Patents

Literature

46results about How to "Guaranteed warm-up effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

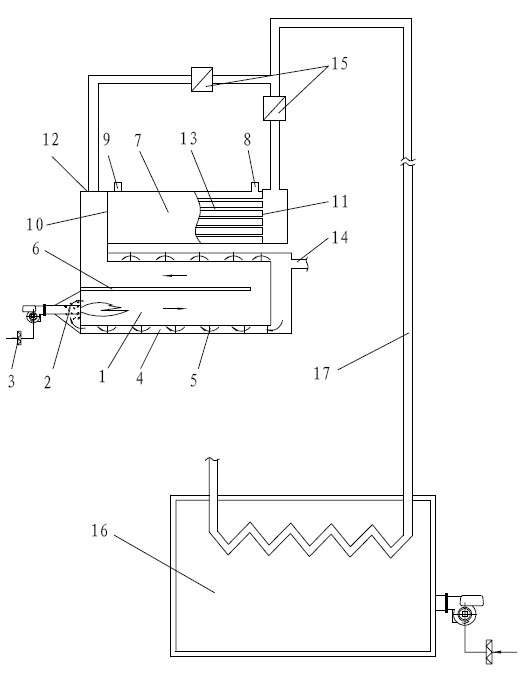

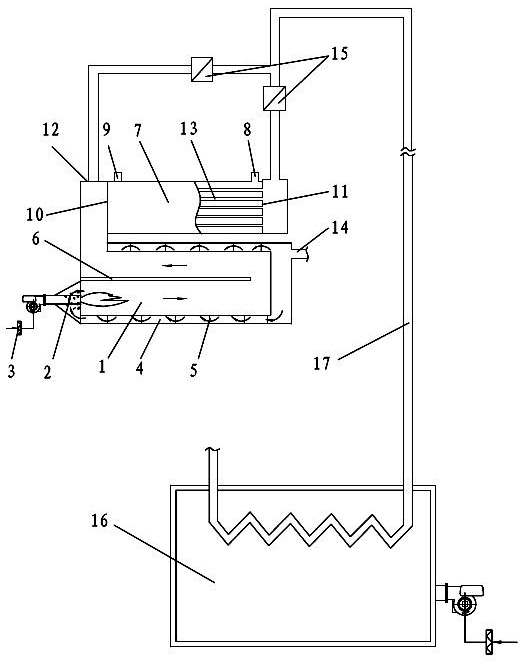

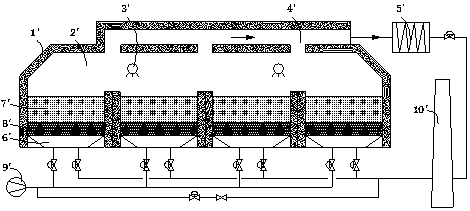

Treatment method and apparatus for recycling ammonia nitrogen wastewater

InactiveCN101318752AReduce dosageGuaranteed preprocessing effectMultistage water/sewage treatmentWater/sewage treatment by heatingResource utilizationSewage

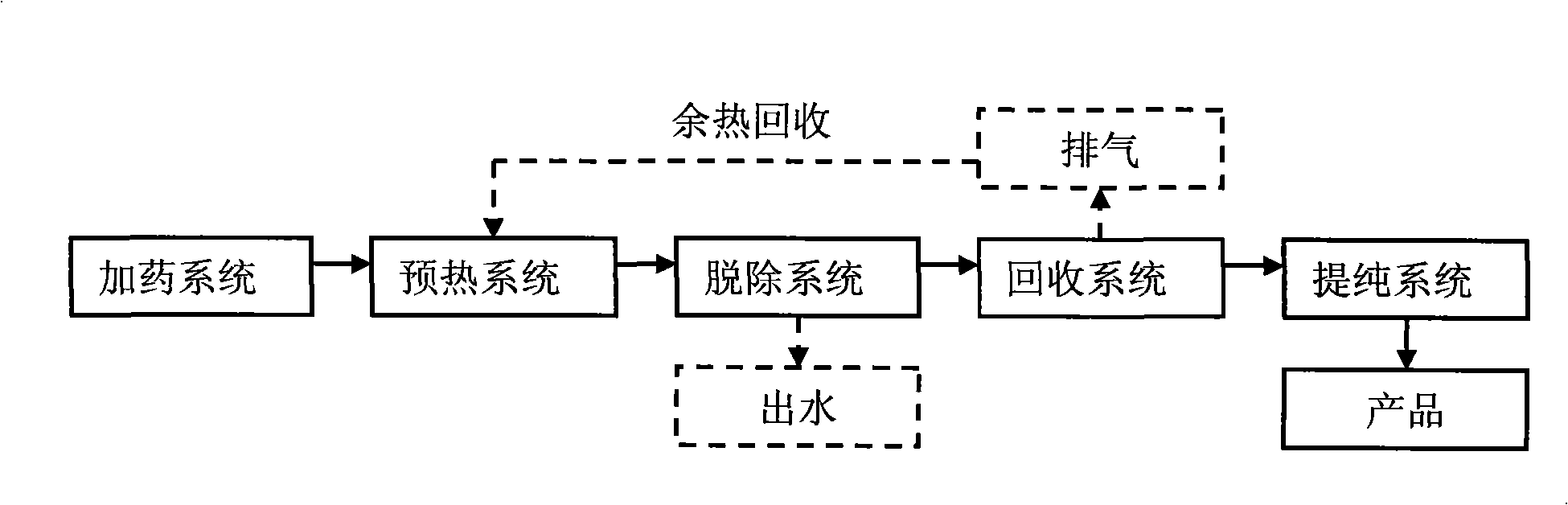

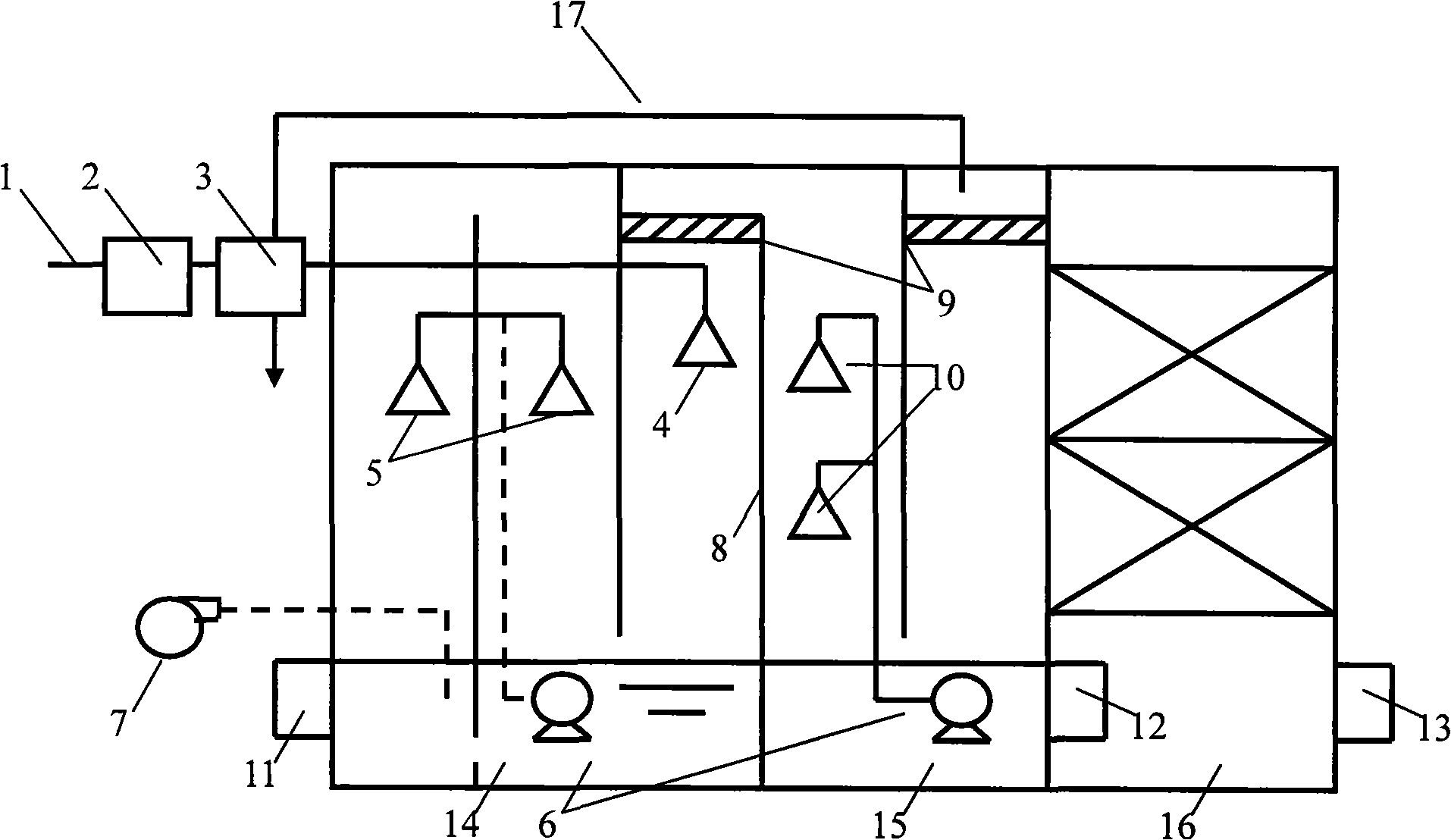

The invention relates to a method and a device for recycling treatment of ammonia nitrogen wastewater. The use method combining the device comprises the following steps that: a PH value of ammonia nitrogen wastewater is adjusted in an automatic medicine addition device; the ammonia nitrogen wastewater is preheated in a preheater, evenly distributed by a spraying device in a removal working section and collected in a bottom liquid storage zone; after ammonia is blown off by adopting forced-air blast, the ammonia in the wastewater is repeatedly removed by a circulating spraying system, purified and discharged from an effluent weir; ammonia-containing waste gas is filtered by a demisting device and subject to multilevel spraying and absorption so as to reclaim an ammonia crude product; and the purified gas is exhausted from the top part. The method and the device for recycling treatment of the ammonia nitrogen wastewater are suitable for ammonia nitrogen wastewater produced in the process of various industrial and agricultural productions, the treatment of domestic sewage and the resource utilization of materials, reclaim useful substances as possible while treating wastewater, reduce the cost for pollutant treatment and the emission of the pollutants and improve economical benefit while protecting environment.

Owner:ZHEJIANG UNIV

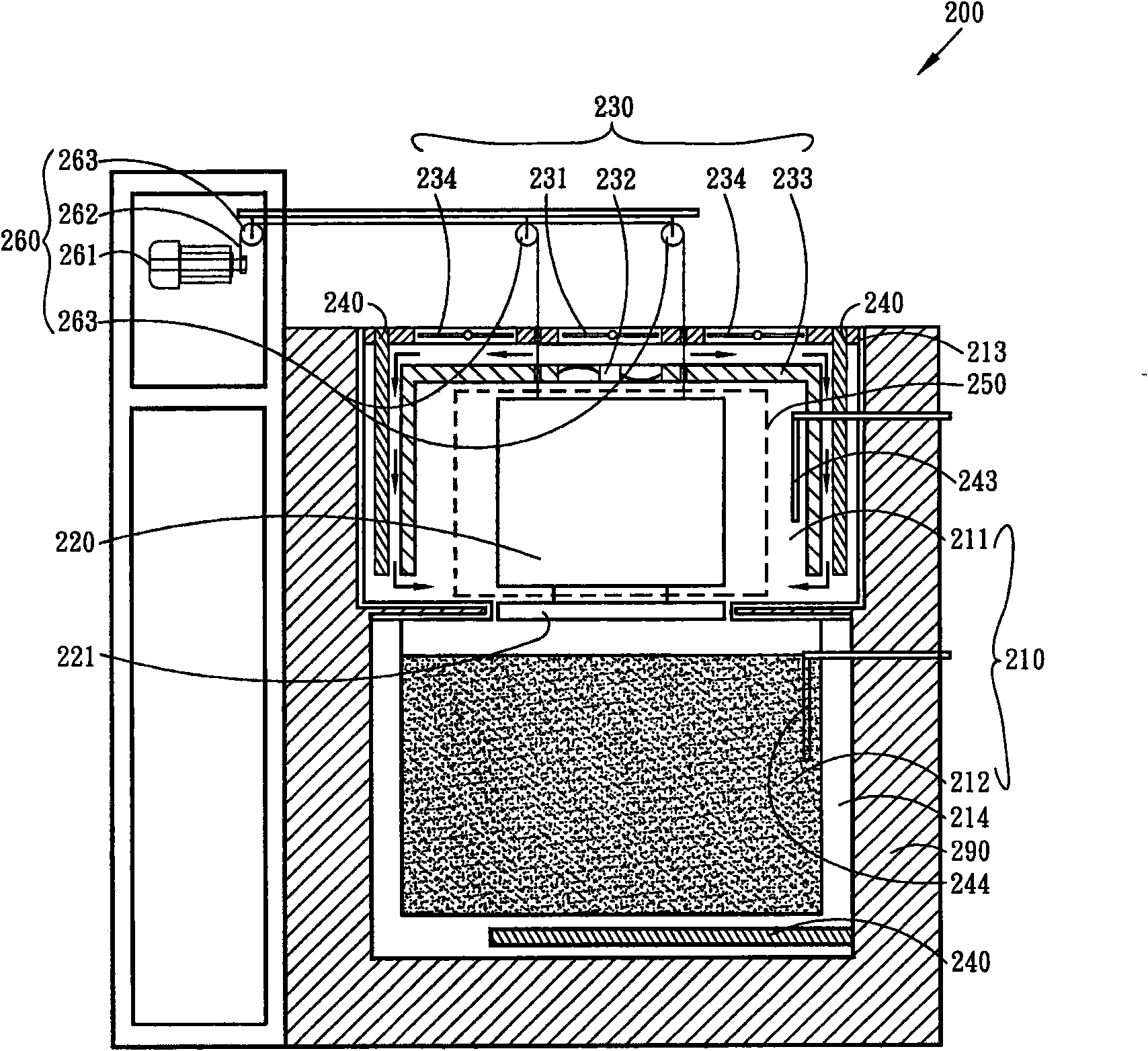

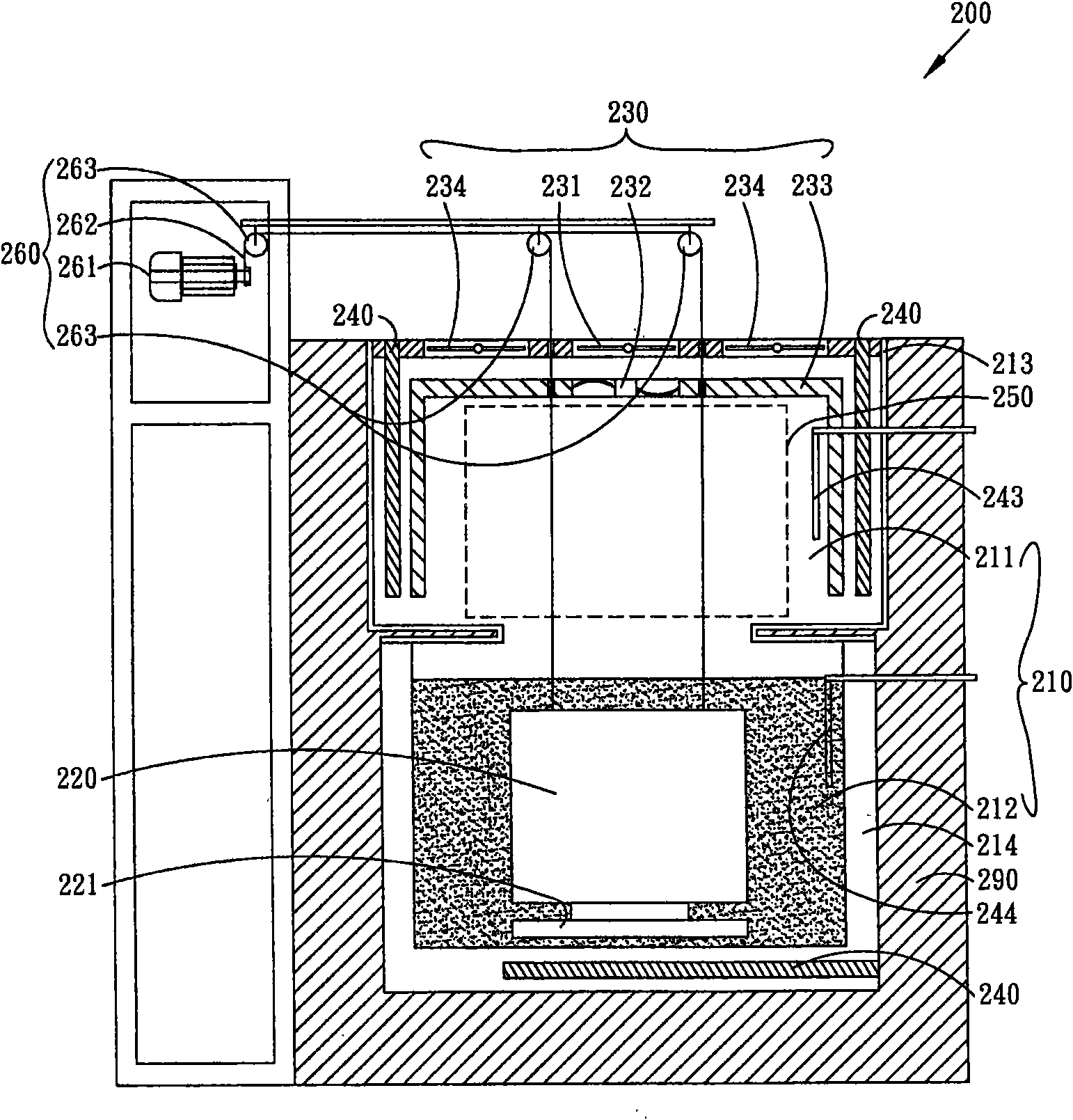

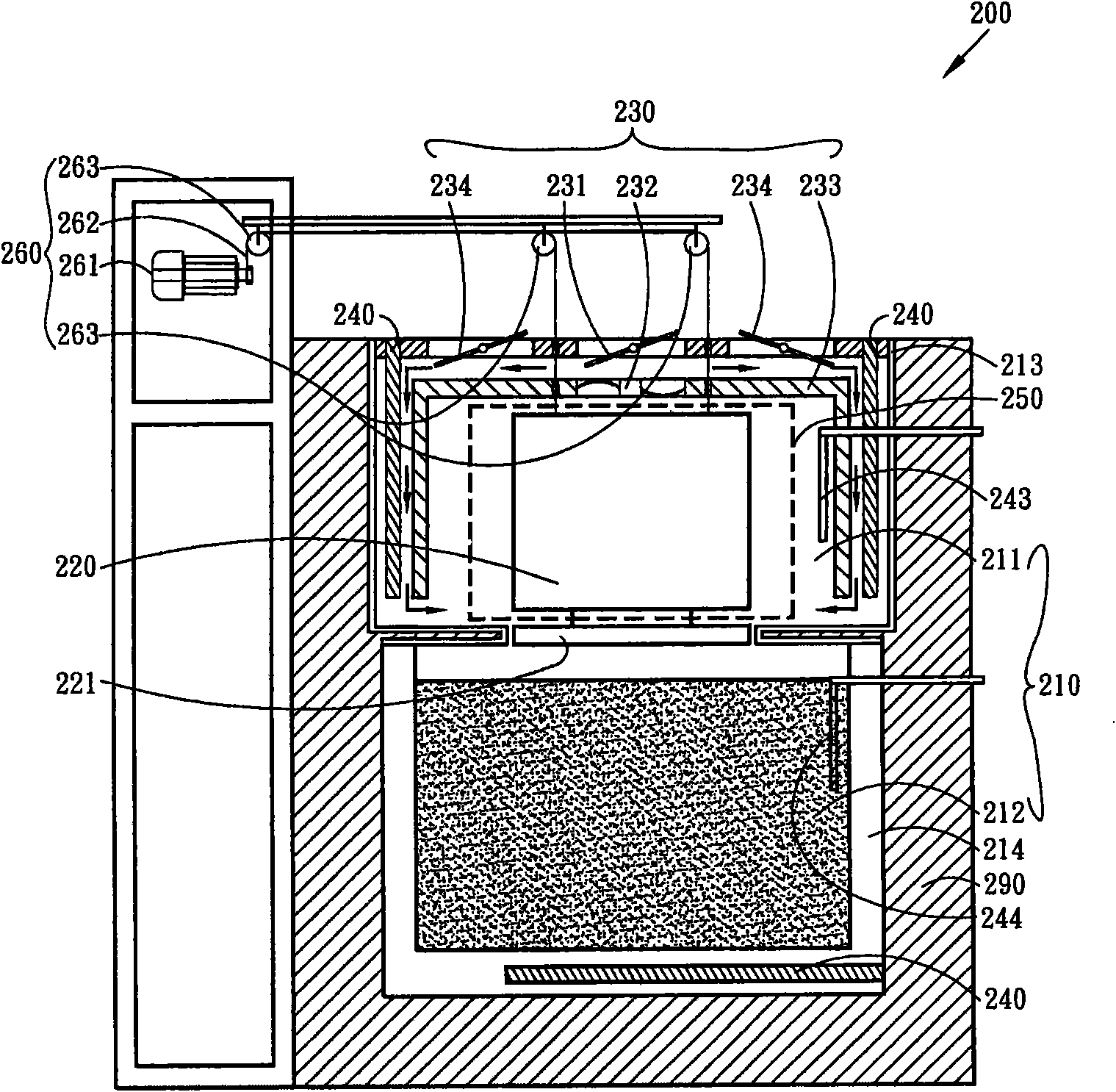

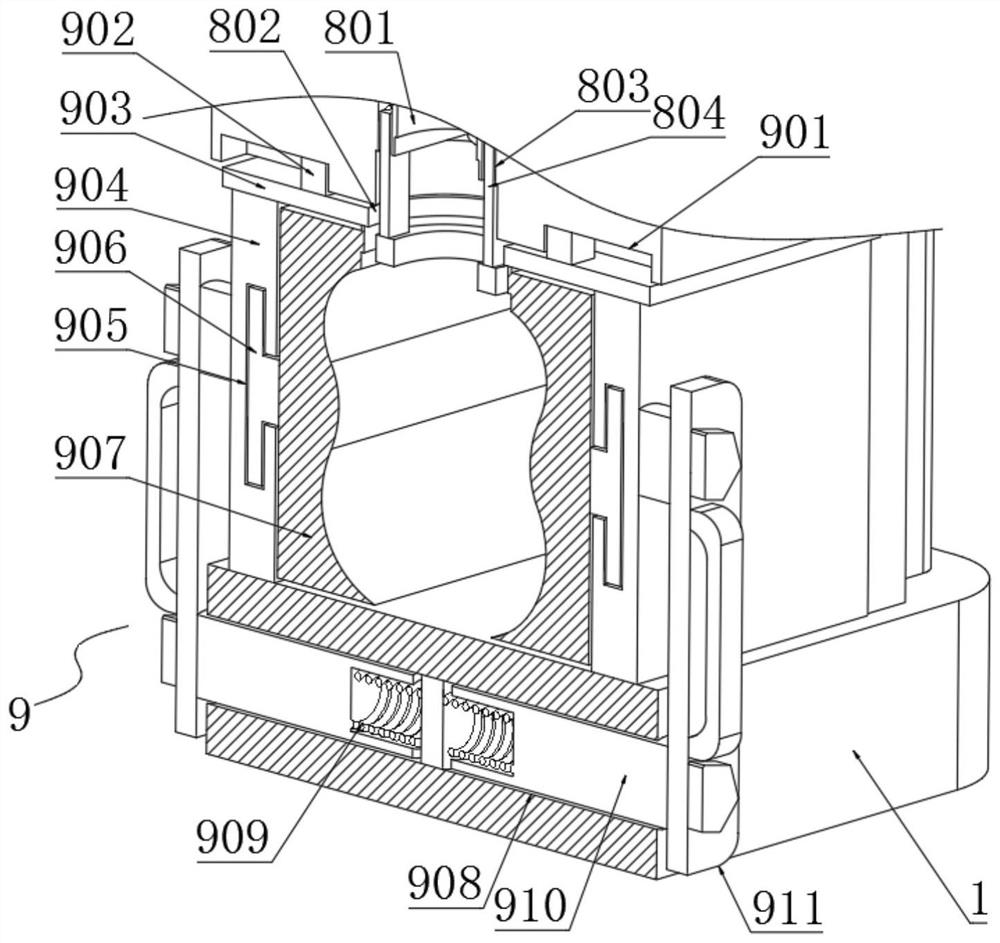

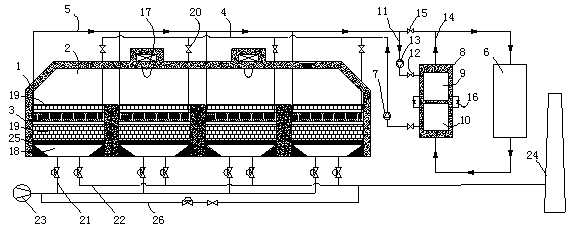

Carbon/carbon composite component chemical vapor infiltration device

ActiveCN104498891AWell mixedIncrease profitChemical vapor deposition coatingPressure controllerCarbon composites

