Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Increase the marriage rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

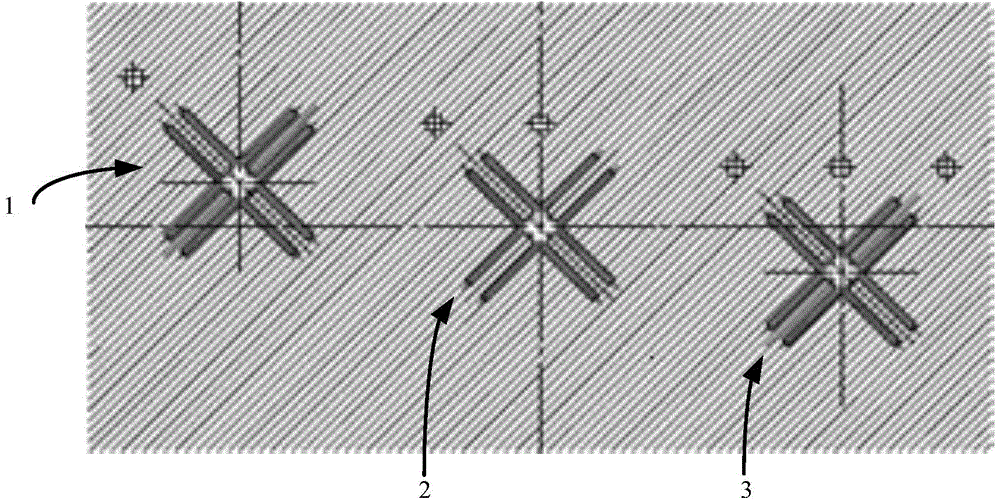

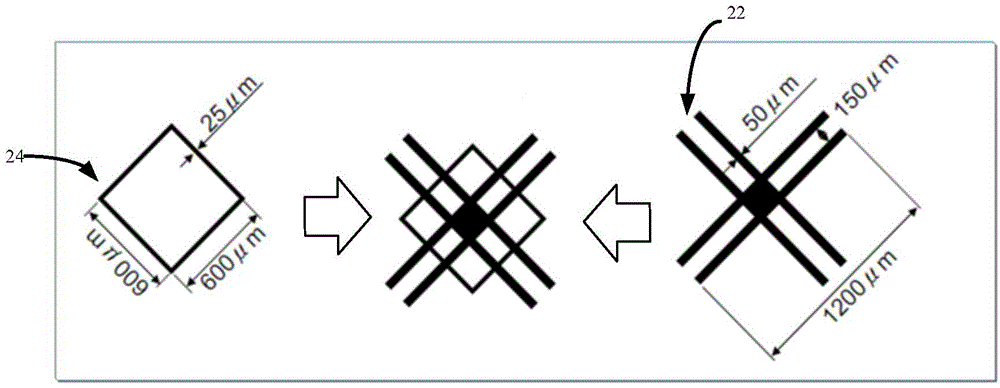

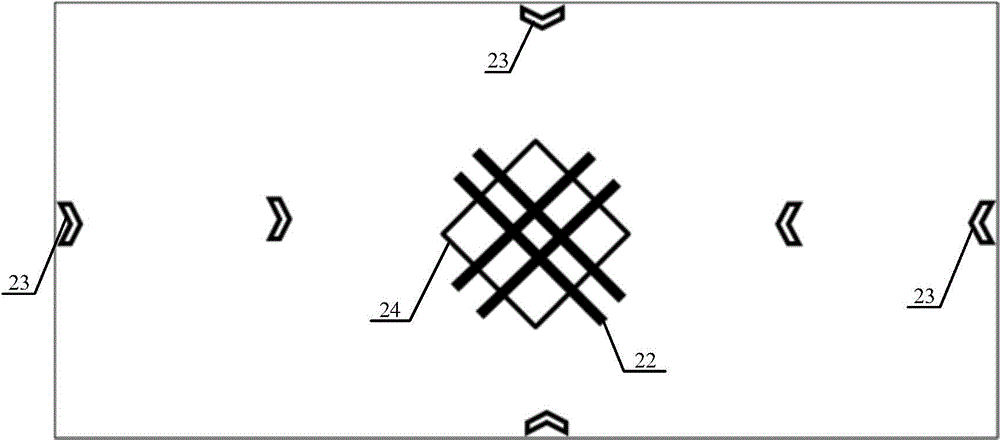

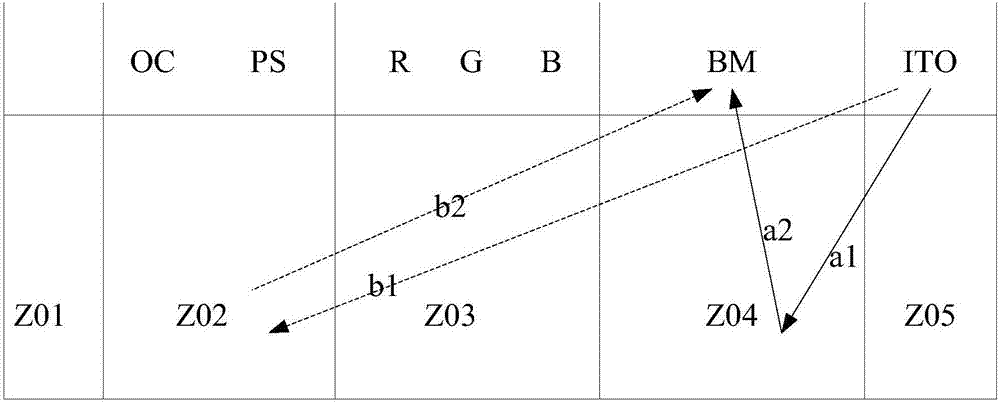

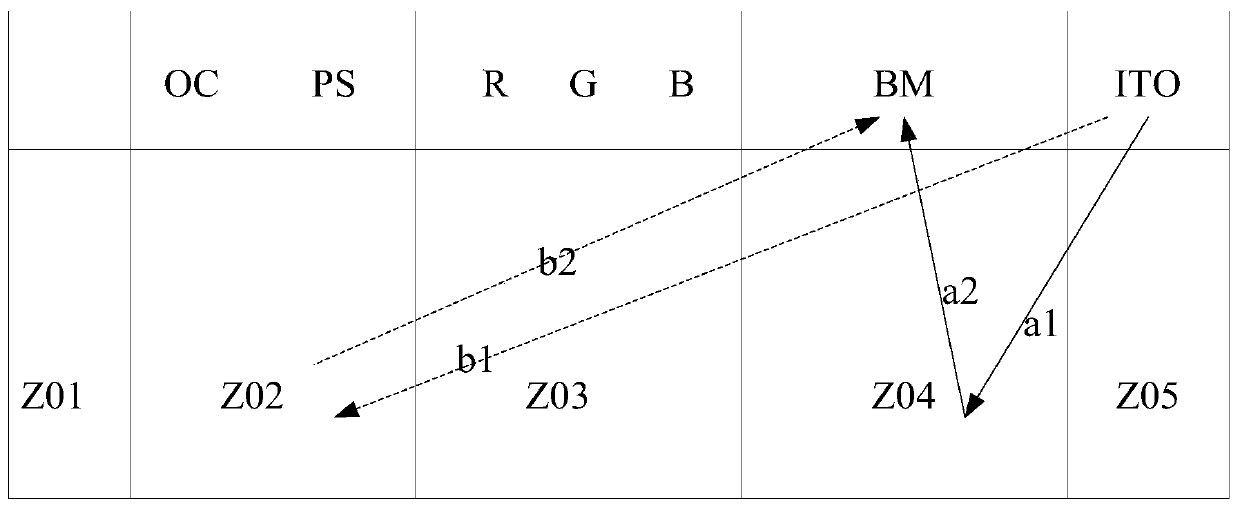

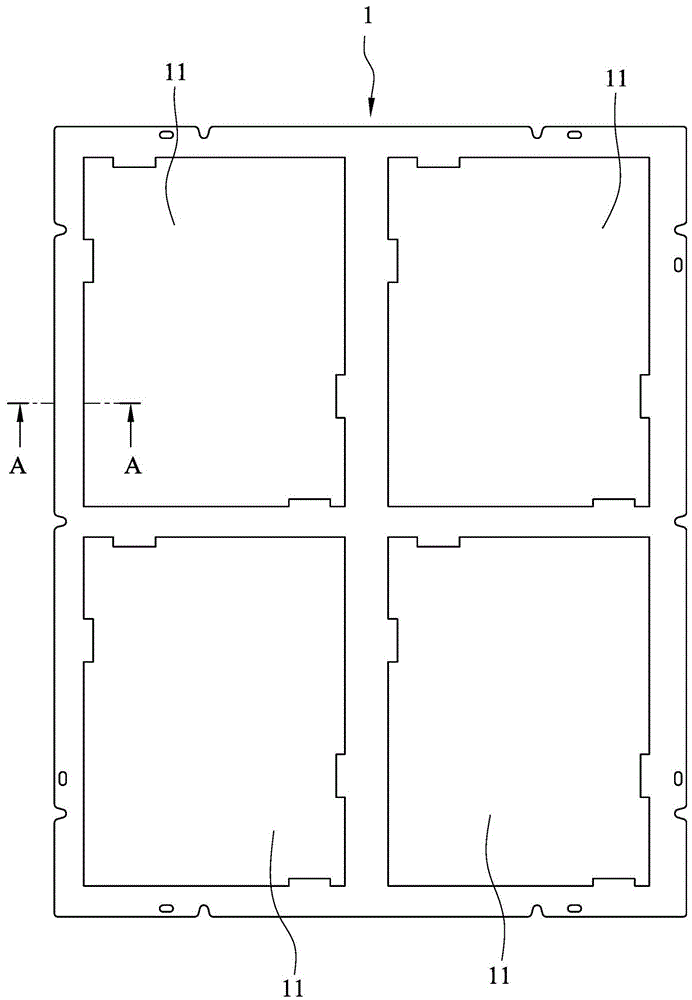

Substrate, mask plate, display device and alignment method

InactiveCN104808434AReduce error rateAvoid confusionOriginals for photomechanical treatmentNon-linear opticsDisplay deviceBiological activation

The invention discloses a substrate, a mask plate, a display device and an alignment method, which relate to the display field, and can be beneficial to reduction of the probability of alignment errors occurring during the working process of a picture composition device, so that the activation of the device is improved. The invention provides the alignment method applicable to utilizing the same mask plate to form a first film layer and a second film layer with same graphs but not coincident on the same substrate. The alignment method comprises the following steps of when manufacturing the first film layer, aligning a first public sign and a second public sign to finish alignment of the mask plate and the substrate, wherein the first public sign is arranged on the substrate, and the second public sign is arranged on the mask plate and corresponds to the first public sign; when manufacturing the second film layer, firstly aligning the first public sign and the second public sign, then utilizing a deviation supplement and correct function of the picture composition device to realize graph deviation of the second film layer and the first film layer, and finishing alignment of the mask plate and the substrate. The invention is used for improving the design of alignment signs on the substrate.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

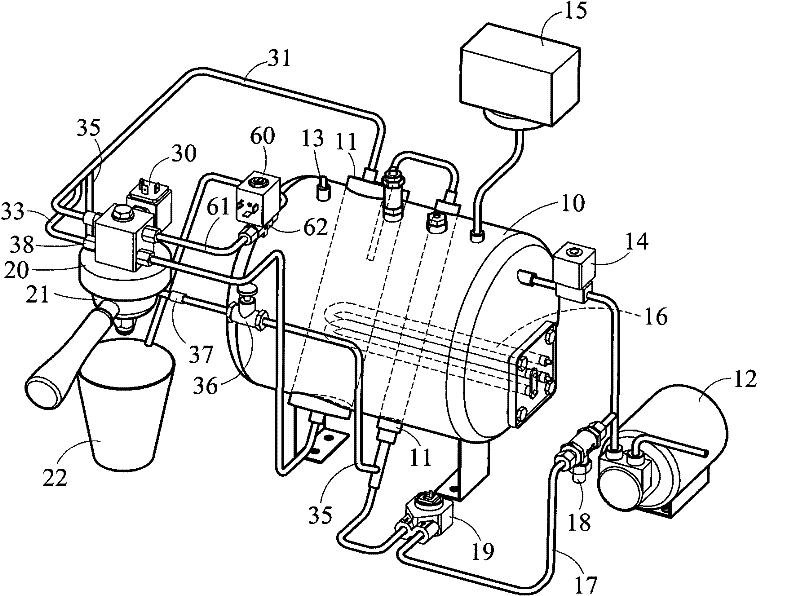

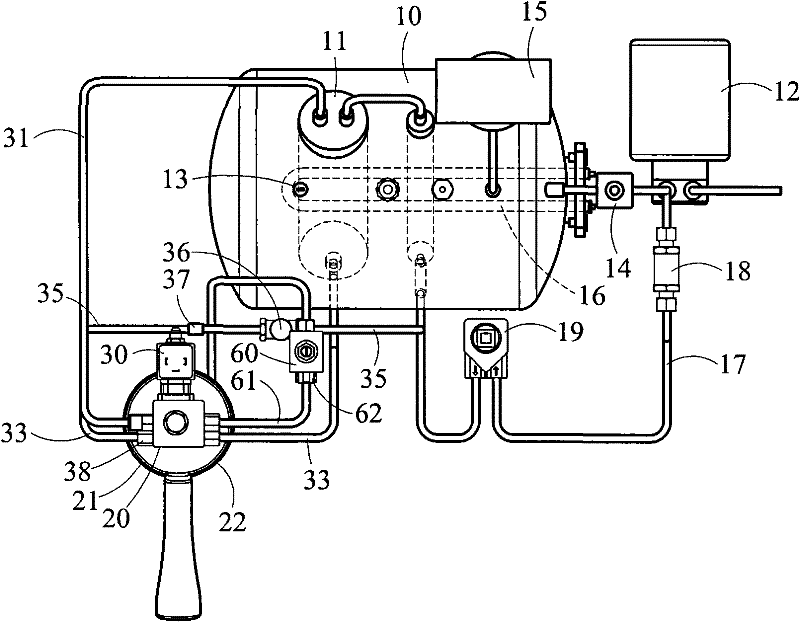

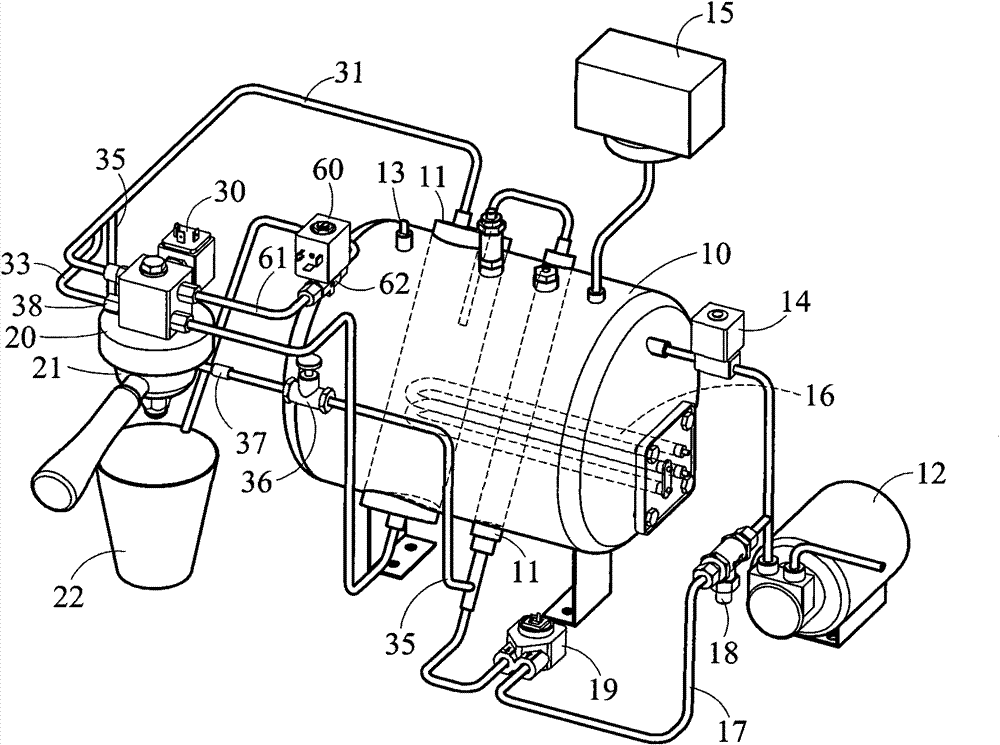

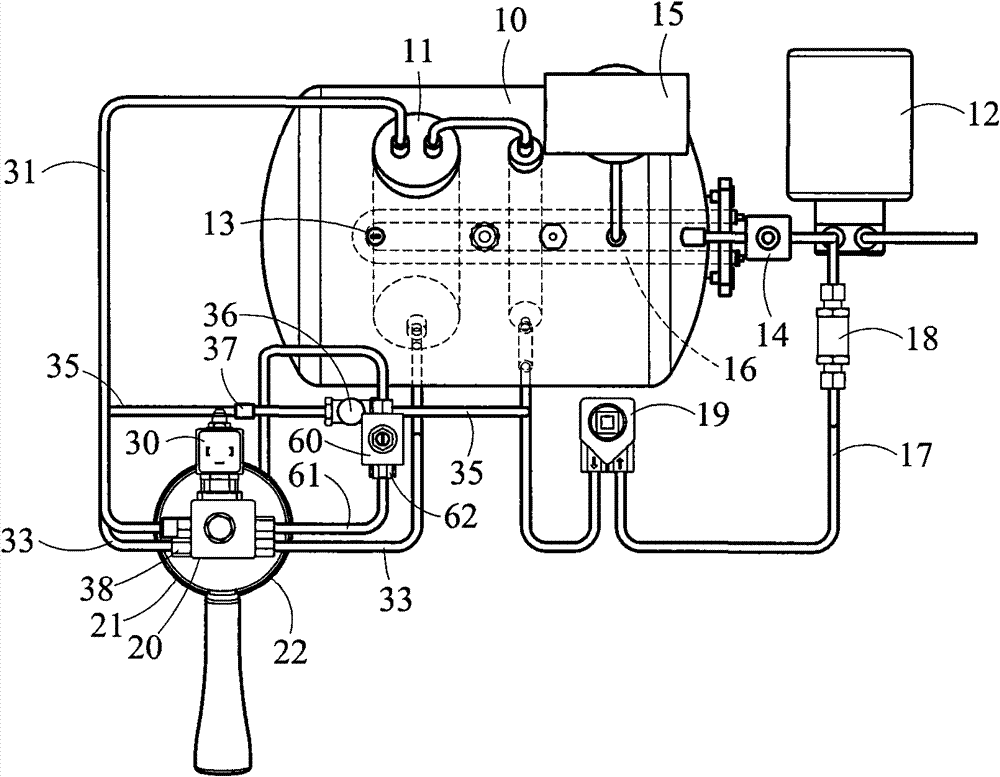

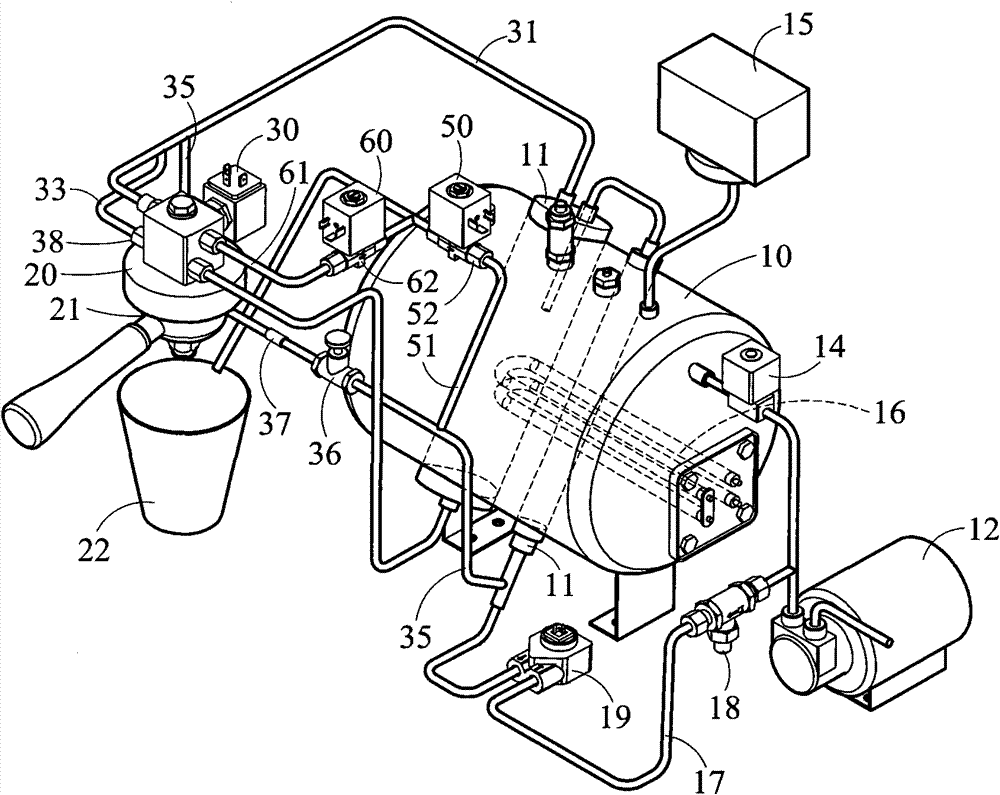

Drink preparation device

The invention discloses a drink preparation device, belonging to the field of machinery. The drink preparation device is mainly used for blending overheated hot water in a hot water pipe with cold water of a set flow rate in a cold water pipe to form a blended water flow with suitable temperature, and transmitting the blended water flow into a liquid dispenser. When a brewing solenoid valve is controlled to be opened, the liquid dispenser dispenses the blended water flow with suitable temperature to a preparation container in which drink components are previously provided so as to prepare drink from the drink components; and when the brewing solenoid valve is controlled to be closed, the liquid dispenser dispenses the blended water flow with suitable temperature to a hot water feeding pipe, and the blended water flow with suitable temperature is directly fed into the drink when a hot water feeding solenoid valve is controlled to be opened. When the brewing solenoid valve and the hot water solenoid valve are both closed, the hot water in a heat exchanger volatiles, passes through a preheating circulation line, and returns to a heat exchanger after being preheated by the liquid dispenser so as to form a preheating circulation.

