Stamping production line for small-volume auto parts and method for processing parts using the production line

A technology for auto parts and production lines, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as the inability of the manipulator to grasp smoothly, the low grasping efficiency of the manipulator, and the insufficient stacking height. The effect of small space, work efficiency and work accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

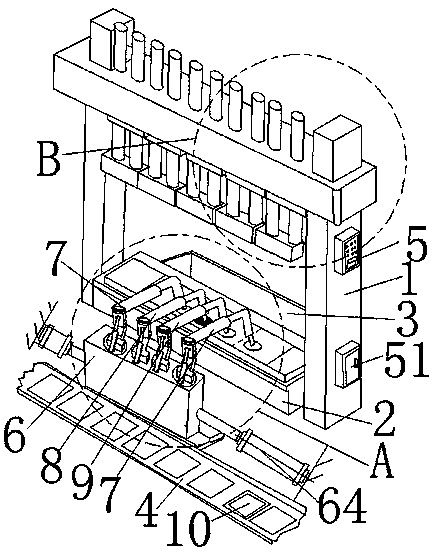

[0049] Example 1. Such as Figure 1-13 As shown, a small-volume auto parts stamping production line is characterized in that: a stamping working system, a grabbing component, a debris holding component, a conveying component, and a control system.

[0050] The stamping work system includes a frame 1, a stamping work platform 2 is arranged below the frame 1, and a number of stamping production lower molds 21 adapted to different stamping processes are arranged horizontally on the stamping work platform 2, and each stamping on each frame 1 Right above the lower mold 21 for production is provided with an upper mold 22 for stamping production corresponding to its stamping production process, and each upper mold 22 for stamping production is connected to the frame 1 through a vertical motion drive device 23 .

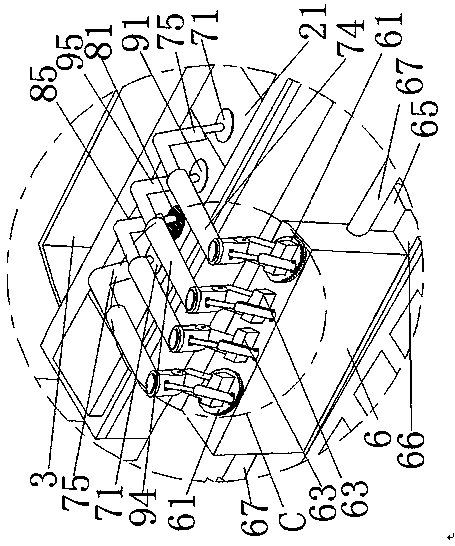

[0051] The grasping assembly includes a manipulator mounting base 6 arranged on the front side of the stamping work platform 2, and the manipulator mounting base 6 is insta...

Embodiment 2

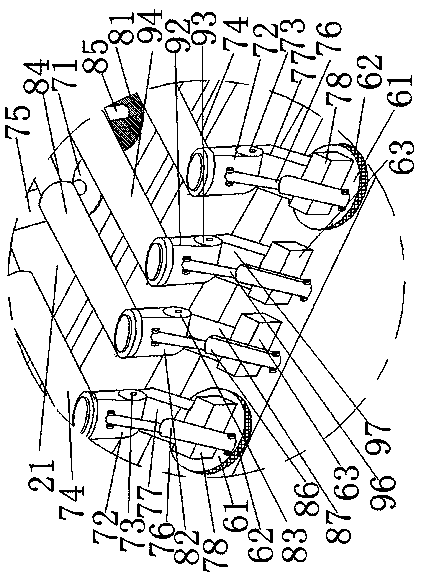

[0066] Example 2, such as Figure 20 , 21 , 17, 18, the difference between this embodiment and embodiment 2 is that: the second auto parts adsorption disc 91, the debris adsorption disc 81, and the first auto parts adsorption disc 71 are vacuum type adsorption discs. Described vacuum suction disc comprises disc body 101, some suction cups 102, vacuum device 103, flexible pipe 104 that are arranged on the bottom surface of disc body 101; Vacuum device 103 comprises vacuum pump 110, vacuum generator 111, vacuum supply electromagnetic valve 105, Vacuum breaking solenoid valve 106, shut-off valve 107, vacuum switch 108, vacuum filter 109, vacuum pump 110, vacuum supply solenoid valve 105, vacuum generator 111, and vacuum filter 109 are connected in series through pipelines; vacuum filter 109 is connected through pipelines They are respectively connected to the suction cups 102 through hoses 104; the vacuum pump 110 is connected to the vacuum breaking solenoid valve 106 through th...

Embodiment 3

[0083] Example 3. Such as Figure 19 As shown, the difference between this embodiment and Embodiment 1 is that the debris storage assembly includes a debris storage box 3 , and the debris storage box 3 is arranged laterally between the stamping work platform 2 and the manipulator mounting base 6 . The progressive automatic stamping parts currently used in the industry can only satisfy flat plate parts, and are not suitable for special-shaped parts, stretched parts, and stamped deformed parts. Because the bottom surface is uneven, it cannot be pushed. The continuous stamping of various parts, and the mixed use of conveyor belts, materials and parts realizes lean production. In this embodiment, small stretched parts can be processed, and complex parts such as oil pans can also be selected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com