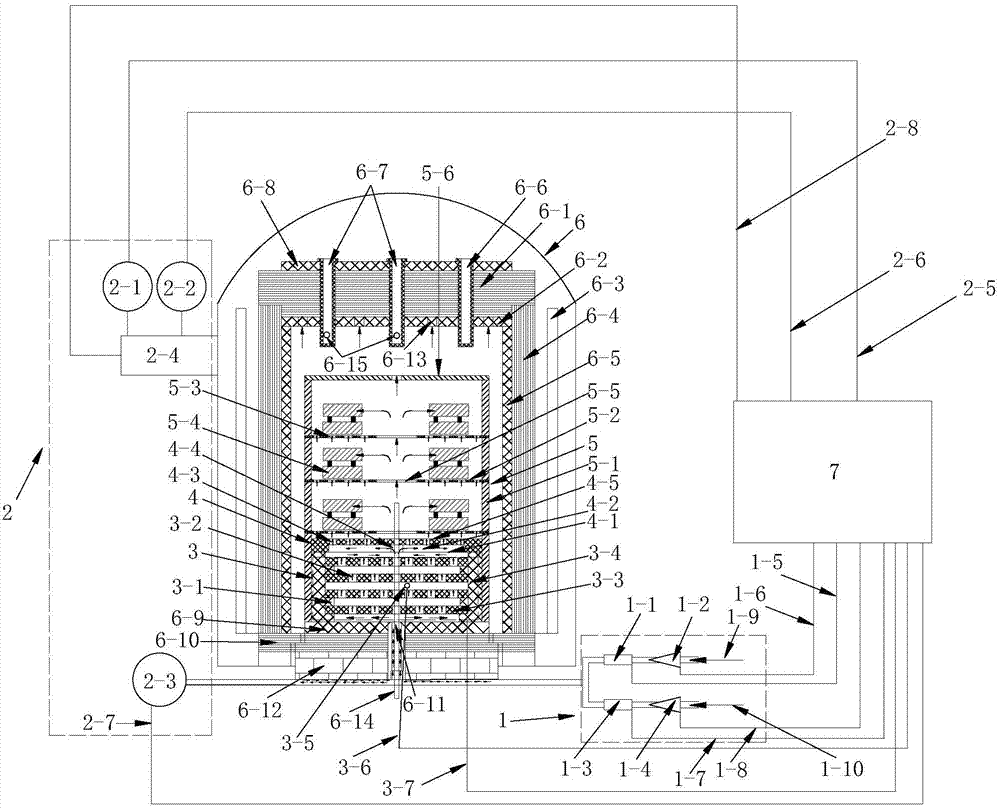

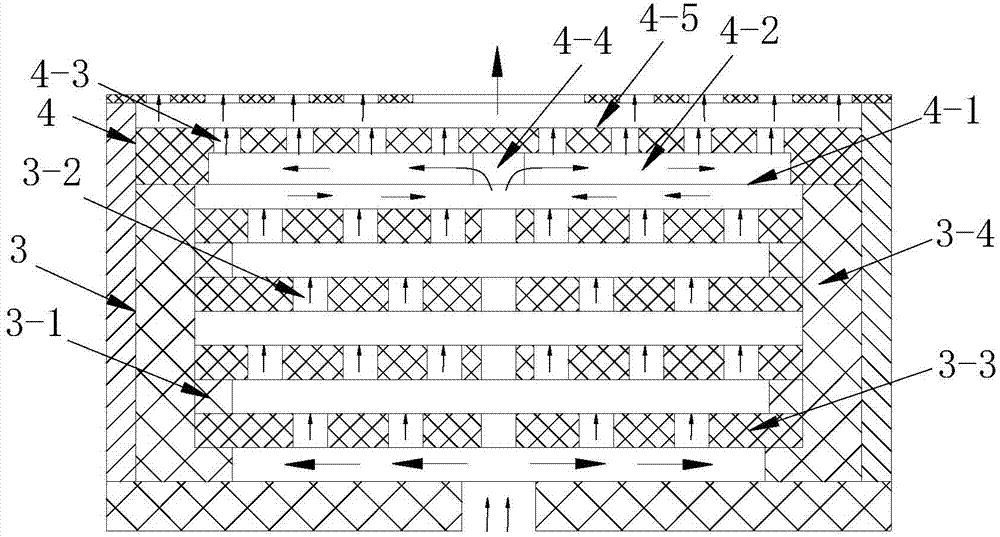

The invention brings forward a carbon / carbon composite component chemical vapor infiltration device and aims to provide a device for solving problems of low reactant gas utilization rate and low infiltration efficiency existing by chemical vapor infiltration in the prior art. The invention is realized by the following technical scheme: a gas mixing and preheating device for primary control of reactant gas diversion direction and a temperature sensor for monitoring preheating temperature of reactant gas are arranged below a deep gas-mixing and outgassing device connected with a sealed infiltration chamber; the regulated and controlled reactant gas enters a gas mixing and preheating device from the bottom of a chemical vapor deposition furnace body through a gas supply device, and a controller automatically regulates electric power on a heater to obtain required preheating temperature; and the preheated reactant gas enters the sealed infiltration chamber and passes through a porous graphite liner plate to infiltrate through a composite preform placed inside the sealed infiltration chamber, and chemical vapor infiltration is performed under constant values by pressure control of a furnace pressure controller and temperature control of a temperature control sensor.

Owner:PLA NO 5719 FACTORY

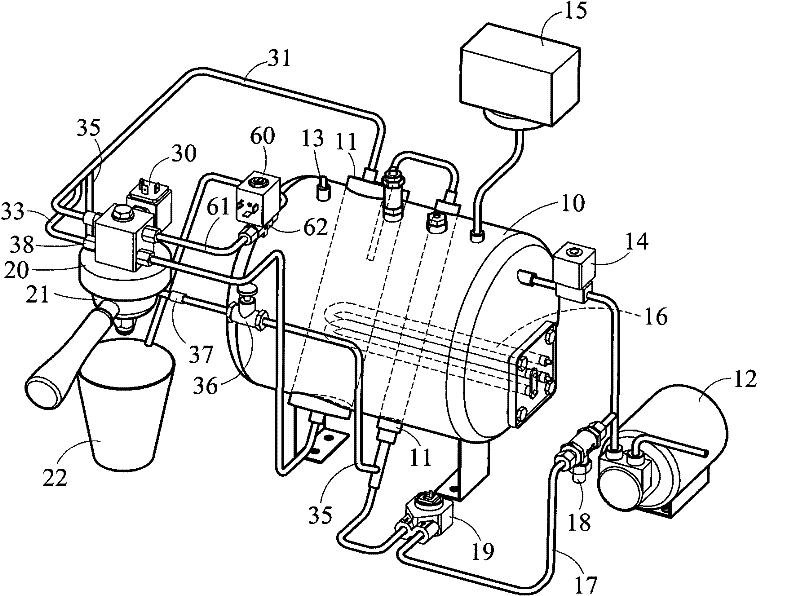

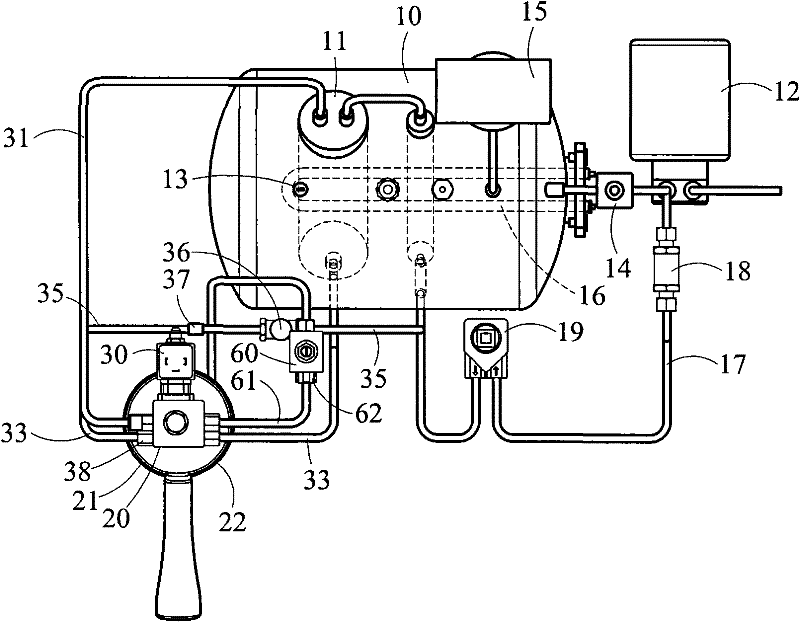

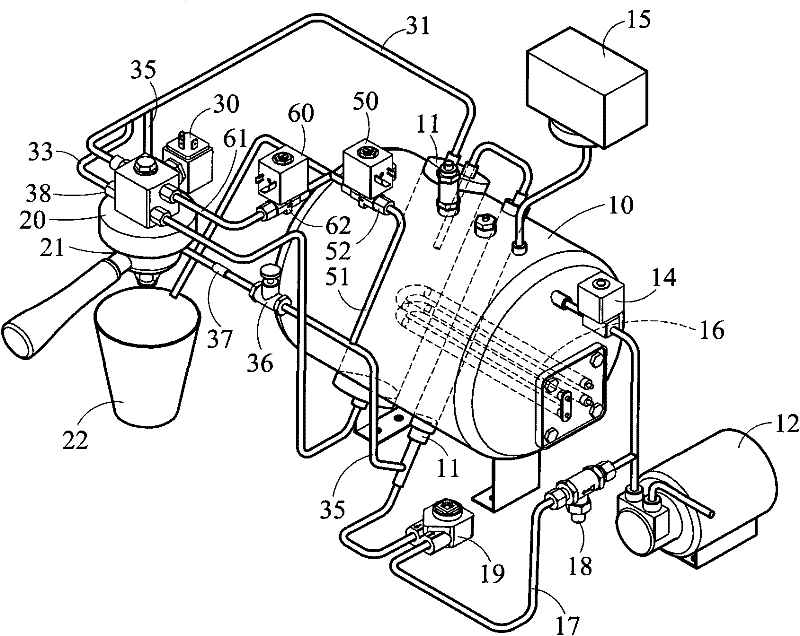

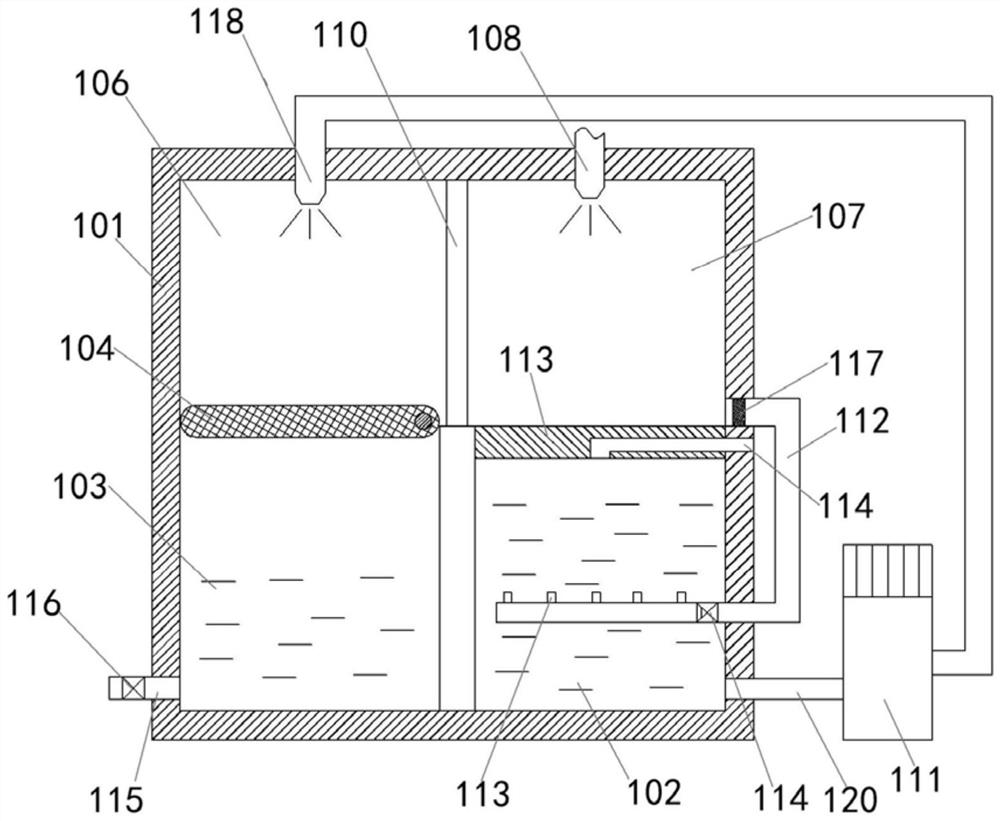

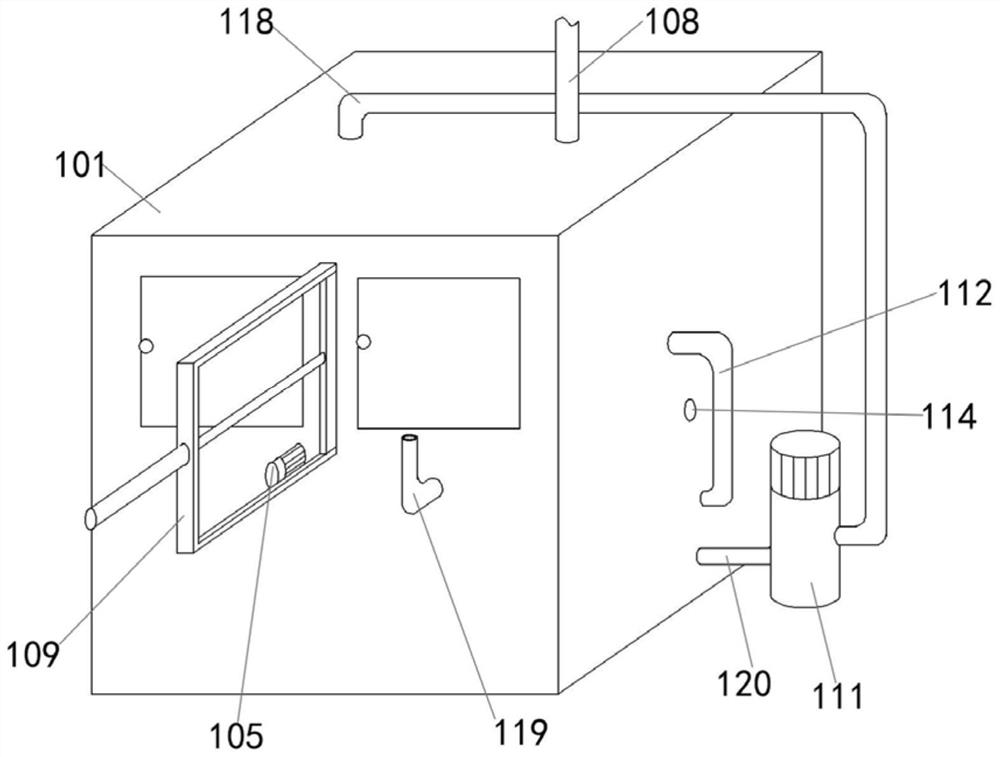

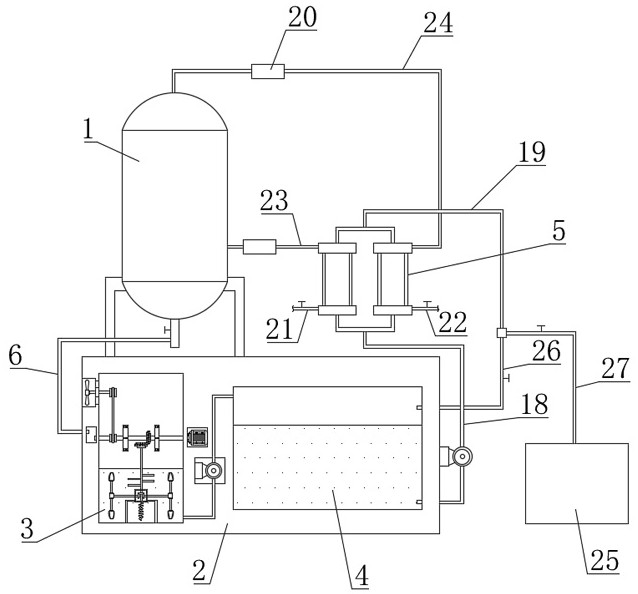

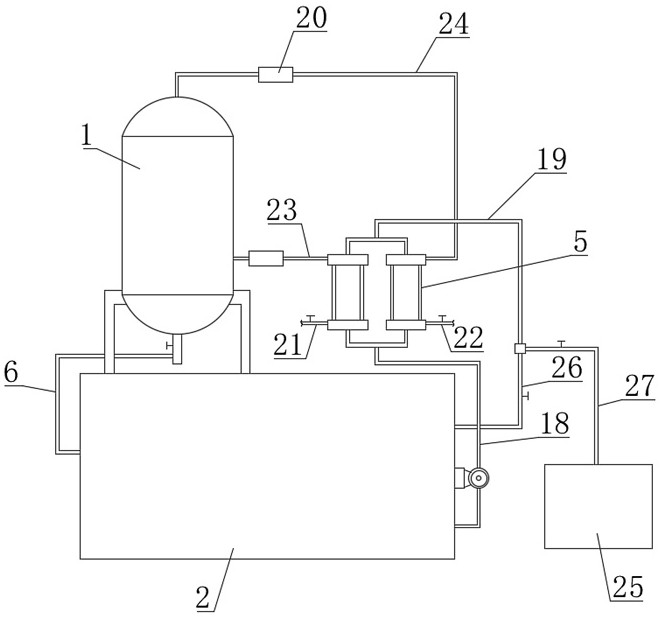

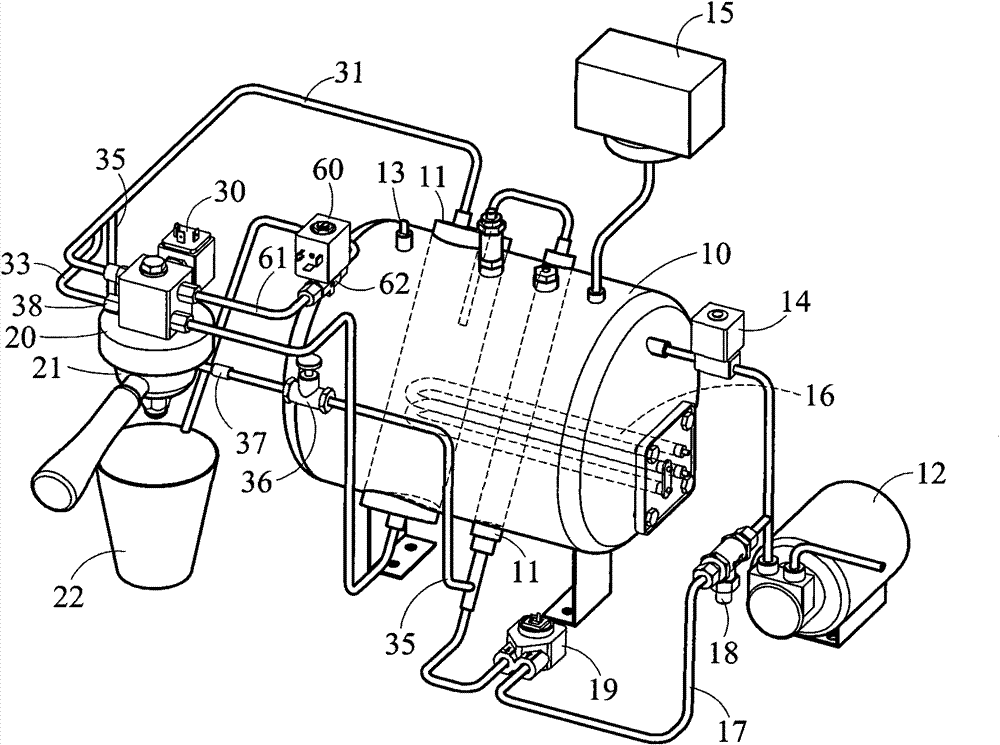

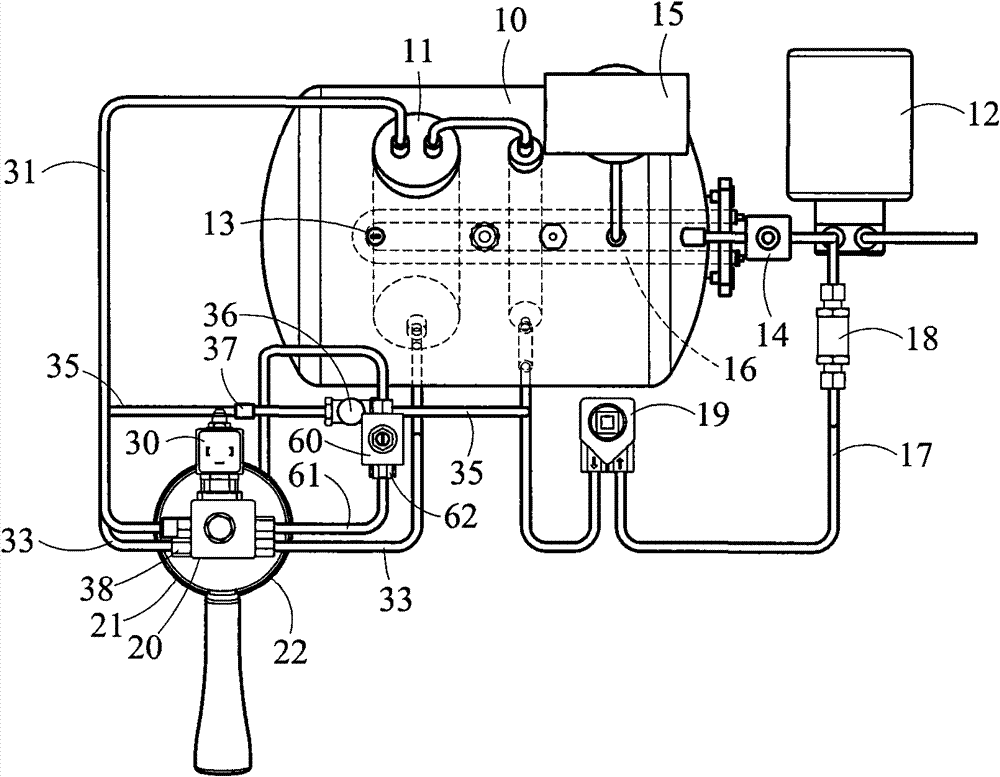

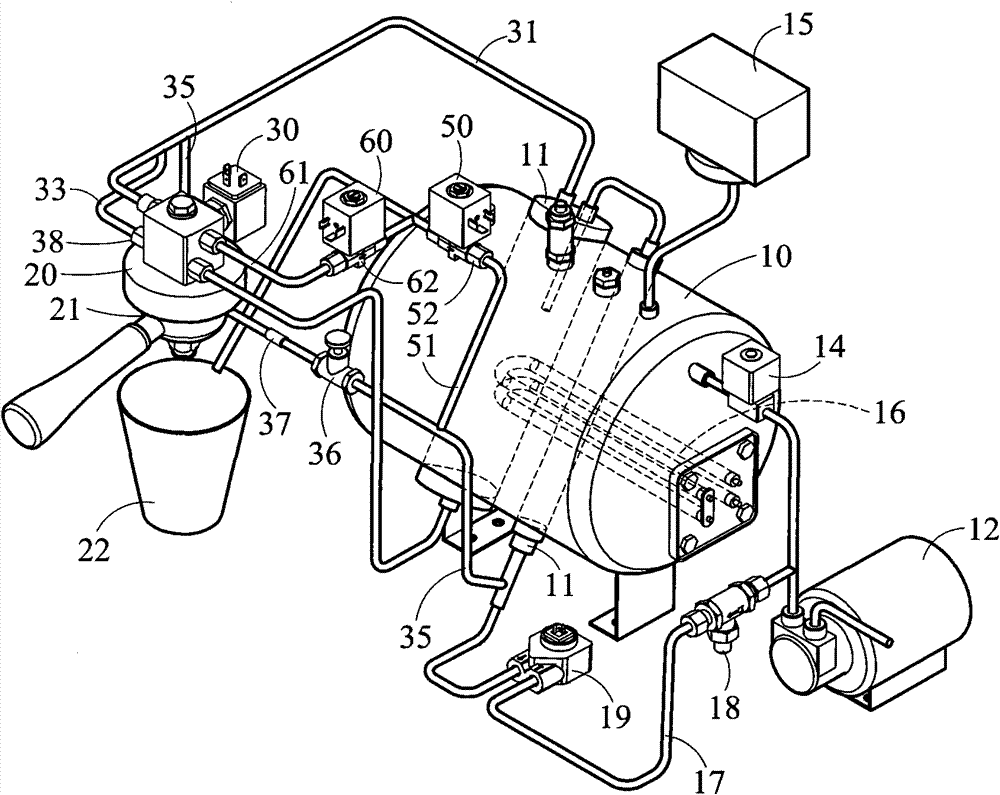

Drink preparation device

The invention discloses a drink preparation device, belonging to the field of machinery. The drink preparation device is mainly used for blending overheated hot water in a hot water pipe with cold water of a set flow rate in a cold water pipe to form a blended water flow with suitable temperature, and transmitting the blended water flow into a liquid dispenser. When a brewing solenoid valve is controlled to be opened, the liquid dispenser dispenses the blended water flow with suitable temperature to a preparation container in which drink components are previously provided so as to prepare drink from the drink components; and when the brewing solenoid valve is controlled to be closed, the liquid dispenser dispenses the blended water flow with suitable temperature to a hot water feeding pipe, and the blended water flow with suitable temperature is directly fed into the drink when a hot water feeding solenoid valve is controlled to be opened. When the brewing solenoid valve and the hot water solenoid valve are both closed, the hot water in a heat exchanger volatiles, passes through a preheating circulation line, and returns to a heat exchanger after being preheated by the liquid dispenser so as to form a preheating circulation.

