The transmission mechanism of the threshing system of the full-feed combine harvester

A combine harvester and transmission mechanism technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems that affect the structural layout of the harvester, the harvester is large in size, and occupies a large space, so as to achieve compact structure and simplified transmission Mechanism, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

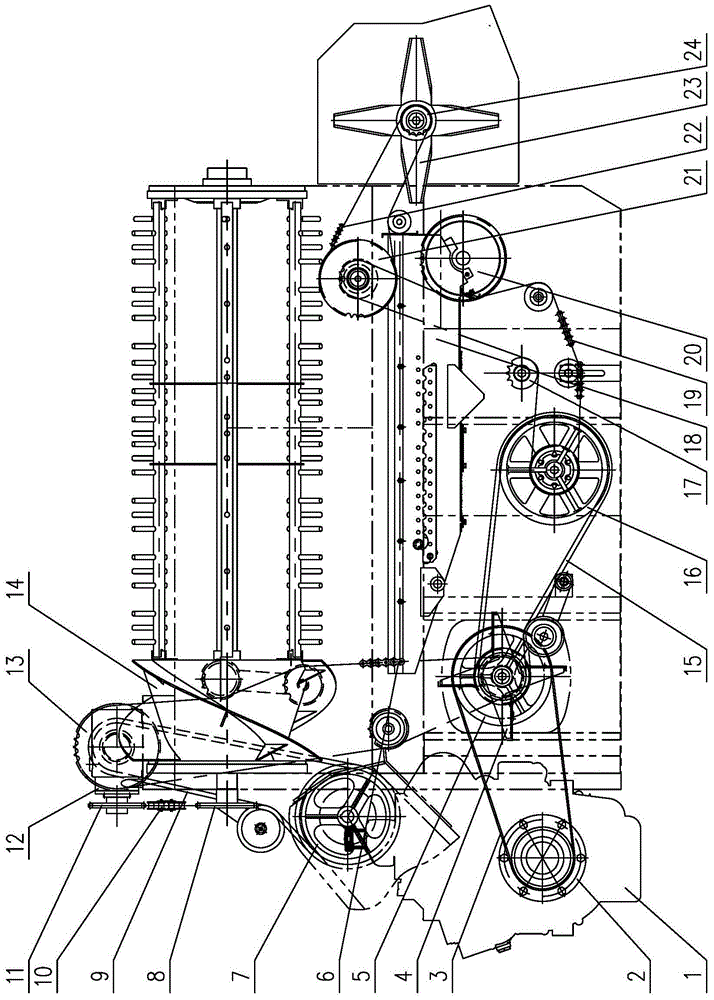

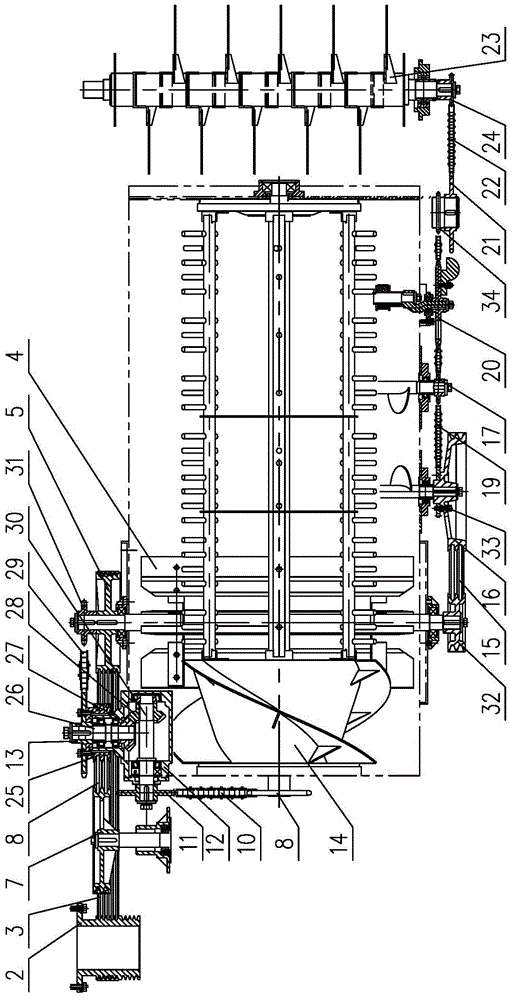

[0018] Such as Figure 1~2 As shown, the present invention mainly comprises engine 1, fan 4, transmission case 12, drum 14, vibrating screen 18, primary auger, secondary auger and grass cutter 23, and engine 1 drives engine 1 rear end by engine pulley mechanism Fan 4 rotates.

[0019] Described engine pulley mechanism comprises engine pulley 2, engine V-belt 3 and first fan pulley 5, the output end of engine 1 is provided with engine pulley 2, and the rotating shaft side of fan 4 is provided with first fan pulley 5 , the engine pulley 2 is connected through the engine V-belt 3 to drive the first fan pulley 5 to rotate.

[0020] The transmission box 12 is provided with a driving shaft 26 and a driven shaft 30, the inner end of the driving shaft 26 is connected with a driving bevel gear 27, and the driven shaft 30 is provided with a driven bevel gear 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com