Special equipment for preparing vegetarian meat from high-temperature meal

A special equipment, vegetarian meat technology, applied in the application, food forming, food science and other directions, can solve the problems of uneven shape, poor product taste, poor production efficiency, etc., to improve the surface temperature and reduce the cost of cooling facilities , the effect of comfortable production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

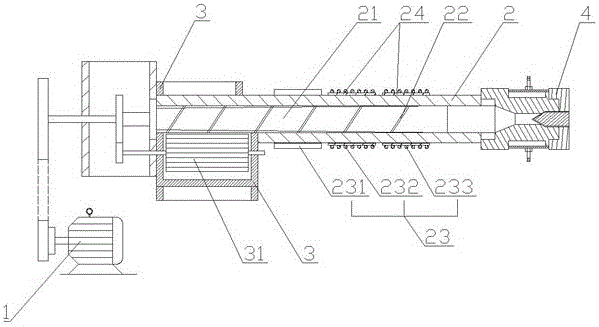

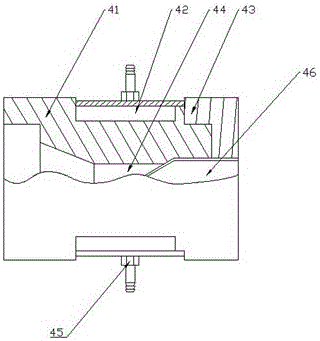

[0028] Such as figure 1 Shown: a special equipment for making vegetarian meat with high-temperature meal, including a motor 1, a conveying sleeve 2, a feeding device 3 and a molding head 4, the feeding device 3 is located at the front end of the conveying sleeve 2, and the end of the conveying sleeve 2 A forming machine head 4 is provided, and a major axis 21 is arranged in the conveying sleeve 2, on which a screw rack 22 is arranged, wherein the major axis 21 is from the front end to the rear end of the conveying sleeve 2, and its shaft diameter varies from small to gradually becomes larger, the pitch of the helical propelling rack 22 gradually becomes smaller, and there is a gap between the helical propelling rack 22 on the major axis 21 and the inner wall of the delivery sleeve 2. In this embodiment, the shaft diameter of the major axis 21 changes from small to Gradually become larger, the screw pitch of the helical rack 22 on the long axis 21 gradually decreases from large...

Embodiment 2

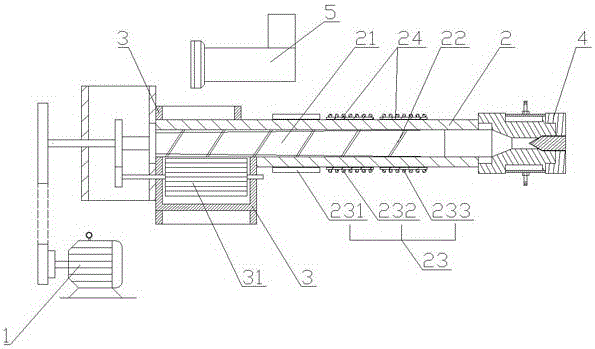

[0030] Such as figure 1 with 3 Shown: Compared with Embodiment 1, this embodiment adds a temperature control device 23, and the temperature control device 23 is arranged on the outside of the delivery sleeve 2. The temperature control device 23 is composed of three sections, which are the front refrigeration device 231 and the middle electromagnetic coil. 232 and the rear electromagnetic coil 233, during the high-temperature meal processing process, the front refrigeration device 231 controls the temperature of the front section of the conveying sleeve 2 at 0°C, and the middle electromagnetic coil 232 controls the temperature of the middle section of the conveying sleeve 2 between 260°C and 280°C In between, the rear electromagnetic coil 233 controls the temperature of the rear section of the conveying sleeve 2 between 280°C and 290°C. In this way, the heating method of internal heating is used to heat the conveying sleeve itself through electromagnetic induction, thereby ensu...

Embodiment 3

[0032] Such as figure 1 with 3 Shown: Compared with embodiment 2, the present embodiment has set up insulation cotton 24, and middle section electromagnetic coil 232 and rear section electromagnetic coil 233 are all provided with insulation cotton 24 between conveying sleeve 2, and in this embodiment insulation cotton 24 Improve the surface temperature of the working environment equipment, make the human body touchable, greatly improve the working environment of the production site, effectively increase the enthusiasm of workers for production, reduce the cost of traditional cooling facilities, and create a more green, energy-saving, safe and comfortable production environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com