Owner:刘宗熹

Self-preheating waste gas incinerator

InactiveCN101832568AEasy to handleImprove purification rateIncinerator apparatusThermal energyExhaust fumes

The utility model discloses a self-preheating waste gas incinerator which comprises an incineration chamber. A diaphragm is arranged in the incineration chamber, the inlet of the incineration chamber is communicated with a preheating pipe, the preheating pipe is sleeved outside the incineration chamber, the outlet of the incineration chamber is communicated with a heat exchanger, and a gas exhaust hole is respectively arranged at the high temperature outlet and the high temperature inlet of the heat exchanger. The utility model has the advantages of reasonable design, simple structure, favorable waste gas treatment effect, high waste gas purification rate through actual detection, small utilization stroke for heat energy recovery and little heat energy loss, saves a set of independent preheating device through a spontaneous preheating structure design, reduces the energy consumption on the basis of ensuring the preheating effect, can more sufficiently decompose the waste gas after preheating, can secondarily recover the heat energy, greatly enhance the recovery efficiency and efficiently save the energy.

Owner:ZHEJIANG HUALI INTELLIGENT EQUIP CO LTD

One-piece tempering furnace

InactiveCN101993192ASimple structureThe influence of ambient temperature difference is smallGlass tempering apparatusMetallurgyMobile phone

The invention relates to a one-piece tempering furnace, comprising a groove body, a material shelf, and a wind circulating system. The groove body comprises a thermoregulation area and a chemical tempering area, wherein the thermoregulation area is arranged above the chemical tempering area, the thermoregulation area and the chemical tempering area are thermally isolated from the outside world, and the temperatures of the thermoregulation area and the chemical tempering area can be adjusted independently; the material shelf can move vertically in a one-dimensional direction and traverse between the thermoregulation area and the chemical tempering area; and the wind circulating system is arranged above the thermoregulation area so that the groove body becomes an airtight space and the temperature of the thermoregulation area can be adjusted. The one-piece tempering furnace has the advantages of simple structure, lower cost and practicability, and the product is isolated from the outside air to guarantee the preheating effect without suffering cold and hot impact, therefore, the one-piece tempering furnace can be applied to the window glass lens of a common mobile phone and to the strengthening of glass with a big size.

Owner:TPK LENS SOLUTIONS INC

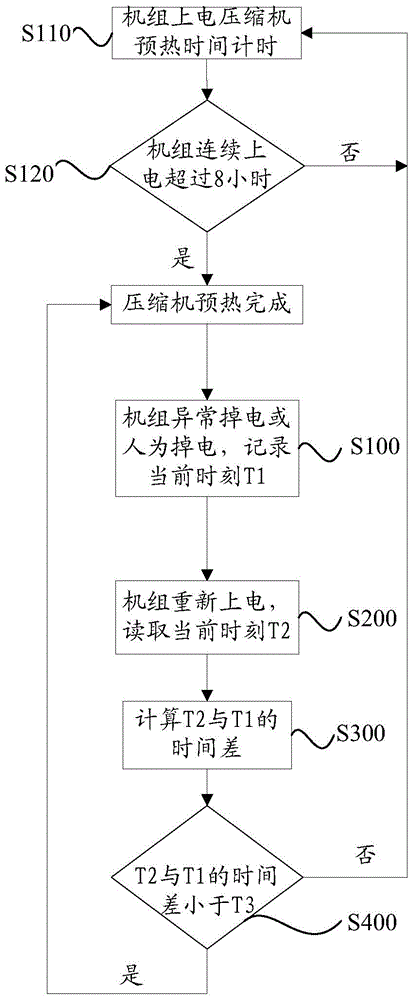

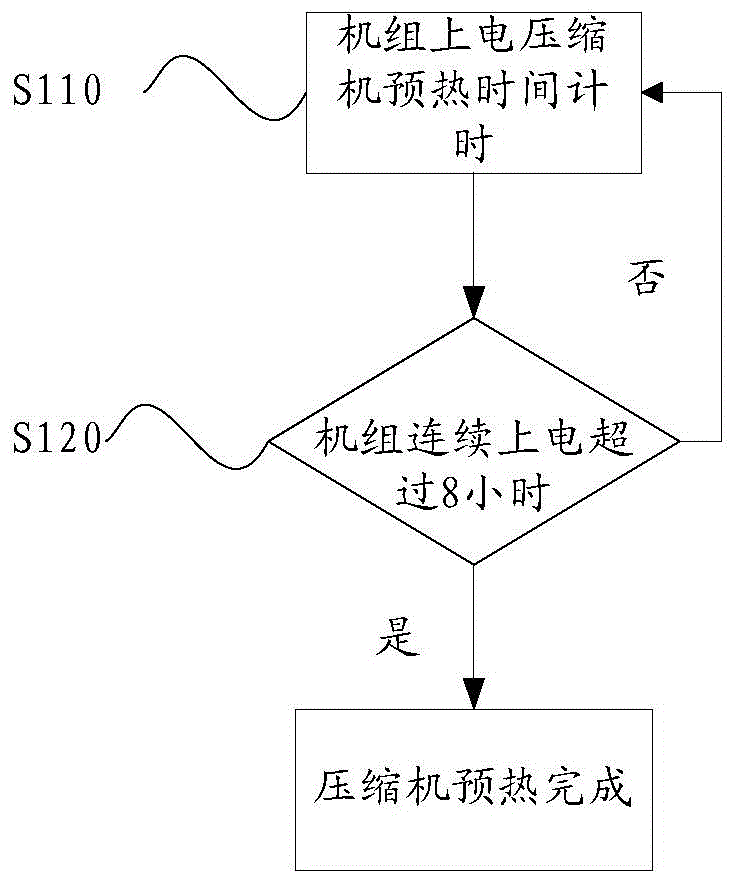

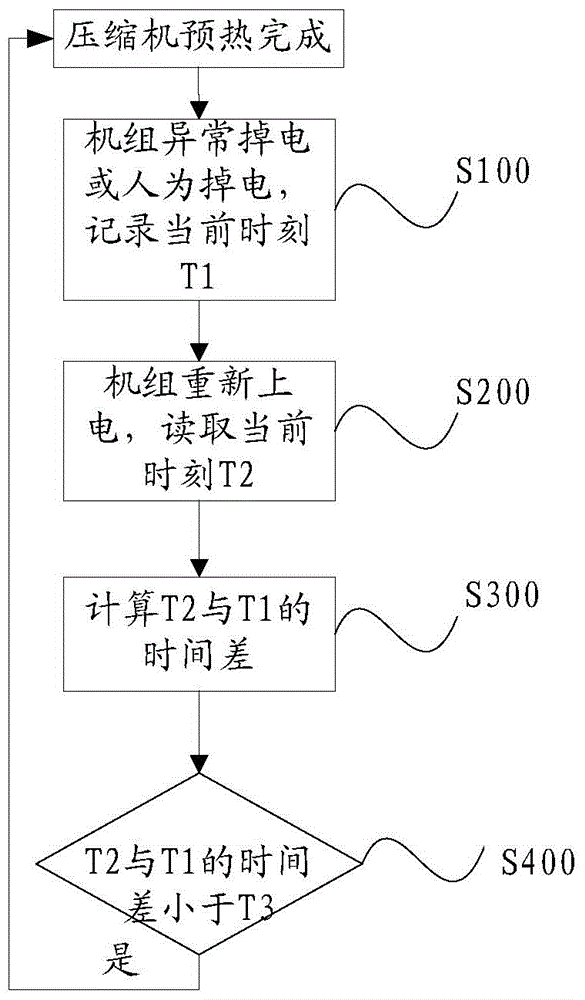

Preheating processing method and device for air conditioning unit compressor

InactiveCN104633839AAvoid warm-up timeImprove debugging efficiencyMechanical apparatusSpace heating and ventilation safety systemsElectricityControl theory

The invention discloses a preheating processing method and device for an air conditioning unit compressor. The method comprises the following steps that after an air conditioning unit is preheated for preset preheating time, the power failure moment is recorded during power failure in the starting-up adjusting process; when the air conditioning unit is powered on again and started after power failure, the power recovery moment is recorded, and the power failure time is worked out according to the power failure moment and the power recovery moment; after the power failure time is compared with the preset warning time, the recovery preheating mode of the air conditioning unit compressor is determined. According to the method and device, on the basis that the preheating effect of the compressor is guaranteed, and the installing and debugging are not affected, the preheating time of the compressor does not need to be spent again, the debugging efficiency is improved, and the time cost is saved.

Owner:GREE ELECTRIC APPLIANCES INC

Energy-saving casting system

The invention discloses an energy-saving casting system. The energy-saving casting system comprises a casting material cleaning device and a casting mold, wherein the casting material cleaning devicecomprises a cleaning shell, the lower part of the cleaning shell is divided into a rust removal liquid storage room and a waste liquid storage room by a fixed baffle, a blocking net is arranged abovethe waste liquid storage room, the blocking net is fixedly connected with an output shaft of a turning motor, the turning motor is fixedly connected with the side wall of the cleaning shell, the spaceabove the blocking net is a rust removal room, a rust removal liquid nozzle is fixed at the upper end of the rust removal room, a hot air drying room is arranged at the right side of the rust removalroom, a hot air nozzle is fixed at the upper end of the hot air drying room, the rust removal room is separated from the hot air drying room by a plate of a slide valve, and the slide valve is fixedon the side wall of the cleaning shell; the rust removal liquid nozzle communicates with the outlet of a delivery pump, an inlet pipe of the delivery pump communicates with the bottom of the rust removal liquid storage room, the bottom of the hot air drying room communicates with a plurality of exhaust gas nozzles by a middle pipe, and a check valve is arranged on the middle pipe.

Owner:徐双伟

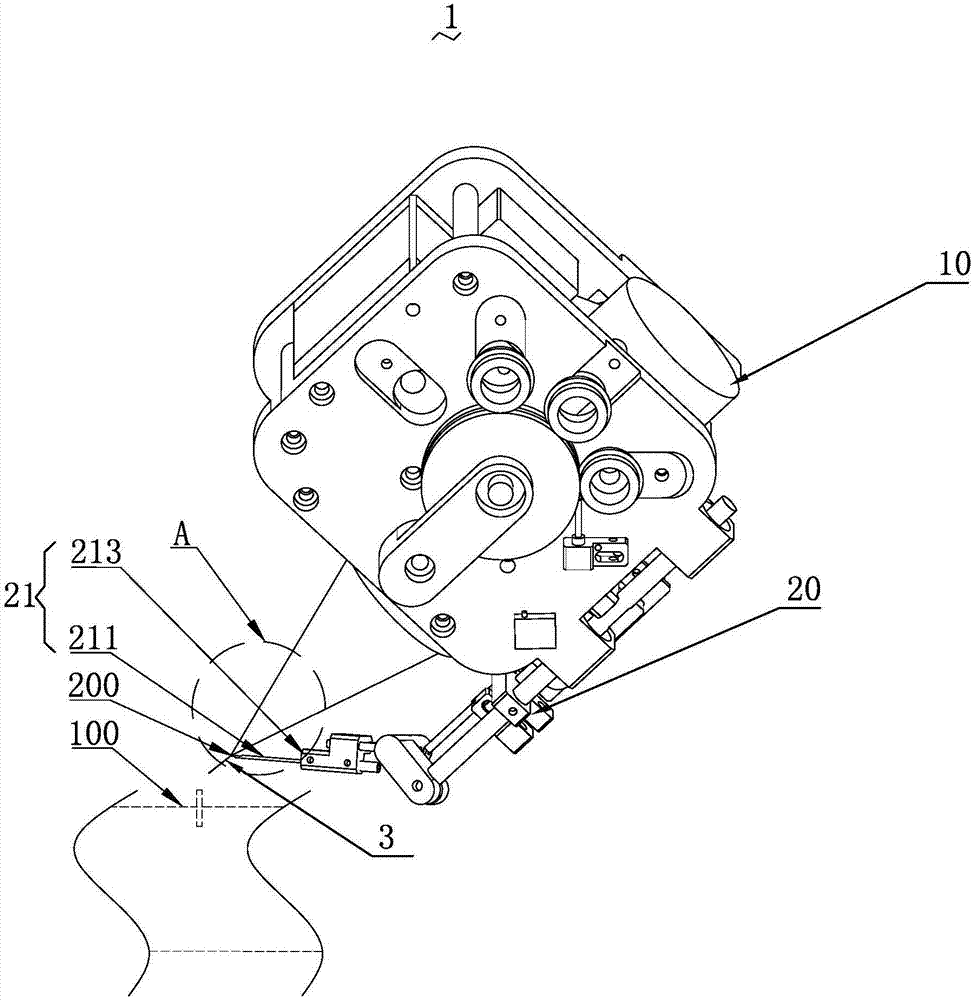

Laser welding method and device

ActiveCN107414227AMelting fastImprove welding efficiencyMetal working apparatusSolder feeding devicesEngineeringNotching

The invention relates to the technical field of welding, in particular to a laser welding method and a device thereof. The laser welding device comprises a laser generating mechanism and a tin feeding mechanism, wherein the tin feeding mechanism comprises a tin feeding needle; the tin feeding needle is a tubular object with an accommodating cavity, and comprises a tube wall which surrounds the accommodating cavity and two end surfaces; and end openings which communicate with the accommodating cavity are separately formed in the two end surfaces; and a notch which communicates with the accommodating cavity is formed in the tube wall, so that a tin wire is fed out from the end openings after being firstly exposed from the notch in a transfer direction. The laser generating mechanism is used for generating laser which acts on the tin wire transferred by the tin feeding needle, so that the tin wire is fed out from the two end openings after being preheated at the notch. The laser welding method adopts the laser welding device to preheat the tin wire, so that a workpiece is welded. The notch which communicates with the accommodating hole is formed in the tube wall, so that the tin wire is fed out from the end openings after being exposed from the notch and being preheated by laser; and the preheated tin wire can be molten more quickly in a welding process, so that welding efficiency is improved.

Owner:深圳云麟科技有限公司

Environment-friendly casting mold capable of recovering waste heat

InactiveCN111618244AEasy to useImprove cooling effectGas treatmentDispersed particle filtrationThermodynamicsProcess engineering

The invention discloses an environment-friendly casting mold capable of recovering waste heat. The environment-friendly casting mold comprises a lower mold base, wherein connecting plates are symmetrically and fixedly connected to the top end of the lower mold base; an upper mold base is fixedly connected to the top ends of the connecting plates; an injection molding pipe is fixedly connected to the center of the top end of the upper mold base; a heating cylinder is fixedly connected to the top end of the injection molding pipe; cooling and waste heat circulating mechanisms are symmetrically and fixedly connected to the outer end of the heating cylinder; and a waste gas purification and waste heat recovery mechanism is fixedly connected to the top end of the heating cylinder. The environment-friendly casting mold is scientific and reasonable in mechanism and safe and convenient to use; the cooling and waste heat circulating mechanisms are arranged, and water in a water tank is used forexchanging heat with a solution in the mold, so that the heat dissipation effect of the solution is improved, the solution can be rapidly cooled, the material forming efficiency is improved, and theproduction efficiency is improved; and meanwhile, the water subjected to heat exchange is fed into a heating chamber through a water outlet pipe, and materials in the heating cylinder are preheated through the heating chamber.

Owner:徐双伟

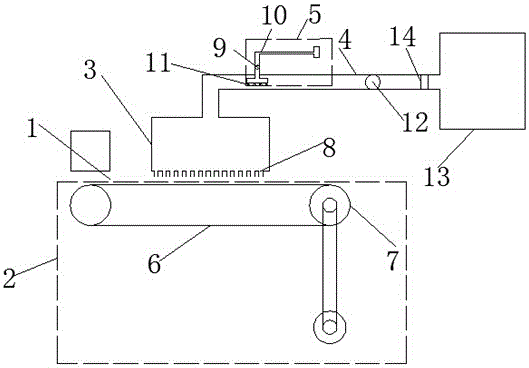

Paper feeding device used for printing

The invention discloses a paper feeding device used for printing. The paper feeding device is characterized by comprising a paper feeding port (1), wherein a belt conveying device (2) is arranged under the paper feeding port (1); a paper smoothing device (3) is arranged above the middle part of the belt conveying device (2); the paper smoothing device (3) is located at the side of the paper feeding port (1); the top part of the paper smoothing device (3) is connected with a hot air supplying pipeline (4); and a humidification device (5) is arranged on the hot air supplying pipeline (4). The paper feeding device has the characteristics that paper can enter the paper feeding port smoothly, and the process procedures are reduced.

Owner:HUZHOU JIANING PRINTING

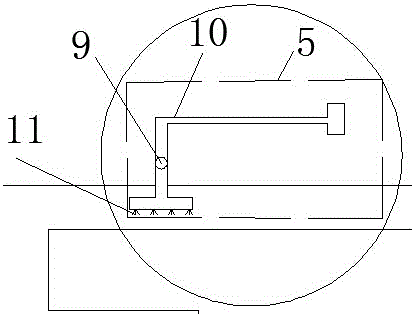

Heating device for laboratory

ActiveCN108180629ATo achieve the purpose of warming upImprove warm-up effectAir heatersHeating effectSlide plate

The invention discloses a heating device for a laboratory. The heating device comprises a machine base, wherein a reciprocation mechanism, a sliding rail, a guiding rail and a pipeline are arranged onthe machine base; the inner part of the sliding rail is connected with a sliding plate in a sliding manner; the inner part of the guiding rail is connected with an air inlet pipe in a sliding manner;a heating passage and a cooling passage are arranged on the air inlet pipe; processing pipes are symmetrically arranged on an inner wall of the pipeline, and elastic thin sheets are arranged in the processing pipes; a pre-heating pipe is arranged between the two processing pipes; a hollow iron ball is arranged in the pipeline; a first heating passage is arranged in the center of the iron ball; the inner part of the first heating passage is connected with a hollow ball body in a sliding manner; an air hole is formed in the ball body; a plurality of second heating passages are symmetrically arranged in a heating ball; a heating electric wire is arranged on an inner wall of the pipeline; an air outlet pipe is also arranged in the pipeline; the inner part of the air outlet pipe is connected with a threaded column; an air outlet is formed in a side wall of the air outlet pipe; a sealing block is arranged on the pipeline; and a collection pipe is arranged on a side wall of the pipeline. According to the scheme disclosed by the invention, the problem of a poor heating effect of current gas heating equipment is mainly solved.