Owner:刘宗熹

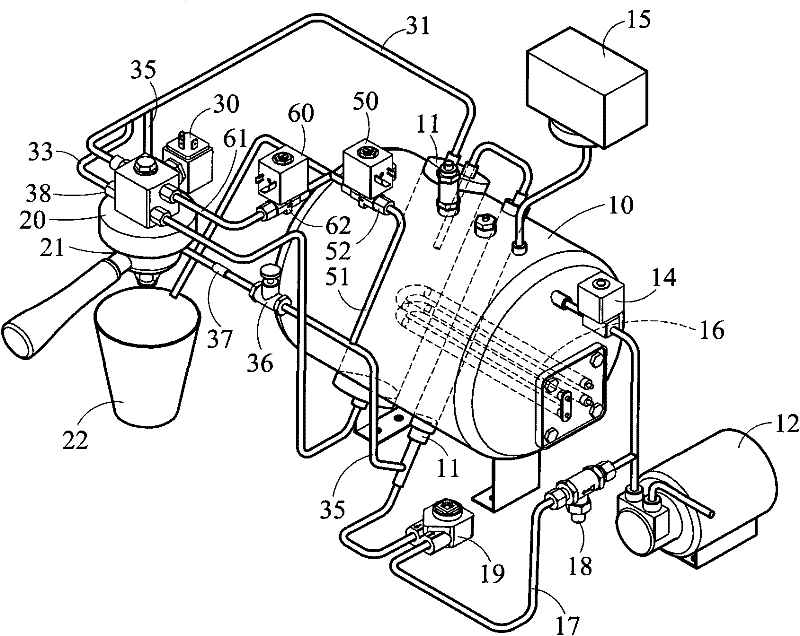

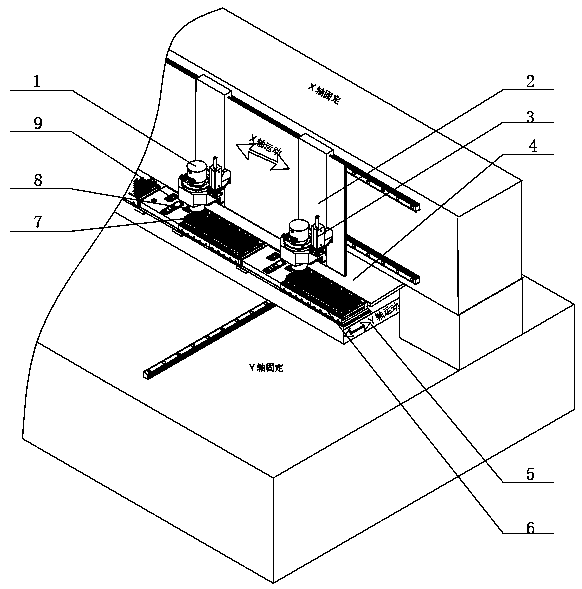

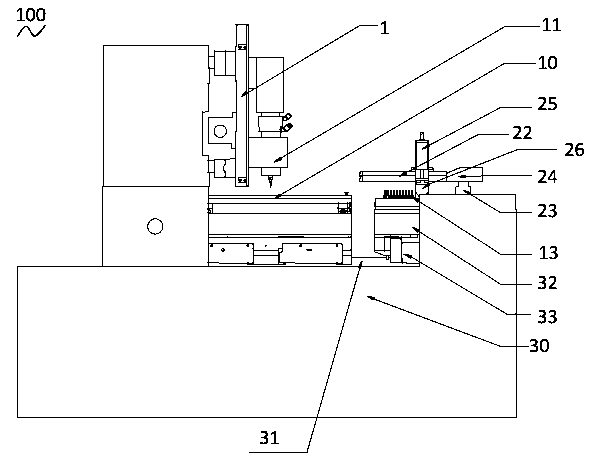

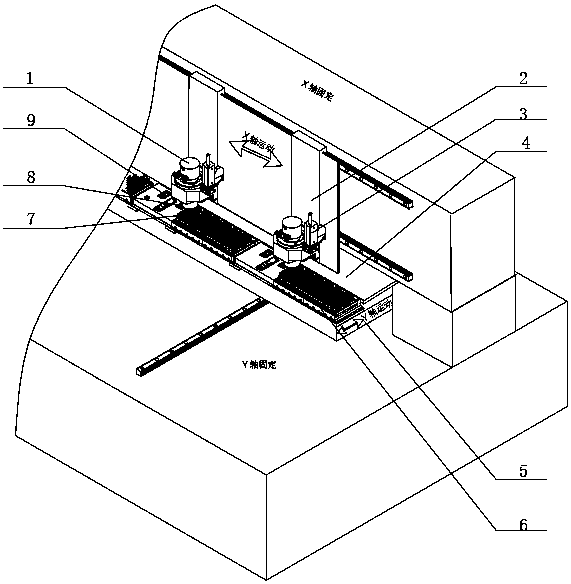

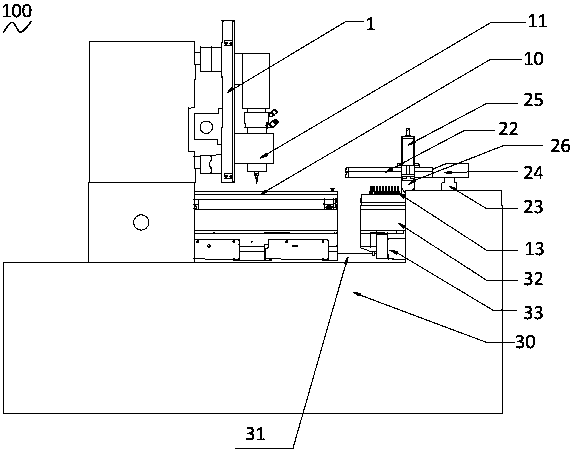

Drilling machine and tool changing method thereof

ActiveCN105500086ASave waiting time for tool changeImprove drilling efficiencyPositioning apparatusMetal-working holdersEngineeringChange positions

The invention provides a drilling machine and a tool changing method thereof. The drilling machine comprises a drilling system and a tool changing system, wherein the drilling system and the tool changing system can simultaneously act independently; the drilling system comprises at least one spindle capable of moving in the up-down direction; the spindles share the tool changing system; the tool changing system comprises a tool magazine device and a manipulator device assembled on the tool magazine device; the tool magazine device comprises tools, a tool pan and a tool apron; the tool pan is used for storing the tools; and the manipulator device comprises a manipulator for capturing and placing the tools. The manipulator captures the tools from the tool pan and places the tools on the tool apron, when tool changing is required for the spindles, the tool changing system is driven by a motor and moves to tool changing positions, and the spindles descend to capture the tools so as to realize tool changing.

Owner:SUZHOU VEGA TECH CO LTD

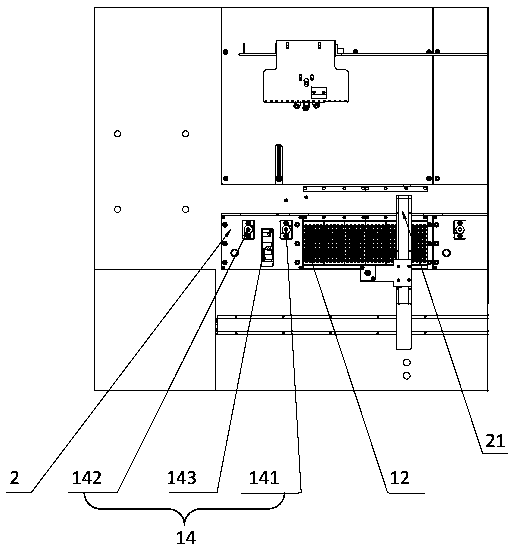

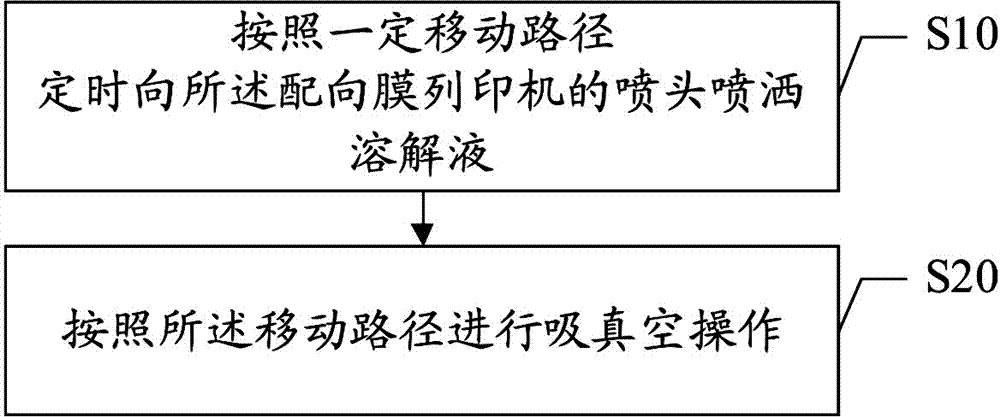

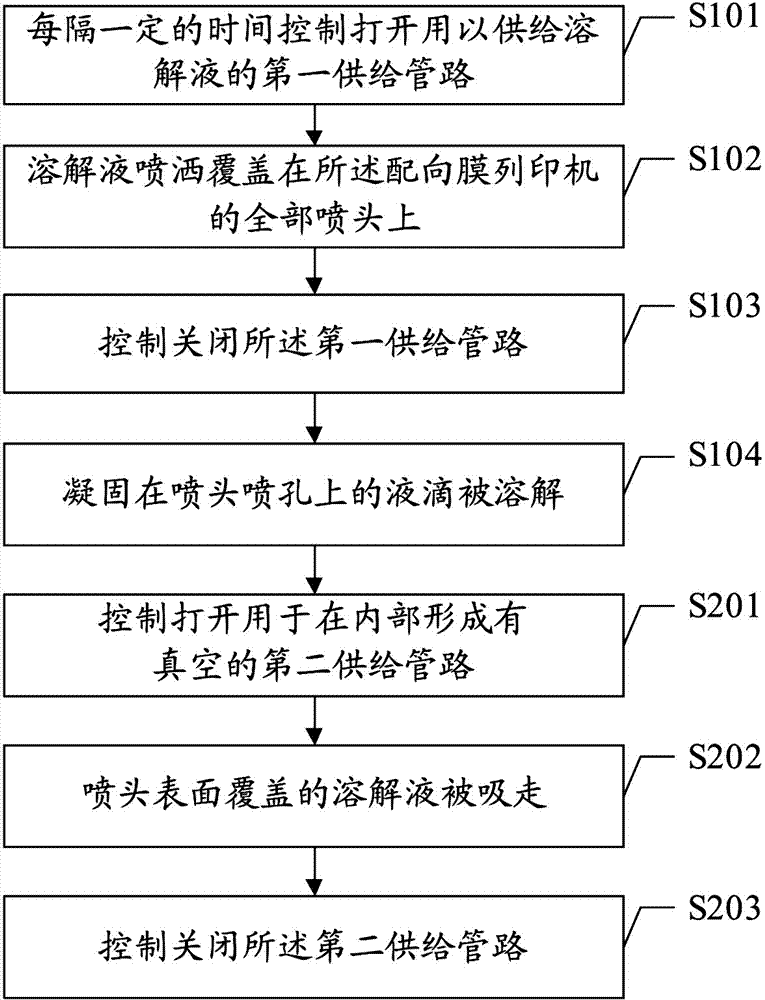

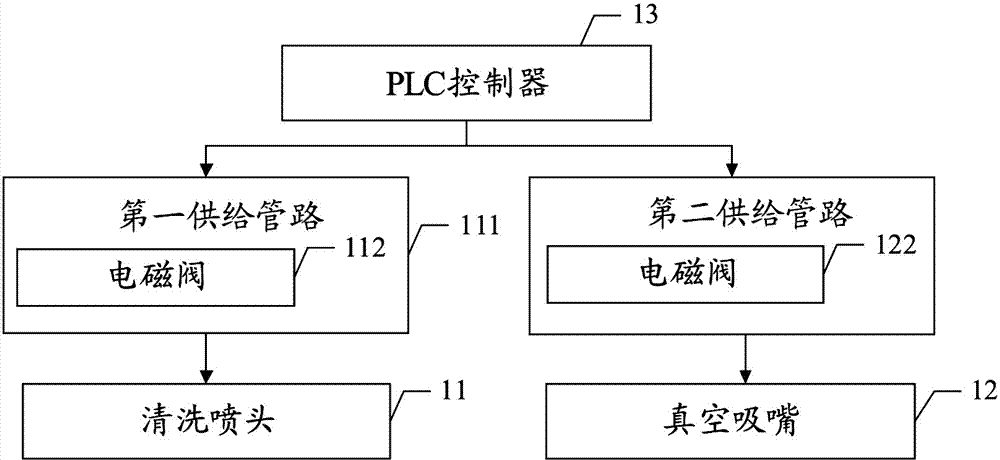

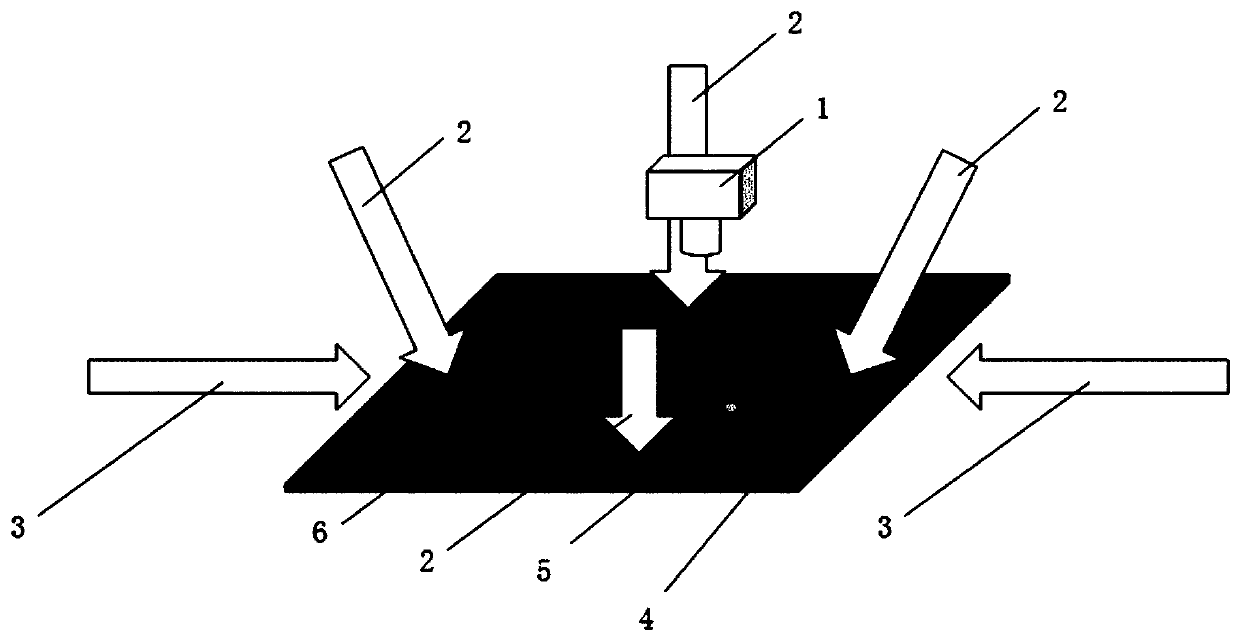

Method and device for cleaning nozzles of alignment film printer

ActiveCN102921663AImprove printing qualityIncrease the marriage rateCleaning using gasesPrintingCleaning methodsEngineering

