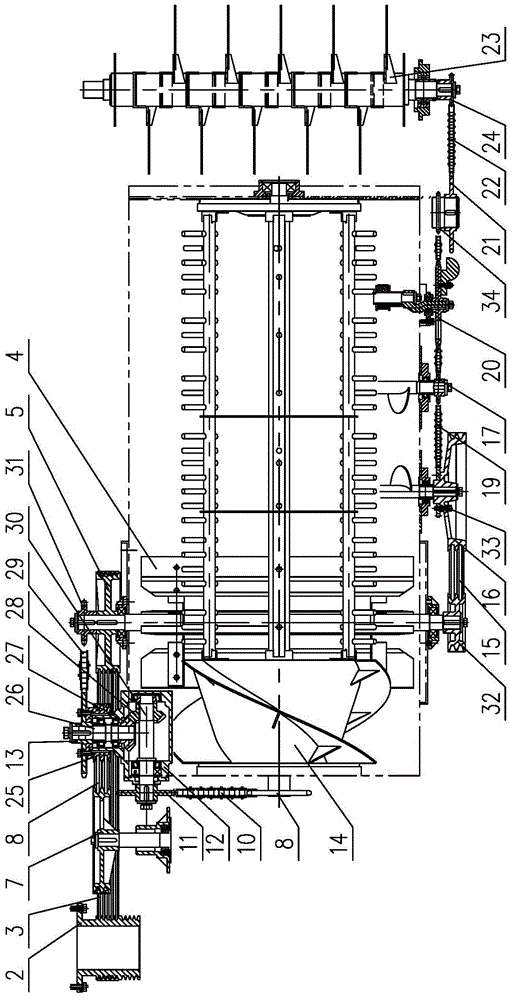

The transmission mechanism of the threshing system of the full-feed combine harvester

The invention relates to a combine harvester, and particularly relates to a transmission mechanism of a whole-feeding combine harvester threshing system, which belongs to the technical field of combine harvesters. The transmission mechanism comprises an engine, a fan, a transmission case, a roller, a vibrating screen, a first auger, a secondary auger and a straw cutter, wherein the fan on the back end of the engine is driven to rotate by the engine through an engine belt pulley mechanism, a driving shaft and a driven shaft are arranged in the transmission case, a driving bevel gear is connected to the inner end of the driving shaft, a driven bevel gear is arranged on the driven shaft, and the driving bevel gear and the driven bevel gear are engaged. The transmission mechanism has the advantage of simple, compact and reasonable structure, the transmission mechanism is simplified, and the transmission space is saved, so that the structure of the combine harvester is compact, the transmission is rationalized, the weight and size of the combine harvester are effectively reduced, and the production cost is reduced.

Owner:WUXI COMBINE HARVESTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com