Guide rail and ball screw structure for lifting of both cross beam and horizontal boring and milling heads at two sides

A technology of ball screw and shared guide rail, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc. It can solve the problems of damaging the ball screw pair itself, affecting the machining accuracy of the machine tool, jumping and noise, etc., to improve Machining accuracy, avoidance of runout and noise, effect of quantity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

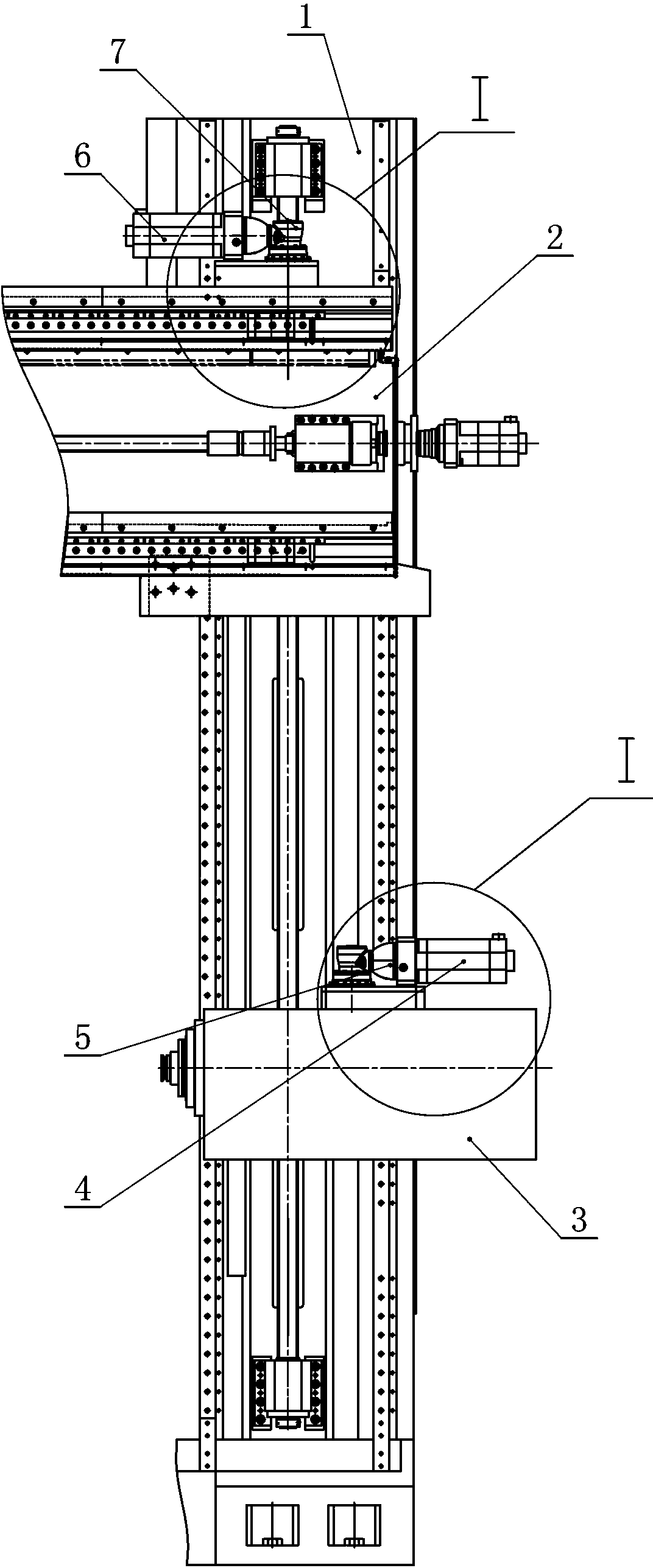

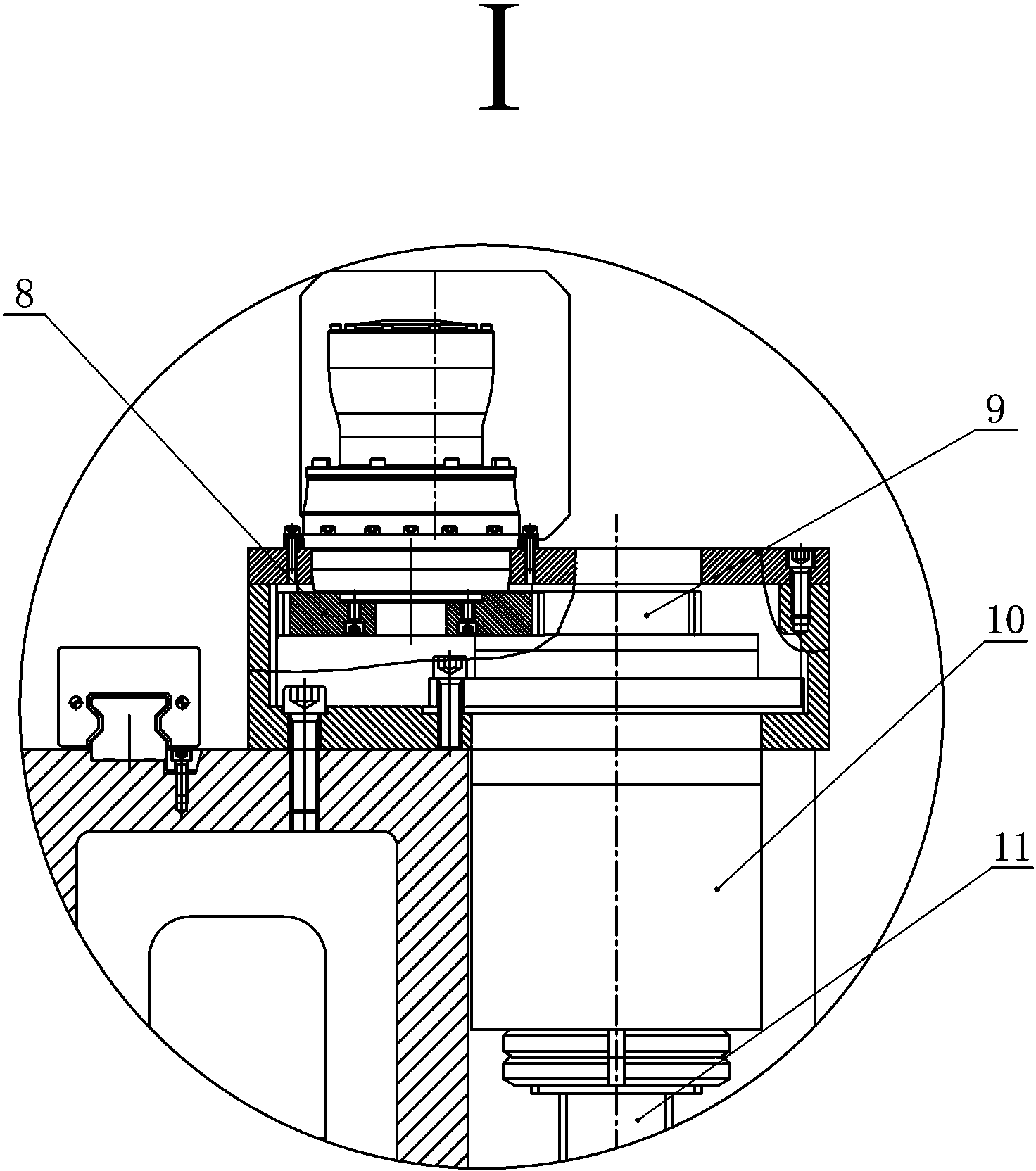

[0011] The present invention as figure 1 , 2 As shown, a beam and a double-sided horizontal boring and milling head lift share a guide rail and a ball screw structure, including a column 1, the left and right sides of the front surface of the column 1 are respectively fixedly connected with line rails, and the line rails slide up and down and connected with line rail sliders. The front surface of the line rail slider is fixedly connected with a crossbeam 2, which is characterized in that: a ball screw 11 is fixedly connected to the column 1, and the upper and lower parts of the ball screw 11 are respectively threaded with a first screw nut 10 and a second screw nut. Both the first wire nut 10 and the second wire nut 10 have a double-layer structure, and the double-layer structures are connected by bearings. The front surface of the first wire nut 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com