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

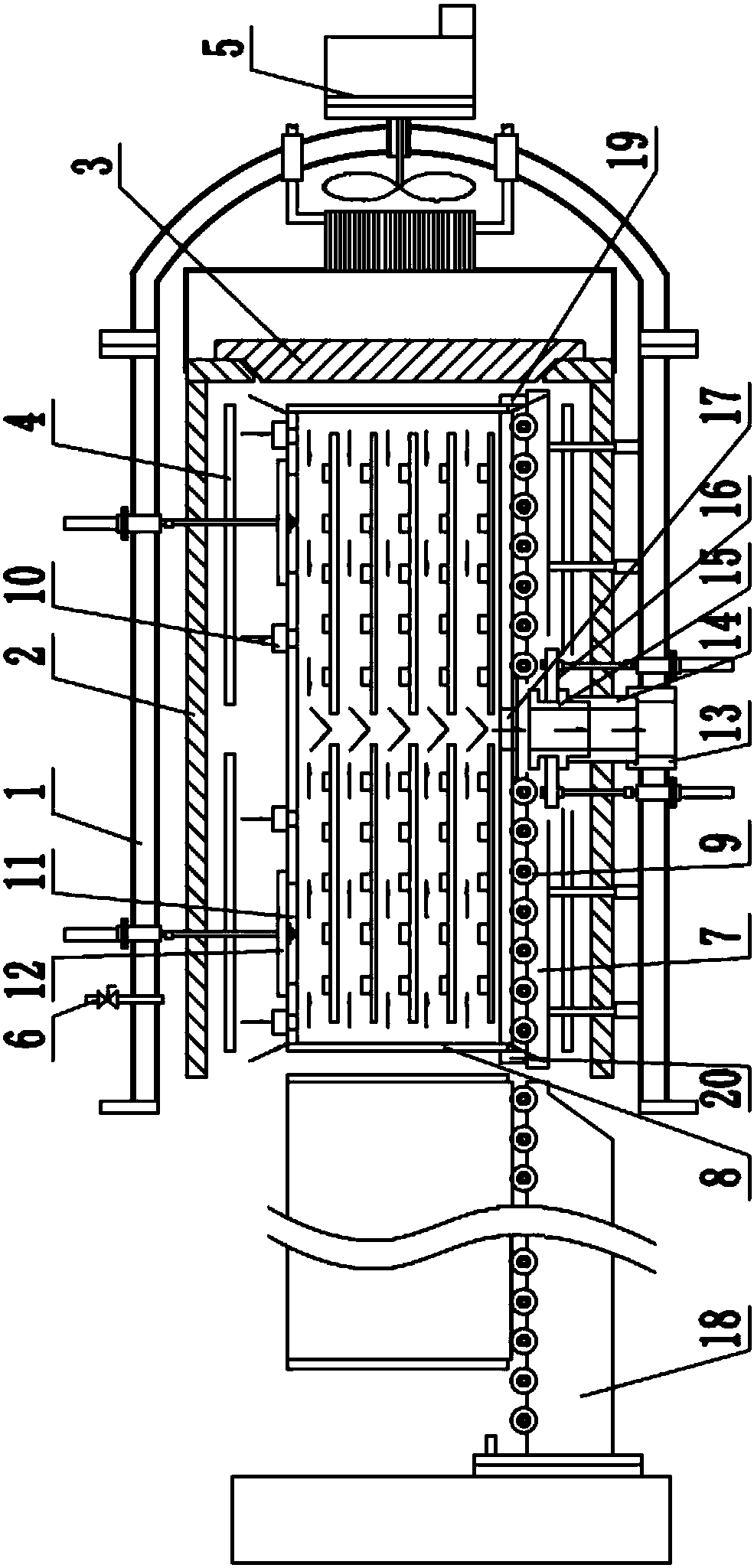

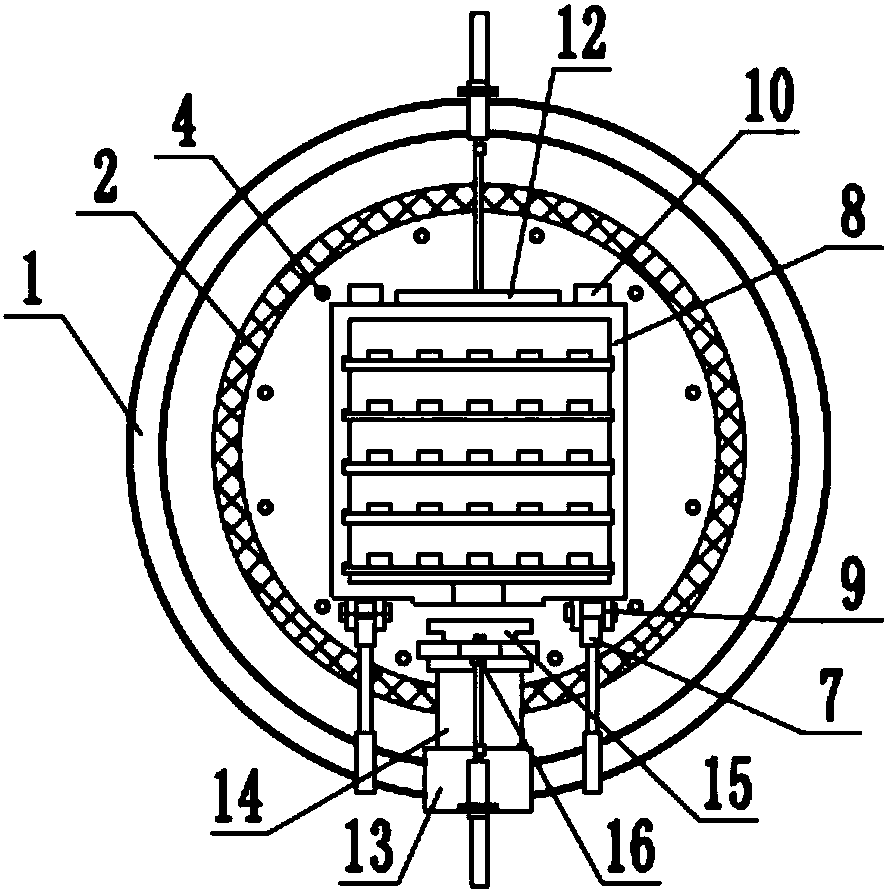

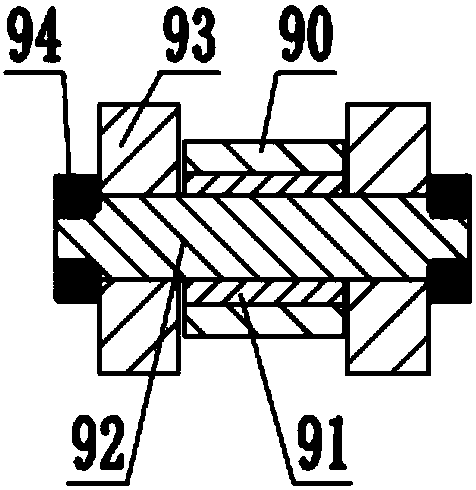

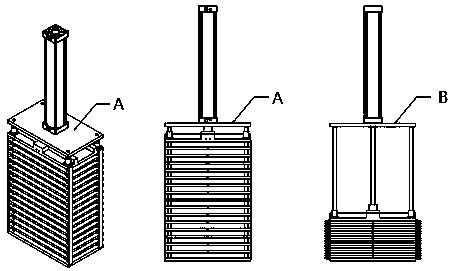

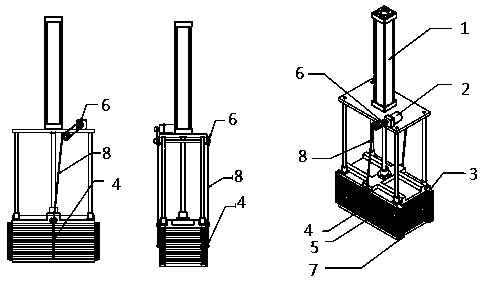

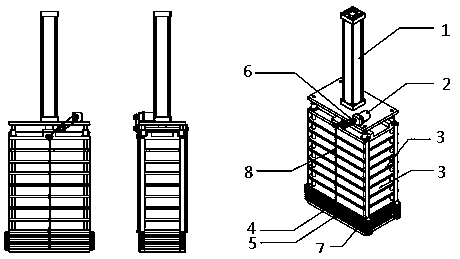

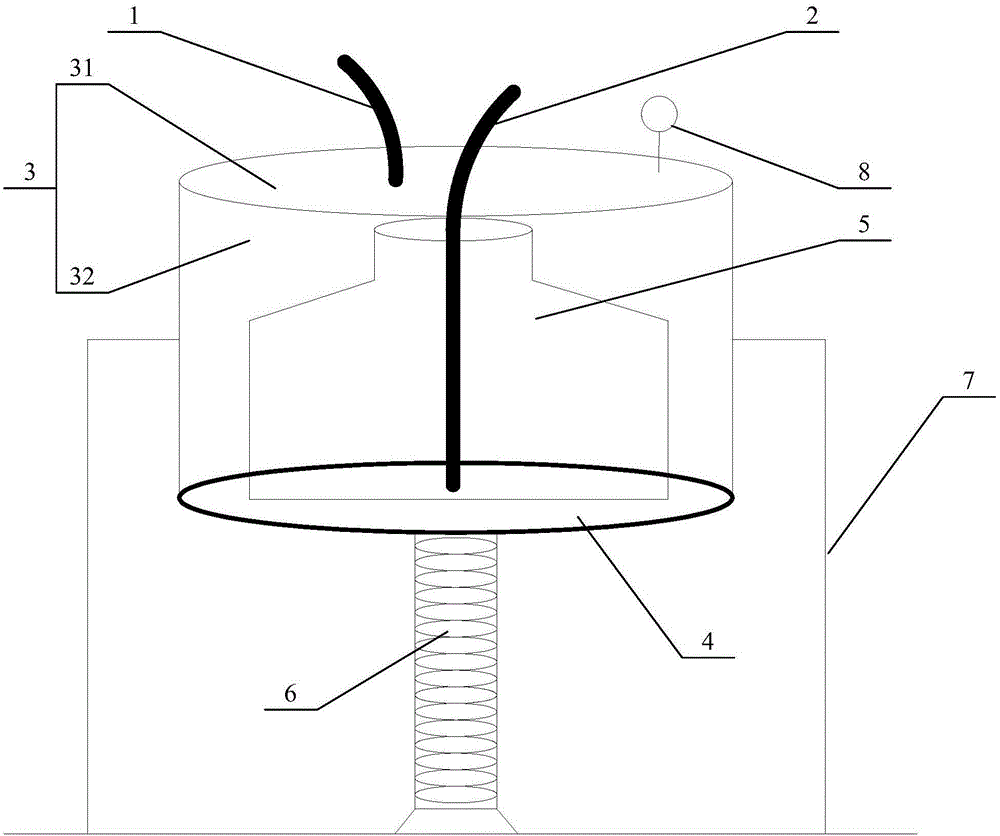

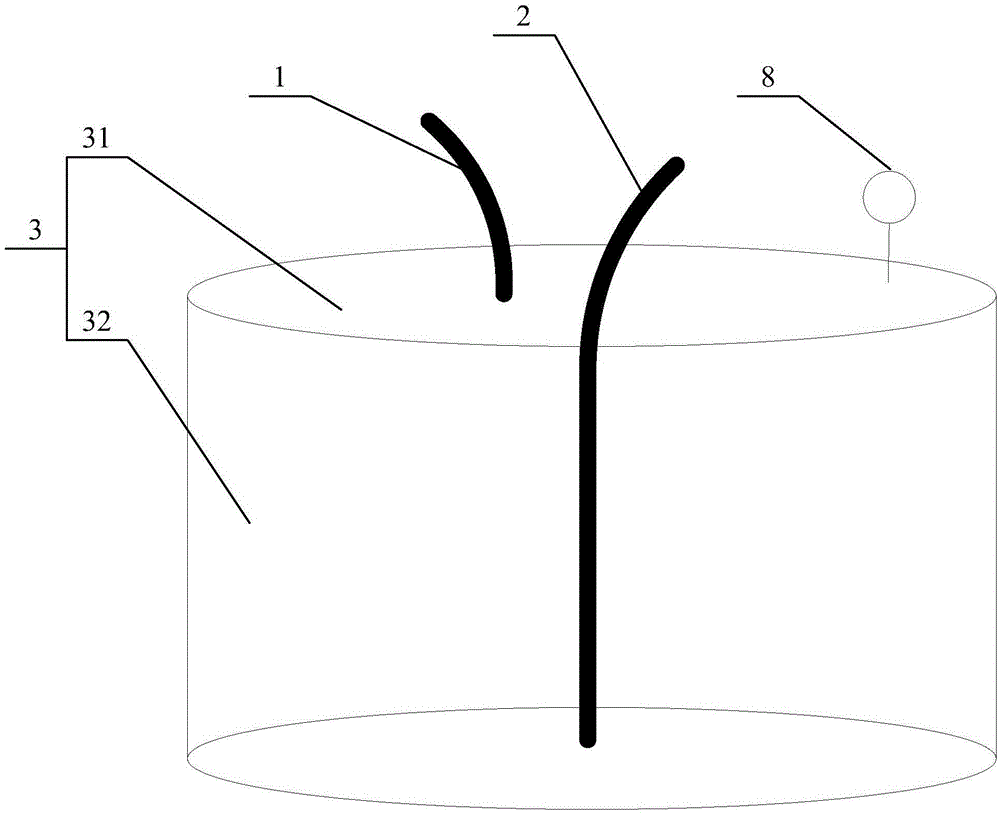

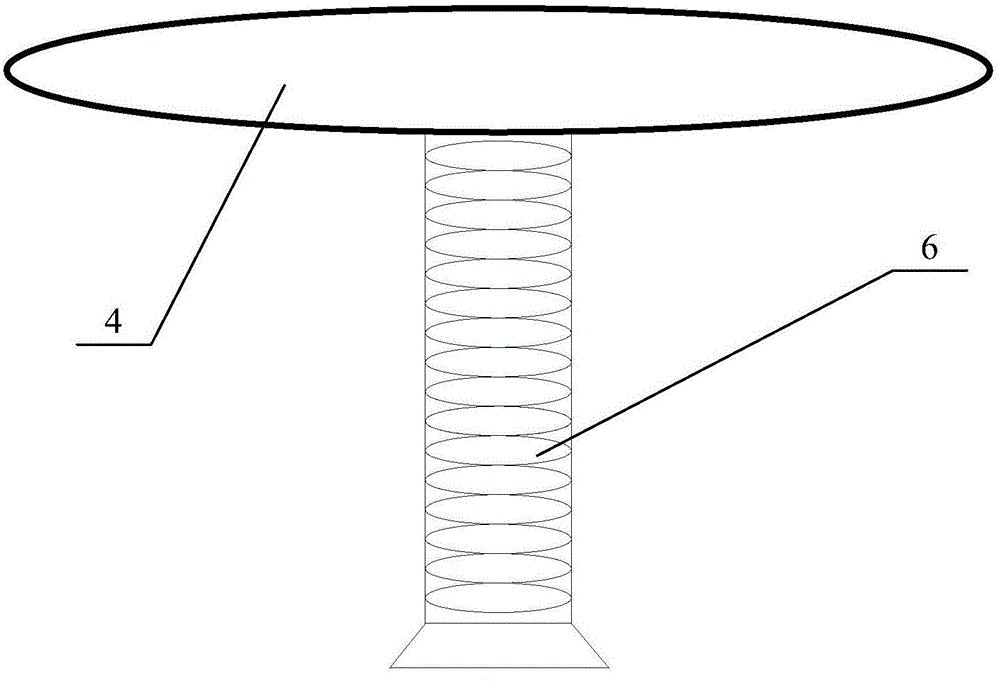

Vacuum degreasing sintering furnace

PendingCN107588662AIncrease the marriage rateIncrease productivityFurnace typesThermal insulationInlet valve

The invention discloses a vacuum degreasing sintering furnace. The furnace comprises a furnace body, and a thermal insulation cylinder and thermal insulation doors which are arranged inside the furnace body, wherein the thermal insulation doors are arranged at the two ends of the thermal insulation cylinder, and a heating body is arranged inside the thermal insulation cylinder; furnace doors are hinged to the two ends of the furnace body, any one of the two furnace doors is provided with a cooling system, a gas inlet pipe is arranged on the furnace body and is communicated with a gas source; the furnace body is connected with a graphite guide rail through a stand column, the graphite guide rail is used for supporting and conveying a work bin and is provided with a plurality of rolling needle bearings, and the work bin can move on the graphite guide rail; a gas inlet valve and a cooling hole are arranged on the work bin, and the cooling hole can be closed by a movable upper cover on thefurnace body; a gas exhaust flange is arranged at the lower part of the furnace body, is communicated with a vacuum pump, and is connected with a lower degreasing pipe and an upper degreasing pipe insequence, and the upper degreasing pipe is driven by a lifting mechanism to move in the lower degreasing pipe and is communicated or separated from a gas discharging hole of the work bin. The vacuumdegreasing sintering furnace has the advantage of high production efficiency.

Owner:NINGBO HIPER VACUUM TECH CO LTD

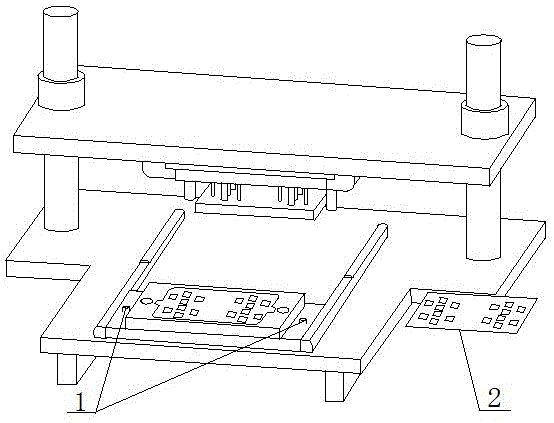

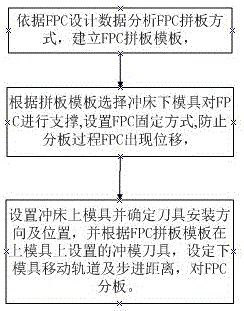

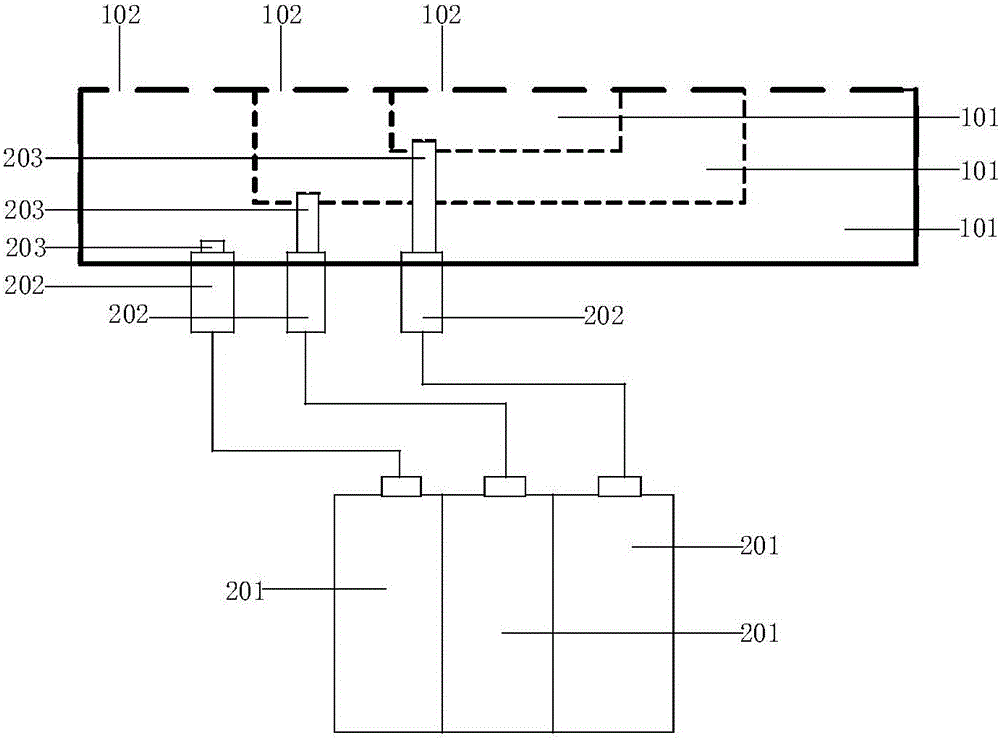

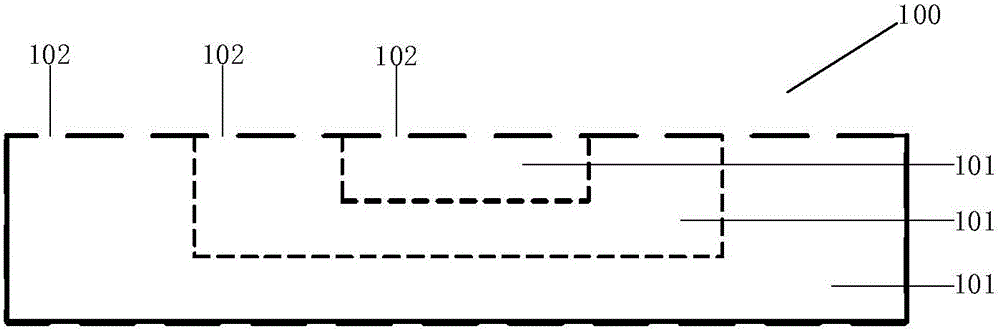

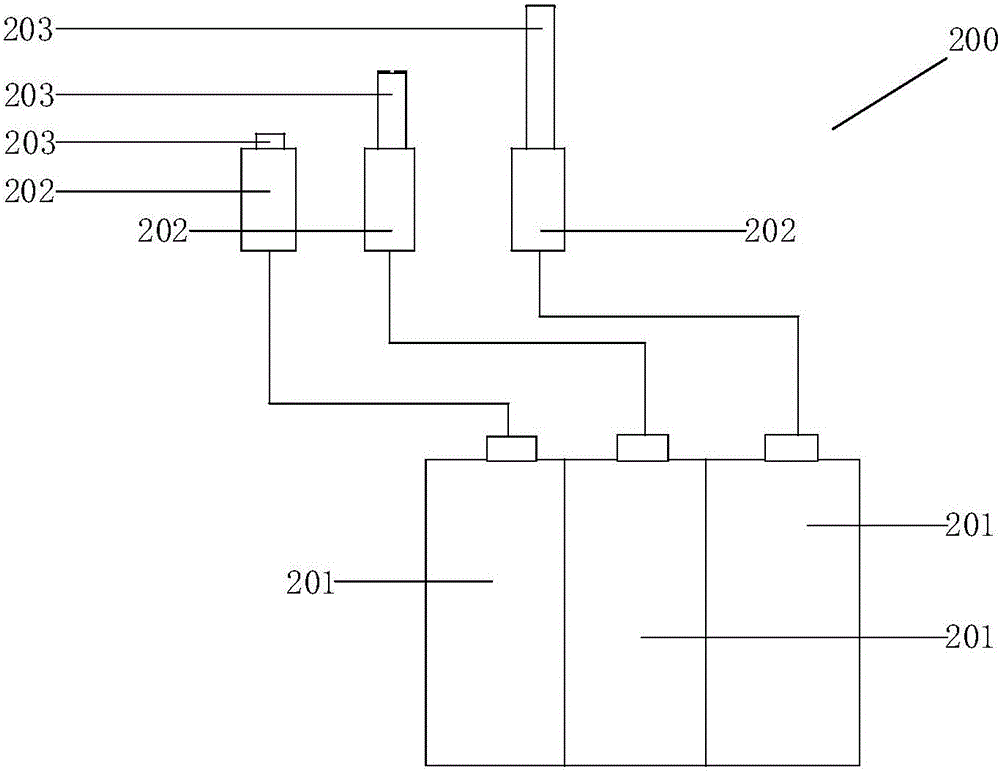

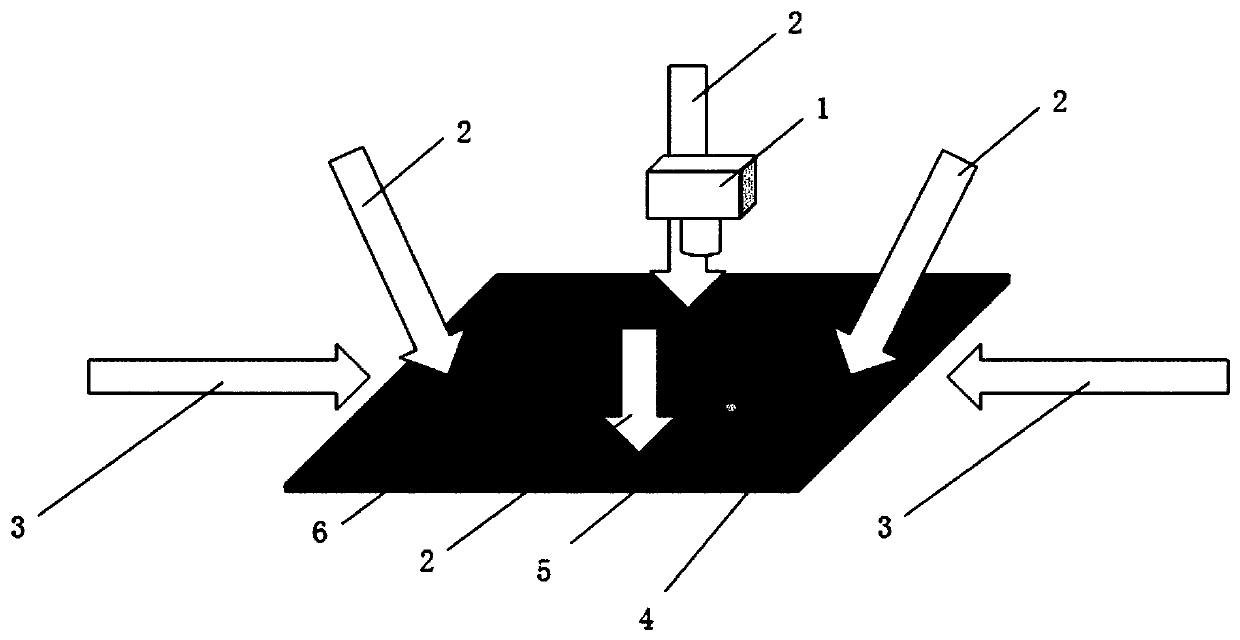

Method for efficient FPC board division

InactiveCN105898992AAvoid displacementIncrease the marriage rateInsulating layers/substrates workingPunch pressEngineering

The invention discloses a method for efficient FPC board division. The method belongs to the technical field of FPC assembly. The method provided by the invention comprises the steps that an FPC board splicing manner is analyzed and an FPC board splicing template is established according to FPC design data; according to the board splicing template, a punching machine lower die is selected for FPC supporting; a FPC fixation manner is disposed; FPC displacement is avoided during the board division; a punching machine upper die is disposed, and an installation direction and an installation position of a cutter are determined; and a moving track and a stepping distance of the lower die are set according to the stamping die cutter which is disposed by the FPC board splicing template on the upper die, so that the FPC board division can be completed.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

False pressure head and operating method thereof

InactiveCN105960106AIncrease productivityReduce throw ratePrinted circuit assemblingElectrical componentsPurchase costEngineering

The invention discloses a false pressure head and an operating method thereof. The false pressure head comprises an adsorption unit and a control unit. The adsorption unit comprises at least two vacuum adsorption structures. Each vacuum adsorption structure comprises an air passage and at least one pore in communication. The control unit is used for controlling the formation of the vacuum environment of each vacuum adsorption structure according to the size of a target object to be adsorbed. The adsorption unit is used for adsorbing the target object to be adsorbed under the control of the control unit. The adsorption functions of the vacuum adsorption structures are regulated according to the sizes of circuit boards so that the false pressure head may adapt to circuit boards in different sizes. As a result, it is not required to replace a tool for false pressure head according to the size of the circuit boards, thereby achieving a universalized purpose, increasing production efficiency, reducing a reject rate of the circuit boards, and decreasing purchase cost.

Owner:BOE TECH GRP CO LTD +1

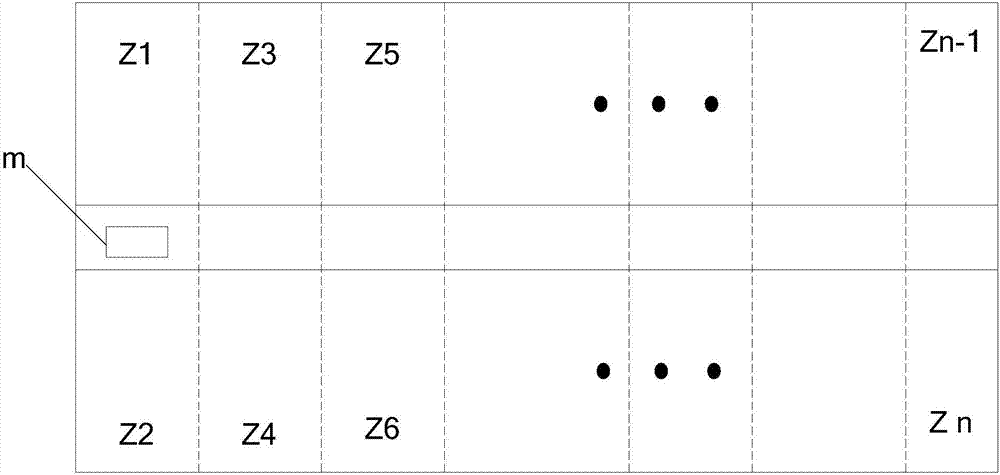

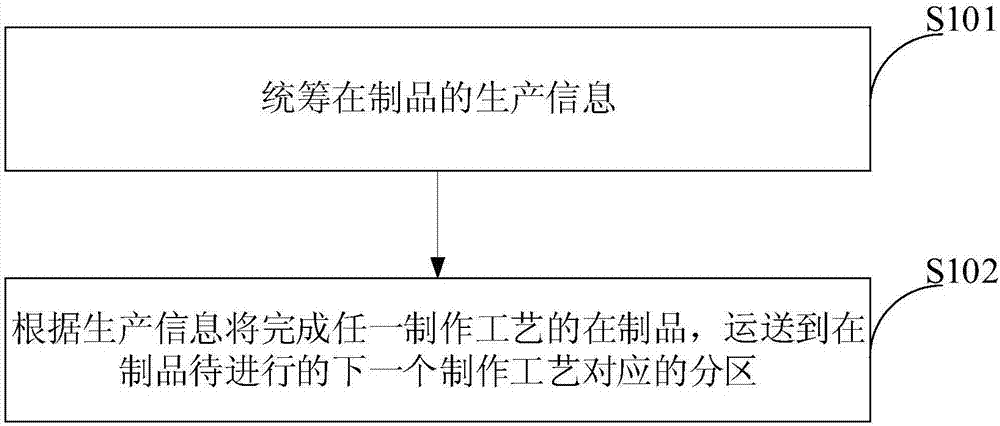

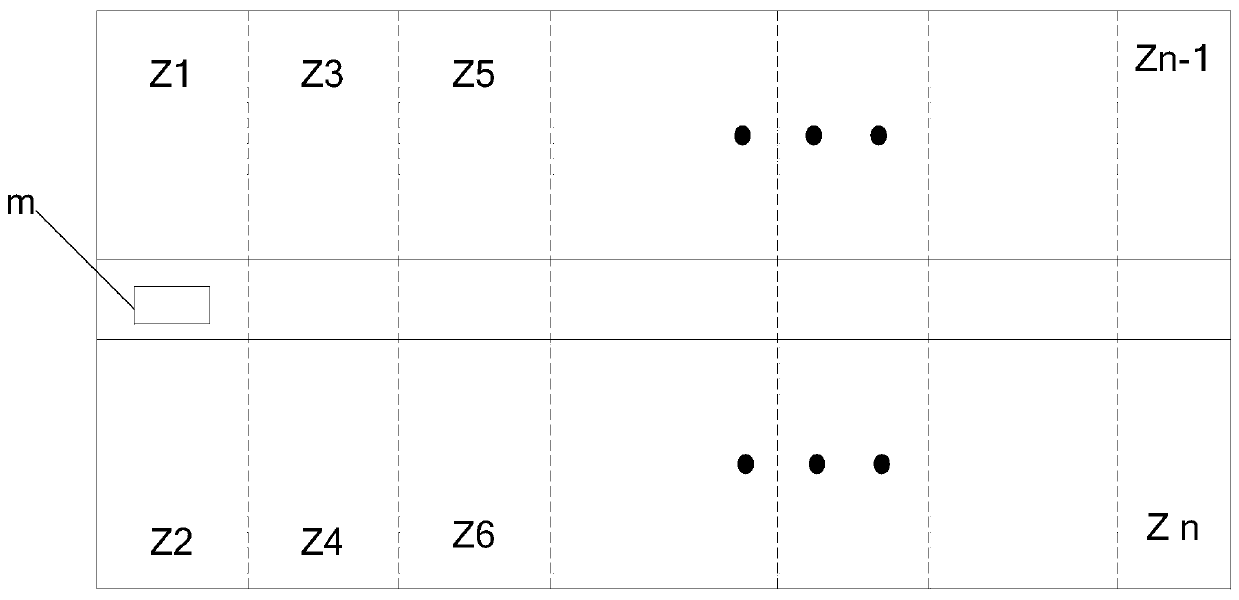

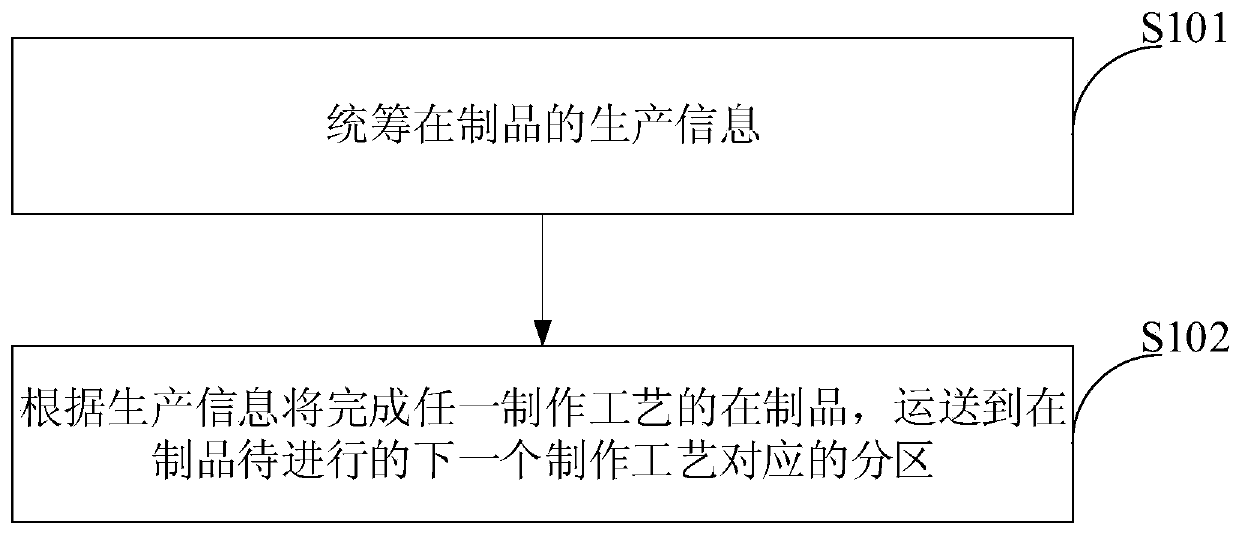

Automatic warehouse system, production line and logistics management method

ActiveCN106976676AImprove handling efficiencyReduce invalidProgramme controlTechnology managementProduction lineManufacturing technology

The invention discloses an automatic warehouse system, a production line and a logistics management method. The automatic warehouse system comprises a plurality of partition areas, a server host, a controlling module and at least one carrying module. Each partition area corresponds to a manufacturing technology of in-making products; the server host is used for overall planning production information of the in-making products and sending the production information to a controlling module; and the controlling module is used for controlling the carrying modules according to the received production information to convey the in-making products subjected to any of the manufacturing technologies to the partition area corresponding to the next manufacturing technology to be conducted on the in-making products. An automatic warehouse is designed in a partitioning mode, each partition area corresponds to one manufacturing technology of the in-making products, the specific positions, inside the automatic warehouse, of the in-making products subjected to each manufacturing technology are designated, and optimal carrying aiming at the next manufacturing technology is achieved, so that invalid and superfluous carrying of the in-making products by the automatic warehouse is reduced, and the carrying efficiency of the automatic warehouse system is improved.