Owner:重庆骄直电气有限公司

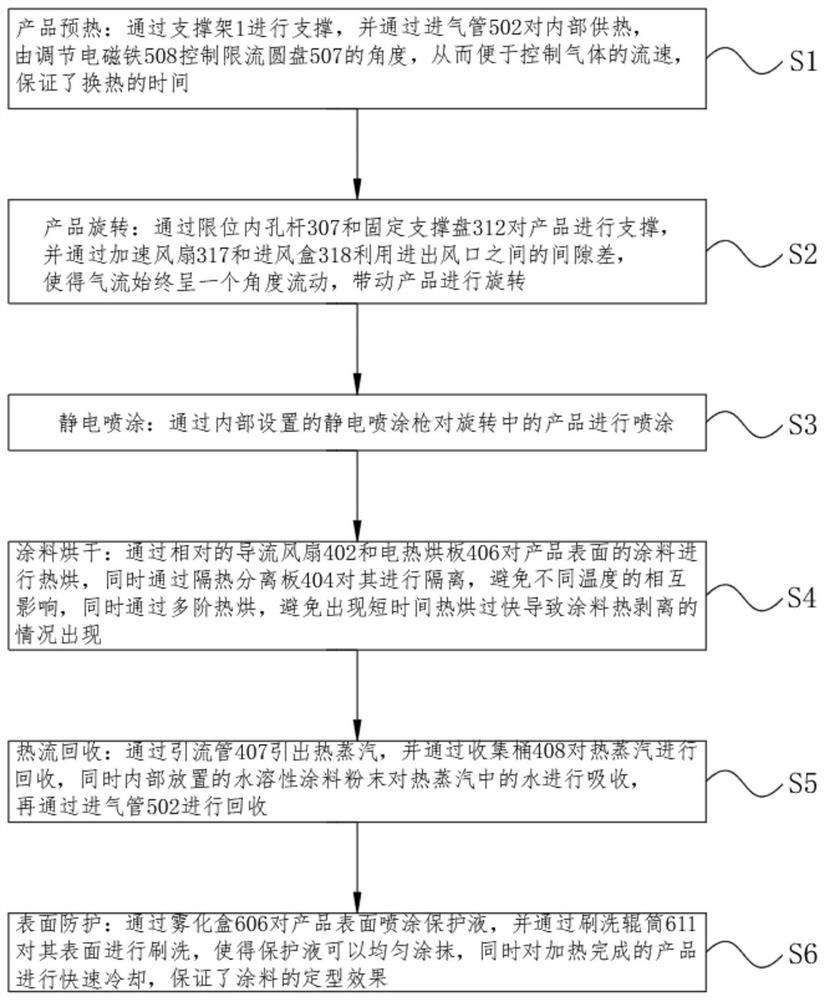

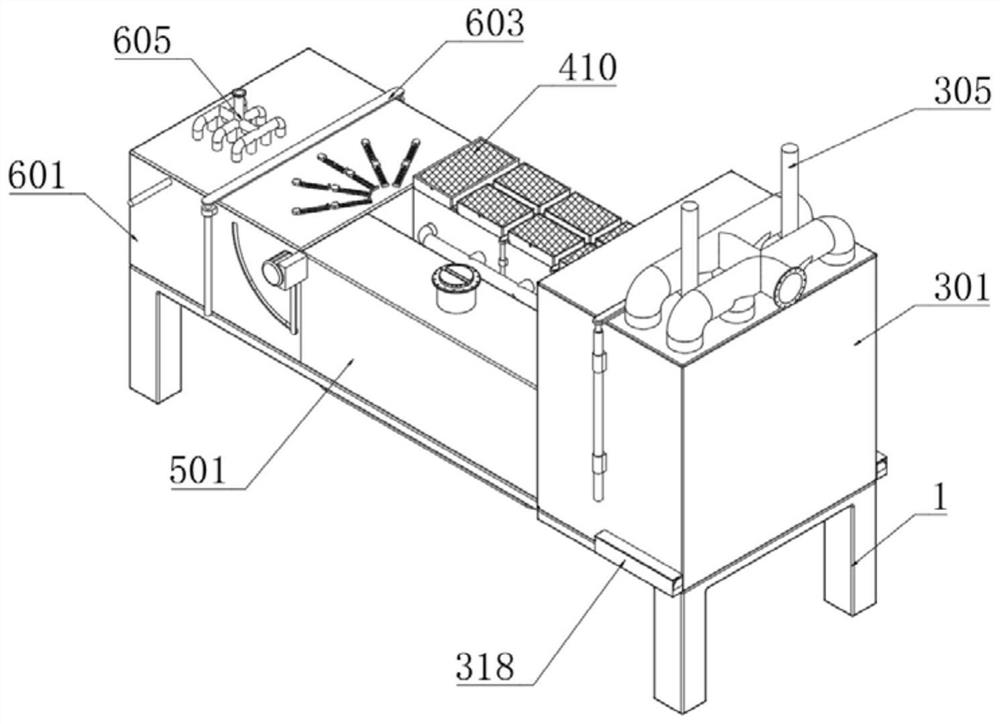

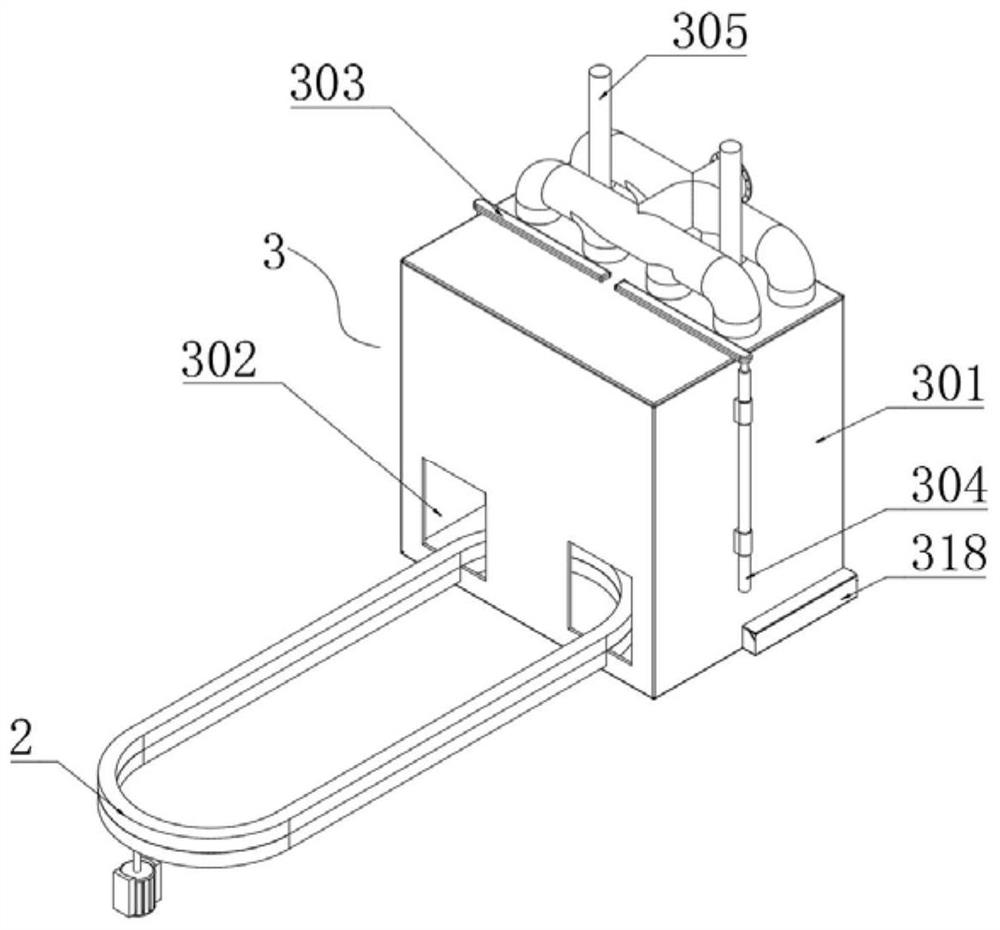

Vertical intelligent multidirectional electrostatic paint spraying method

InactiveCN113198698AFirmly attachedUniform adhesionLiquid spraying plantsPretreated surfacesHeat flowProcess engineering

The invention discloses a vertical intelligent multidirectional electrostatic paint spraying method. The vertical intelligent multidirectional electrostatic paint spraying method comprises the following steps: S1, product preheating, S2, product rotating, S3, electrostatic spraying, S4, paint drying, S5, heat flow recovery and S6, surface protection. According to the invention, products are preheated, so that the situation of non-uniform electrostatic charge distribution caused by direct spraying for the cold products is avoided, and then the uniformity of the products during spraying is ensured; by rotating the products, excessive paint is prevented from being accumulated on the surfaces of the products, and then orange-stripe-shaped stripes on the surfaces of the products caused by flowing of the paint are avoided, so that the spraying quality for the products is ensured; the products are subjected to hot drying after the spraying is completed, and through symmetrical hot drying at the two ends, the paint is prevented from flowing during the hot drying, so that orange-stripe-shaped flowing marks are further avoided while paint distribution is ensured; and meanwhile, the products gradually adapt to different temperatures through multi-step hot drying, so that hot stripping caused by instant high temperature is avoided.

Owner:刘华

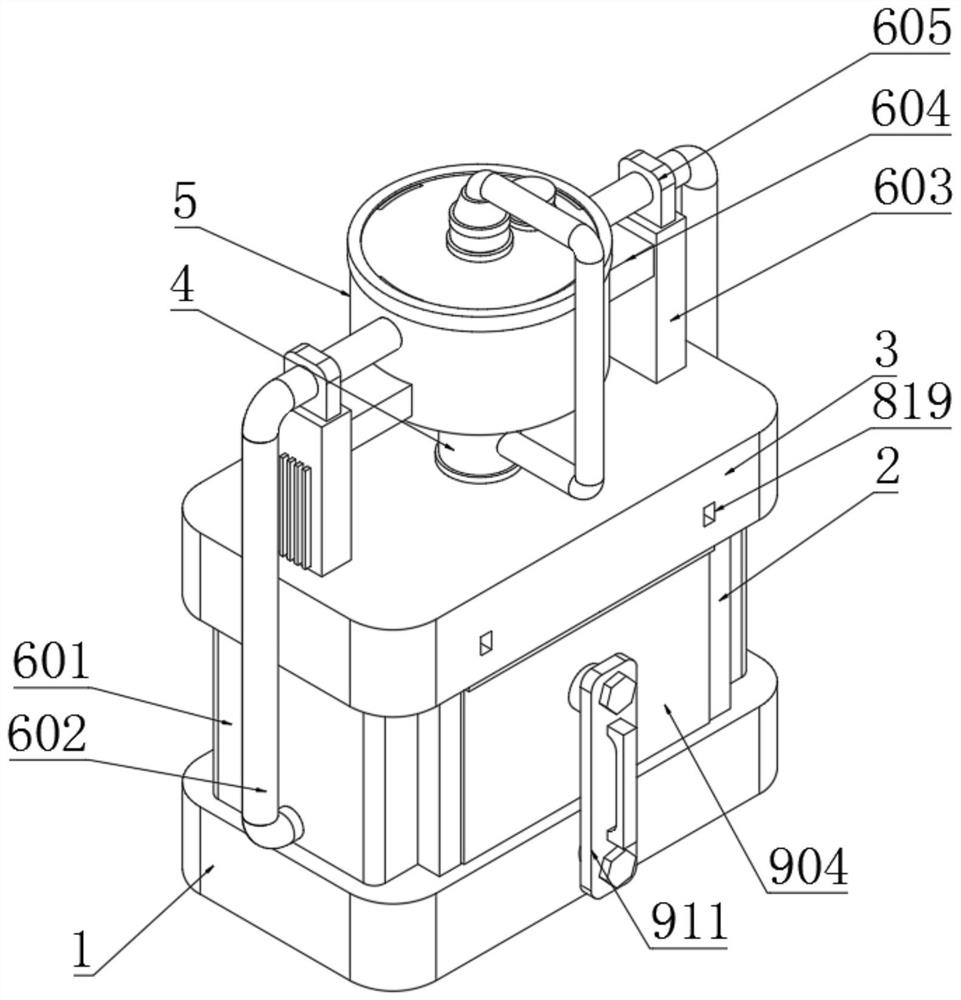

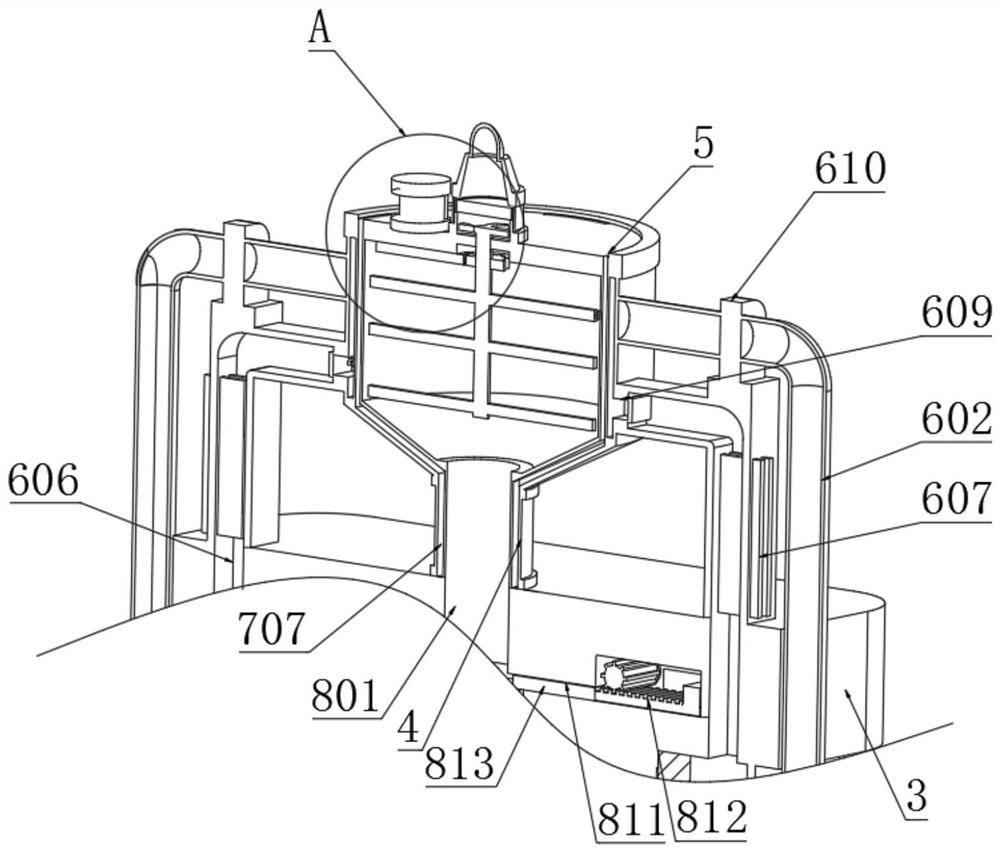

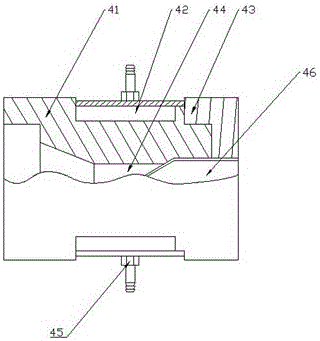

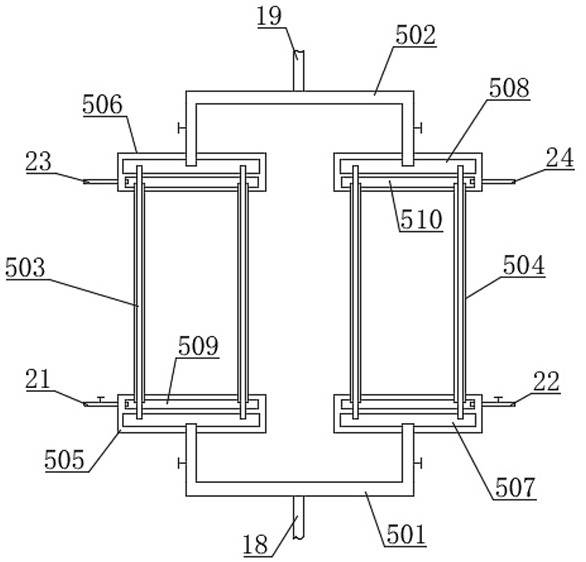

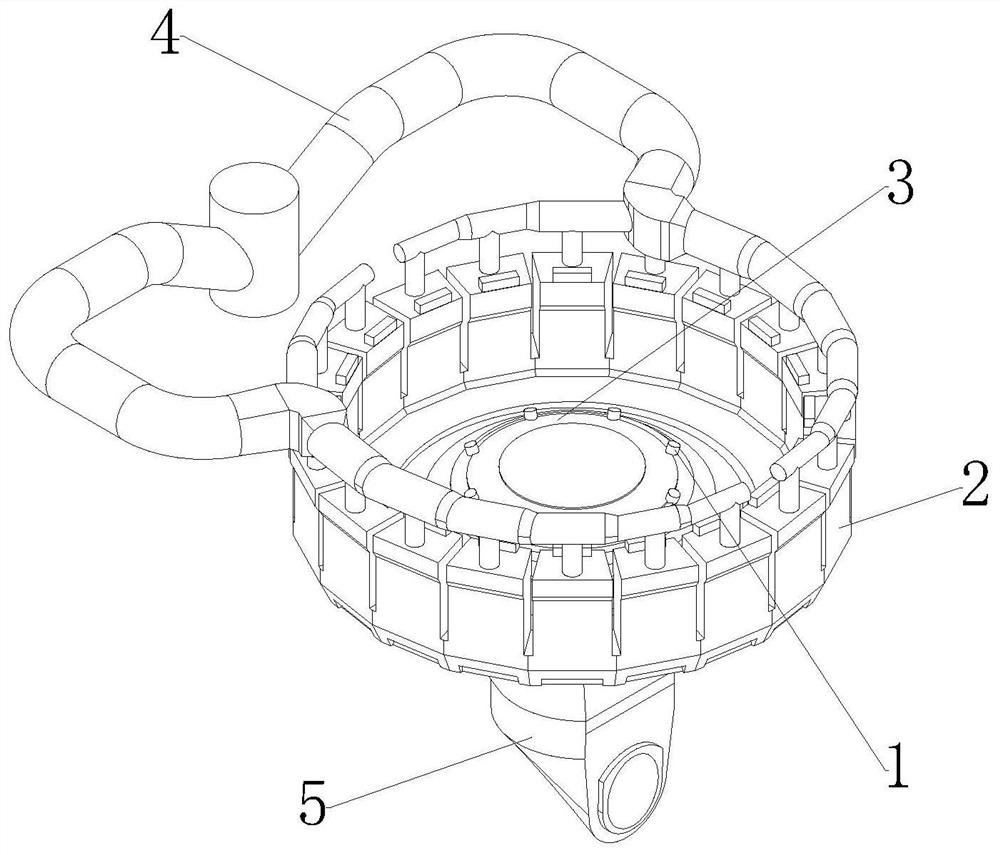

Regent preheating and reaction device and sample analyzer

PendingCN108982754ASimple structureWarm-up performance guaranteeMaterial analysisEngineeringHeat supply

The invention relates to a regent preheating and reaction device. The regent preheating and reaction device comprises a heat converter, a plate type preheating tank and a reaction tank, wherein the heat converter is used for supplying heat and comprises a first part and a second part; the plate type preheating tank forms the first part of the heat converter, a preheating space for accommodating areagent is formed in the plate type preheating tank, and the plate type preheating tank is used for preheating the regent in the preheating space through heat supplied by the heat converter; and the reaction tank forms the second part of the heat converter, a reaction space for accommodating the reagent is formed in the reaction tank, and the preheated reagent reacts with a sample in the reactionspace. The invention provides a sample analyzer. According to the regent preheating and reaction device and the reaction device, the plate type preheating tank and the reaction tank are integrally arranged on the heat converter and can share a set of temperature control system, so that the structure can be simplified, and the cost is lowered.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

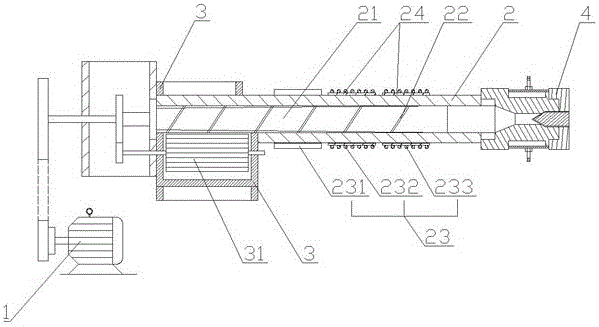

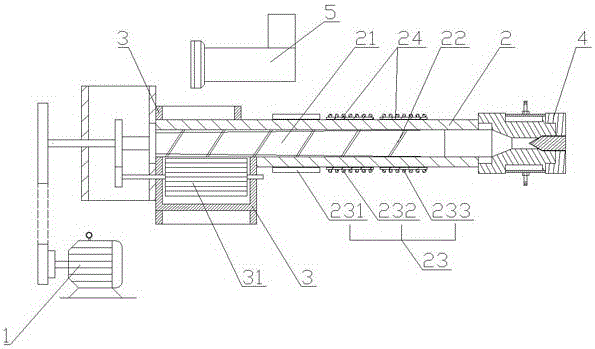

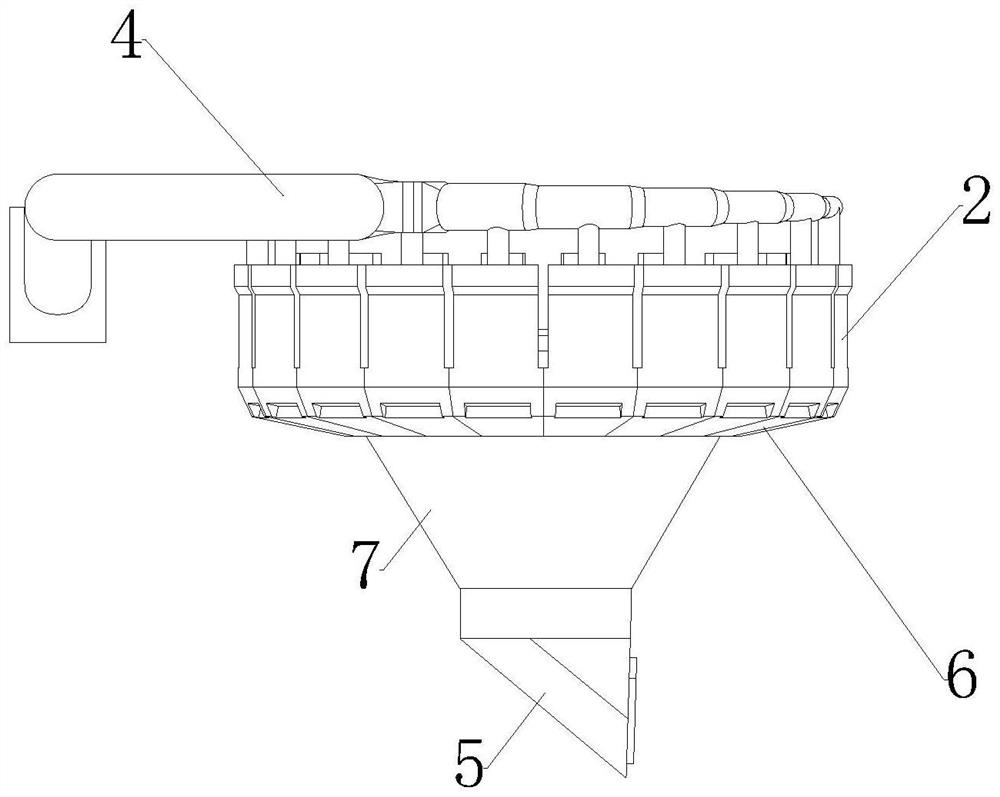

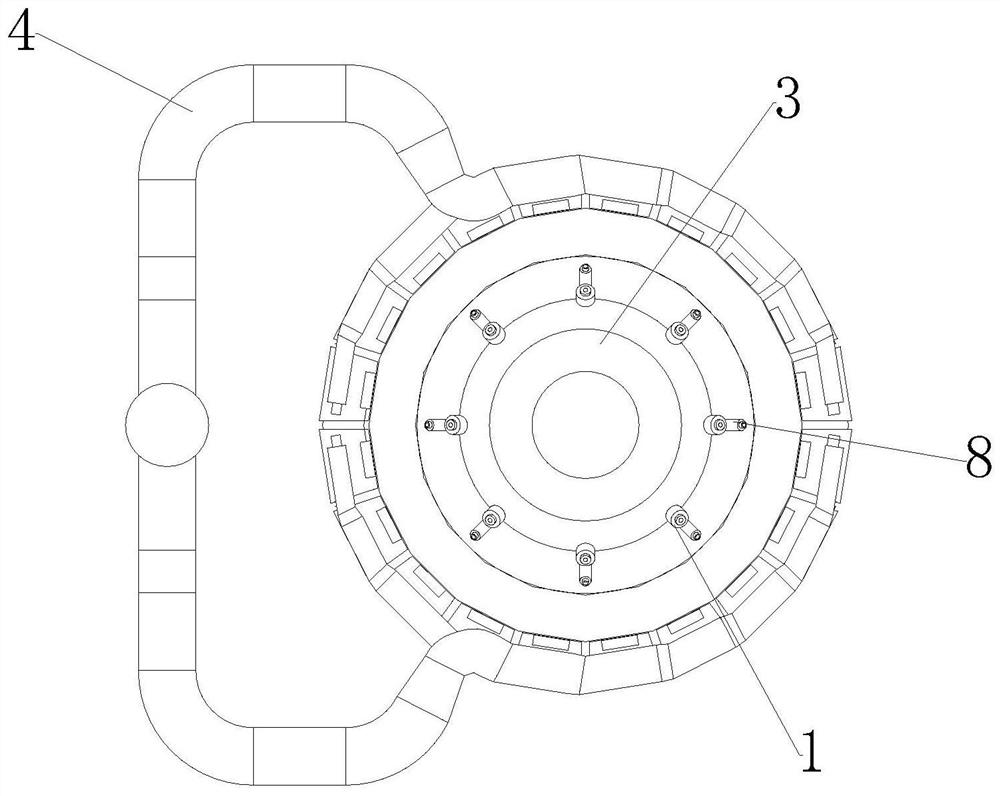

Special equipment for preparing vegetarian meat from high-temperature meal

The invention discloses special equipment for preparing vegetarian meat from high-temperature meal. The special equipment comprises a motor, a conveying sleeve, a feeding device and a molding machine head, wherein the feeding device is positioned at the front end of the conveying sleeve; the molding machine head is arranged at the tail end of the conveying sleeve; a long shaft is arranged in the conveying sleeve; a screw propulsion rack is arranged on the long shaft; from the front end of the conveying sleeve to the rear end of the conveying sleeve, the shaft diameter of the long shaft is gradually increased while the screw pitch of the screw propulsion rack is gradually reduced; a clearance is kept between the screw propulsion rack on the long shaft and the inner wall of the conveying sleeve. The special equipment has the following beneficial effects: as the shaft diameter of the long shaft is gradually increased, and the screw pitch of the screw propulsion rack on the long shaft is gradually reduced, the production efficiency is improved, meanwhile, the vegetarian meat prepared from the high-temperature meal is more compact, and therefore, the taste is better.

