An automated warehouse system, production line and logistics management method

An automated warehouse and logistics management technology, applied in technical management, general control system, control/adjustment system, etc., can solve problems such as round-trip transportation, reduced equipment life, and short distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

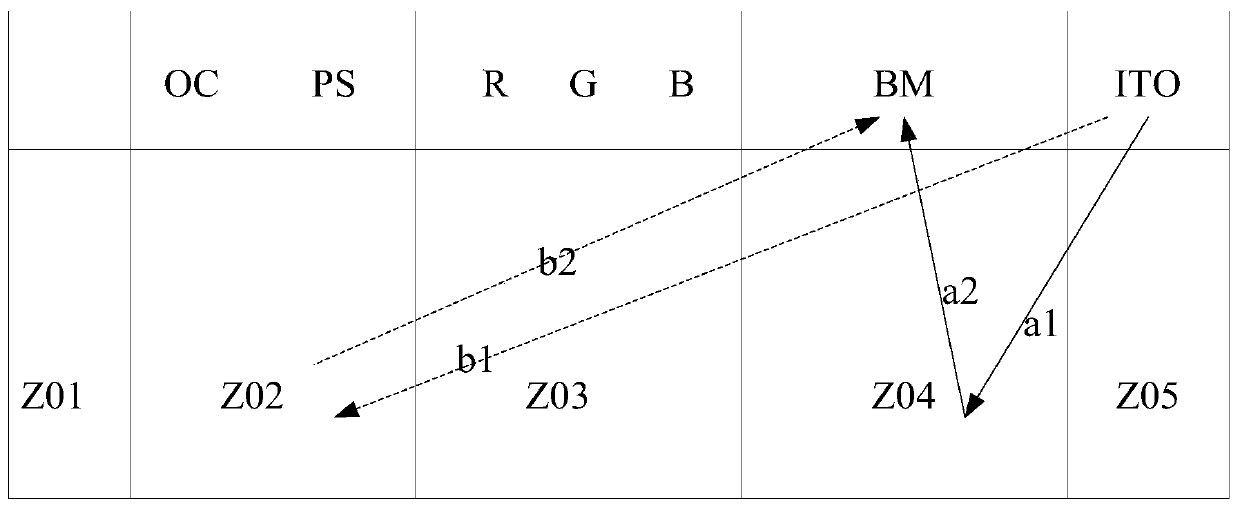

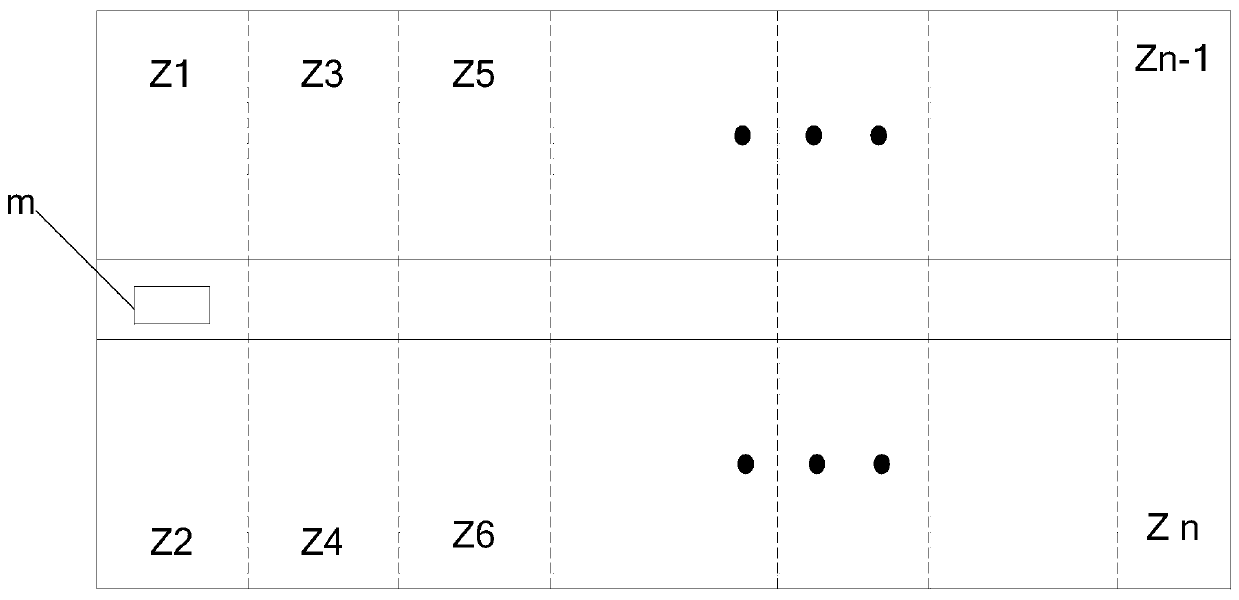

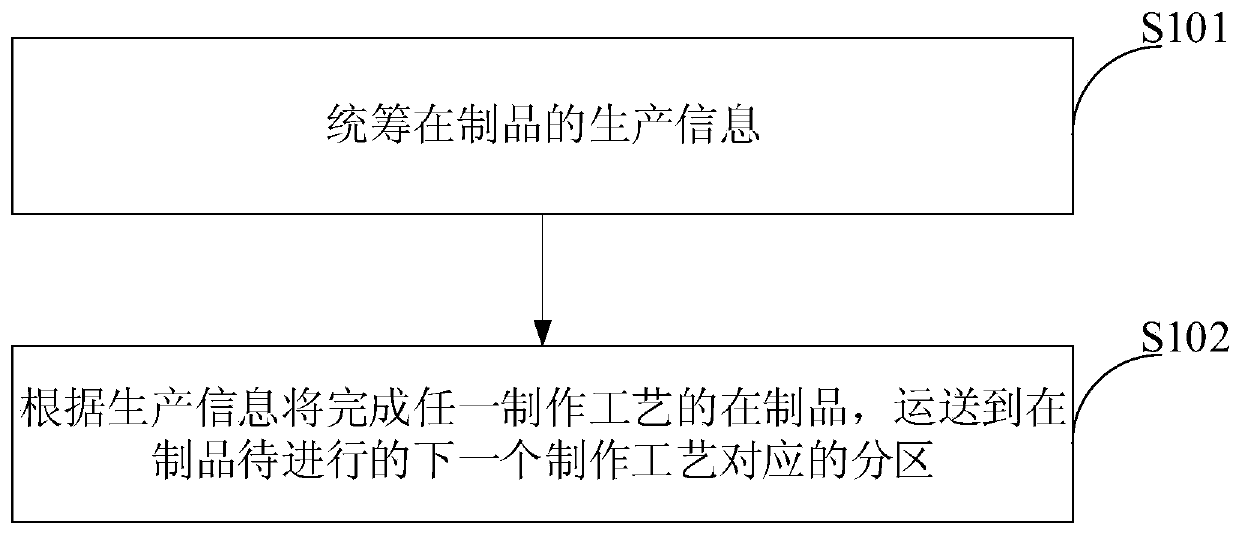

[0037] The specific implementation manners of the automated warehouse system, production line and logistics management method provided by the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] An embodiment of the present invention provides an automated warehouse system for the production line of display panels, such as figure 2 As shown, the automated warehouse system may include: multiple partitions Z1-Zn, server host ( figure 2 not shown), the control module ( figure 2 not shown) and at least one handling module m; wherein,

[0039] Each zone Zn corresponds to a manufacturing process of WIP;

[0040] Each partition Zn is used to store the work-in-progress of the manufacturing process corresponding to the partition Zn;

[0041] The server host is used to coordinate the production information of the work in progress and send the production information to the control module;

[0042] The control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com