Owner:BOE TECH GRP CO LTD +1

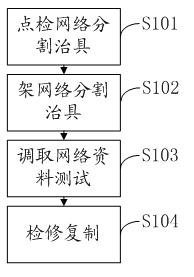

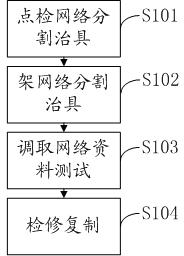

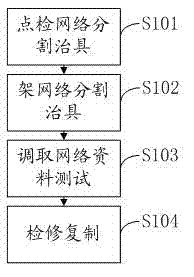

Network partitioning method and network partitioning device of electrical performance testing points of PCB (printed circuit board)

ActiveCN102680850AReduce test densityIncrease the marriage rateElectrical testingTest efficiencyManagement efficiency

The invention discloses a network partitioning method and a network partitioning device of electrical performance testing points of a PCB (printed circuit board). The method comprises the following steps: partitioning initial testing points on the PCB in terms of network forms, testing points or network; and reserving a plurality of testing points for electrical performance test after partitioning. With the adoption of the network partitioning method and the network partitioning device, the electrical performance testing efficiency of the PCB is improved; the testing cost is reduced; furthermore the network partitioning method and the network partitioning device are not limited by the products and the testing machine tools; the test is more convenient and rapid; the production capacity is increased greatly; and the activation of the testing machine tool is improved. With the network partitioning method and the network partitioning device, the problem that the selection of the testing instruments and testing machine tools is limited because the PCB product is light, thick, short and small and dense in circuits and pores is solved; and the testing production capacity and the management efficiency of the PCB are improved.