Owner:三门峡市美乐福大豆加工专用设备有限公司

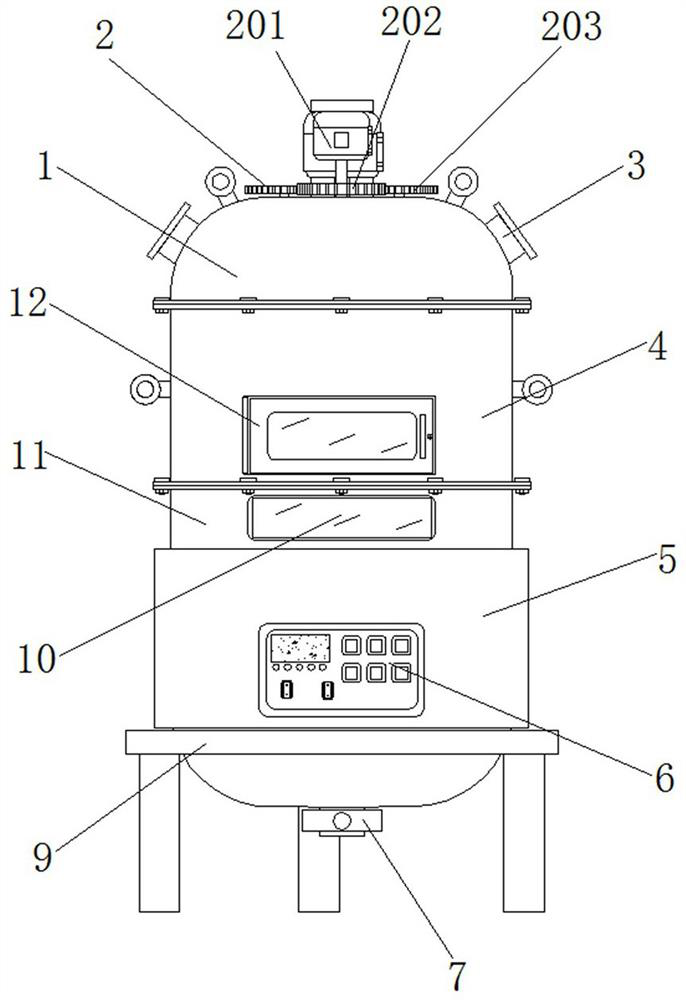

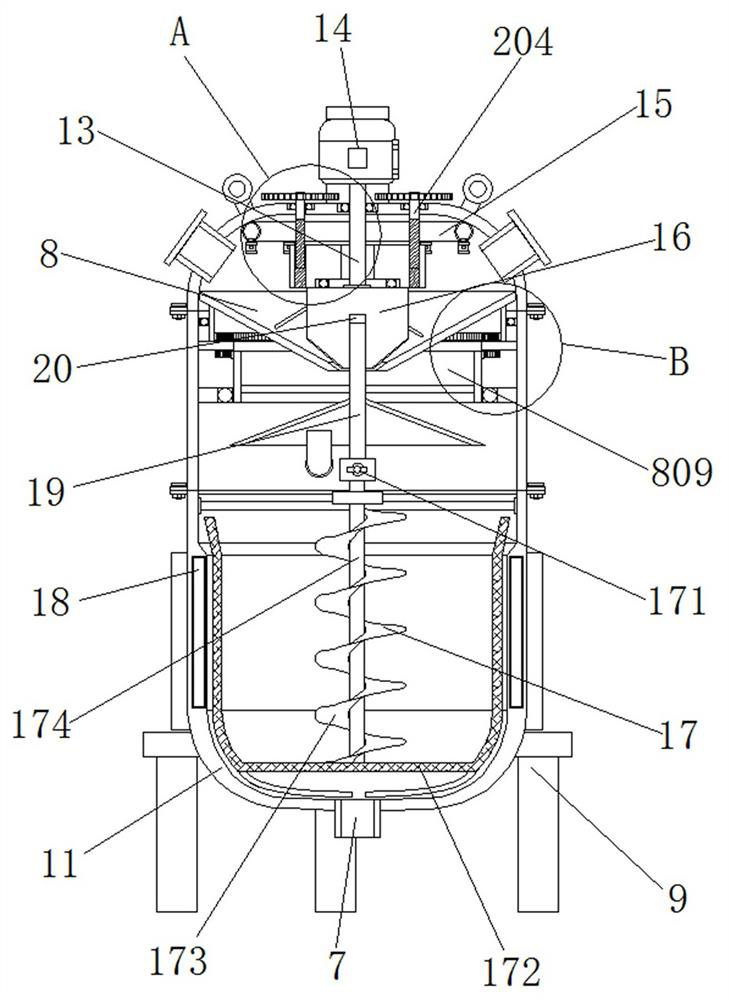

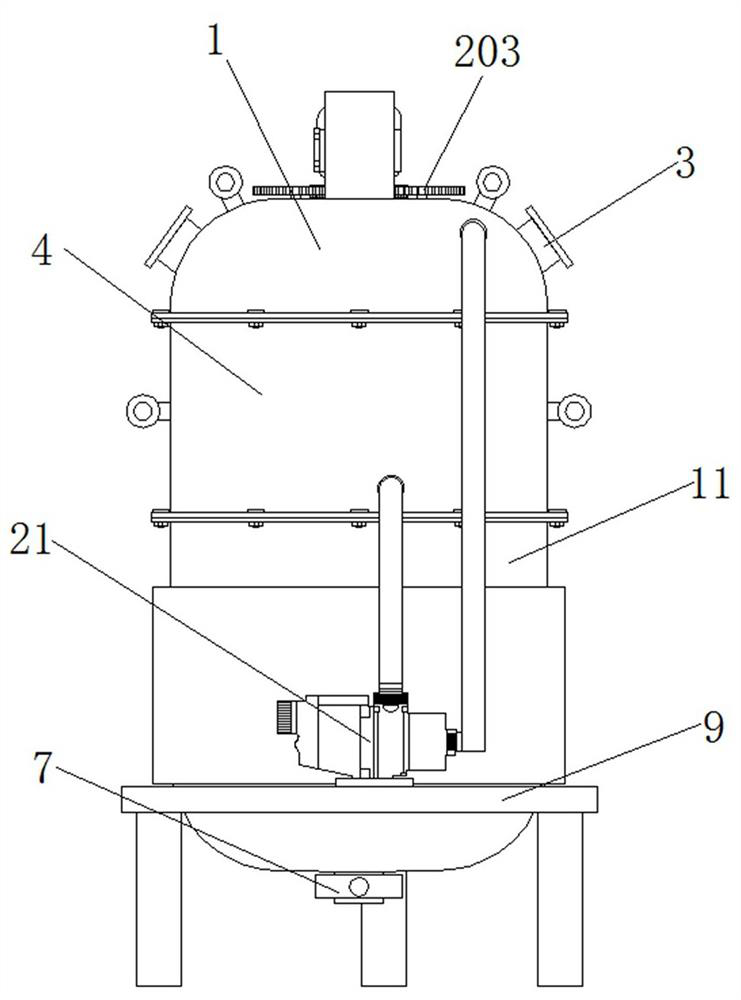

Progress-visualized high-molecular polymerization reaction kettle

InactiveCN113145056AImprove grinding efficiencyEasy to heat and meltChemical/physical/physico-chemical stationary reactorsGrain treatmentsElectric machineEngineering

The invention discloses a progress visualized macromolecule polymerization reaction kettle which comprises a top bin, a middle bin and a bottom bin, a heat preservation bin is arranged on the outer side of the bottom bin, a supporting frame is installed at the bottom of the outer side of the bottom bin, a progress observation window is formed in the top of the outer side of the bottom bin, and a driving motor is installed in the center of the top of the top bin. A first main rotating shaft is installed at the output end of the driving motor, and the bottom of the first main rotating shaft extends into the top bin and is provided with a grinding head. Through cooperative use of the top bin, the middle bin, the auxiliary grinding assembly, the first main rotating shaft and the grinding head, through cooperation of the funnel bin and the grinding head, the first main rotating shaft drives the grinding head to rotate in the forward direction, and the first main rotating shaft drives the funnel bin to rotate in the reverse direction; and the high polymer material grinding efficiency of the device can be greatly improved without increasing the rotating speed of the driving motor, and the crushed high polymer material is easier to heat and melt in the bottom bin, so that the polymerization efficiency of the high polymer material is improved.

Owner:荡麦金属表面技术处理(上海)中心

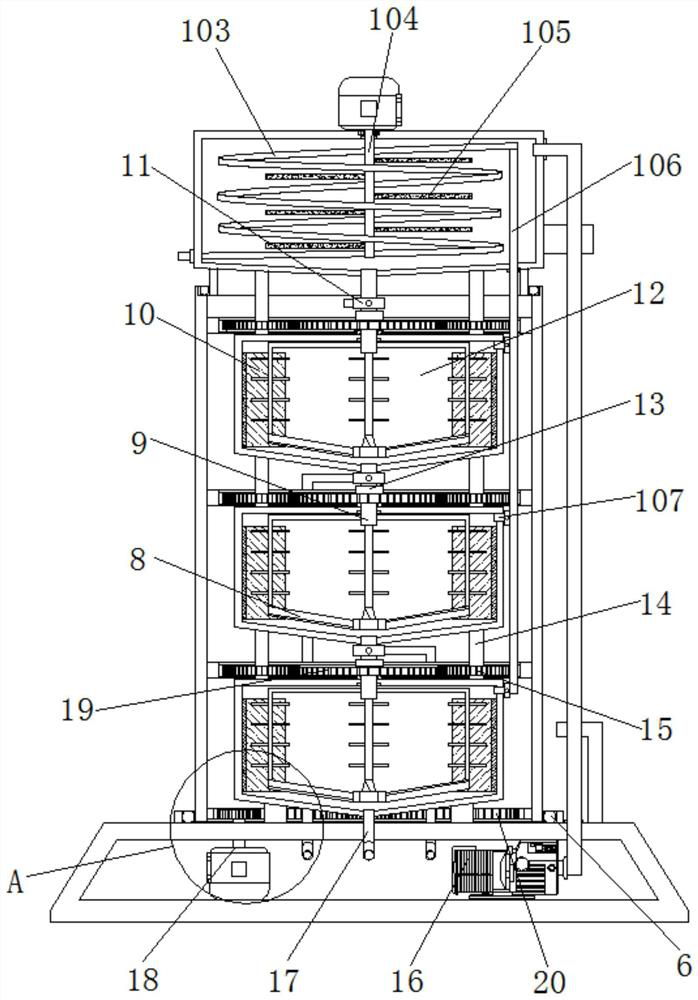

A roasting rotary kiln

ActiveCN112728930BImprove uniformityPrevent escapeRotary drum furnacesPreheating chargesThermodynamicsSilo

The invention relates to the field of cement preparation, in particular to a roasting rotary kiln, comprising a kiln body, one end of the kiln body is provided with a preheating module, a side of the preheating module close to the kiln body is provided with a connecting groove, and the kiln body and the connecting groove are correspondingly arranged The preheating module is provided with a raw material bin with a circular arc structure, a No. 1 rotating shaft is arranged on the inner wall of the raw material bin, and the end of the No. 1 rotating shaft away from the inner wall of the raw material bin is provided with a cylindrical hollow structure. The outer diameter is consistent with the inner diameter of the raw material silo. The raw material silo is provided with a feeding port. A preheating silo with a circular structure is arranged in the preheating module and below the raw material silo. The preheating silo is connected to the raw material silo and is connected with The feeding port is set correspondingly, the No. 2 rotating shaft is set in the preheating bin, and the No. 2 rotating shaft is set with a rotor with a cylindrical structure. The invention can directly preheat the cement raw materials quickly, avoid the heat dissipation when the cement raw materials are introduced into the rotary kiln, and is suitable for popularization.

Owner:河南鑫诚耐火材料股份有限公司

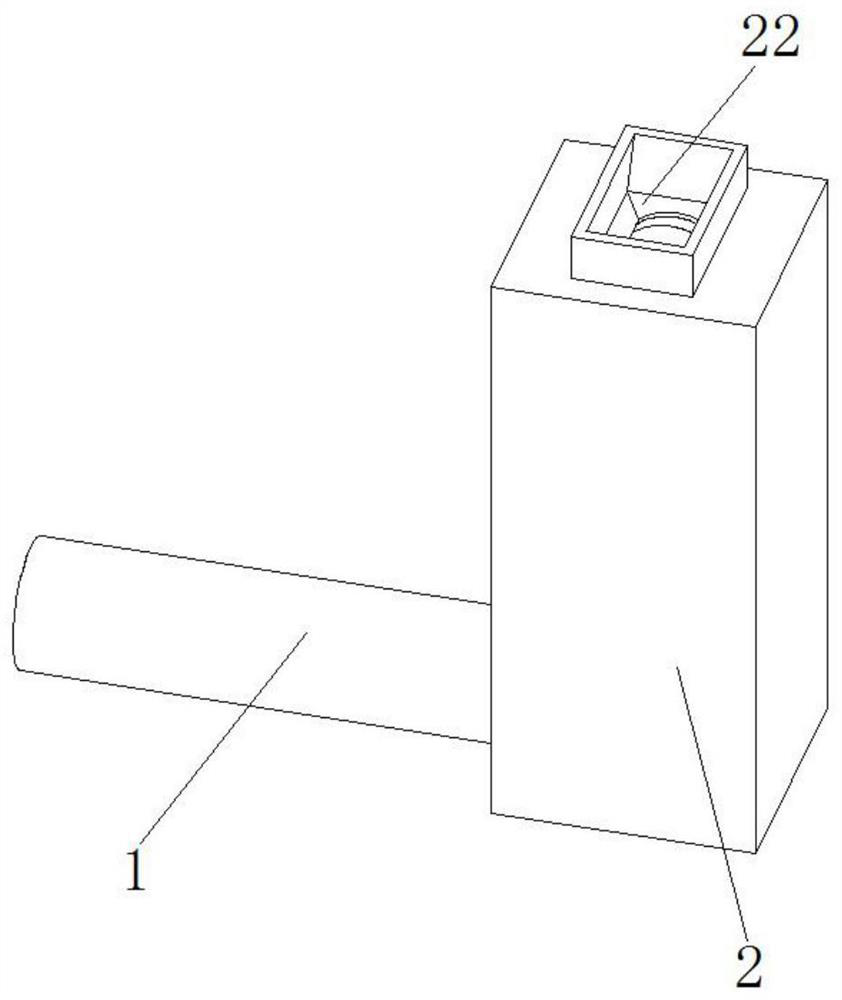

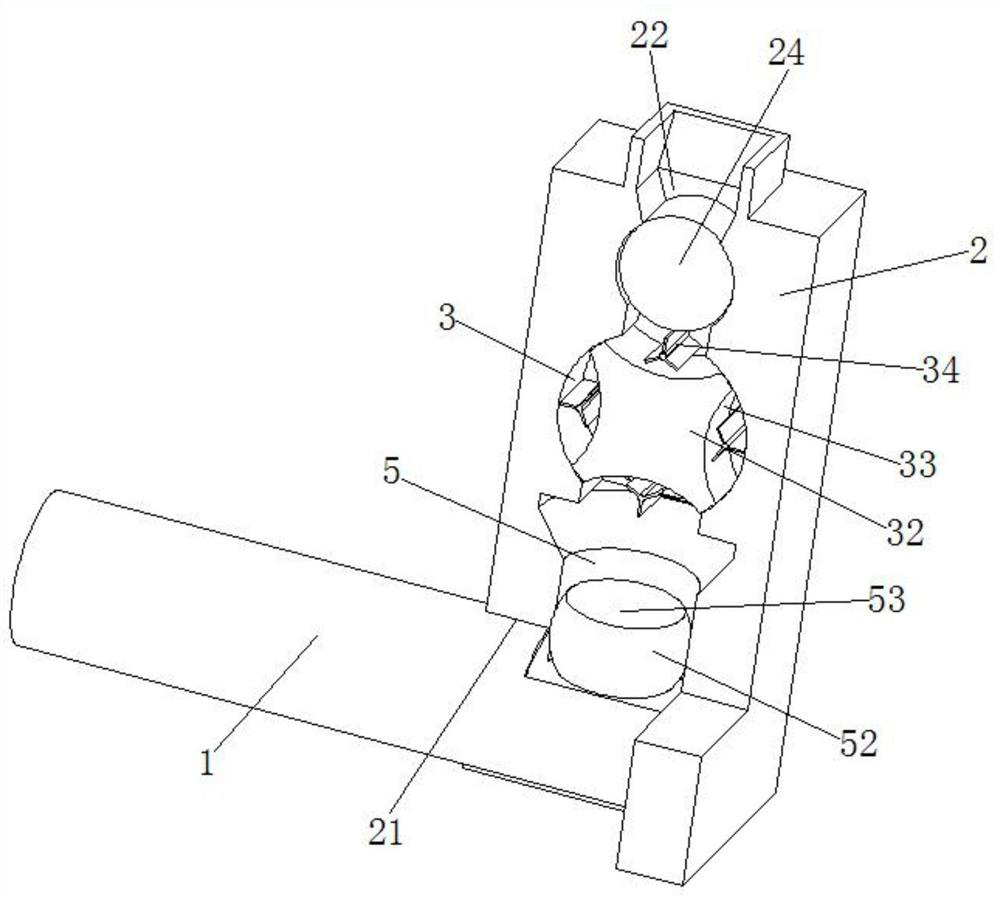

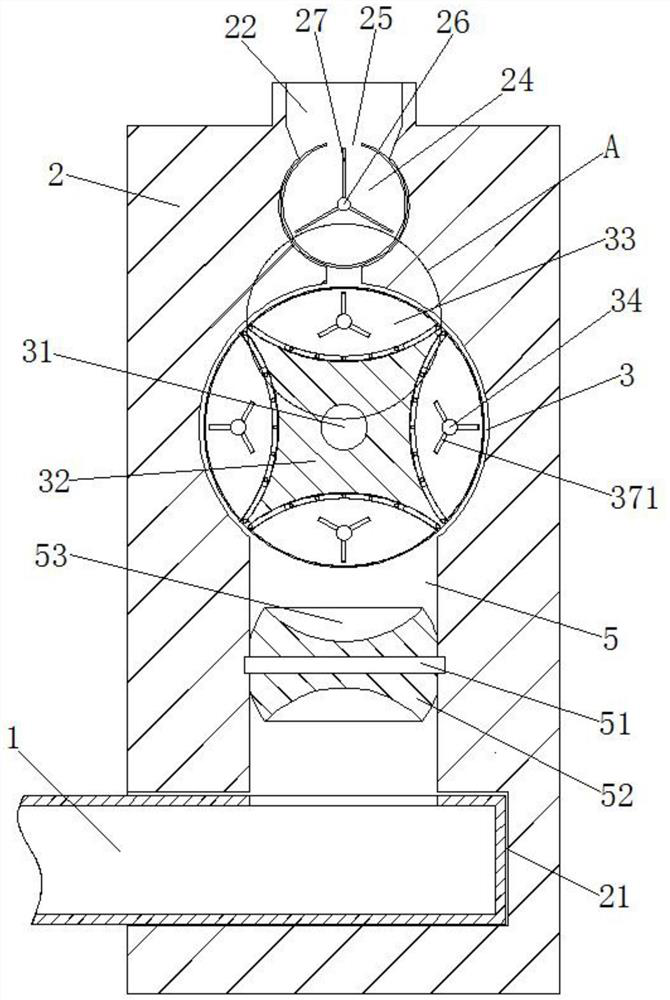

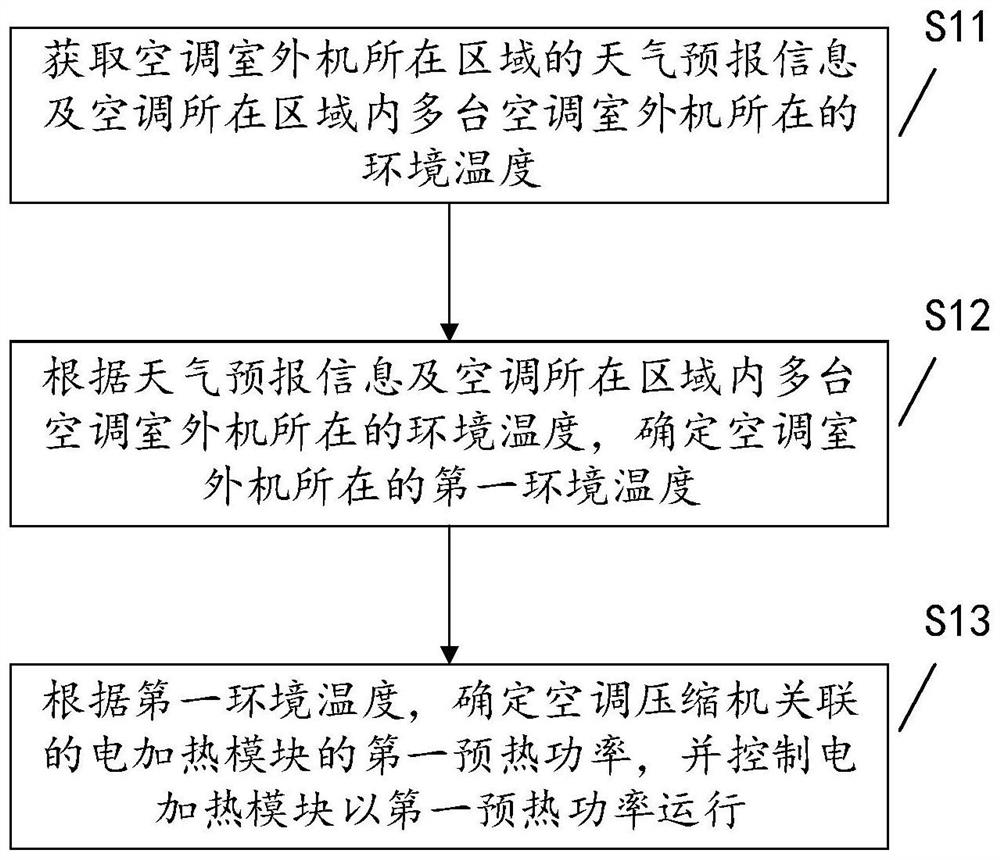

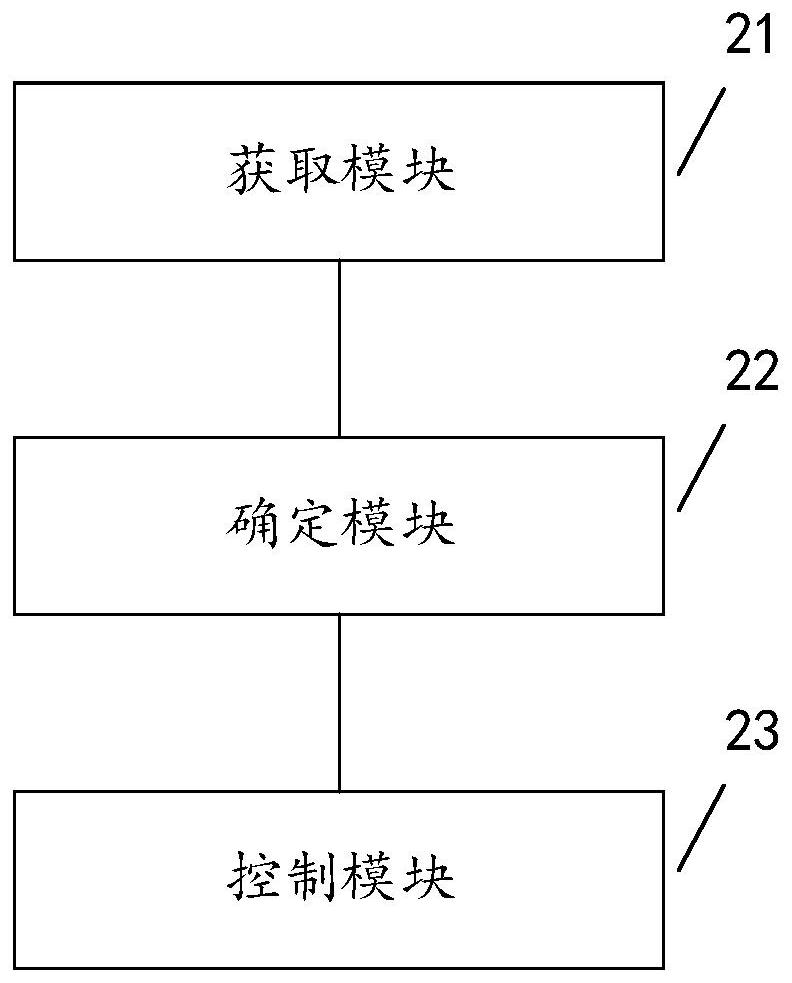

Preheating method, device and system for air conditioner compressor

ActiveCN113091275AGuaranteed warm-up effectImprove experienceMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsHeat power