Owner:PALWONN ELECTRONICS SUZHOU CO LTD

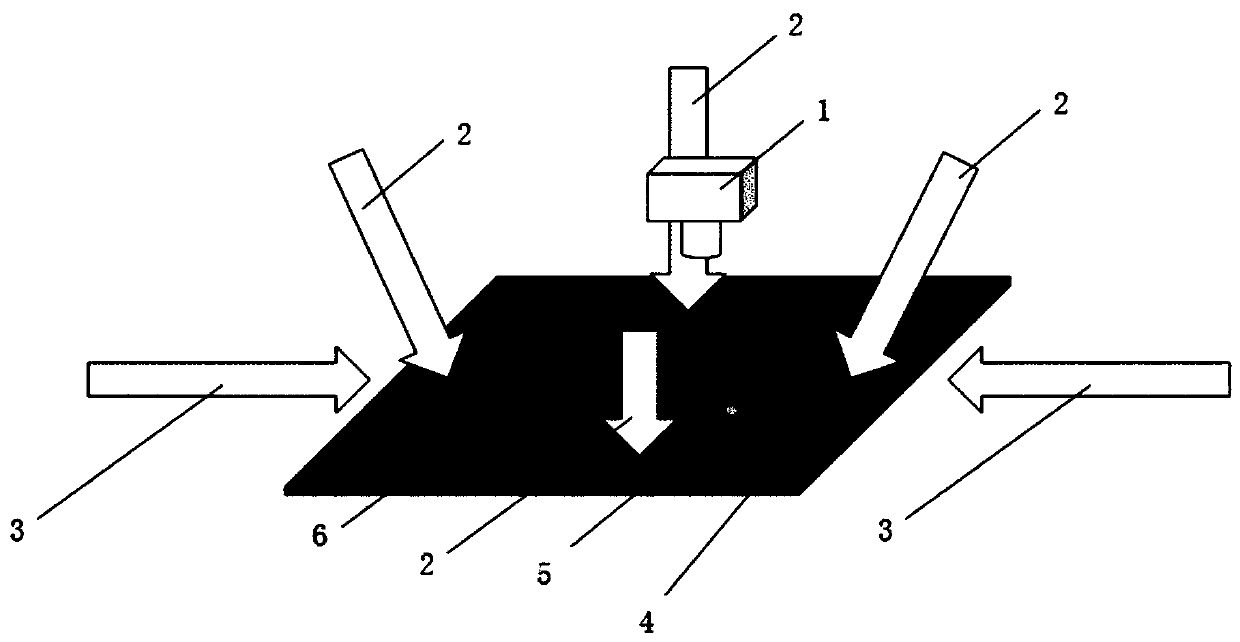

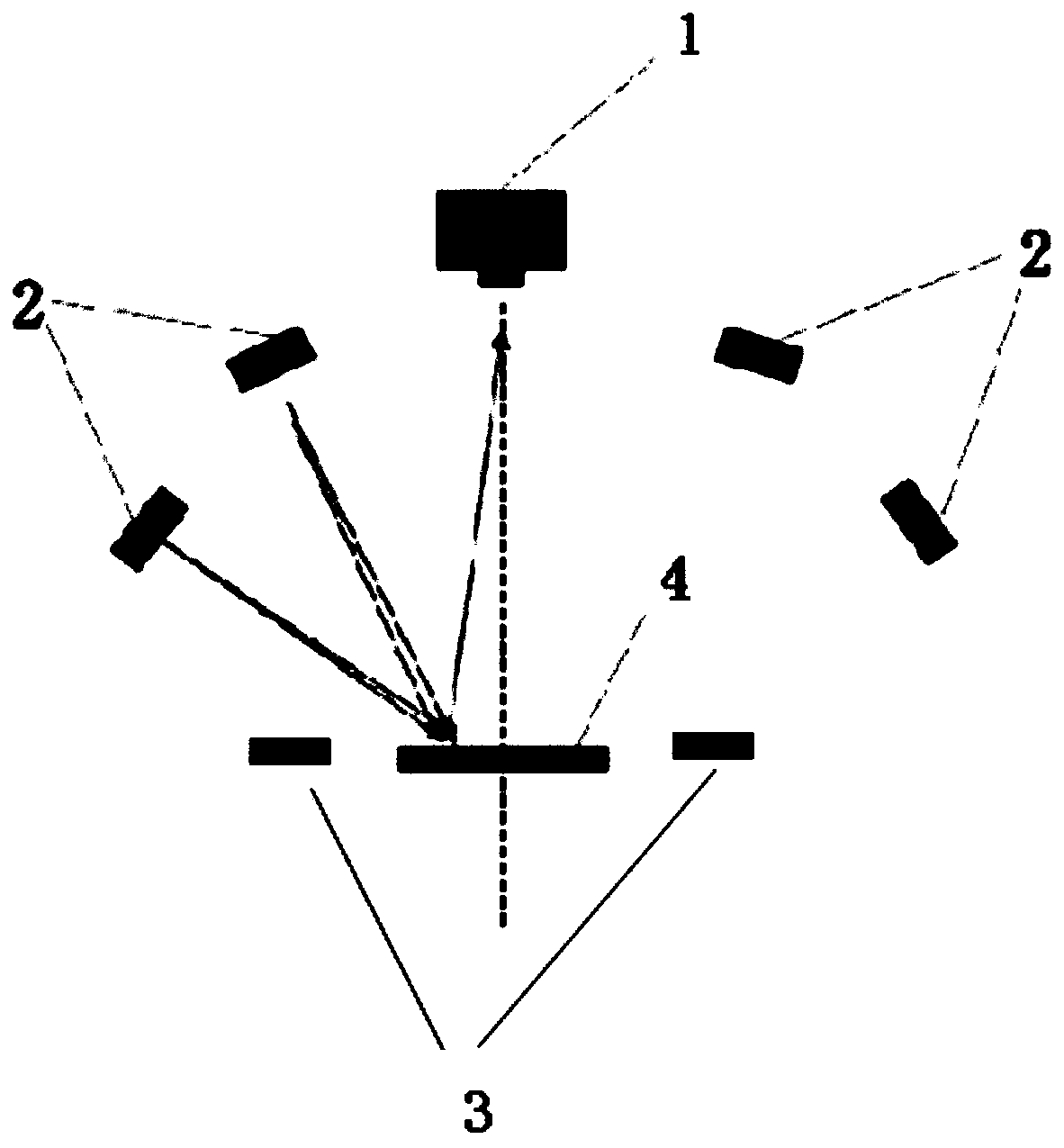

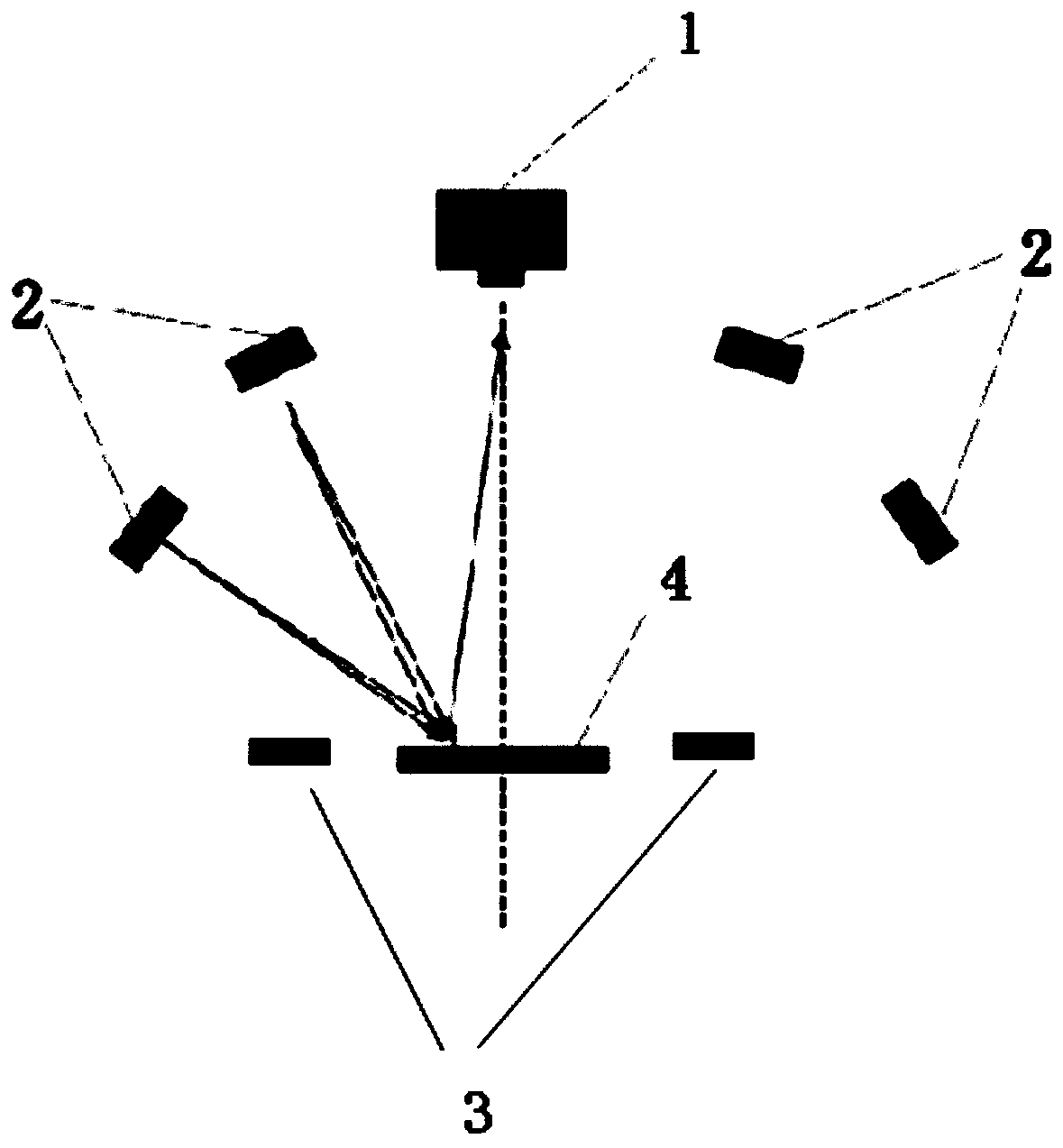

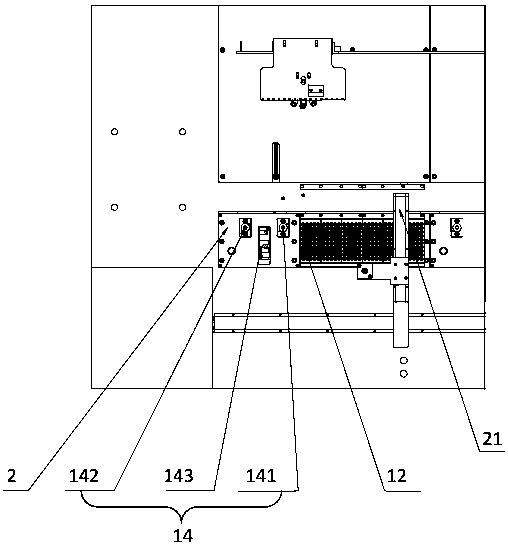

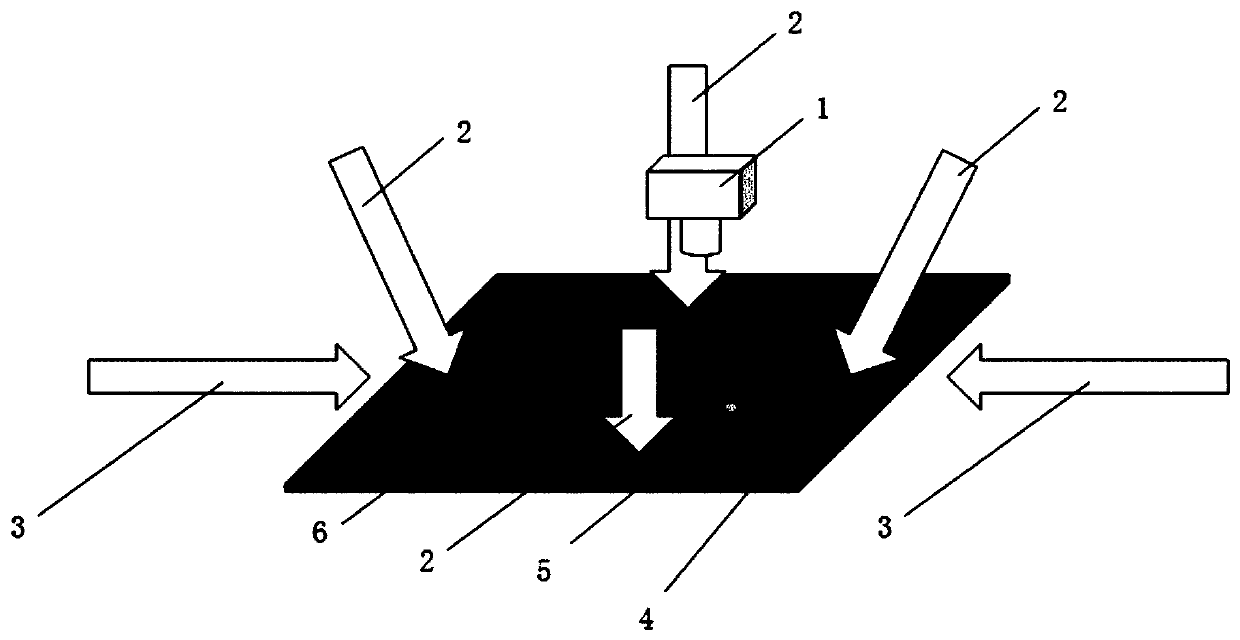

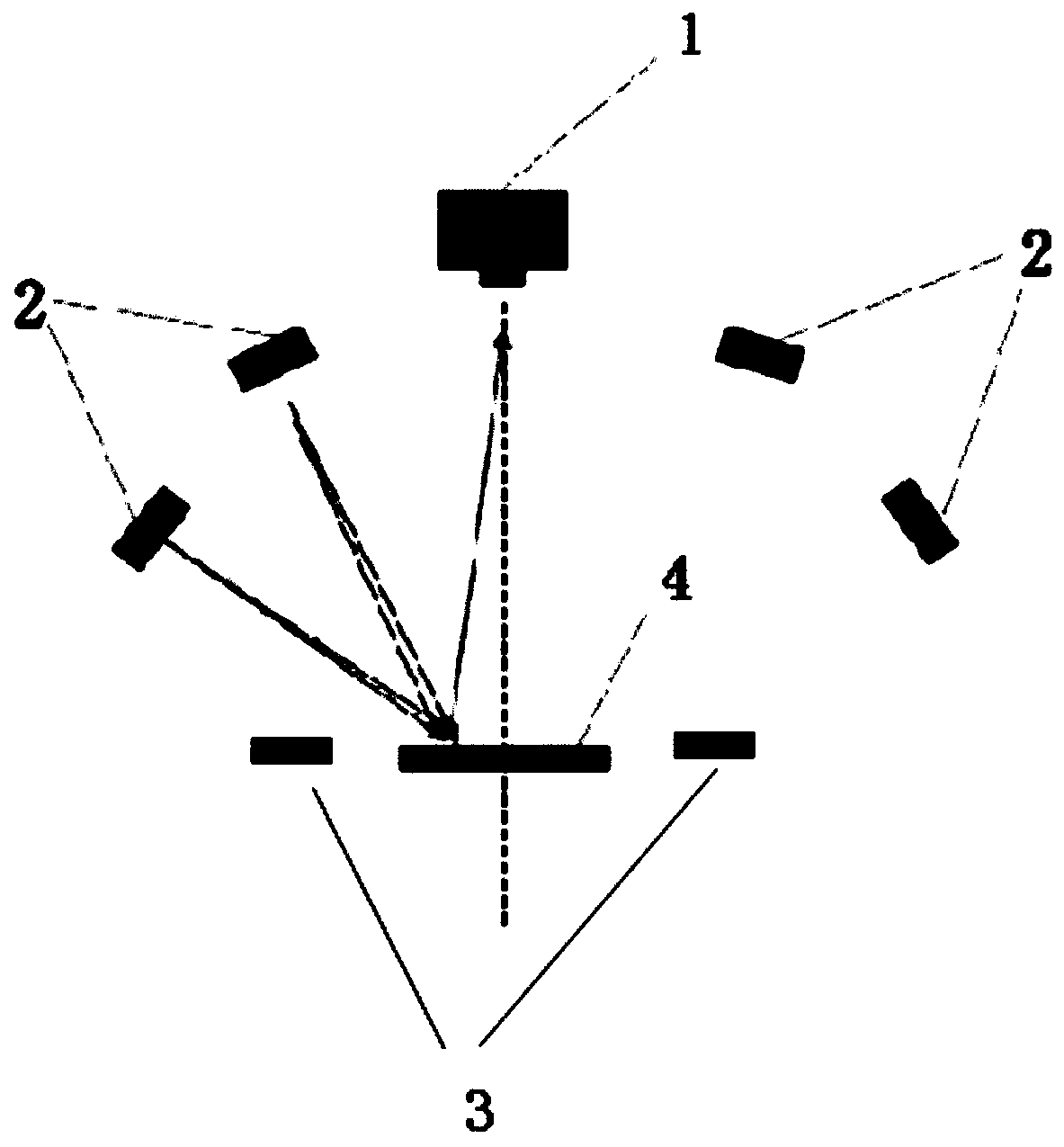

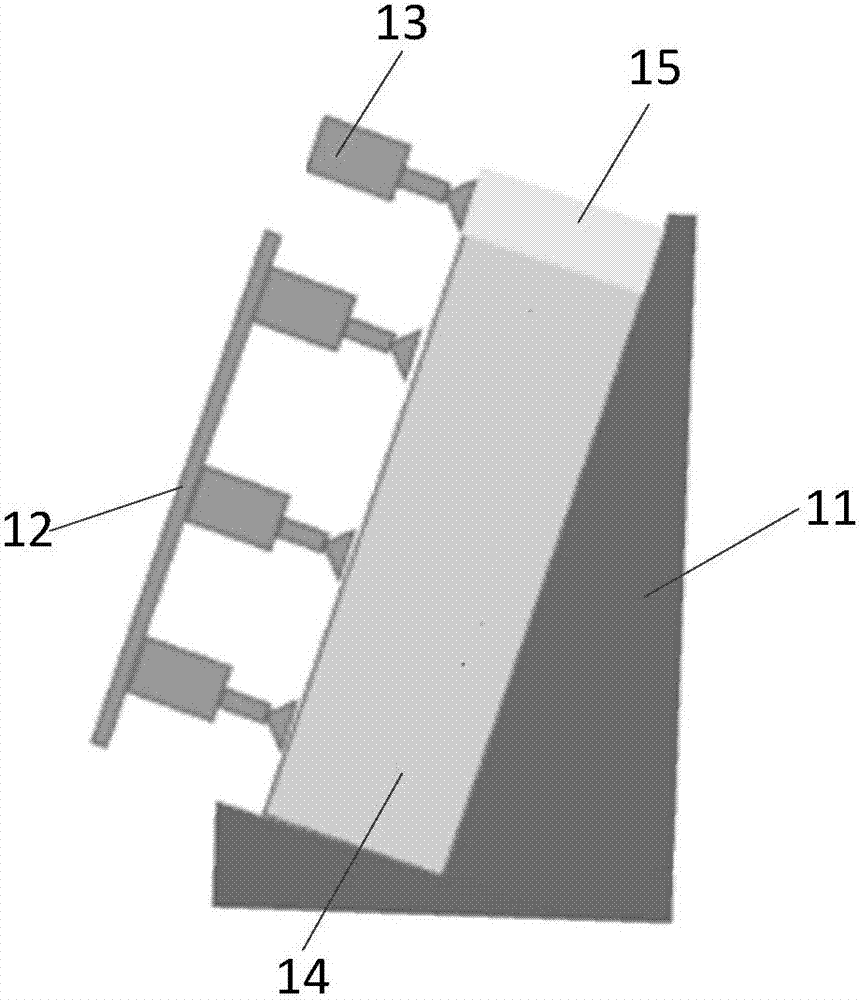

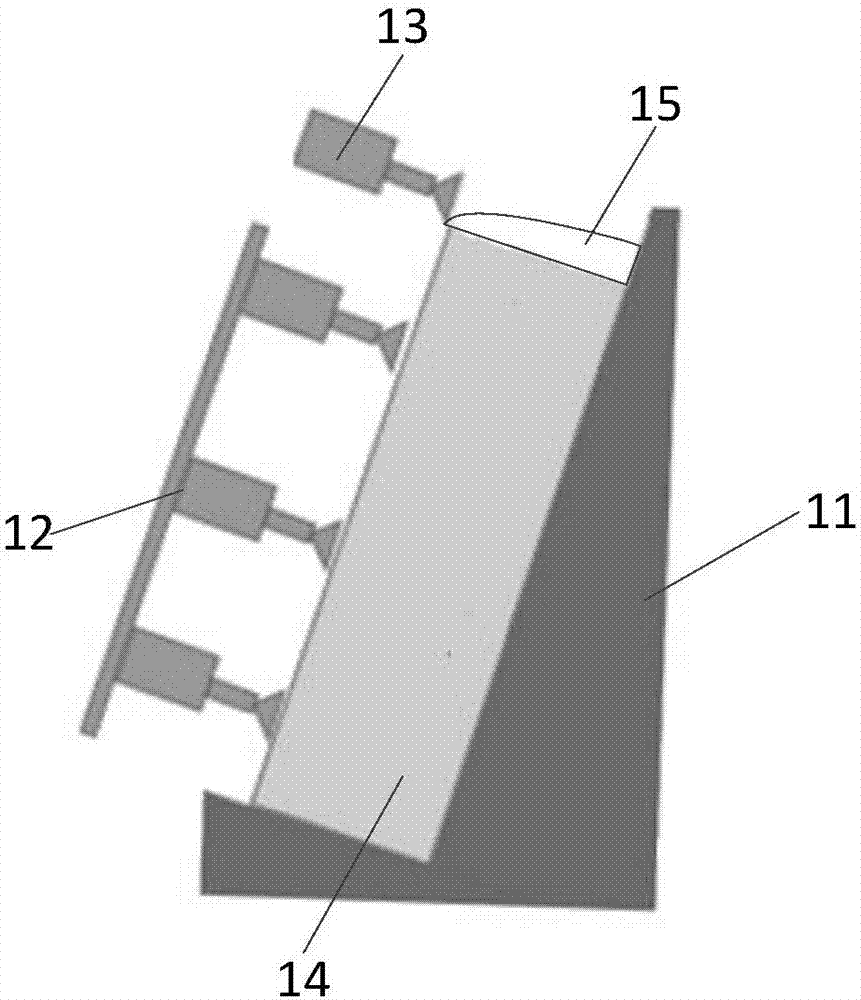

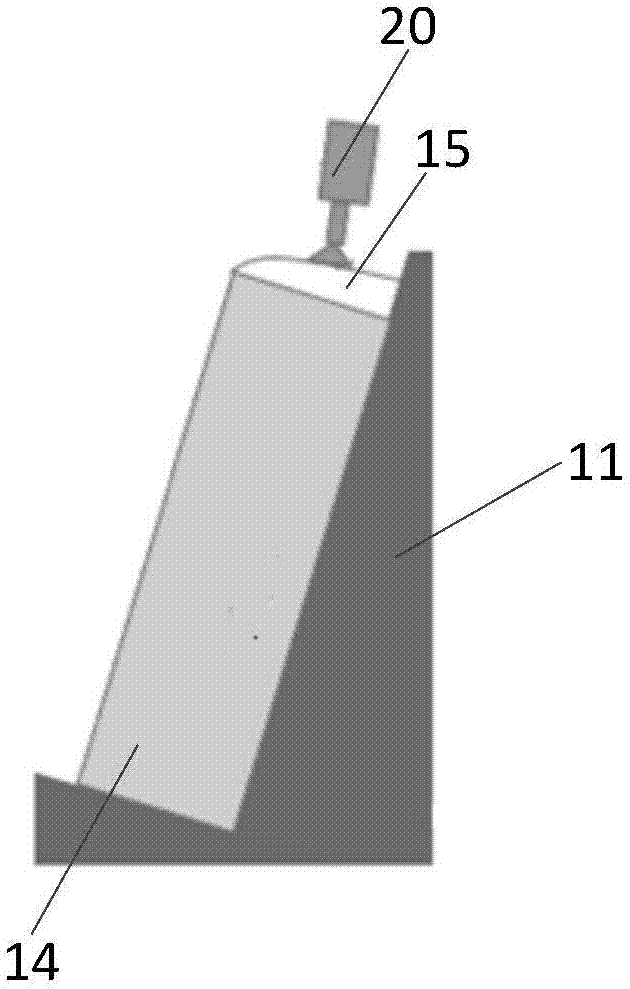

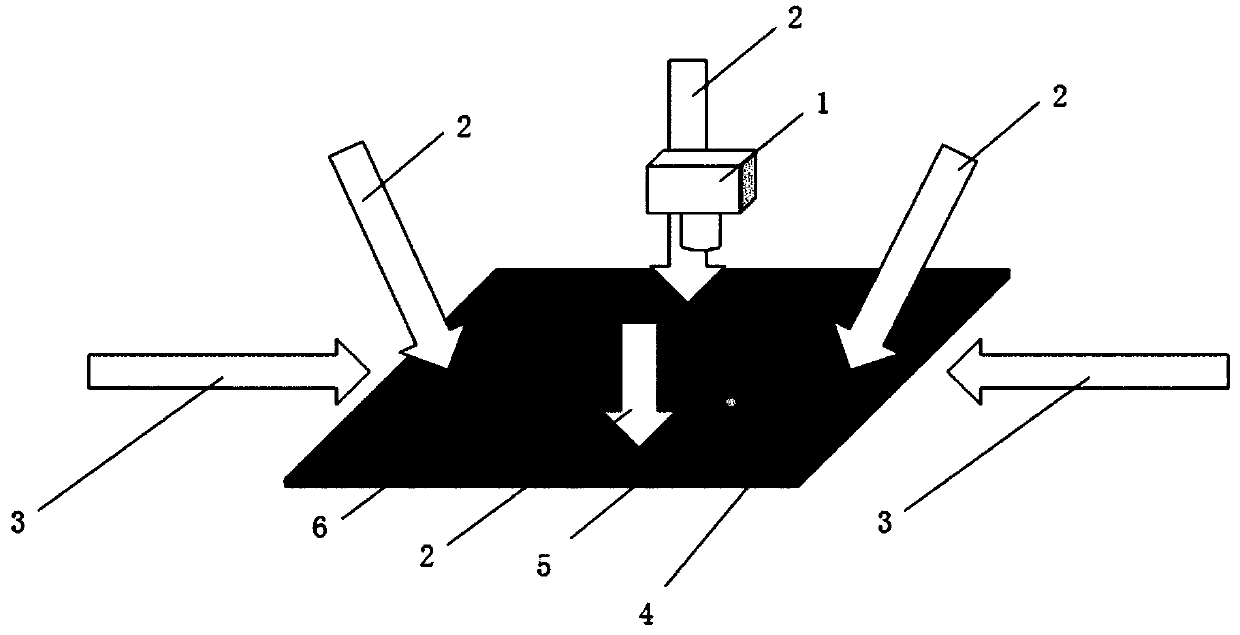

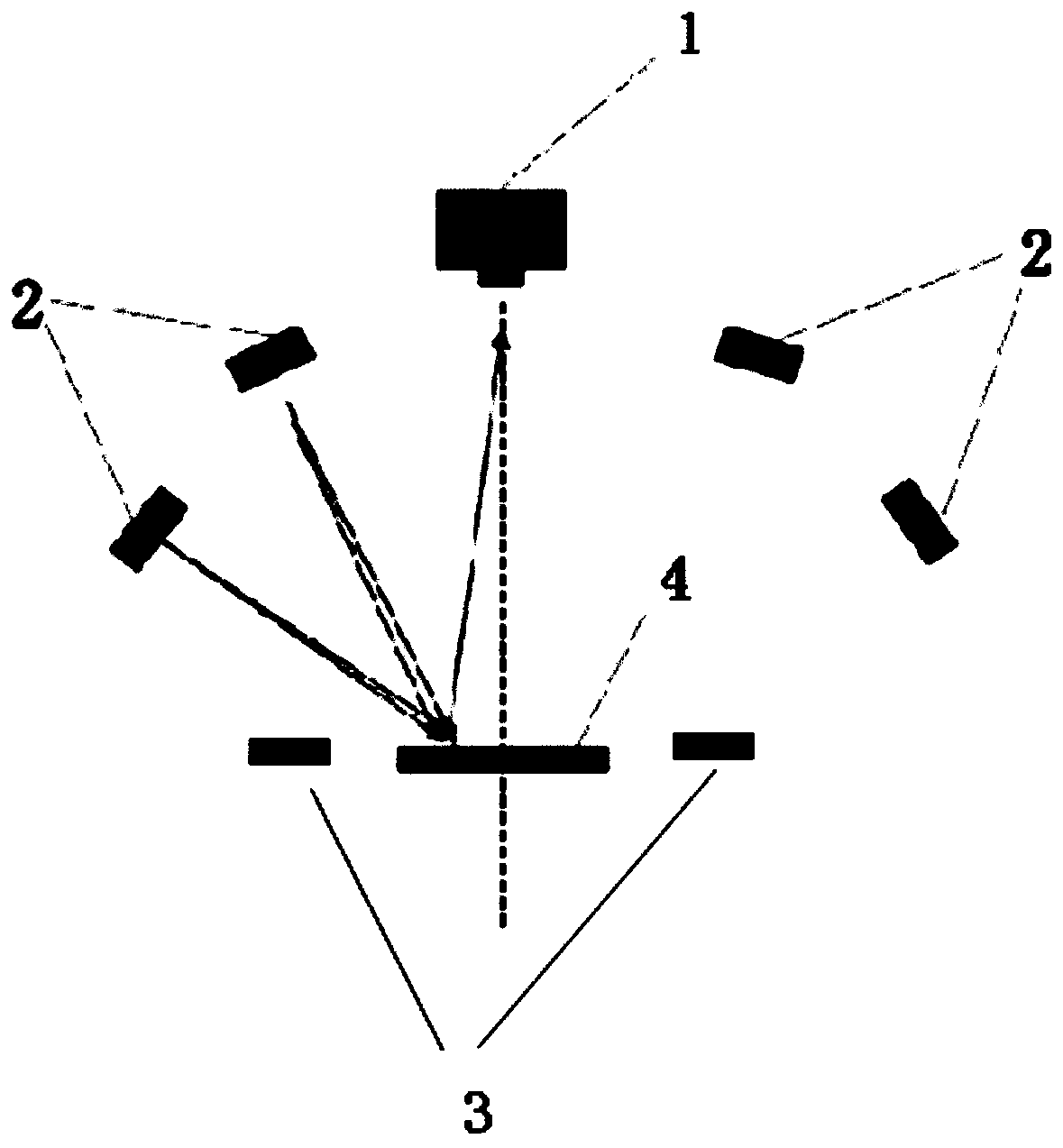

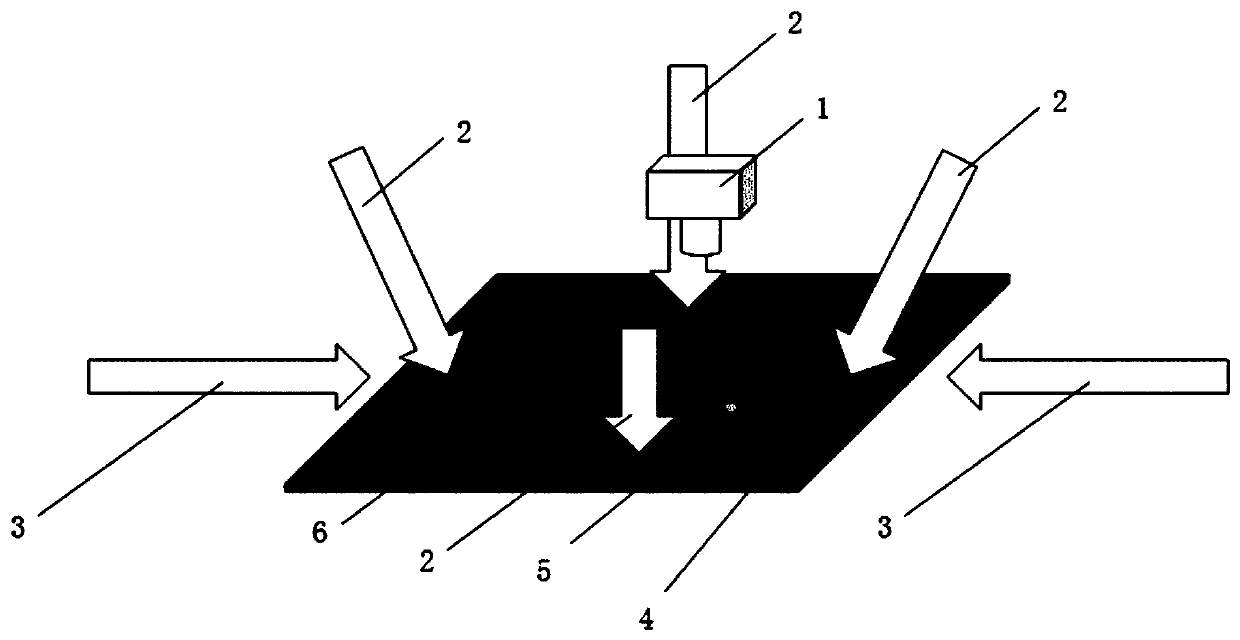

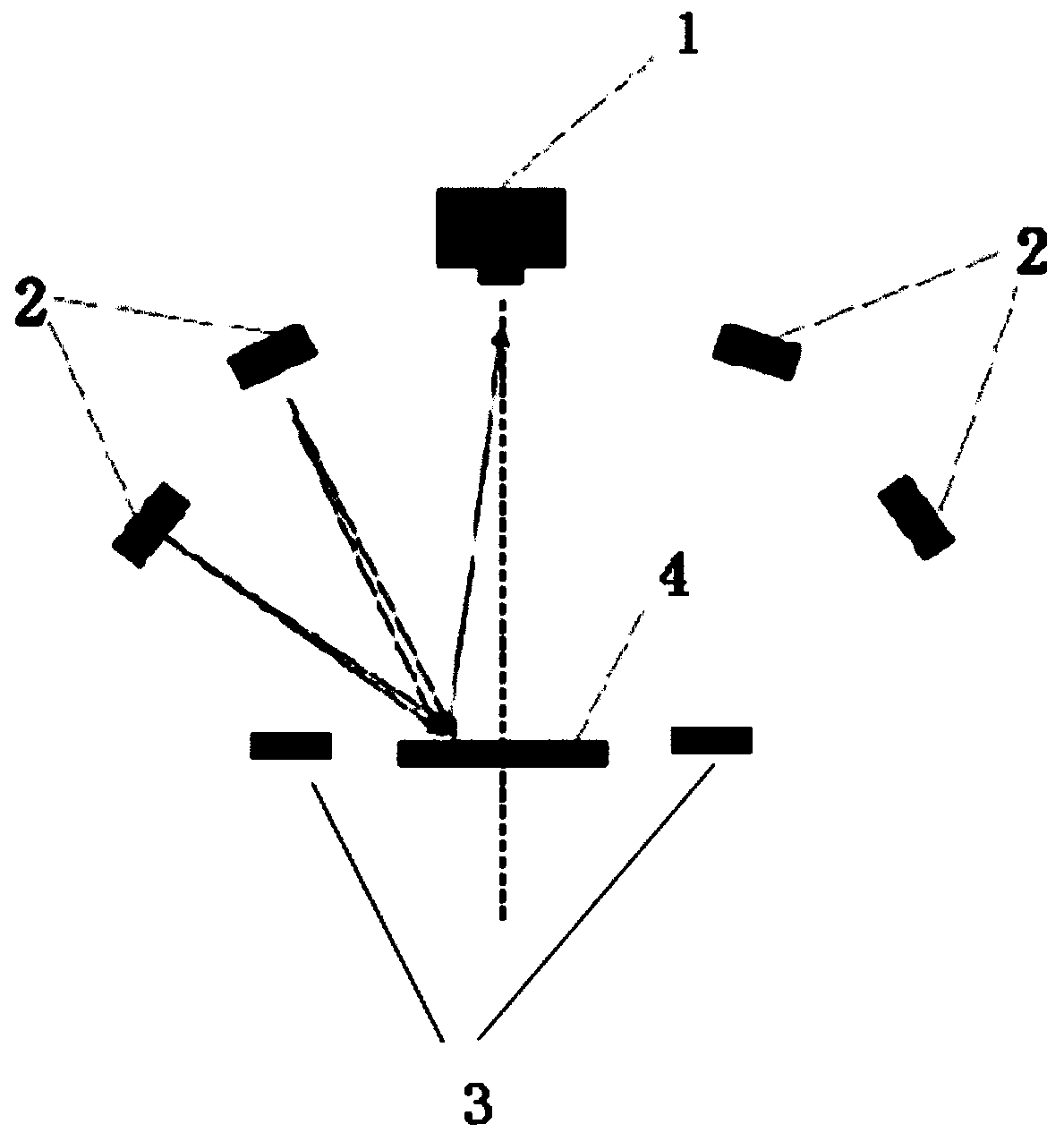

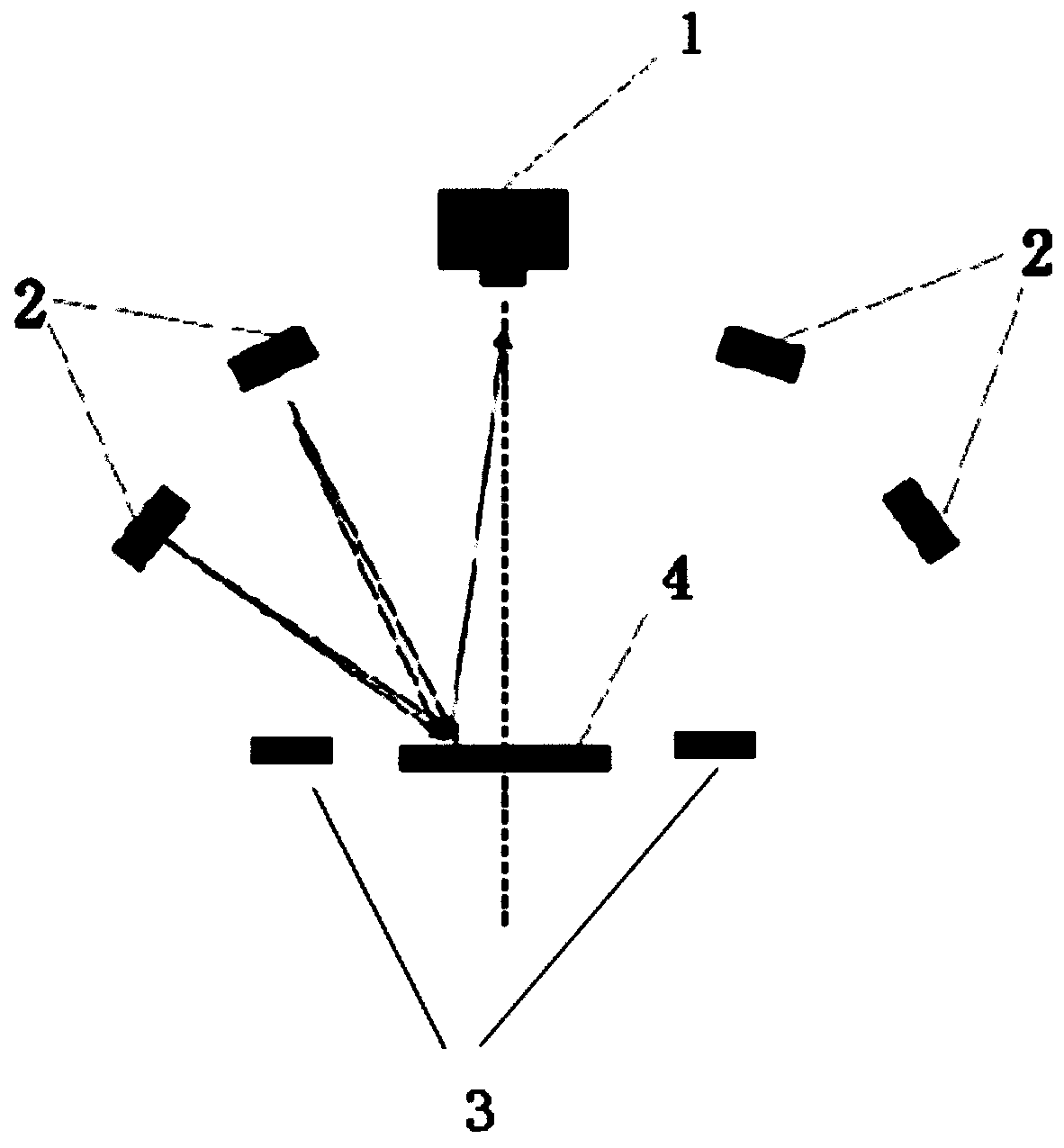

Novel display panel surface defect detection system

InactiveCN110849906ASimple and quick distinctionSimplify image processingOptically investigating flaws/contaminationWork benchesImaging processingMachine vision

The invention provides a novel display panel surface defect detection system. A defect identification subsystem comprises an image acquisition device, a main optical unit, an auxiliary optical unit and an image processing unit. The image acquisition device is connected with the image processing unit; and the system further comprises a reversible double-sided adsorption device and a light source brightness self-adaptive adjustment system. The system has the advantages that: (1) in the bad identification subsystem, the image processing unit can simply and quickly distinguish real bad defects andsurface foreign matters in a picture, and the system has the advantages of the simple image processing process, the high speed and the high efficiency; (2) in the reversible double-sided adsorption device, a panel is adsorbed from a bottom surface, the adsorption is stable and reliable, and the machine vision photographing is not influenced; and the double-sided adsorption structure can rotate the panel by 180 degrees and can stably adsorb the panel again; and (3) the light source brightness self-adaptive adjustment system can greatly prolong the service life of the light source, can improvethe activation rate of the device and can effectively reduce the maintenance cost of the device.