The invention relates to the technical field of intelligent air conditioner control, and discloses a preheating method for an air conditioner compressor. The preheating method for the air conditioner compressor comprises the following steps of acquiring weather forecast information of an area where air conditioner outdoor units are located and environment temperature of multiple air conditioner outdoor units in the area where the air conditioner is located; according to the weather forecast information and the environment temperature of the multiple air conditioner outdoor units in the area where the air conditioner is located, determining first environment temperature of the air conditioner outdoor units; and according to the first environment temperature, determining a first preheating power of an electric heating module associated with the air conditioner compressor, and controlling the electric heating module to operate at the first preheating power. According to the scheme, the preheating power of the electric heating module can be accurately determined according to the determined outdoor environment temperature, and the electric heating module is controlled to operate at the preheating power, so that the preheating effect of the air conditioner compressor is guaranteed, and the user experience feeling is improved. The invention further discloses a preheating device and system for the air conditioner compressor.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

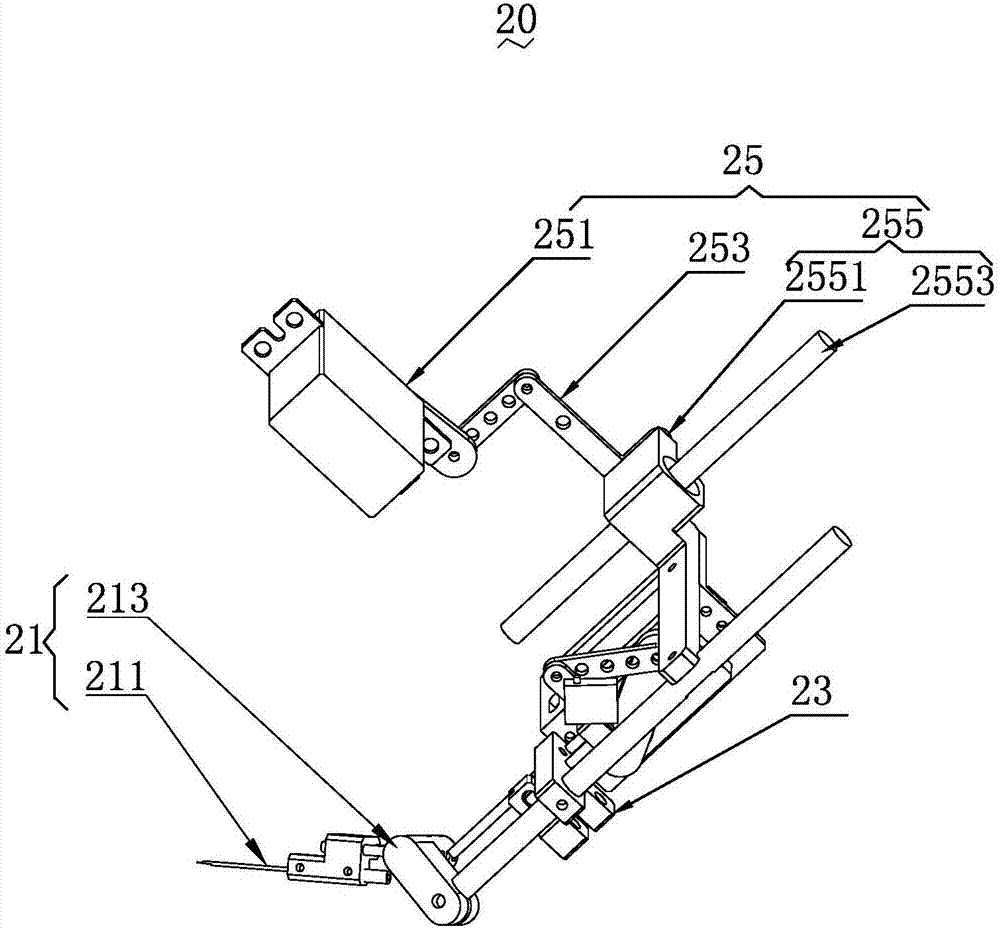

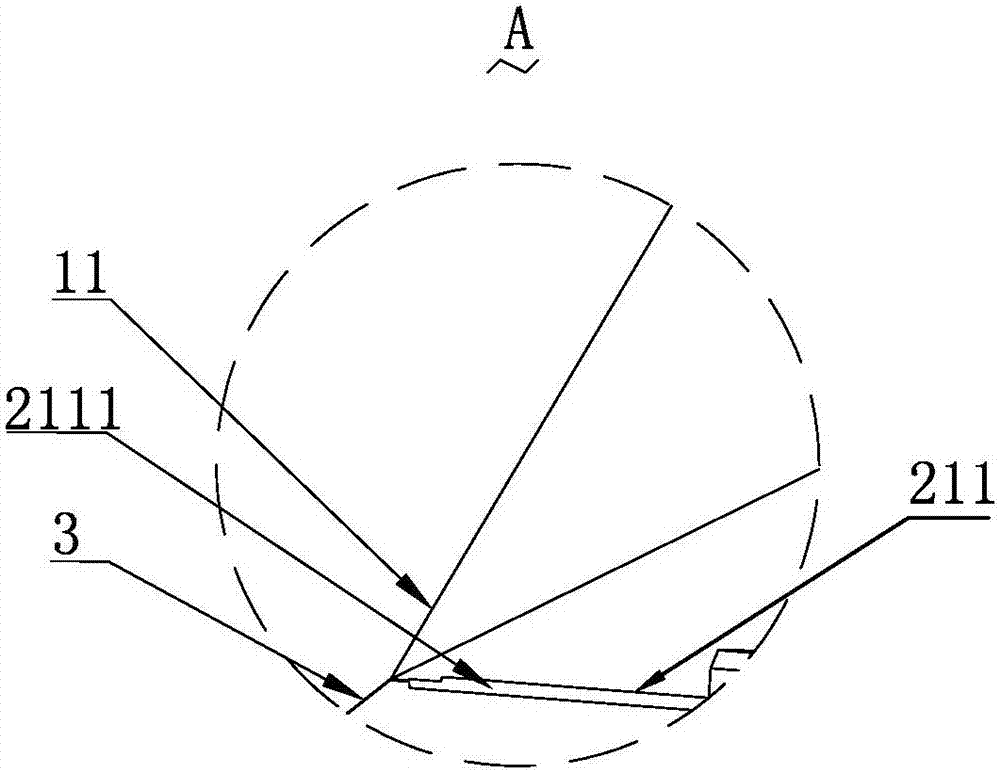

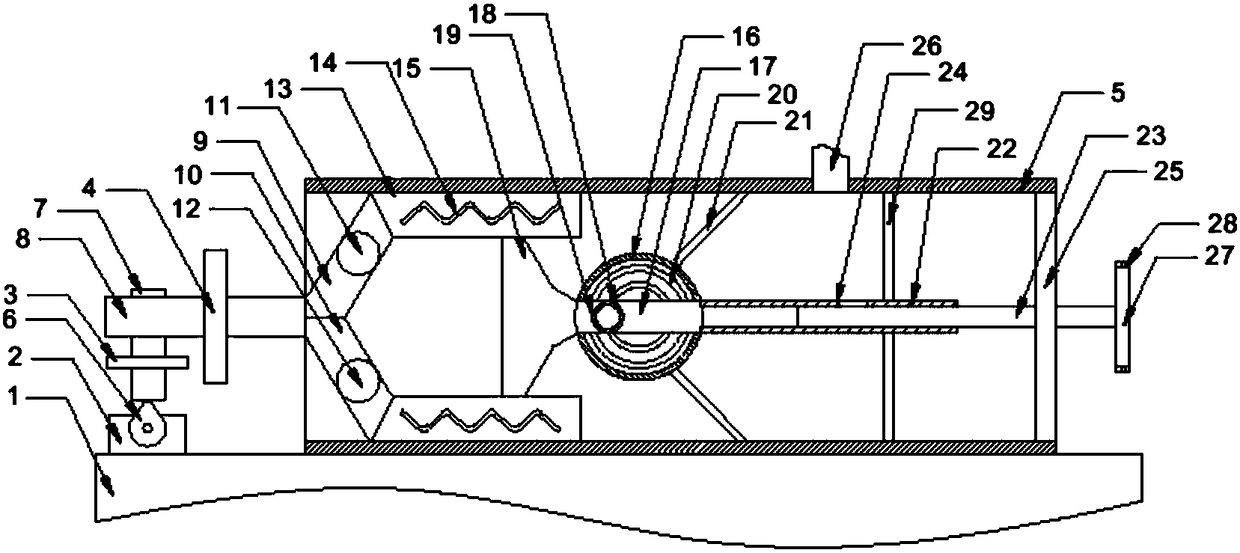

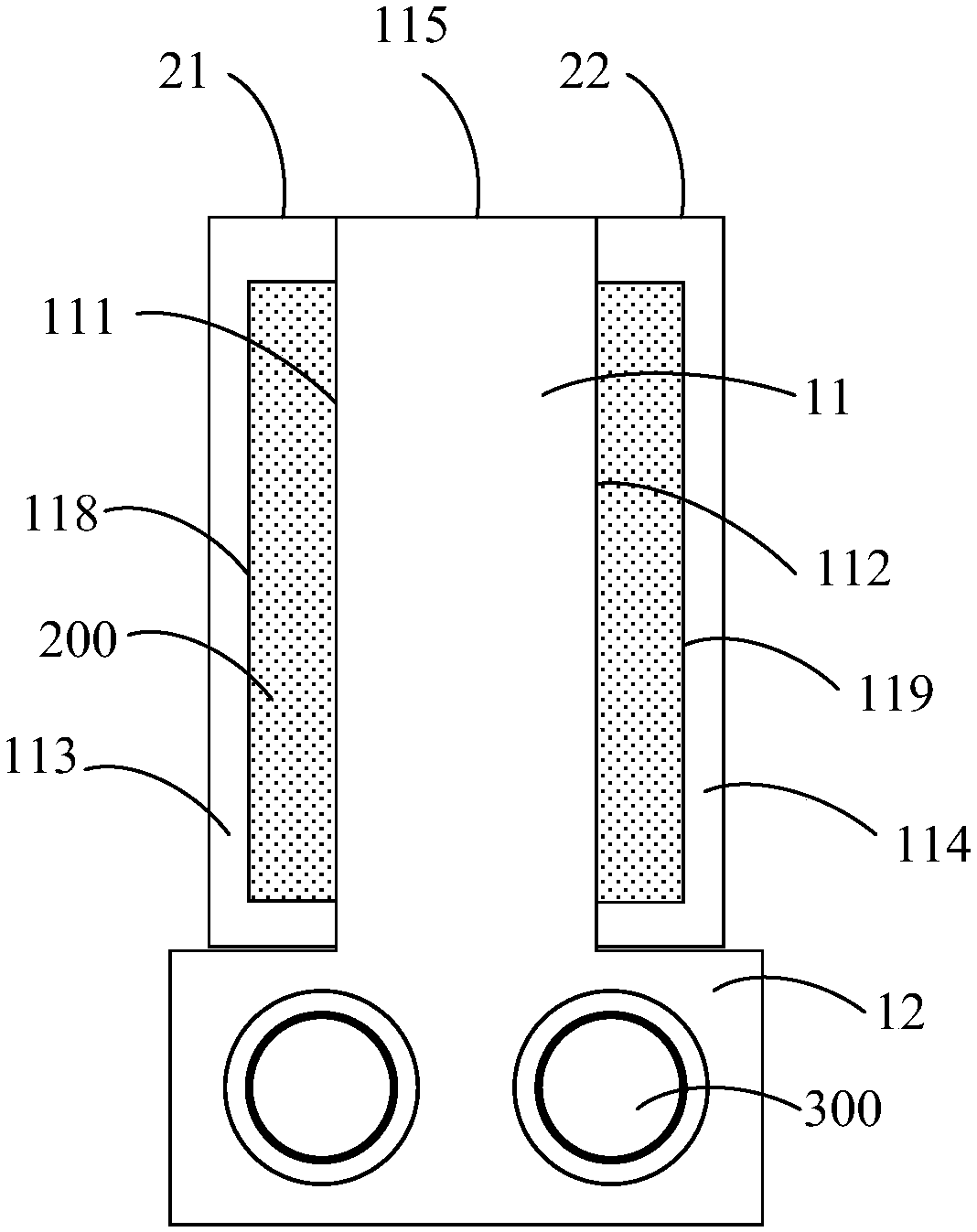

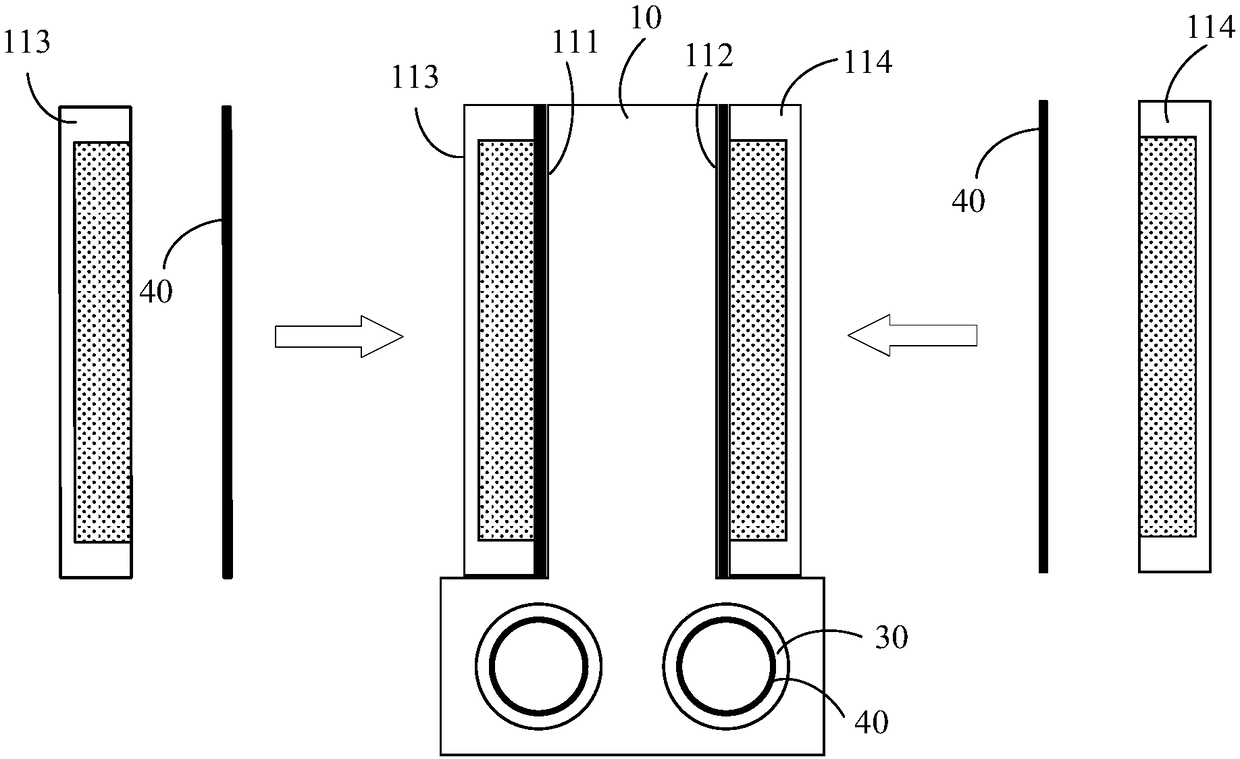

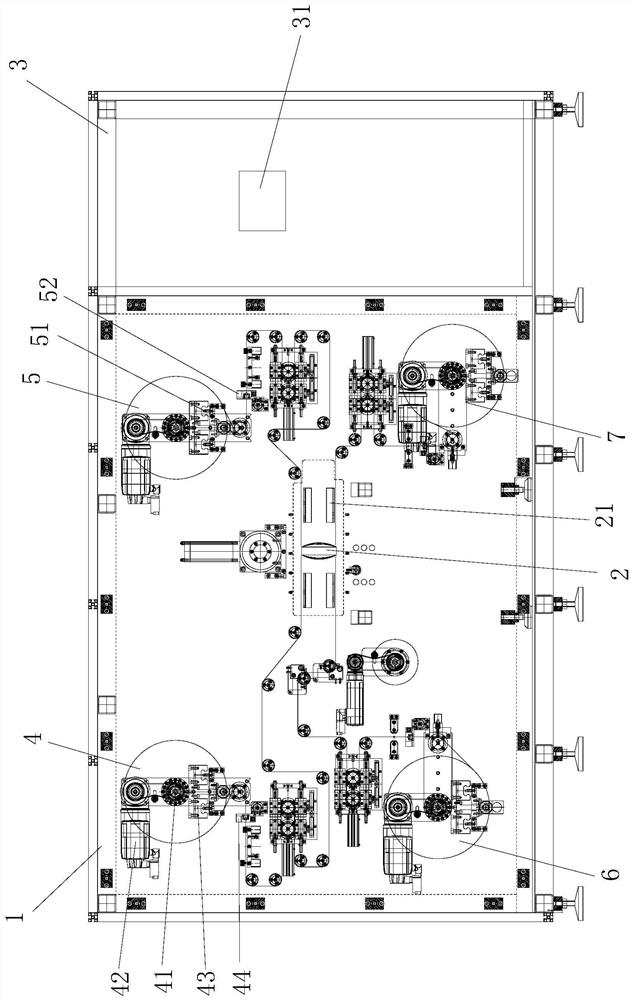

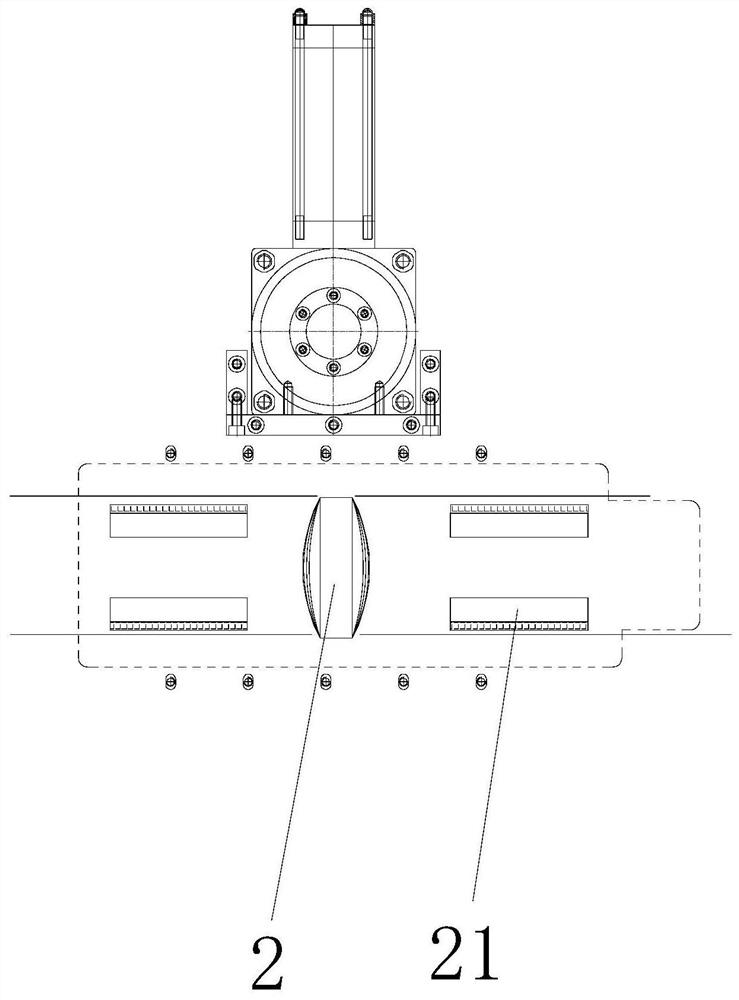

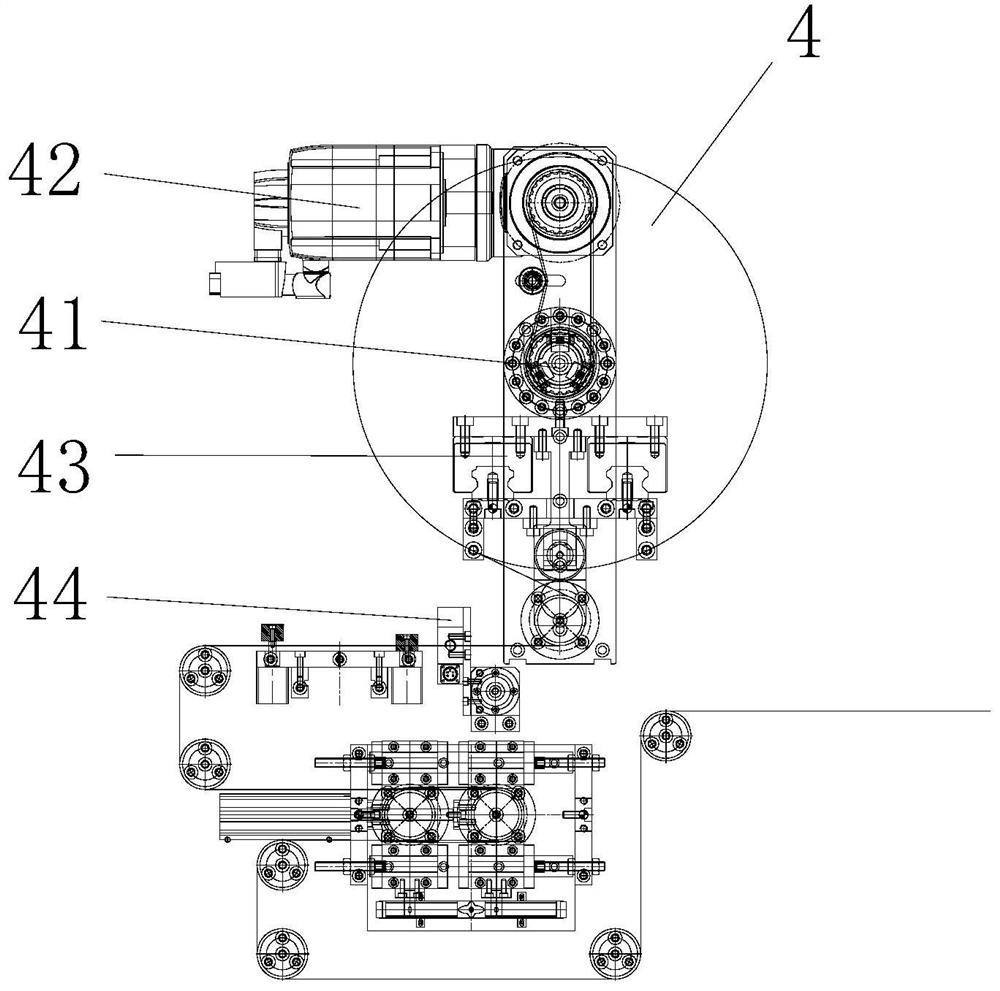

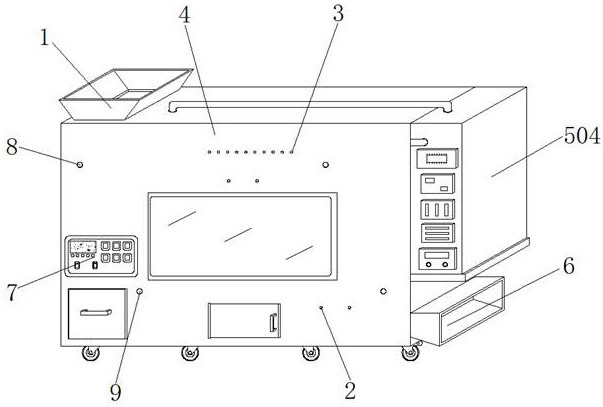

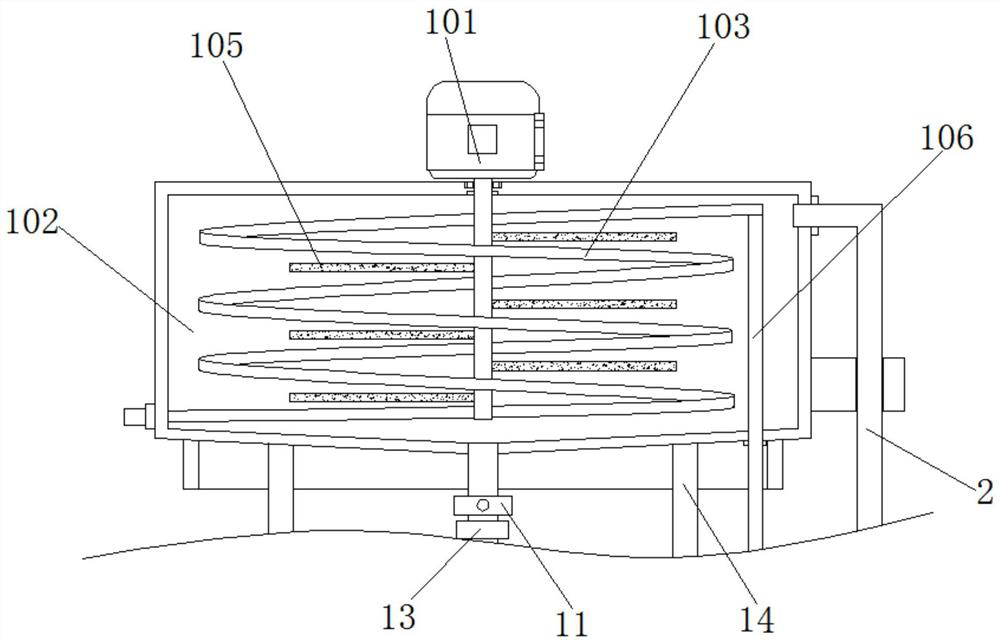

Medium-frequency preheating winding machine for lithium battery cell

PendingCN111668556AReduce production processGuaranteed warm-up effectAssembling battery machinesFinal product manufactureWinding machineElectrical connection

The invention discloses a medium-frequency preheating winding machine for a lithium battery cell. The winding machine comprises a case, a pole piece feeding mechanism, a diaphragm feeding mechanism, awinding mechanism and an electric cabinet, the pole piece feeding mechanism, the diaphragm feeding mechanism and the winding mechanism are all electrically connected with a controller in the electriccabinet; a plurality of medium-frequency heating modules are arranged in the winding mechanism, are electrically connected with the controller, and are used for heating a pole piece and a diaphragm which are conveyed to the winding mechanism by the pole piece feeding mechanism and the diaphragm feeding mechanism. The medium-frequency preheating module is integrated on the winding machine, so thatthe lithium battery cell is preheated in the winding process, preheating furnace equipment is not needed to preheat the cell, the production process of the lithium battery can be effectively reduced,and the production time and cost are saved.