Owner:周娇

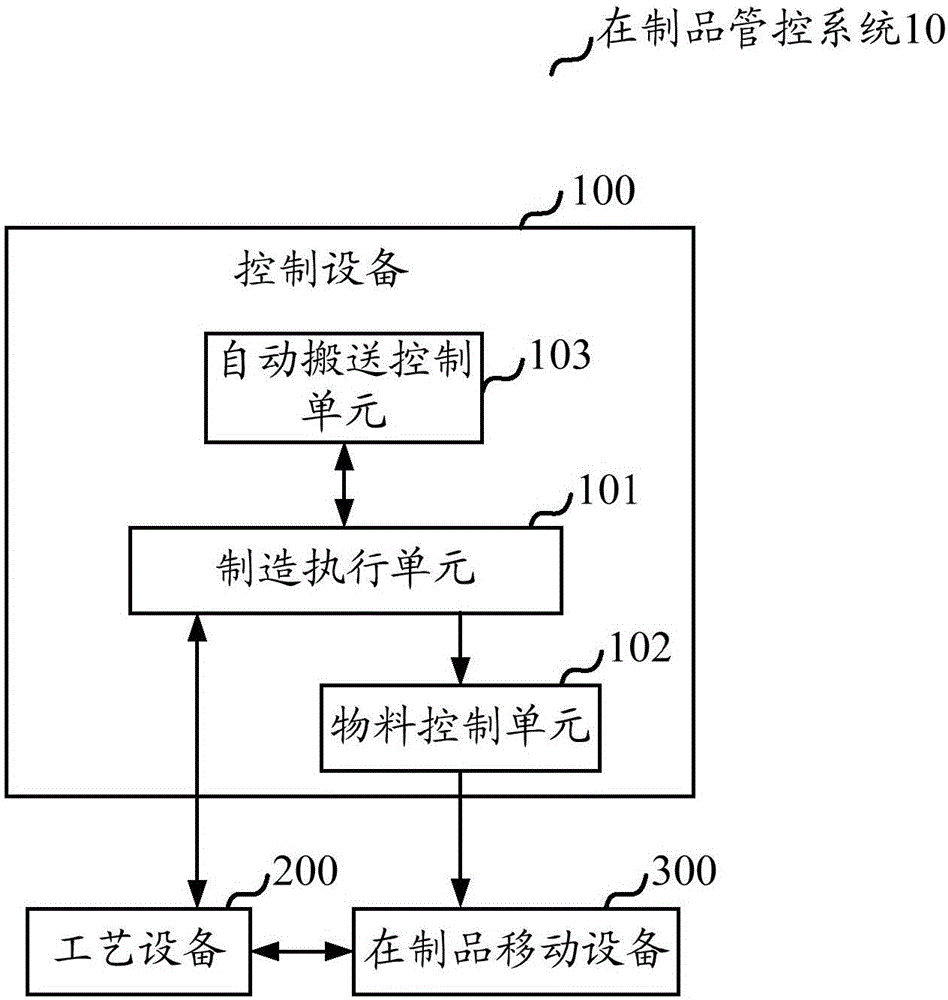

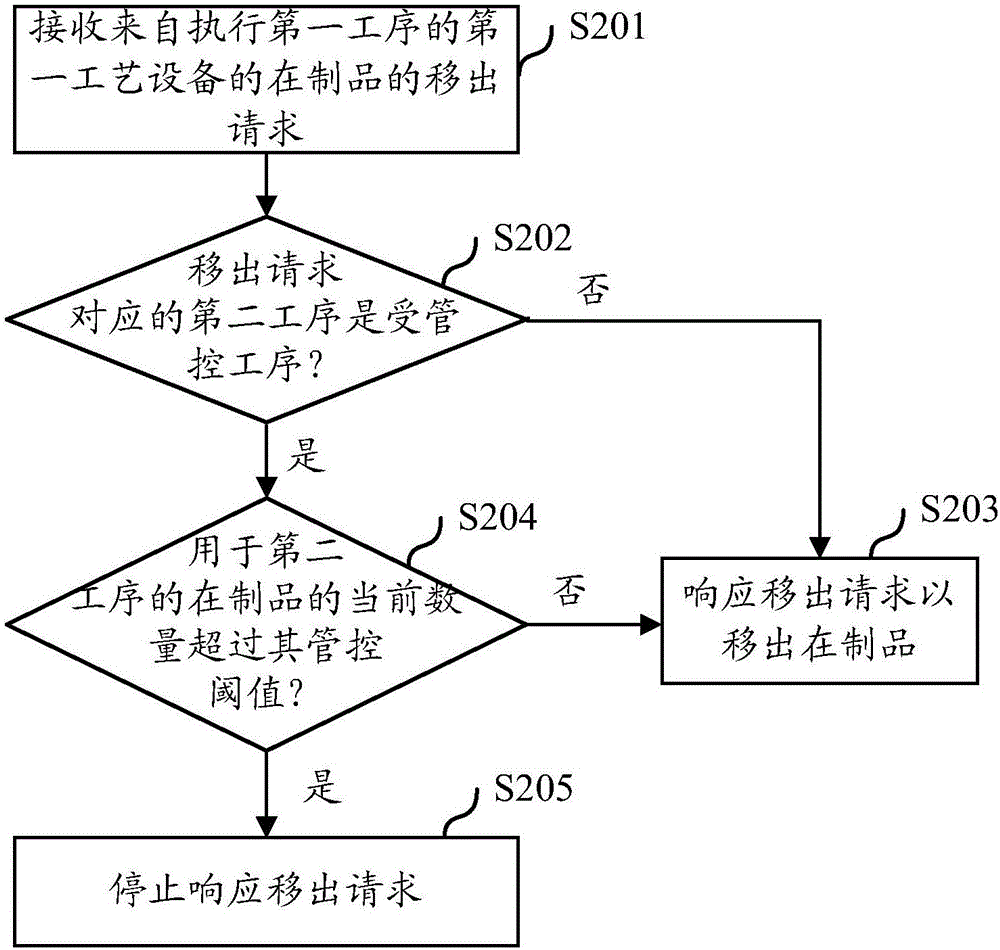

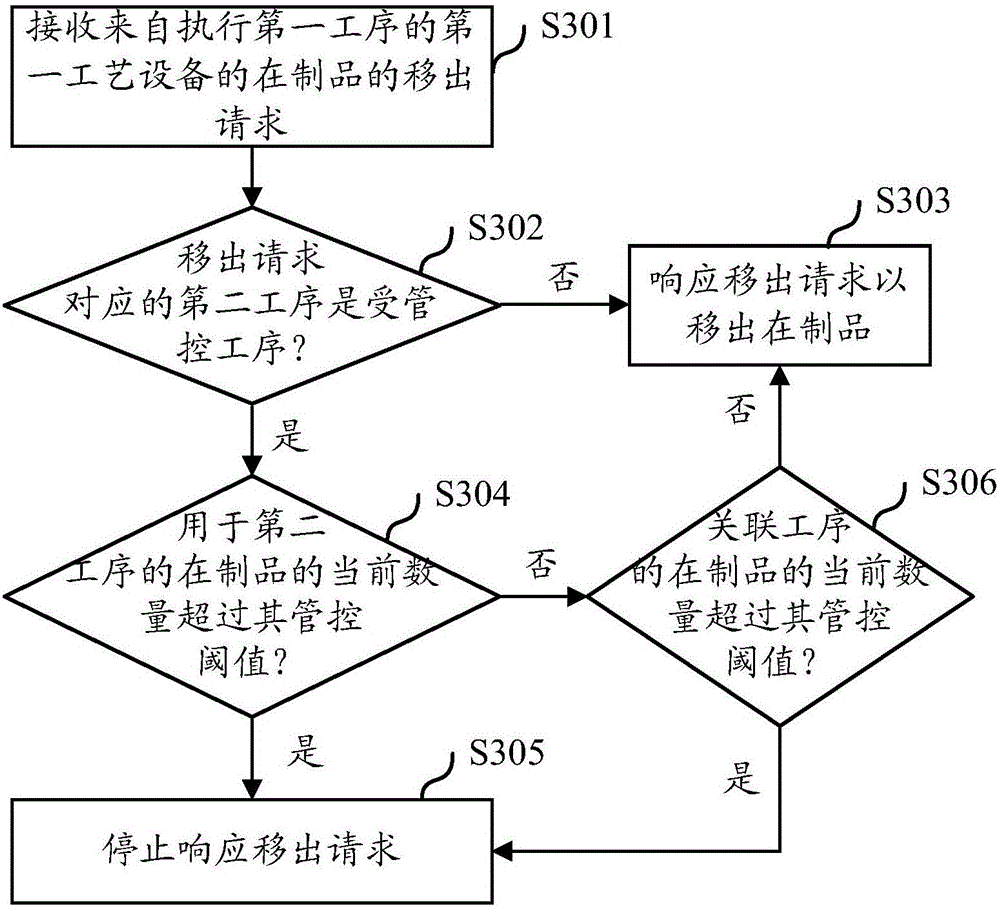

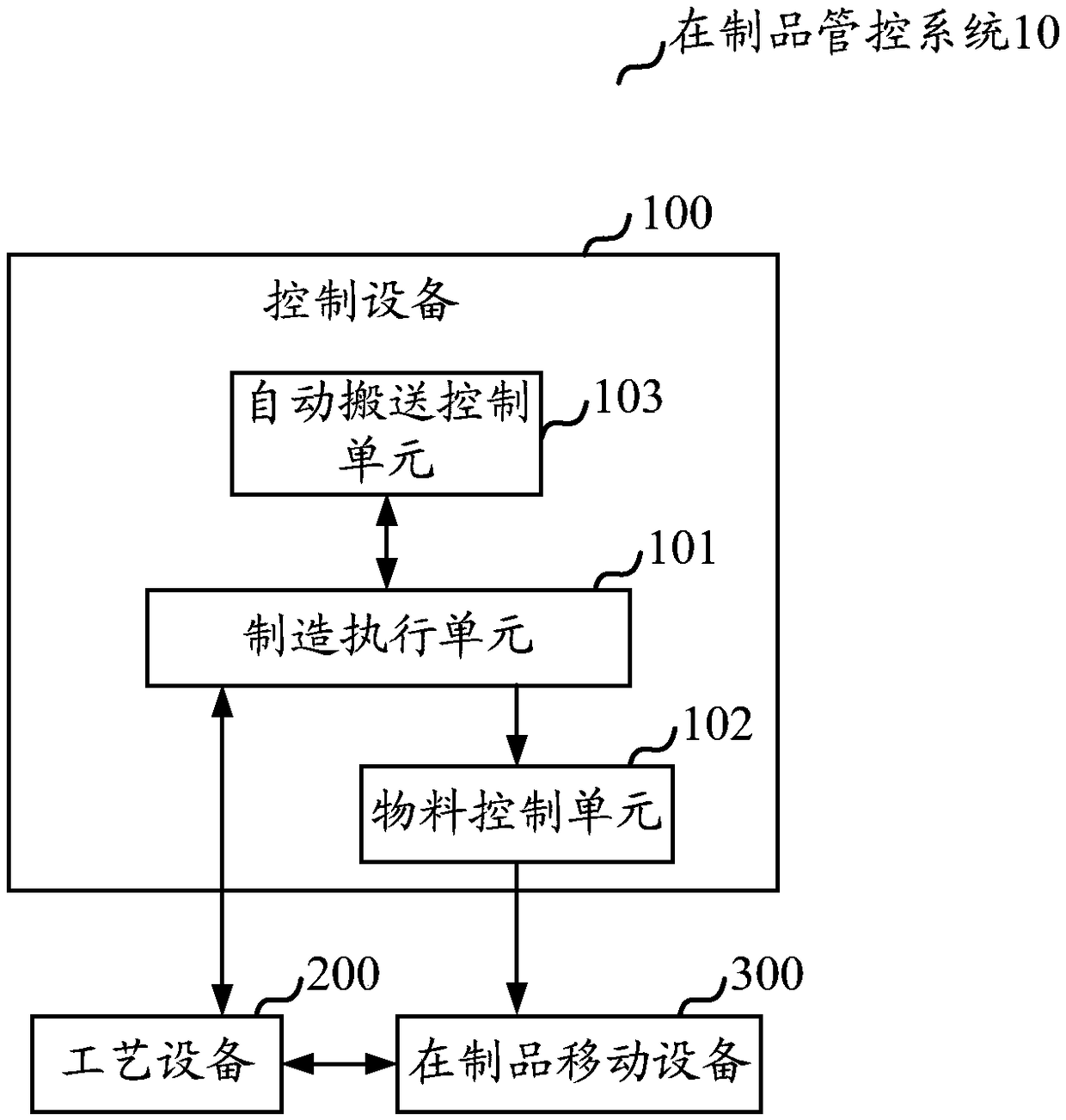

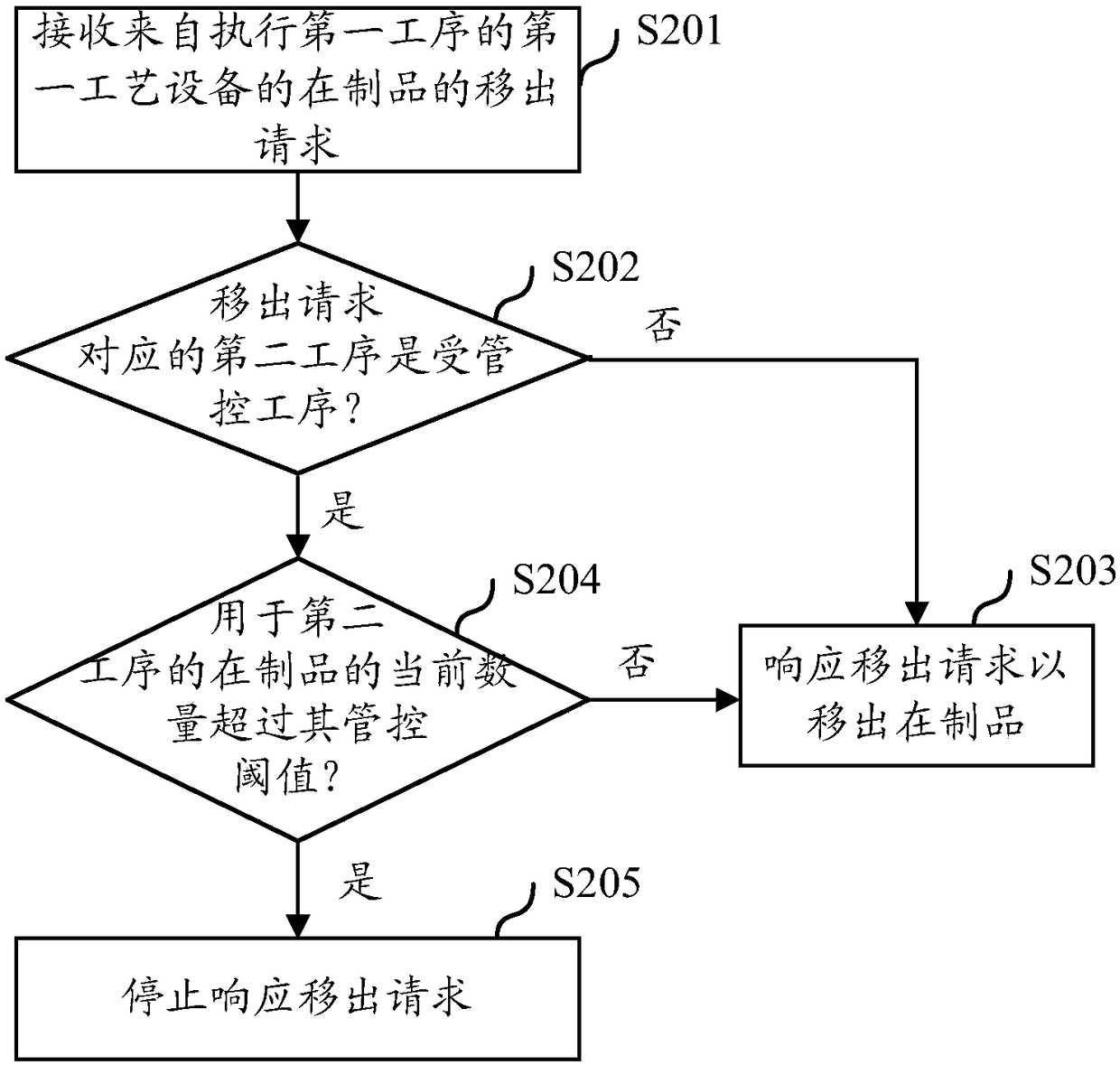

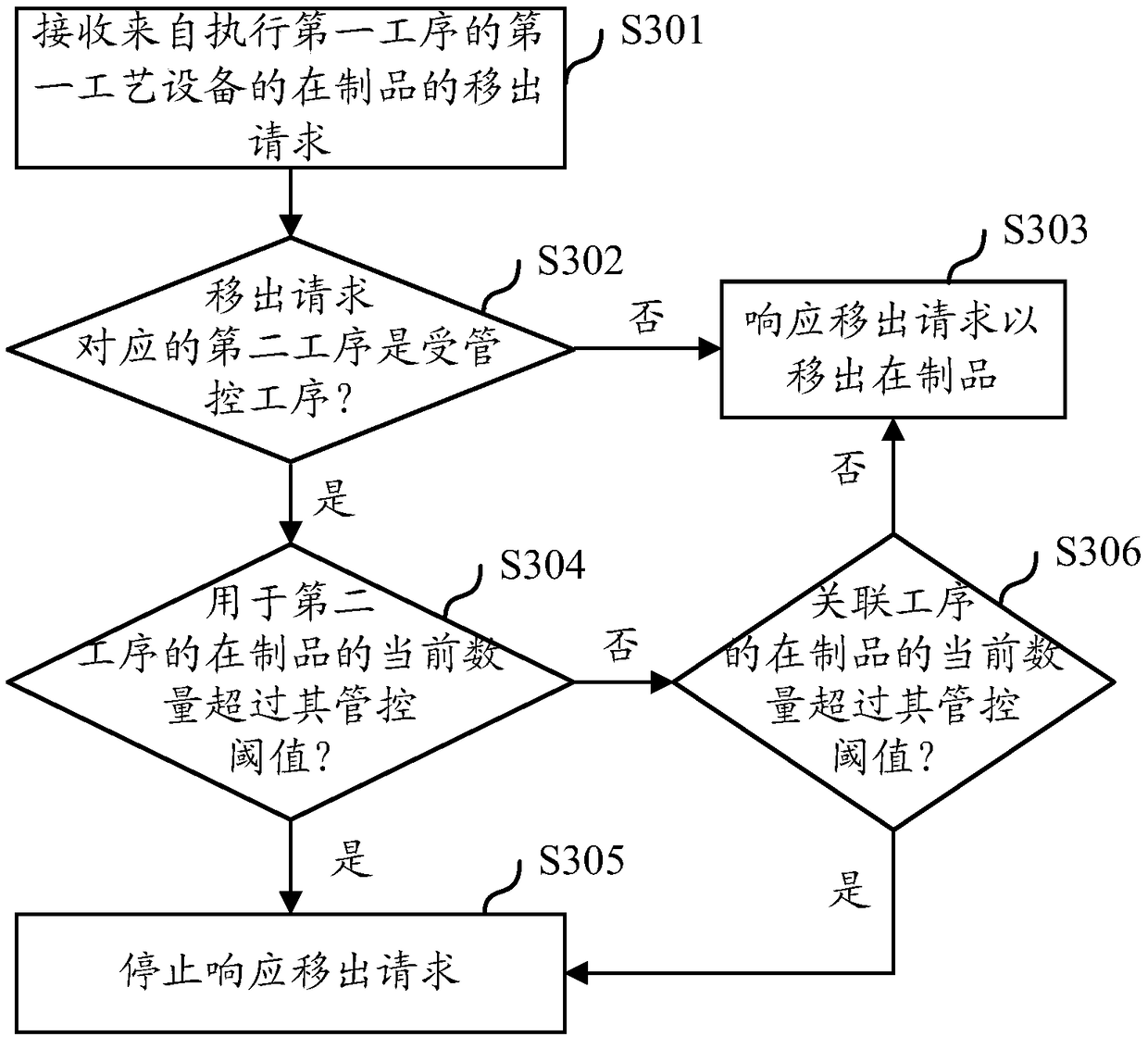

Method and system for management and control of articles being processed

ActiveCN106774196AReduce turnaround timeImprove transfer efficiencyTotal factory controlProgramme total factory controlProcess equipmentProcess engineering

The present invention relates to a method and system for management and control of articles being processed in an automatic production manufacture environment. The method comprises: receiving a shift-out request of articles being processed from a first process unit of a first working procedure; determining whether a second working procedure corresponding to the shift-out request is a managed and controlled working procedure or not; in the condition that the second working procedure is not the managed and controlled working procedure, responding to the shift-out request to shift out the articles being processed, and in the condition that the second working procedure is the managed and controlled working procedure, determining the current number of the articles being processed used in the second working procedure exceeds a management and control threshold or not; and in the condition that the current number of the articles being processed used in the second working procedure exceeds a management and control threshold, stopping responding to the shift-out request.

Owner:BOE TECH GRP CO LTD +1

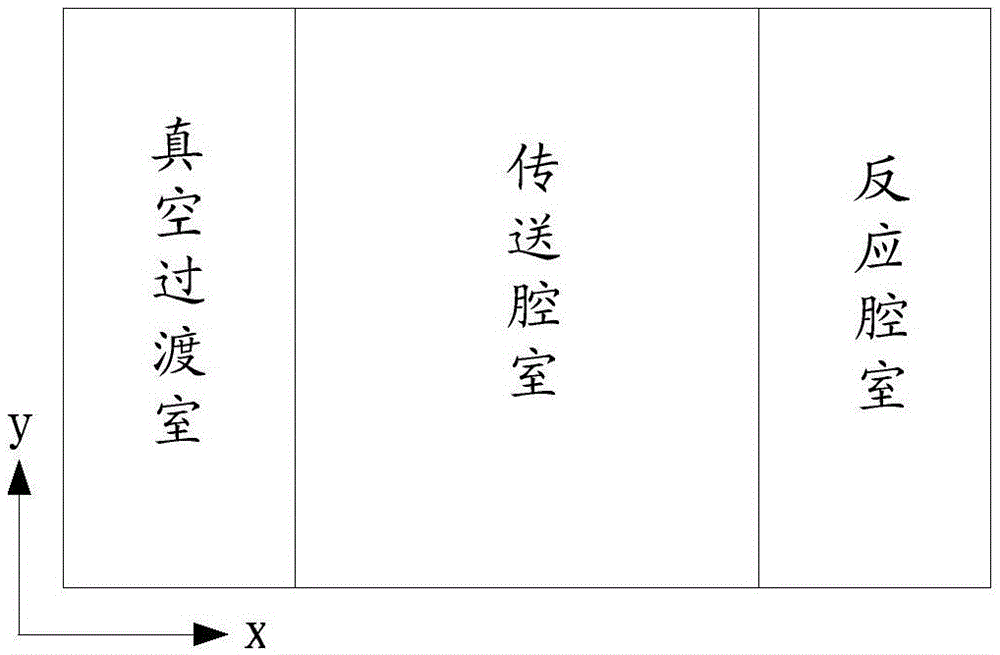

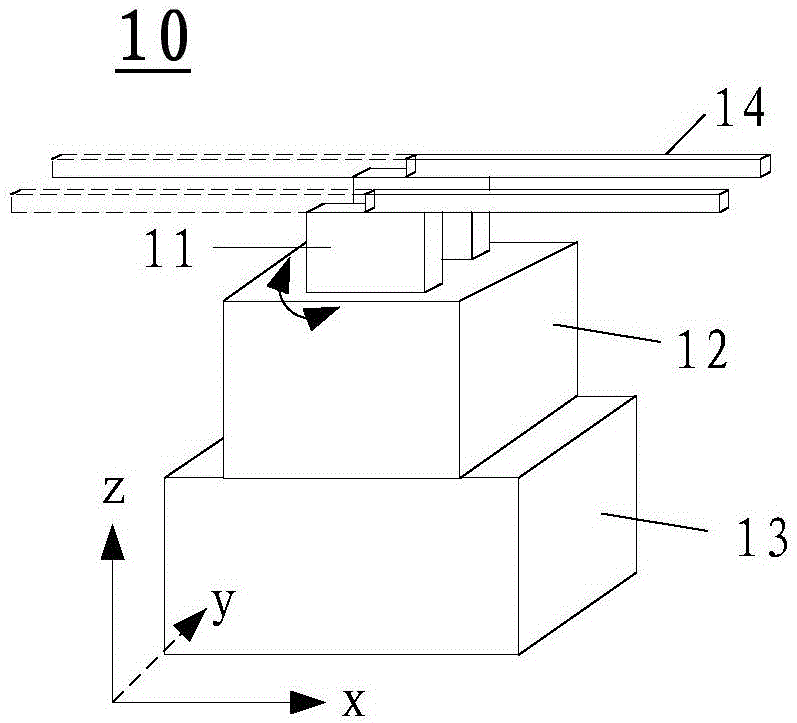

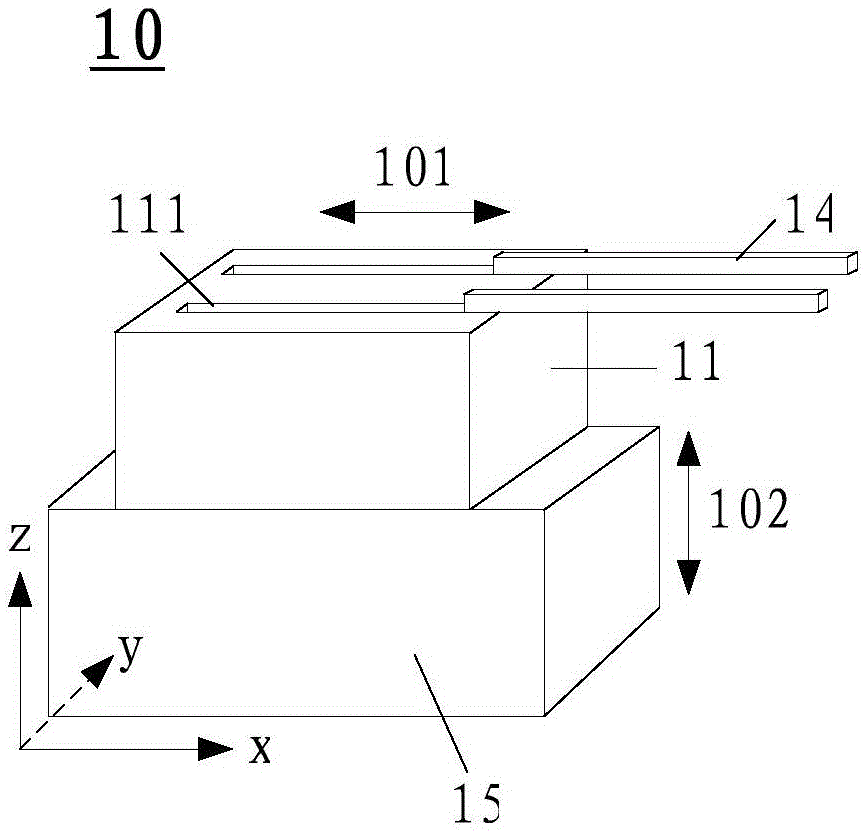

Mechanical arm

ActiveCN105151776AReduced risk of breakageIncrease the marriage rateSemiconductor/solid-state device manufacturingCharge manipulationEngineeringManipulator

The invention provides a mechanical arm, and relates to the field of automation. The mechanical arm solves the problems that when a conventional mechanical arm takes and places boards, the conventional mechanical arm needs to rotate, so that the occupied space is large, and the rate of qualified products is reduced. The mechanical arm is mounted between a first chamber and a second chamber of vacuum reaction equipment, and used for moving the boards in the first chamber to the second chamber. The mechanical arm comprises a first supporting structure, arms and a vertically-moving mechanism, wherein railways in the first direction of a horizontal plane are formed in the first supporting structure; the first chamber and the second chamber are respectively positioned at two opposite ends of the railways; the arms are mounted on the first mounting structure and used for bearing the boards; the arms can move along the railways; the first supporting structure and the arms are mounted on the vertically-moving mechanism, and the first supporting structure and the arms can be driven by the vertically-moving mechanism to move in the vertical direction.

Owner:BOE TECH GRP CO LTD +1

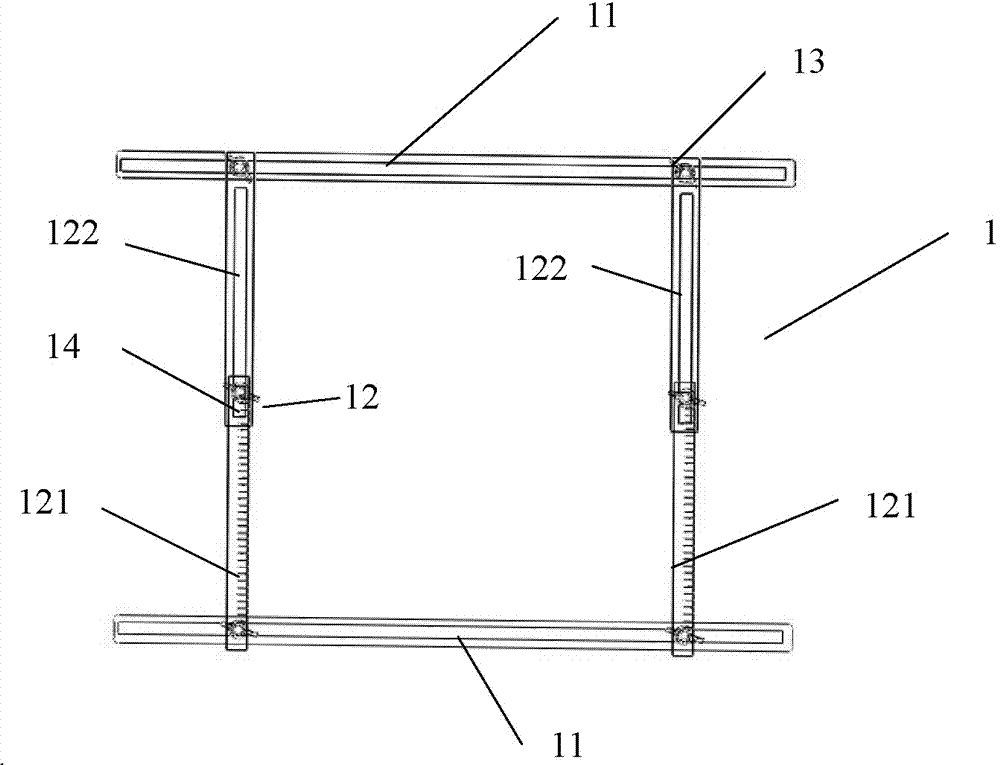

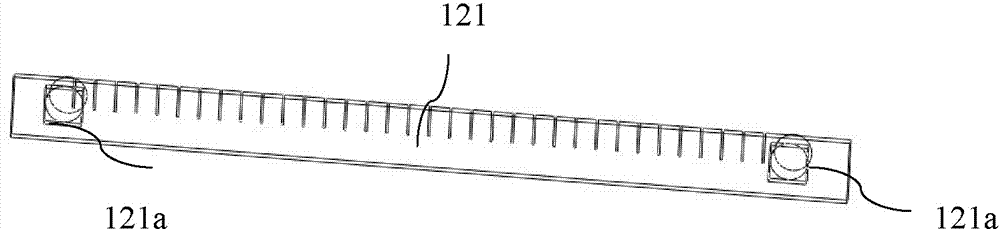

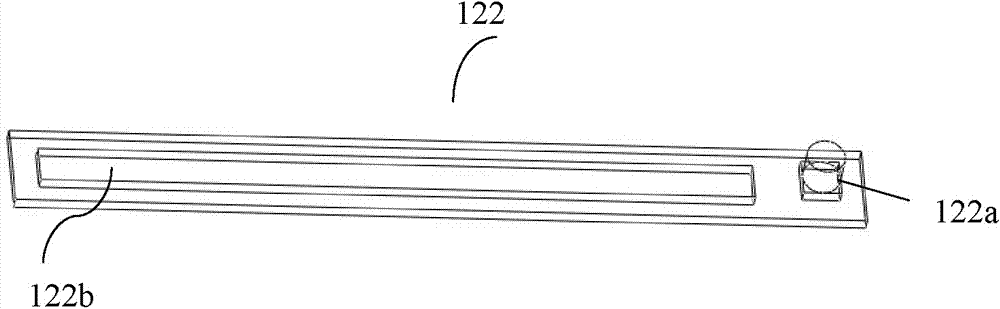

Parallel ruler for roller spacing adjustment

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

Novel display panel surface defect detection system

InactiveCN110849904ASimple and quick distinctionSimplify image processingOptically investigating flaws/contaminationWork benchesImaging processingMachine vision

The invention provides a novel display panel surface defect detection system. A defect identification subsystem comprises an image acquisition device, a main optical unit, an auxiliary optical unit and an image processing unit. The image acquisition device is connected with the image processing unit; and the display panel surface defect detection system further comprises a reversible double-sidedadsorption device and a light source brightness self-adaptive adjustment system. The display panel surface defect detection system has the advantages that: (1) in the bad identification subsystem, theimage processing unit can simply and quickly distinguish real bad defects and surface foreign matters in a picture, and the system has the advantages of the simple image processing process, the highspeed and the high efficiency; (2) in the reversible double-sided adsorption device, a panel is adsorbed from a bottom surface, the adsorption is stable and reliable, and the machine vision photographing is not influenced; and the double-sided adsorption structure can rotate the panel by 180 degrees and can stably adsorb the panel again; and (3) the light source brightness self-adaptive adjustmentsystem can greatly prolong the service life of the light source, can improve the activation rate of the device and can effectively reduce the maintenance cost of the device.

Owner:周娇

Drilling machine and its tool changing method

ActiveCN105500086BSave waiting time for tool changeImprove drilling efficiencyPositioning apparatusMetal-working holdersEngineeringChange positions

The invention provides a drilling machine and a tool changing method thereof. The drilling machine comprises a drilling system and a tool changing system, wherein the drilling system and the tool changing system can simultaneously act independently; the drilling system comprises at least one spindle capable of moving in the up-down direction; the spindles share the tool changing system; the tool changing system comprises a tool magazine device and a manipulator device assembled on the tool magazine device; the tool magazine device comprises tools, a tool pan and a tool apron; the tool pan is used for storing the tools; and the manipulator device comprises a manipulator for capturing and placing the tools. The manipulator captures the tools from the tool pan and places the tools on the tool apron, when tool changing is required for the spindles, the tool changing system is driven by a motor and moves to tool changing positions, and the spindles descend to capture the tools so as to realize tool changing.

Owner:SUZHOU VEGA TECH CO LTD

Novel display panel surface defect detection system

InactiveCN110849903ASimple and quick distinctionSimplify image processingOptically investigating flaws/contaminationWork benchesImaging processingMachine vision

Owner:周娇

Mechanical arm and application method thereof

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Novel display panel surface defect detection system

InactiveCN110849902ASimple and quick distinctionSimplify image processingOptically investigating flaws/contaminationWork benchesImaging processingMachine vision

The invention provides a novel display panel surface defect detection system. A defect identification subsystem comprises an image acquisition device, a main optical unit, an auxiliary optical unit and an image processing unit. The image acquisition device is connected with the image processing unit; and the system further comprises a reversible double-sided adsorption device and a light source brightness self-adaptive adjustment system. The system has the advantages that: (1) in the defect identification subsystem, the image processing unit can simply and quickly distinguish real bad defectsand surface foreign matters in a picture, and the system has a simple image processing process, a high speed and high efficiency; (2) in the reversible double-sided adsorption device, a panel is adsorbed from a bottom surface, the adsorption is stable and reliable, and the machine vision photographing is not influenced; and the double-sided adsorption structure can rotate the panel by 180 degreesand can stably adsorb the panel again; and (3) the light source brightness self-adaptive adjustment system can greatly prolong the service life of the light source, can improve the activation rate ofequipment and can effectively reduce the maintenance cost of the device.

Owner:周娇

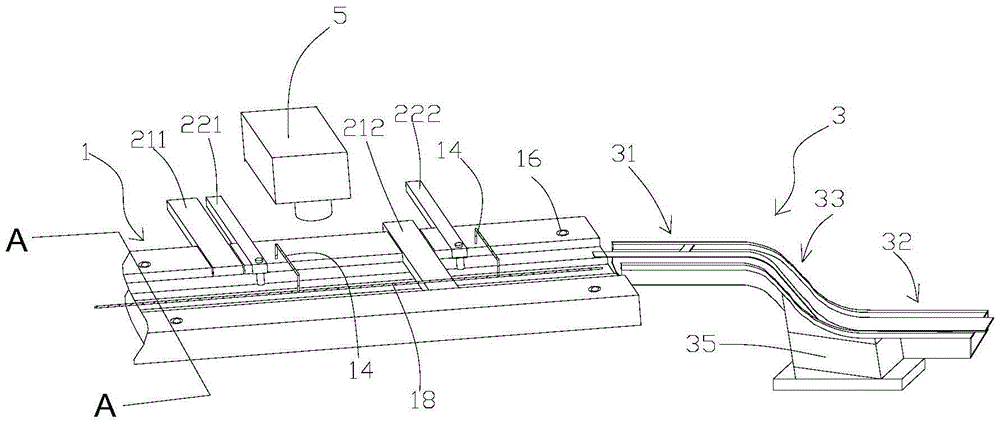

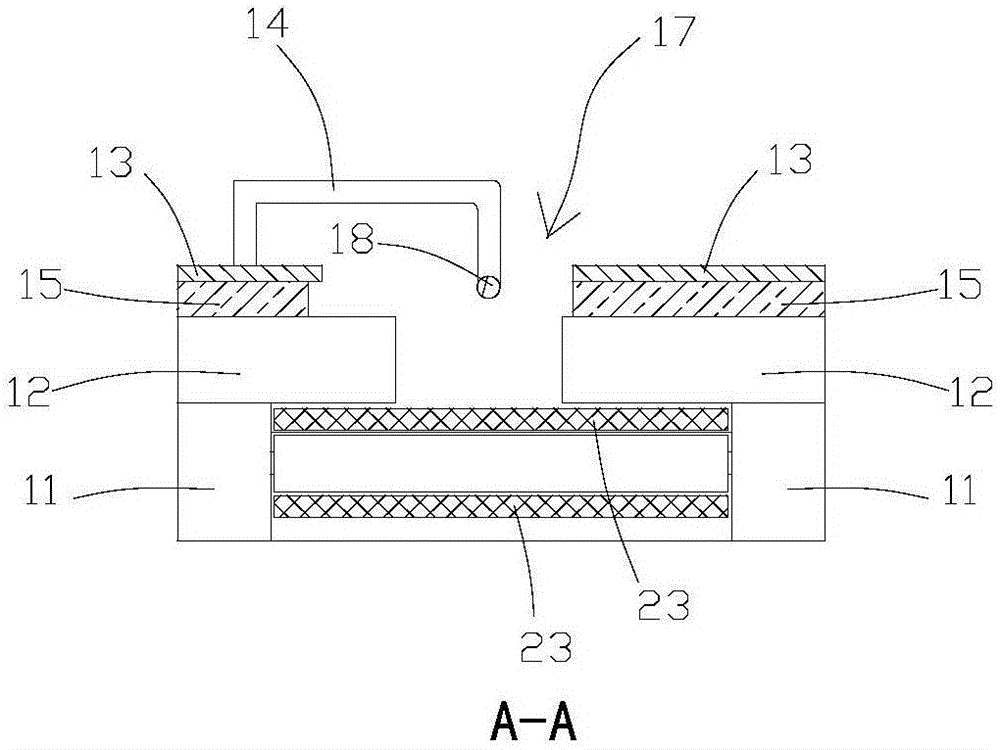

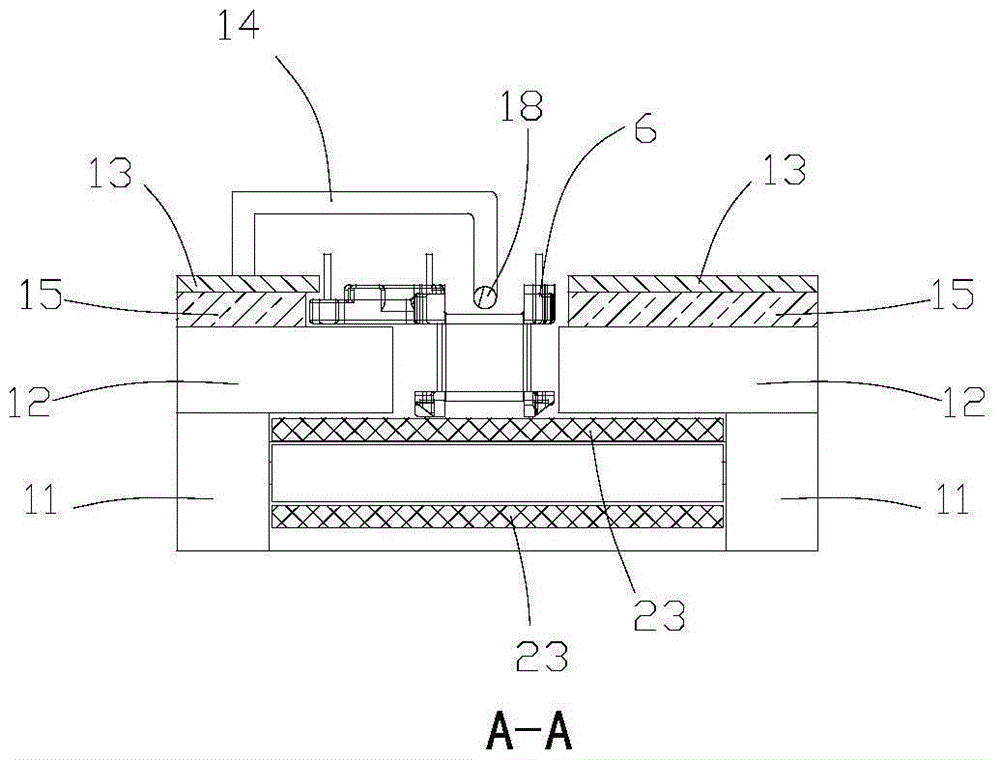

Portable charger transformer automatic production linkage mechanism and its use method

ActiveCN105244160BReduce participationIncrease the marriage rateInductances/transformers/magnets manufactureGroove widthTransformer

The invention discloses a portable charger transformer automatic production linkage mechanism and a method for using the same. It is provided with a conveyor belt (23), and is also provided with a fool-proof limit track (1), an overturning guide rail (3), and a fool-proof limit rail (3). A positionable control device on the track (1) for controlling the movement or stop of the transformer with the running conveyor belt (23), a counting device for counting the number of transformers passing through its position, and controlling the conveyor belt (23), the control device, and the counting device Device, overturn guide rail (3) PLC control system for the working process; the groove width and groove depth of the guide groove are suitable for various transformers; the equipment in the front and rear processes can be connected efficiently as a whole, reducing personnel participation, reducing equipment waiting time, and improving equipment operation Efficiency, reducing resource waste and saving labor costs by more than 50%, can effectively reduce production costs, save resources, and greatly increase product profits.

Owner:江西吉安奥海科技有限公司

A network segmentation method and device for PCB electrical performance test points

ActiveCN102680850BReduce test densityIncrease the marriage rateElectrical testingTest efficiencyElectrical performance

The invention discloses a network partitioning method and a network partitioning device of electrical performance testing points of a PCB (printed circuit board). The method comprises the following steps: partitioning initial testing points on the PCB in terms of network forms, testing points or network; and reserving a plurality of testing points for electrical performance test after partitioning. With the adoption of the network partitioning method and the network partitioning device, the electrical performance testing efficiency of the PCB is improved; the testing cost is reduced; furthermore the network partitioning method and the network partitioning device are not limited by the products and the testing machine tools; the test is more convenient and rapid; the production capacity is increased greatly; and the activation of the testing machine tool is improved. With the network partitioning method and the network partitioning device, the problem that the selection of the testing instruments and testing machine tools is limited because the PCB product is light, thick, short and small and dense in circuits and pores is solved; and the testing production capacity and the management efficiency of the PCB are improved.

Owner:PALWONN ELECTRONICS SUZHOU CO LTD

Novel display panel surface defect detection system

InactiveCN110849905ASimple and quick distinctionSimplify image processingOptically investigating flaws/contaminationWork benchesImaging processingMachine vision

The invention provides a novel display panel surface defect detection system. A defect identification subsystem comprises an image acquisition device, a main optical unit, an auxiliary optical unit and an image processing unit. The image acquisition device is connected with the image processing unit; and the display panel surface defect detection system further comprises a reversible double-sidedadsorption device and a light source brightness self-adaptive adjustment system. The system has the advantages that: (1) in the bad identification subsystem, the image processing unit can simply and quickly distinguish real bad defects and surface foreign matters in a picture, and the system has the advantages of simple image processing process, high speed and high efficiency; (2) in the reversible double-sided adsorption device, a panel is adsorbed from a bottom surface, the adsorption is stable and reliable, and the machine vision photographing is not influenced; and the double-sided adsorption structure can rotate the panel by 180 degrees and can stably adsorb the panel again; and (3) the light source brightness self-adaptive adjustment system can greatly prolong the service life of thelight source, can improve the activation rate of the device and can effectively reduce the maintenance cost of the device.

Owner:周娇

Drink preparation device

The invention discloses a drink preparation device, belonging to the field of machinery. The drink preparation device is mainly used for blending overheated hot water in a hot water pipe with cold water of a set flow rate in a cold water pipe to form a blended water flow with suitable temperature, and transmitting the blended water flow into a liquid dispenser. When a brewing solenoid valve is controlled to be opened, the liquid dispenser dispenses the blended water flow with suitable temperature to a preparation container in which drink components are previously provided so as to prepare drink from the drink components; and when the brewing solenoid valve is controlled to be closed, the liquid dispenser dispenses the blended water flow with suitable temperature to a hot water feeding pipe, and the blended water flow with suitable temperature is directly fed into the drink when a hot water feeding solenoid valve is controlled to be opened. When the brewing solenoid valve and the hot water solenoid valve are both closed, the hot water in a heat exchanger volatiles, passes through a preheating circulation line, and returns to a heat exchanger after being preheated by the liquid dispenser so as to form a preheating circulation.

Owner:刘宗熹

An automated warehouse system, production line and logistics management method

ActiveCN106976676BImprove handling efficiencyReduce invalidProgramme controlTechnology managementInformation controlProduction line

Owner:BOE TECH GRP CO LTD +1

Work in process control method and work in process control system

ActiveCN106774196BReduce turnaround timeImprove transfer efficiencyTotal factory controlProgramme total factory controlControl systemWork in process

The invention relates to a work-in-process control method in an automated production and manufacturing environment and a work-in-process control system using the work-in-process control method. The work-in-process control method includes: receiving a removal request for the work-in-process from the first process equipment executing the first process; determining whether the second process corresponding to the removal request is a controlled process; In the case of a controlled process, respond to the removal request to remove the work-in-process; in the case of the second process being a controlled process, determine whether the current quantity of the work-in-process used in the second process exceeds its control a threshold; and when the current quantity of work-in-progress used for the second process exceeds its control threshold, stop responding to the removal request.

Owner:BOE TECH GRP CO LTD +1

A method for increasing the distance between the pressing plates of the forming cabinet of the polymer lithium-ion battery fixture

ActiveCN107516747BIncrease platen spacingIncrease productivityFinal product manufactureSecondary cellsElectrical batteryDrive motor

A method for increasing the distance between pressing plates of a polymer lithium-ion battery fixture forming cabinet, comprising: a drive motor that divides the pressing plate into two lifts; a locking pin and a connecting belt that controls the second movement of the pressing plate; connecting the locking pin and driving The fixing bracket of the motor and the connecting belt of the pressure plate. Install the locking pin on the middle pressing plate of the fixture forming cabinet; install the fixing bracket connecting the locking pin and the driving motor on the pressing plate connected to the cylinder on the uppermost layer of the fixture forming cabinet, and the driving motor rotates to tighten or loosen the locking pin The connecting belt ensures that only half of the clamping cabinets are opened in the same space, thereby increasing the spacing of the clamping plates, facilitating operation, maintenance or increasing the number of cabinet points, and improving equipment utilization.