Owner:广东坤川实业有限公司

Processing device for producing propylene glycol and use method thereof

InactiveCN113499745AShorten the heating timeStable temperatureEvaporator accessoriesPreparation by OH group eliminationEvaporation PurificationGlycerol

The invention belongs to the technical field of propylene glycol production, and aims to solve the problems of low synthesis efficiency, incapability of integrating synthesis and dehydration operation of propylene glycol and poor use effect due to the fact that heating of hydrogen and a glycerol solution needs a certain time in the conventional propylene glycol processing device. In particular, the invention provides a processing device for producing propylene glycol and a use method thereof. The processing device comprises a synthesis reaction kettle, the synthesis reaction kettle is fixed to the top of a purification storage box, and an evaporation purification chamber and a heat preservation storage chamber are formed in the purification storage box; through the arrangement of the preheating assembly, heat in a propylene glycol solution can be effectively utilized, hydrogen and glycerin can be preheated, the heating time of the hydrogen and glycerin solution in the synthesis reaction kettle is shortened, and the synthesis efficiency is improved; the stirring assembly, the exhaust assembly and the structure for spraying the propylene glycol solution are combined, so that evaporation of water is remarkably accelerated, and the water content of the propylene glycol solution is reduced.

Owner:DONGYING HEBANG CHEM CO LTD

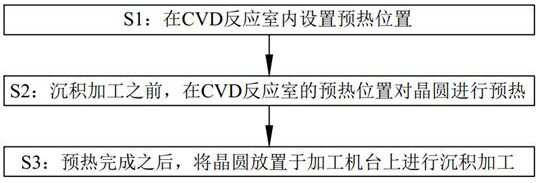

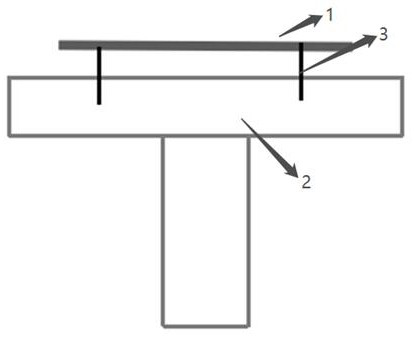

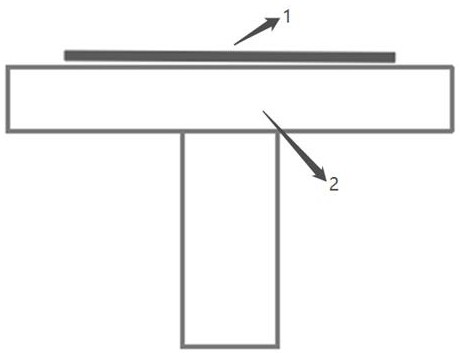

Wafer deposition processing method for CVD equipment

PendingCN114086158AAddress stressReduce Fragmentation RateChemical vapor deposition coatingMetallurgyWafer

The invention relates to the technical field of CVD equipment processing, and particularly relates to a wafer deposition processing method for CVD equipment. The method comprises the following steps: setting a preheating position in a CVD reaction chamber; before deposition processing, preheating the wafer at the preheating position of the CVD reaction chamber; and after preheating is completed, placing the wafer on a processing machine table for deposition processing. According to the wafer deposition processing method, the wafer breakage rate during wafer CVD deposition processing can be reduced so that the utilization rate of CVD equipment can be improved in an auxiliary manner.

Owner:重庆忽米网络科技有限公司

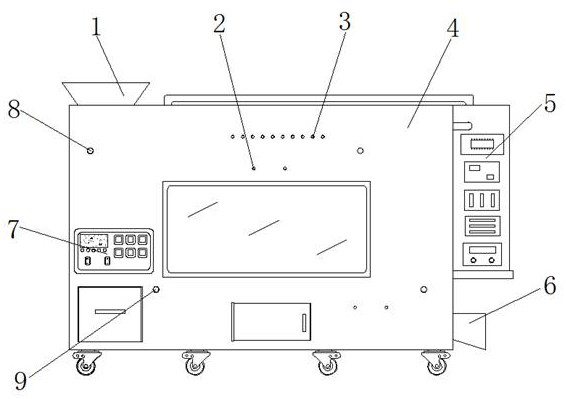

Wrapping type raw material preheating assembly for biomass fuel production

InactiveCN113483556AImprove functionalityImprove utilizationSievingConveyorsProcess engineeringThermal efficiency

The invention discloses a wrapping type raw material preheating assembly for biomass fuel production. The assembly comprises a main body bin, wherein a feeding guide bin is installed at one end of the top of the main body bin, a first conveying belt device and a second conveying belt device are arranged at the top end and the bottom of the interior of the main body bin correspondingly, an electric heating baking lamp is installed in the middle of the top in the main body bin, and a dehumidification preheating assembly matched with the first conveying belt device is arranged at the top in the main body bin. Through cooperative use of the main body bin, the screen drum and the driving device, after biomass fuel raw materials enter the screen drum, the screen drum is driven by the driving device to rotate slowly, the biomass fuel raw materials are screened, and the crushed biomass fuel raw materials fall onto the second conveying belt device through screen holes in the screen drum; and guided by the screen drum, larger wood blocks, stones or iron blocks fall into the second collecting bin, so that the preheating efficiency of the whole preheating assembly is not influenced, and the functionality of the preheating assembly is also improved.

Owner:许苗苗

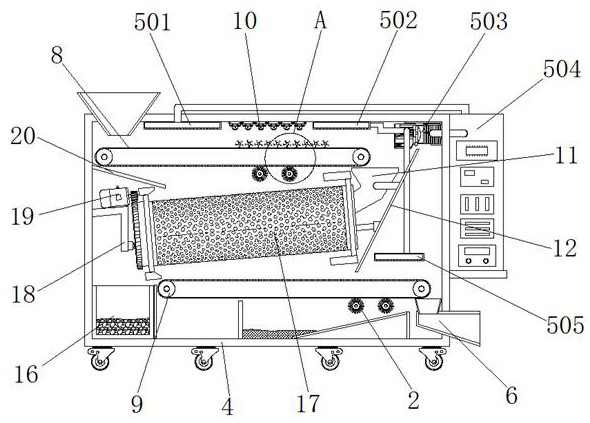

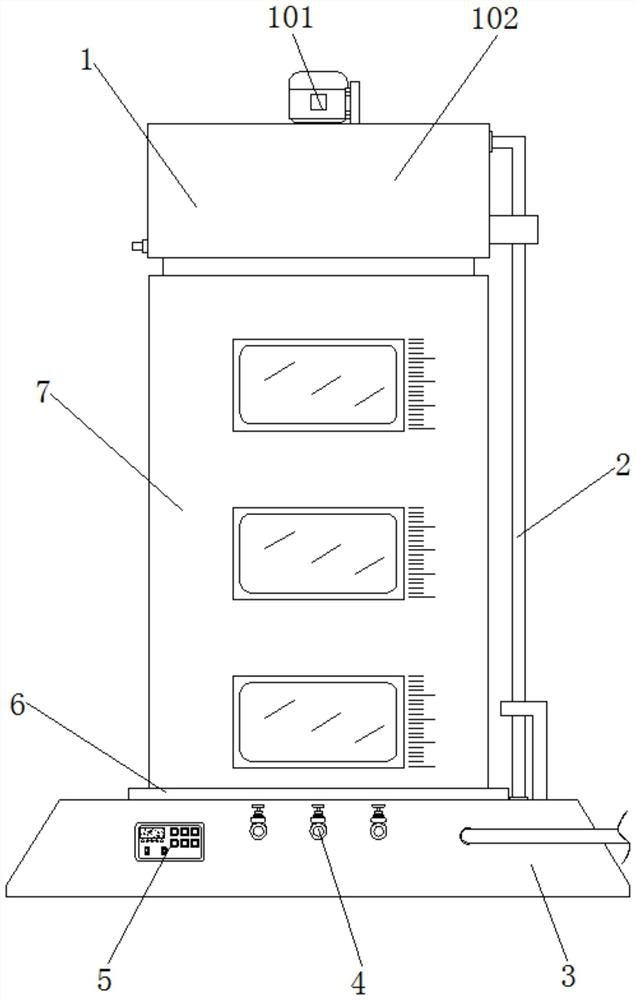

Concentration device for hydrogen peroxide production and use method thereof

ActiveCN113289364AImprove sexual functionEasy to useDistillation regulation/controlPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesDistillationProcess engineering

The invention discloses a concentration device for hydrogen peroxide production and a use method thereof. The concentration device comprises a base bin, a large bearing is installed at the top of the base bin, a protection bin is installed on the inner side of the large bearing, and three distillation bins are sequentially stacked in the protection bin; the group of distillation bin located at the lowest end is fixedly connected with the top of the base bin, four groups of connecting columns are uniformly mounted at the edge positions of the tops of the distillation bins, and every two adjacent groups of distillation bins are fixedly connected through the four groups of connecting columns. Through cooperative use of the mounting pipe, the arc-shaped electric heating plate, the driving assembly, the annular rack, the small bearing and the connecting bearing, three-stage distillation is performed on hydrogen peroxide through three groups of distillation bins so that the hydrogen peroxide can be concentrated to different concentrations, and the hydrogen peroxide in the corresponding distillation bins can be discharged at any time; and the device can be used for simultaneously processing hydrogen peroxide with three different concentration degrees so that the functionality and the use effect of the device are greatly improved.

Owner:重庆宏大化工科技有限公司

A gas oxidation combustion utilization method based on desulfurization and dehydration pretreatment

ActiveCN108980863BGuaranteed warm-up effectFull and reliable combustionGas treatmentDispersed particle separationCombustionDesorption

Owner:CHONGQING UNIV

Smoke waste heat utilization type preheater of lime rotary kiln

PendingCN112923735AImprove decomposition efficiencyShort calcination timePreheating chargesWaste heat treatmentSteelmakingCombustion chamber

The invention discloses a smoke waste heat utilization type preheater of a lime rotary kiln. The smoke waste heat utilization type preheater of the lime rotary kiln comprises a combustion chamber; the combustion chamber is composed of a guide cone and a suspended ceiling; preheating bins arranged at equal intervals are arranged on the circumferential outer wall of the combustion chamber, and a smoke exhaust pipe is arranged at the top of each preheating bin; a discharging groove is formed in the top of the position, on one side of each smoke exhaust pipe, of the corresponding preheating bin; a material guiding bin communicated with the rotary kiln is arranged below the guiding cone; a combustor is arranged on the suspended ceiling; and a combustion fan is installed on the combustor. The device has the beneficial effects that by-product gas generated by steelmaking is recovered, and then combusted and heated, in cooperation with flue gas generated during calcination in the rotary kiln, so that limestone in the preheating bins can be heated, the utilization efficiency of the by-product gas is improved, high-calorific-value fuel consumed during limestone calcination is reduced, and then the production cost is reduced.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