Owner:江西格林德能源有限公司

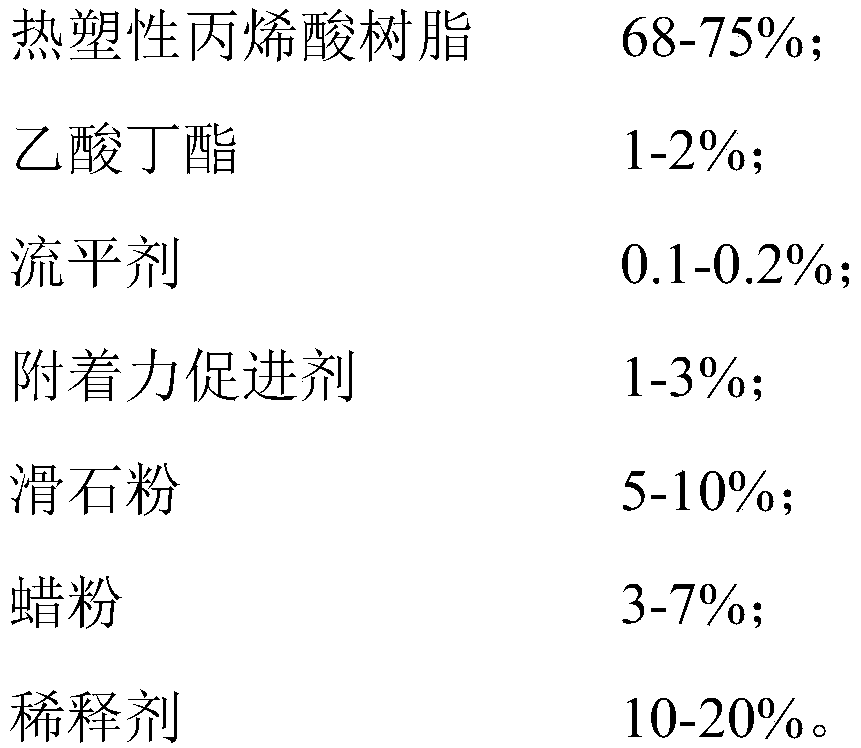

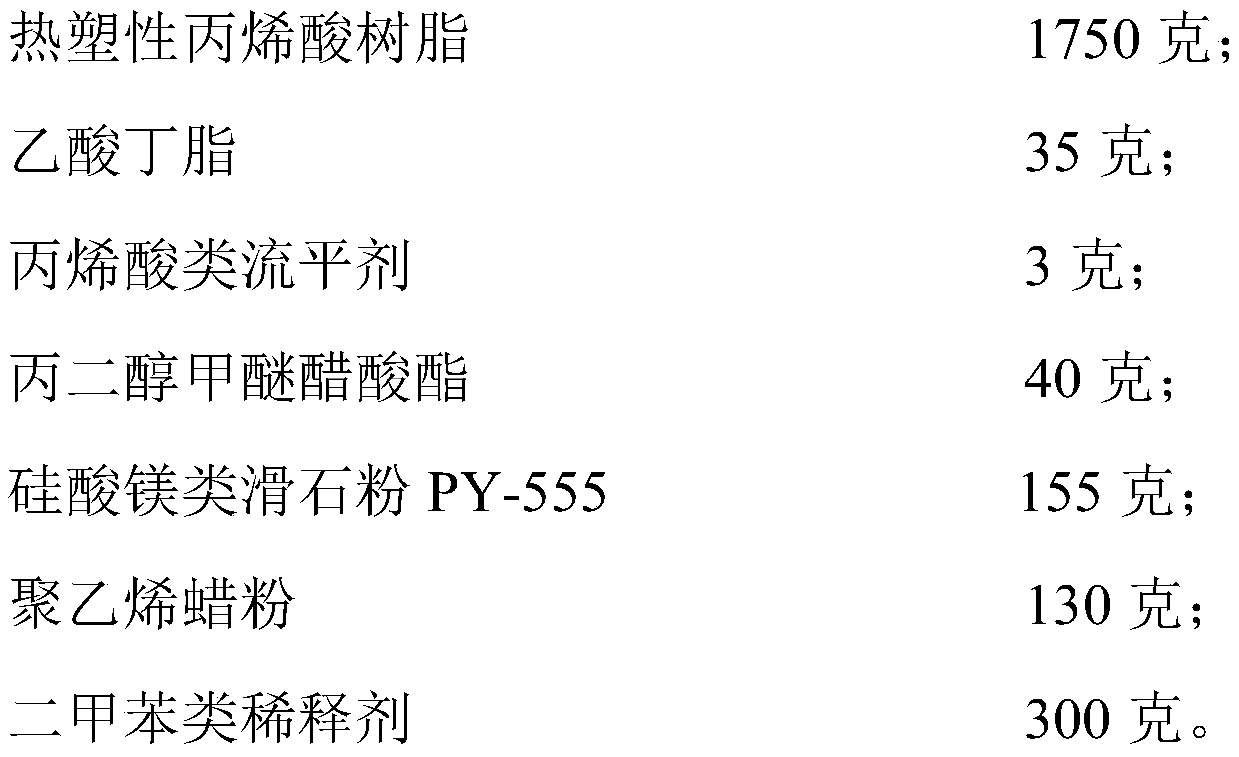

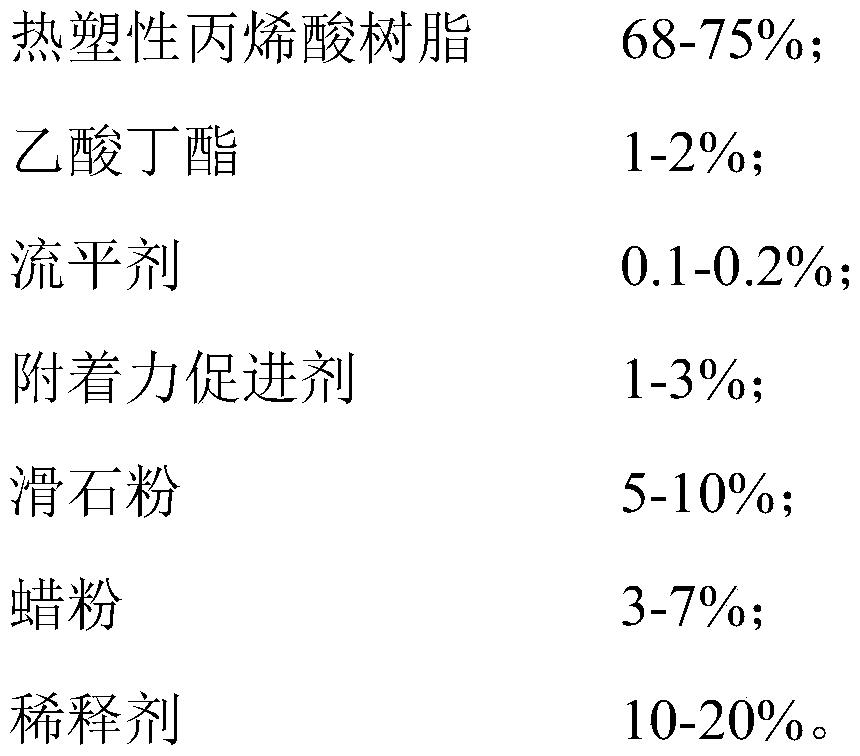

Glass fiber treatment agent for surface spraying treatment of glass fiber plastic parts and its application

The invention provides a glass fiber treating agent for surface spraying treatment of a glass fiber plastic component. The glass fiber treating agent contains the following components in percentage by mass (100% in total): 68%-75% of thermoplastic acrylic resin, 1%-2% of butyl acetate, 0.1%-0.2% of a flatting agent, 1%-3% of an adhesion promoter, 5%-10% of talcum powder, 3%-7% of wax powder and 10%-20% of a diluent.

Owner:深圳铭锋达精密技术有限公司

Novel display panel surface defect detection system

InactiveCN110849907ASimple and quick distinctionSimplify image processingOptically investigating flaws/contaminationWork benchesImaging processingMachine vision

The invention provides a novel display panel surface defect detection system. A defect identification subsystem comprises an image acquisition device, a main optical unit, an auxiliary optical unit and an image processing unit. The image acquisition device is connected with the image processing unit; and the system further comprises a reversible double-sided adsorption device and a light source brightness self-adaptive adjustment system. The system has the advantages that: (1) in the bad identification subsystem, the image processing unit can simply and quickly distinguish real bad defects andsurface foreign matters in a picture, and the system has the advantages of the simple image processing process, the high speed and the high efficiency; (2) in the reversible double-sided adsorption device, a panel is adsorbed from a bottom surface, the adsorption is stable and reliable, and the machine vision photographing is not influenced; and the double-sided adsorption structure can rotate the panel by 180 degrees and can stably adsorb the panel again; and (3) the light source brightness self-adaptive adjustment system can greatly prolong the service life of the light source, can improvethe activation rate of the device and can effectively reduce the maintenance cost of the device.

Owner:周娇

Glue supplying device and coating machine applying same

InactiveCN104549912AAvoid normal workAvoid security issuesLiquid surface applicatorsCoatingsPulp and paper industryCoating

The invention discloses a glue supplying device and a coating machine applying the glue supplying device and relates to the technical field of membrane preparation through coating. The phenomenon that an air inlet pipe or a glue supplying pipe can be easily broken or damaged when feed glue of a glue supplying device is added or replaced in the prior art is avoided, so that the glue supplying device can be in normal operation and no accident occurs. The glue supplying device provided by the invention comprises a cover and a base, wherein an air inlet pipe and a glue supplying pipe are fixedly arranged on the cover, and the base is matched and connected with the cover; a glue barrel is arranged at the upper side of the base, and a lifting device is fixedly arranged at the lower side of the base; the lifting device can drive the base to be separated from or convoluted with the cover; and when the base is separated from the cover, the glue barrel can be completely exposed from the bottom end of the cover. The glue supplying device disclosed by the invention is mainly applied to the coating machine.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

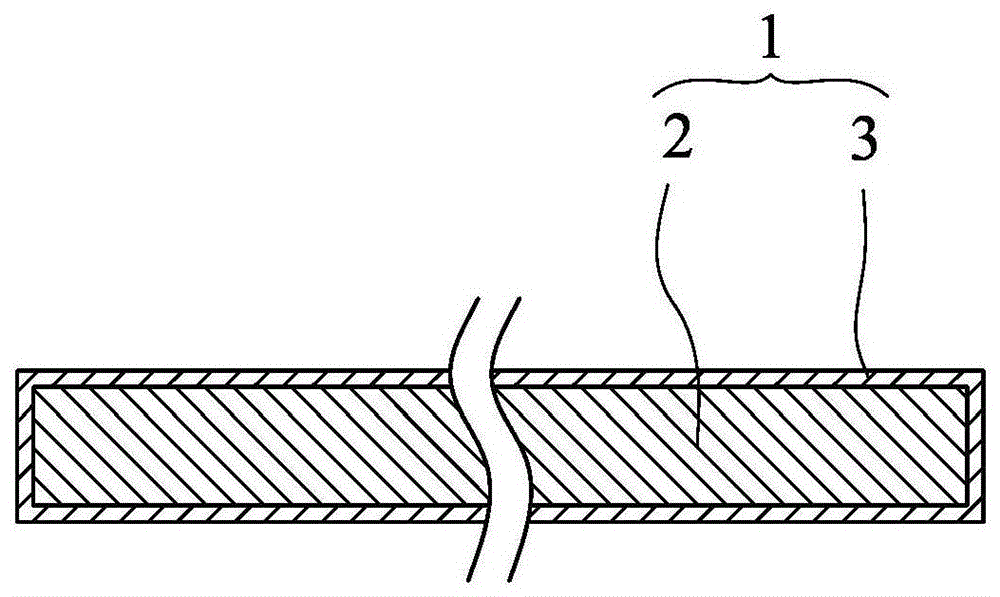

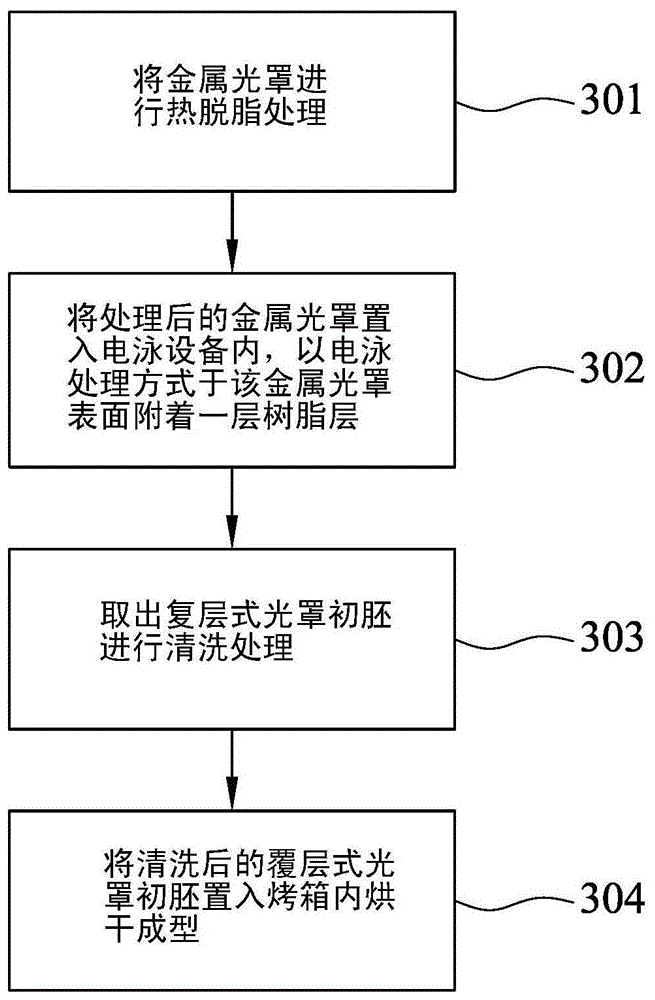

Manufacturing method of metal-plastic multilayer photomask

ActiveCN103676466BExtended service lifeReduce scratchesOriginals for photomechanical treatmentMetal layered productsManufacturing technologyElectrophoresis

The invention discloses a metallic-plastic multi-layered photomask and a manufacturing method thereof, which are mainly used in the manufacturing technology of photoelectric products. The multi-layered photomask is composed of a metallic photomask and a resin layer formed on the surface of the metallic photomask, wherein the resin layer is softer than the metallic photomask. The manufacturing method of the multi-layered photomask comprises the following steps: performing thermal debinding on the metallic photomask, further coating the surface of the metallic photomask with a resin layer by means of electrophoresis treatment, and then, orderly performing the operations of cleaning, drying and molding, thus forming the multi-layered photomask. Due to the resin layer, the multi-layered photomask provided by the invention can achieve the effects of buffering and wear resistance in the clamping fixation work of the manufacturing technology, so that the replacement cycle and service life of the multi-layered photomask are prolonged, and the quality of the manufacturing technology is also improved.

Owner:世禾科技股份有限公司

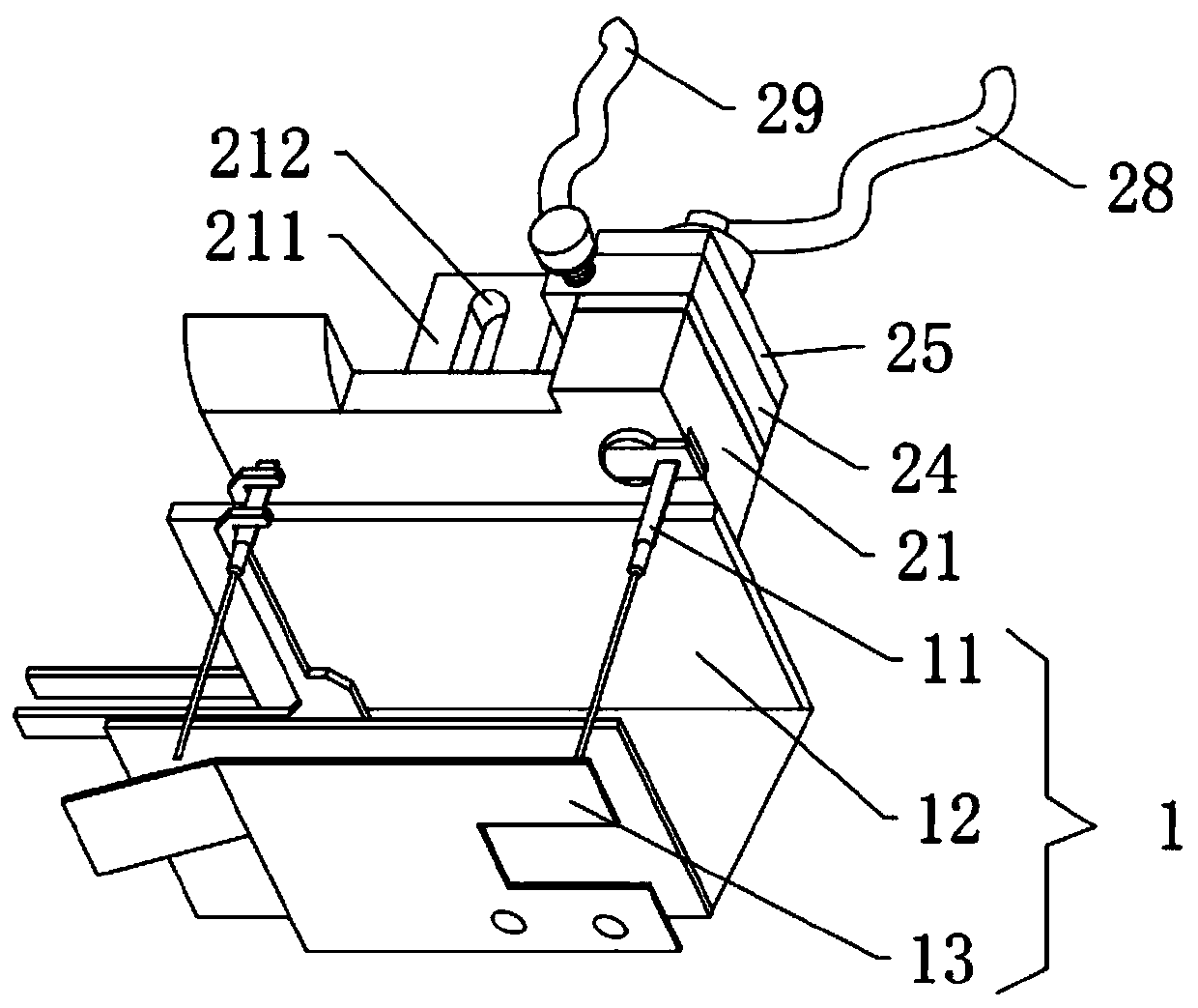

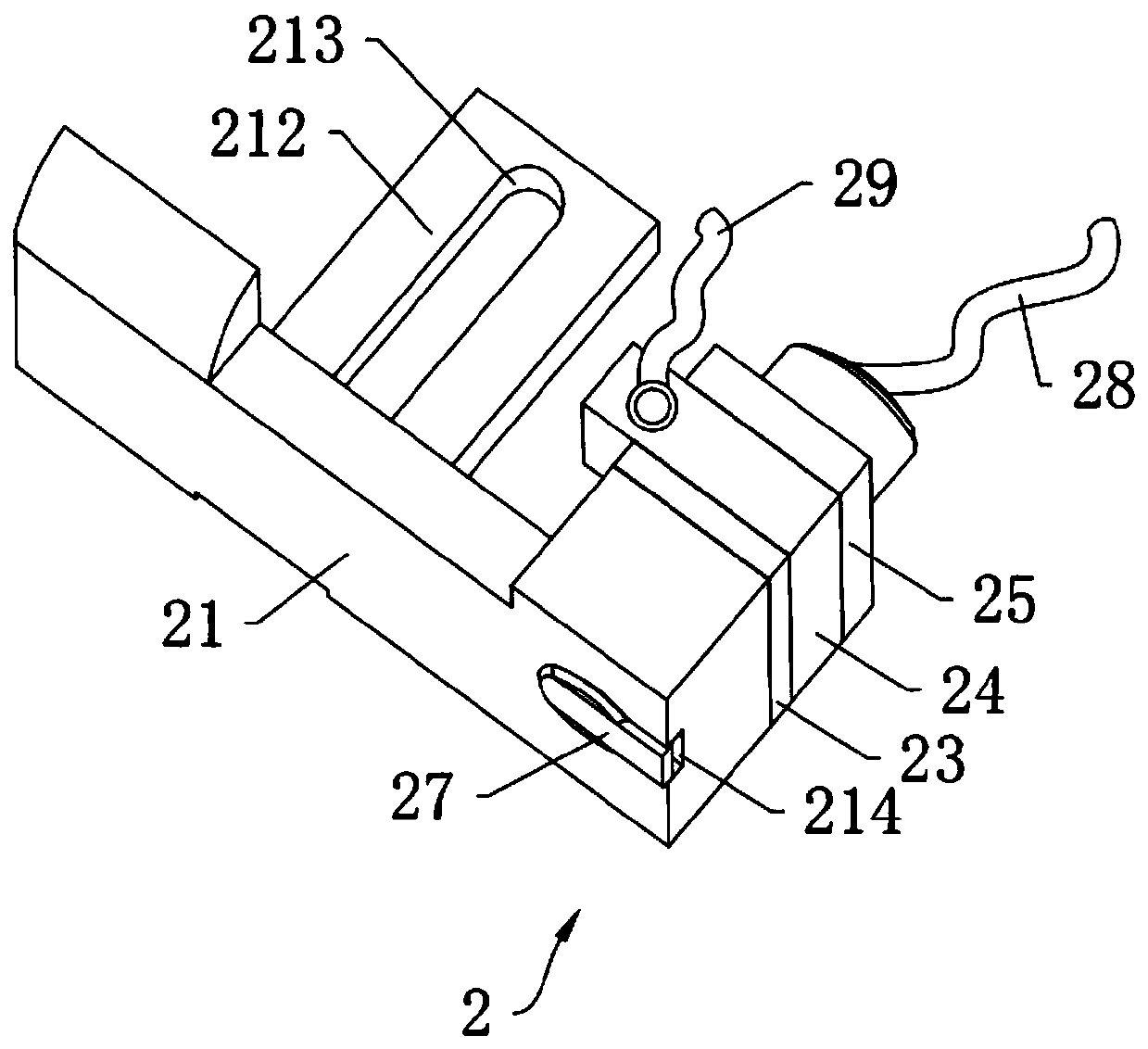

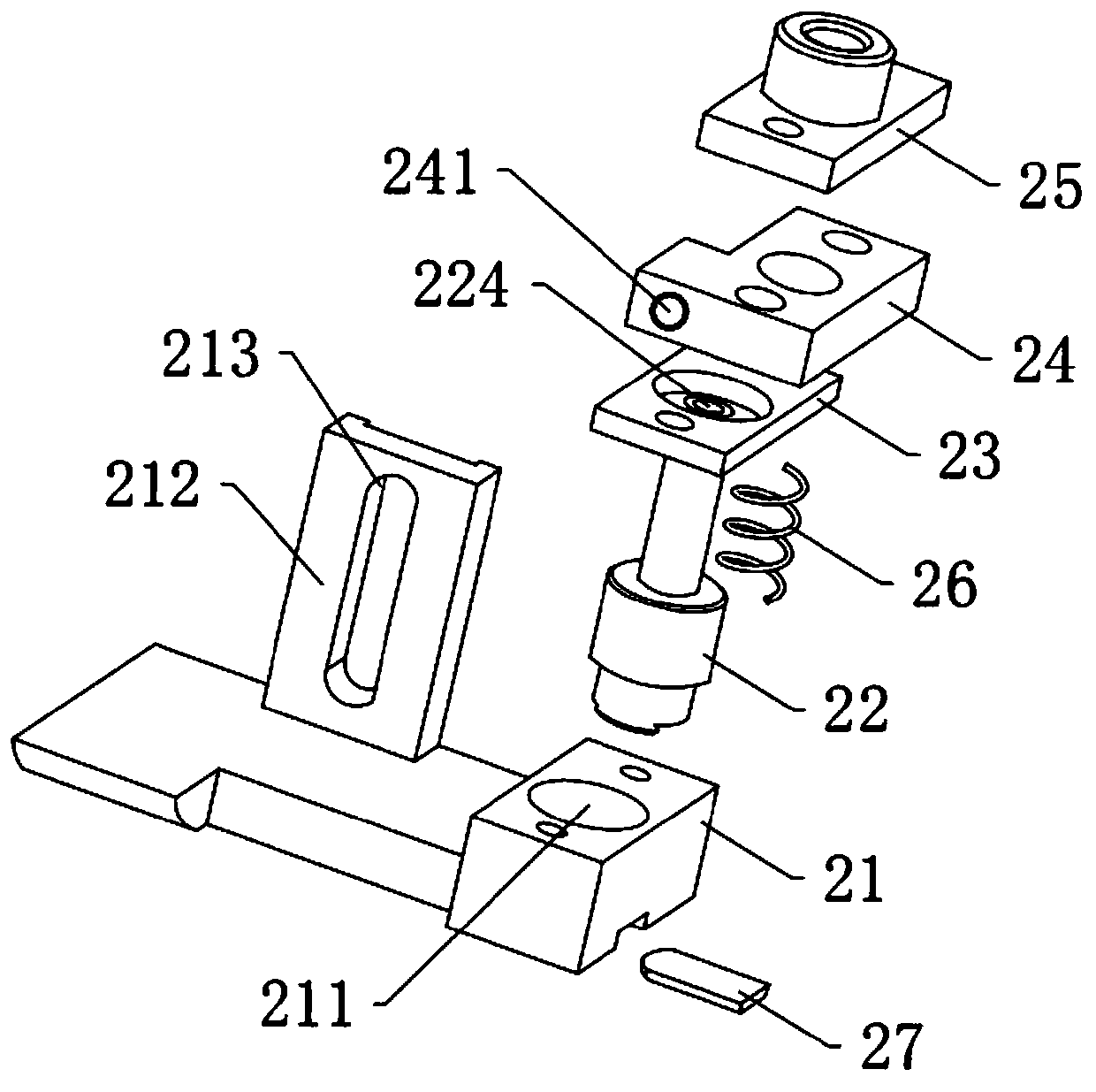

Aluminum electrolytic capacitor winding and nailing machine guide pin unloading detection device

PendingCN110275080AGuaranteed process rotationImprove performanceElectrical testingMeasurement instrument housingProgrammable logic controllerEngineering

The invention belongs to the technical field of capacitor manufacturing equipment and discloses an aluminum electrolytic capacitor winding and nailing machine guide pin unloading detection device. The aluminum electrolytic capacitor winding and nailing machine guide pin unloading detection device comprises a feeding assembly and a detection assembly; the feeding assembly comprises a guide pin, a guide pin groove and a pin push sheet; the detection assembly comprises a base, a detection shaft, a separation plate, a cover plate, a shaft sleeve and an elastic piece; the guide pin groove is located to one side of the detection assembly and is used for driving the guide pin to move along the X axis of the guide pin groove to the detection assembly; the pin push sheet is arranged to one side of the guide pin groove, wherein the one side of the guide pin groove backs onto the detection assembly and is used for pushing the guide pin to move along the Y axis of the guide pin groove to the detection assembly and turn on the detection assembly; and the detection assembly is externally connected with a PLC (programmable logic controller) and an LED (light emitting diode) signal lamp. The aluminum electrolytic capacitor winding and nailing machine guide pin unloading detection device of the invention has the advantages of simple design and reasonable structure. According to the prior art, whether a guide pin is located in a positioning range cannot be ensured, and as a result, the deviation of the guide pin from a working station during the unloading of the guide pin tends to occur, and the problem of poor machining quality of the guide pin can be brought about. However, with the aluminum electrolytic capacitor winding and nailing machine guide pin unloading detection device of the invention adopted, the problems in the prior art can be solved.

Owner:CAPXON ELECTRONIC (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com