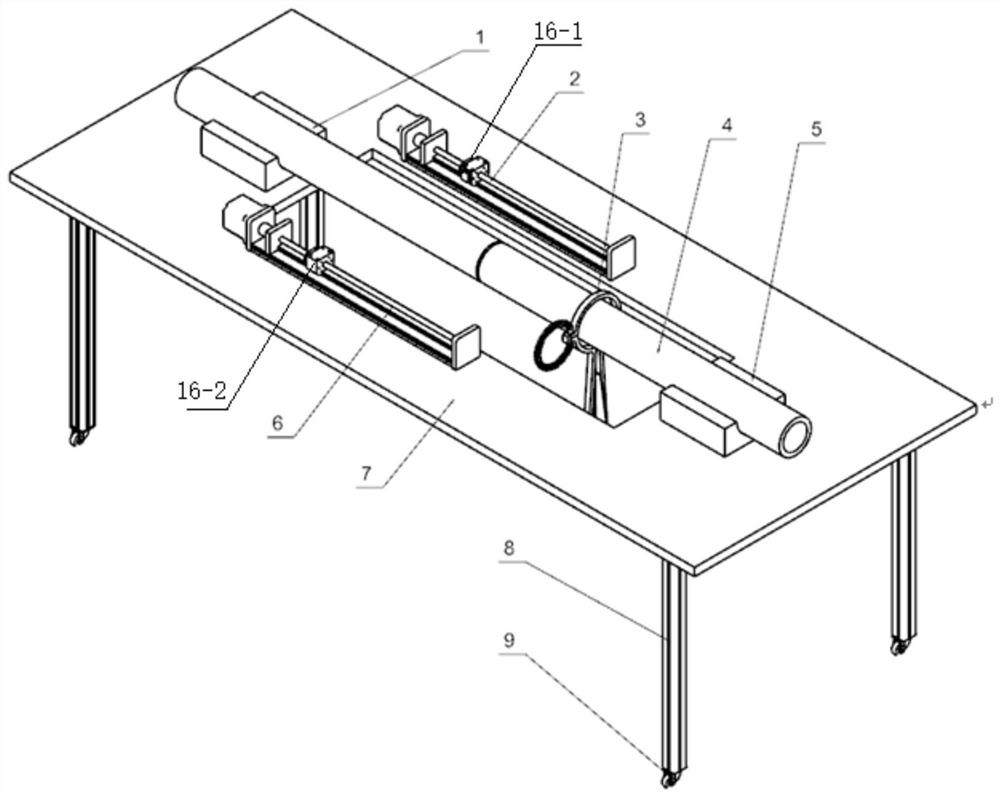

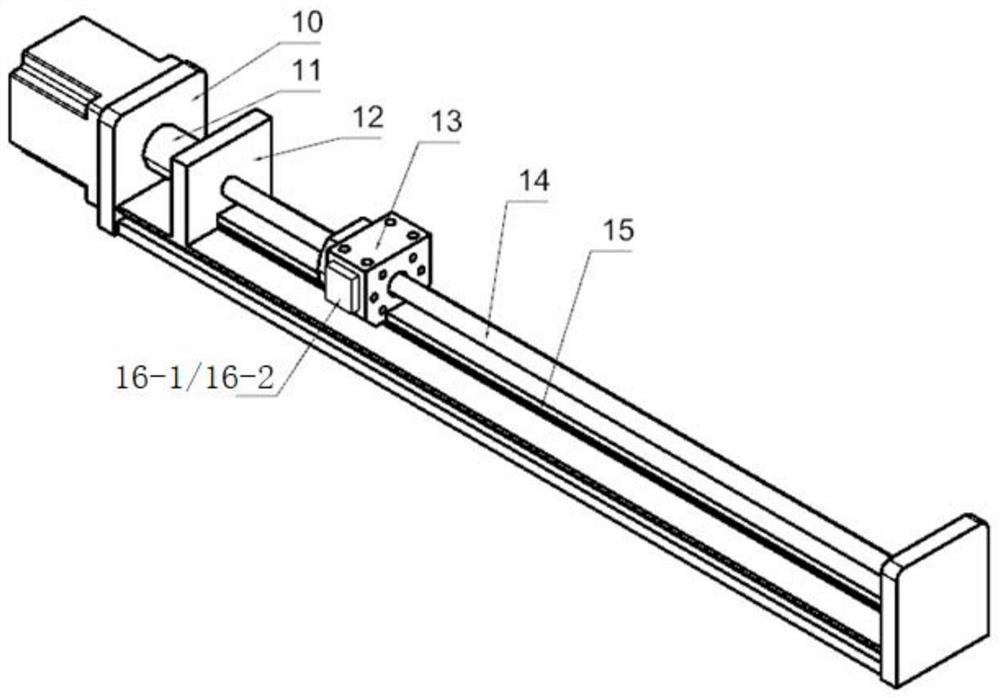

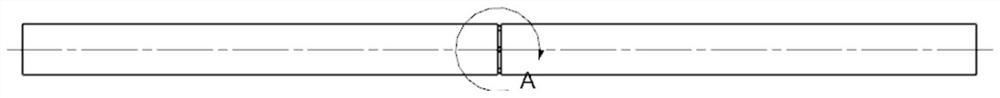

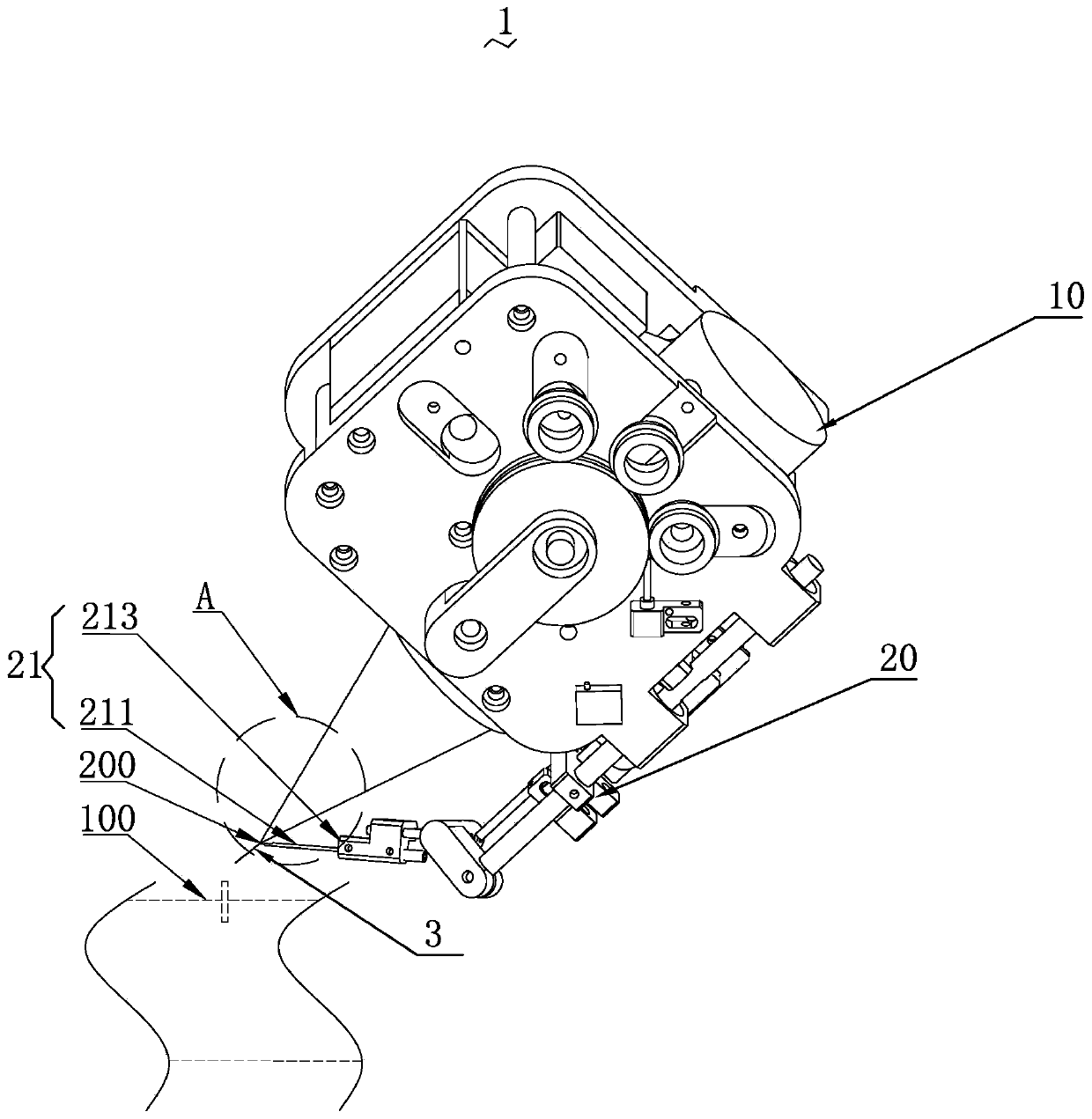

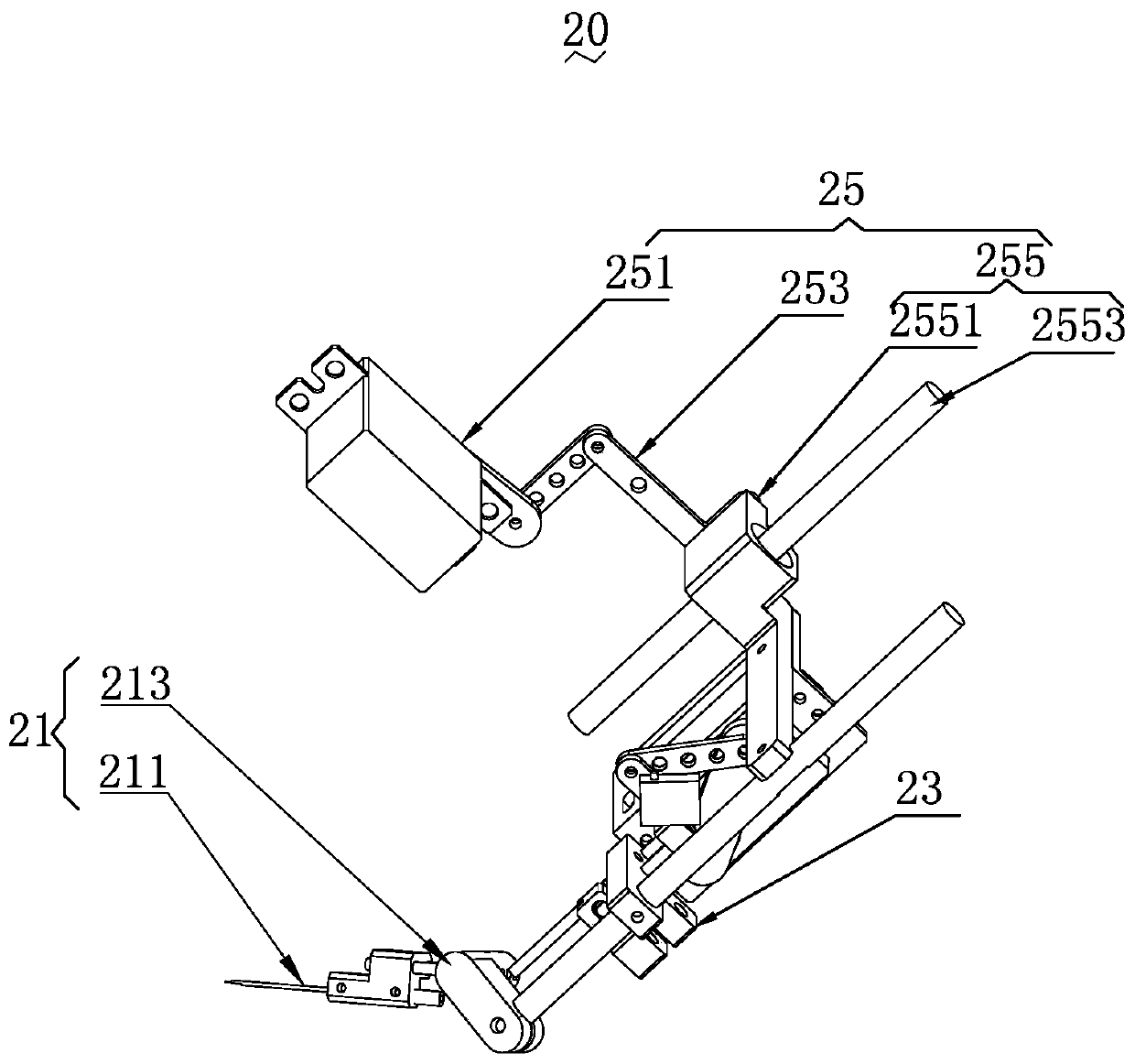

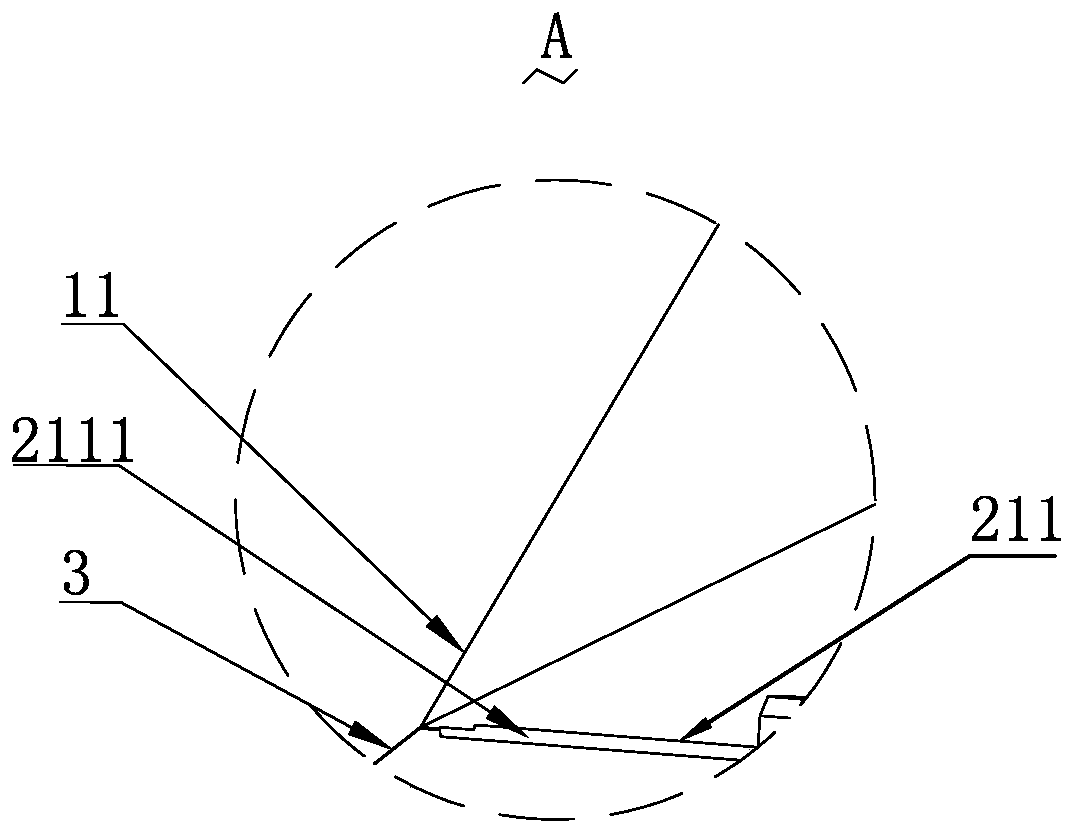

Positioning device for continuous pipeline welding

PendingCN113020851ARealize automatic positioningAutomate operationsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention relates to a positioning device for continuous pipeline welding. The positioning device is used for automatically positioning a spot welding position of a steel pipe completing spot welding and is characterized by comprising a left side positioning and moving assembly and a right side positioning and moving assembly; a transmitting module and a receiving module of a correlation type photoelectric sensor are arranged on the left side positioning and moving assembly and the right side positioning and moving assembly correspondingly, and a control unit controls the transmitting module and the receiving module to move synchronously in the axial direction of the steel pipe through the left side positioning and moving assembly and the right side positioning and moving assembly; in the synchronous movement process, the transmitting module and the receiving module are kept relatively static; and only when the transmitting module and the receiving module move to the spot welding position of the steel pipe, the receiving module receives an optical signal transmitted by the transmitting module. According to the positioning device for continuous pipeline welding, the spot welding position of the steel pipe can be automatically positioned, the later preheating position can be conveniently determined to ensure the preheating effect, and automatic operation of steel pipe welding can be easily achieved.

Owner:BAMAC ELECTRIC EQUIP SHANGHAI +1

Laser welding method and device

ActiveCN107414227BMelting fastImprove welding efficiencyMetal working apparatusSolder feeding devicesLaser solderingWelding process

The invention relates to the technical field of welding, in particular to a laser welding method and a device thereof. The laser welding device comprises a laser generating mechanism and a tin feeding mechanism, wherein the tin feeding mechanism comprises a tin feeding needle; the tin feeding needle is a tubular object with an accommodating cavity, and comprises a tube wall which surrounds the accommodating cavity and two end surfaces; and end openings which communicate with the accommodating cavity are separately formed in the two end surfaces; and a notch which communicates with the accommodating cavity is formed in the tube wall, so that a tin wire is fed out from the end openings after being firstly exposed from the notch in a transfer direction. The laser generating mechanism is used for generating laser which acts on the tin wire transferred by the tin feeding needle, so that the tin wire is fed out from the two end openings after being preheated at the notch. The laser welding method adopts the laser welding device to preheat the tin wire, so that a workpiece is welded. The notch which communicates with the accommodating hole is formed in the tube wall, so that the tin wire is fed out from the end openings after being exposed from the notch and being preheated by laser; and the preheated tin wire can be molten more quickly in a welding process, so that welding efficiency is improved.

Owner:深圳云麟科技有限公司

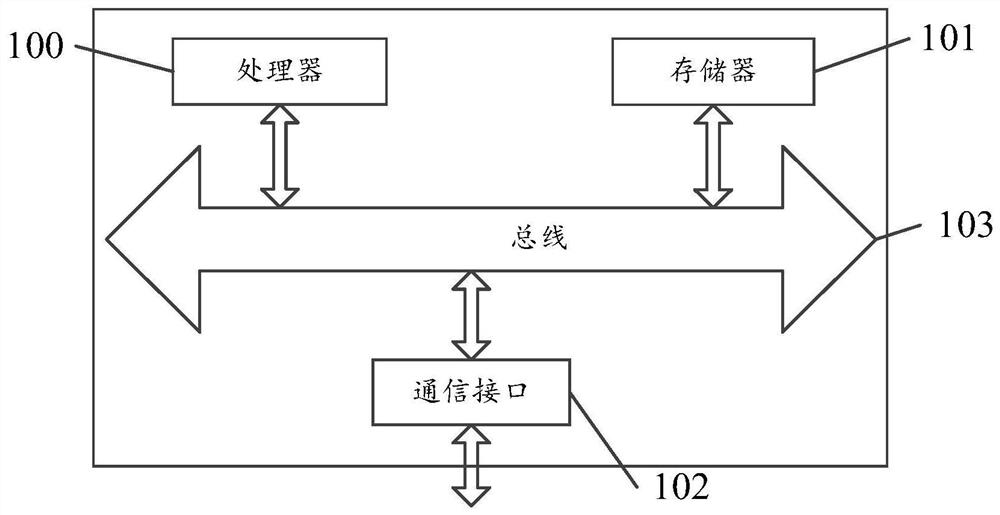

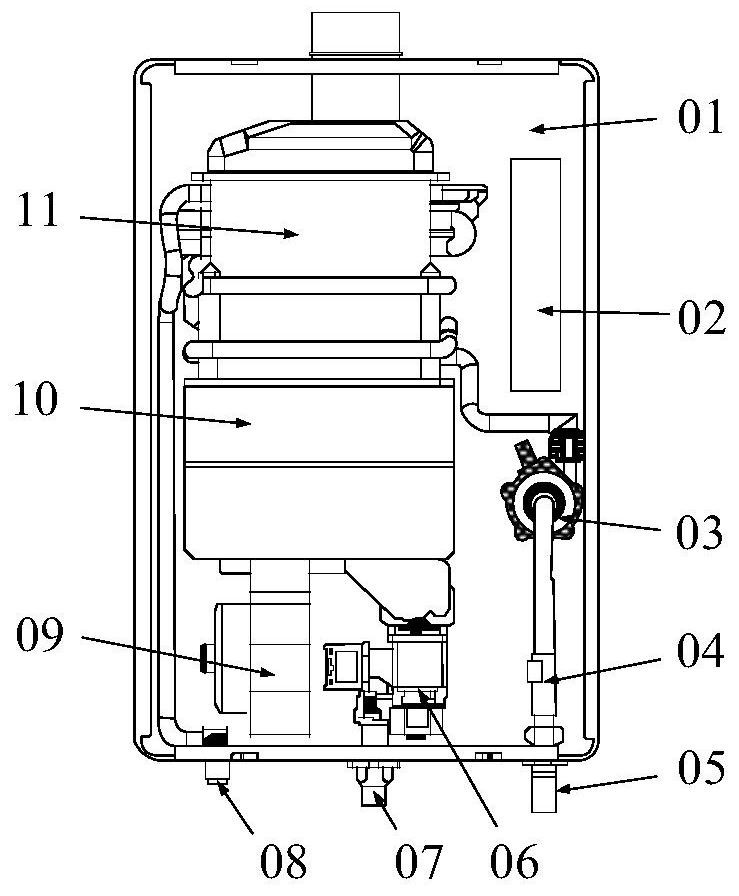

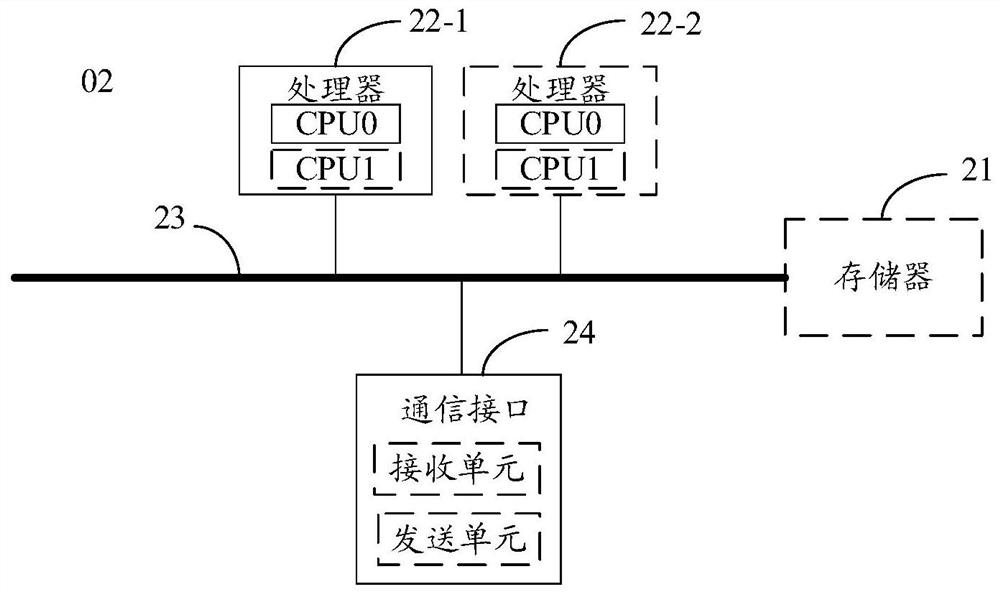

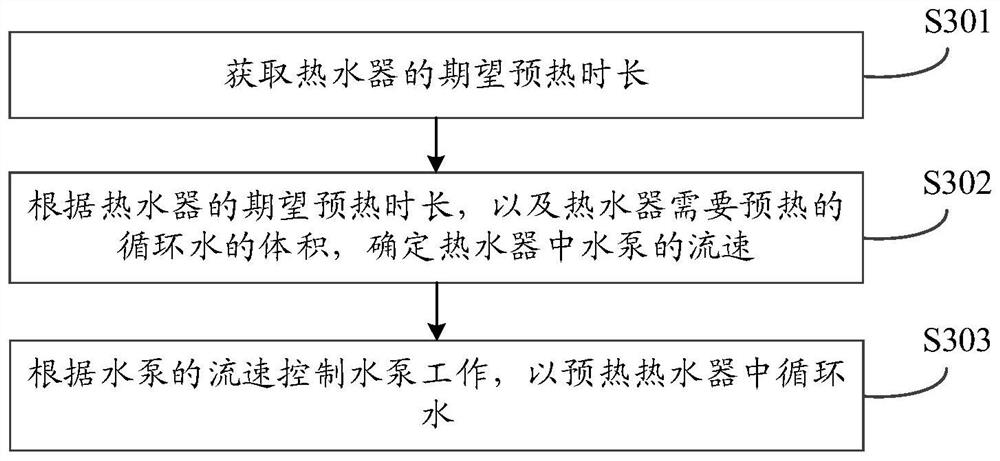

Control method and control device of water heater

PendingCN113357822AReasonable matching of flow rateGuaranteed warm-up effectFluid heatersThermodynamicsProcess engineering

The embodiment of the invention provides a control method and a control device of a water heater, relates to the technical field of household appliances, and aims to reasonably match the flow speed of a water pump of the water heater in a preheating stage, reduce the noise of the water heater in the preheating stage and prolong the service life of the water pump in the water heater while ensuring the preheating effect of the water heater. The control method comprises the steps that the expected preheating time length of the water heater is obtained, wherein the expected preheating time length is used for indicating the time length needed by the water heater to preheat circulating water to reach the expected preheating temperature; according to the expected preheating time length of the water heater and the volume of the circulating water, needing to be preheated, of the water heater, the flow speed of the water pump in the water heater is determined; and the water pump is controlled to work according to the flow speed of the water pump to preheat the circulating water in the water heater.

Owner:GUANGDONG HISENSE HOME APPLIANCES CO LTD

Drink preparation device

The invention discloses a drink preparation device, belonging to the field of machinery. The drink preparation device is mainly used for blending overheated hot water in a hot water pipe with cold water of a set flow rate in a cold water pipe to form a blended water flow with suitable temperature, and transmitting the blended water flow into a liquid dispenser. When a brewing solenoid valve is controlled to be opened, the liquid dispenser dispenses the blended water flow with suitable temperature to a preparation container in which drink components are previously provided so as to prepare drink from the drink components; and when the brewing solenoid valve is controlled to be closed, the liquid dispenser dispenses the blended water flow with suitable temperature to a hot water feeding pipe, and the blended water flow with suitable temperature is directly fed into the drink when a hot water feeding solenoid valve is controlled to be opened. When the brewing solenoid valve and the hot water solenoid valve are both closed, the hot water in a heat exchanger volatiles, passes through a preheating circulation line, and returns to a heat exchanger after being preheated by the liquid dispenser so as to form a preheating circulation.

Owner:刘宗熹

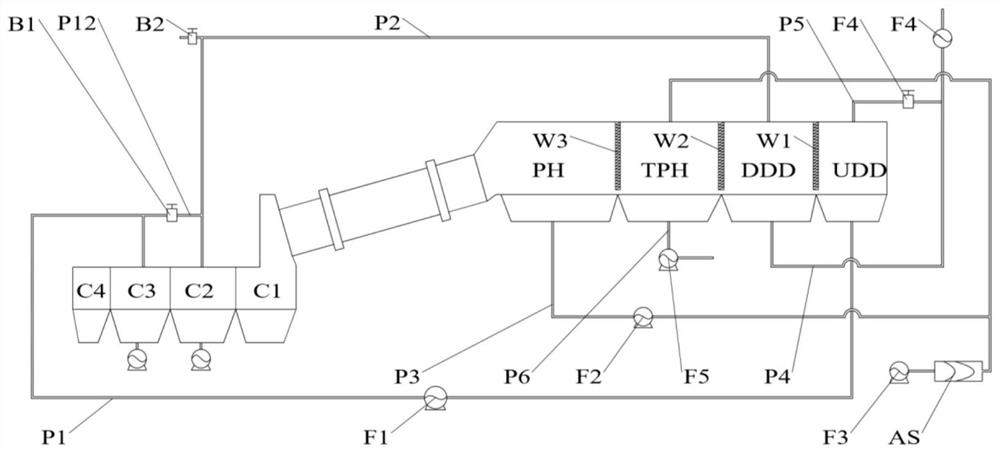

Chain grate rotary kiln hot air system suitable for active coke desulfurization and denitrification process

PendingCN113188335AGuaranteed to passPrevent mutual circulationGas treatmentDispersed particle separationCokeProcess engineering

The utility model discloses a chain grate rotary kiln hot air system suitable for an active coke desulfurization and denitrification process. The chain grate rotary kiln hot air system comprises a chain grate forced air drying section (UDD), an air draft drying section (DDD), a preheating section I (TPH), a preheating section II (PH), a circular cooler section I (C1) and a circular cooler section II (C2); a first hot air pipeline (P1) is arranged between the forced air drying section (UDD) and a circular cooler section III (C3); a second hot air pipeline (P2) is arranged between the induced draft drying section (DDD) and the second annular cooler section (C2); and the first hot air pipeline (P1) and the second hot air pipeline (P2) are connected through a hot air connecting pipeline (P12). The hot air of a circular cooler is used for drying pellets; harmful gas of HCl generated in a pellet drying process is prevented from entering the active coke desulfurization and denitrification system; and stable and smooth operation of the active coke desulfurization and denitrification system is guaranteed.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

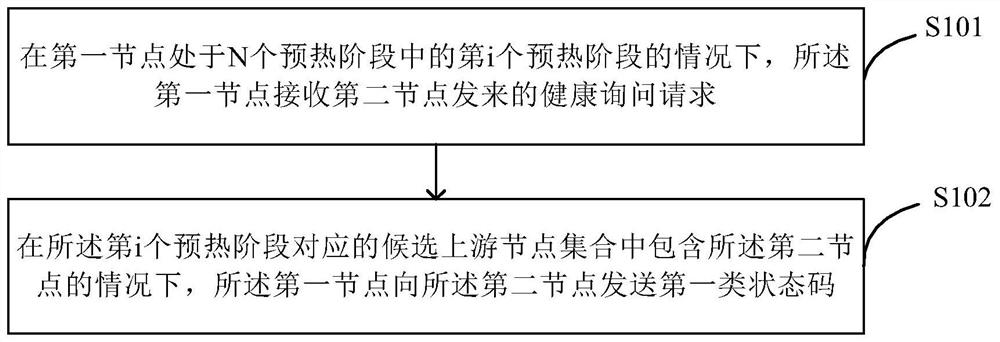

Node processing method and system, node, medium and computing equipment

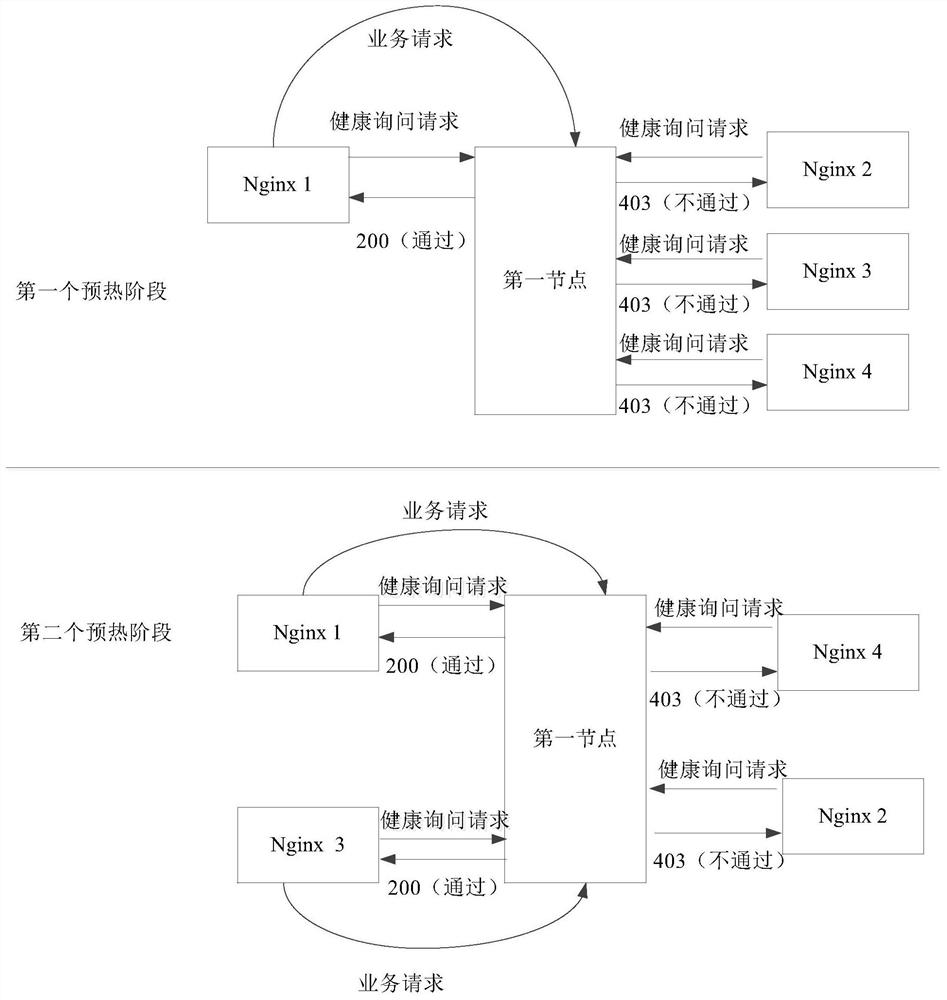

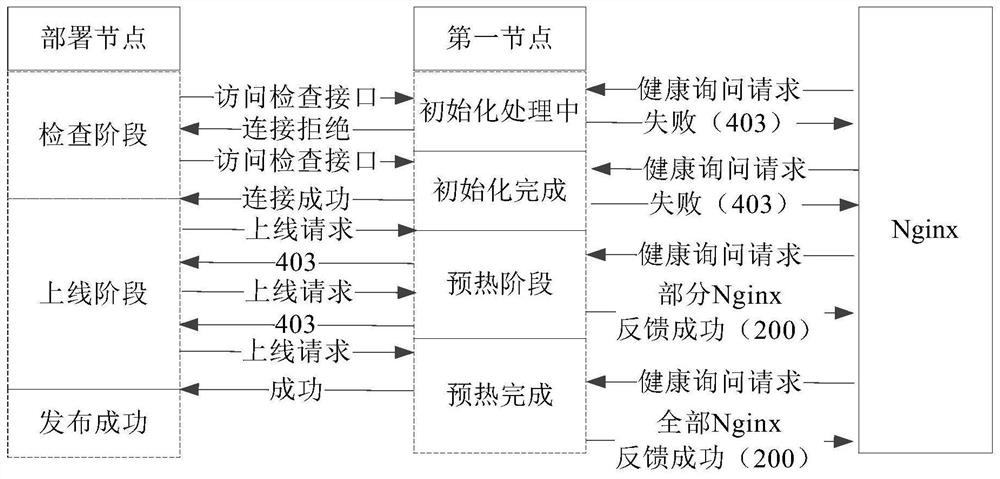

ActiveCN113190274AGuaranteed warm-up effectEffect of warm-up effectProgram initiation/switchingResource allocationComputer networkEngineering

The invention provides a node processing method and system, a node, a medium and computing equipment, and the method comprises the steps: enabling a first node to receive a health inquiry request sent by a second node under the condition that the first node is in the ith preheating stage of N preheating stages, wherein N is an integer greater than or equal to 2, and i is an integer greater than or equal to 1 and less than or equal to N, the second node is one of upstream nodes of the first node; under the condition that the candidate upstream node set corresponding to the ith preheating stage contains the second node, enabling the first node to send a first type of state code to the second node, wherein the first type of state code is used for indicating that the first node is in a state capable of processing the service request of the second node, the number of the candidate upstream nodes in the candidate upstream node set corresponding to the ith preheating stage is smaller than the number of the upstream nodes of the first node.

Owner:HANGZHOU NETEASE CLOUD MUSIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com