Vertical intelligent multidirectional electrostatic paint spraying method

An electrostatic spraying, multi-directional technology, applied in electrostatic spraying devices, spray booths, spraying devices, etc., can solve problems affecting product quality, insufficient steam exhaust speed, and products not preheated, so as to avoid thermal peeling and reduce scratches , Safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

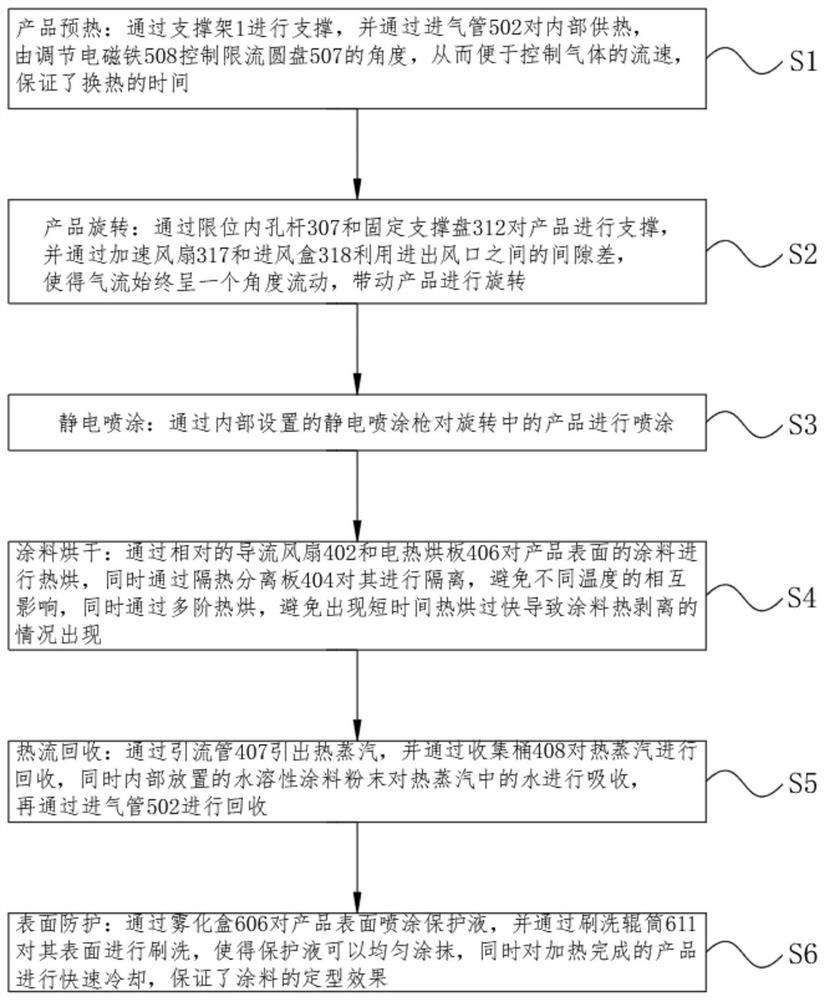

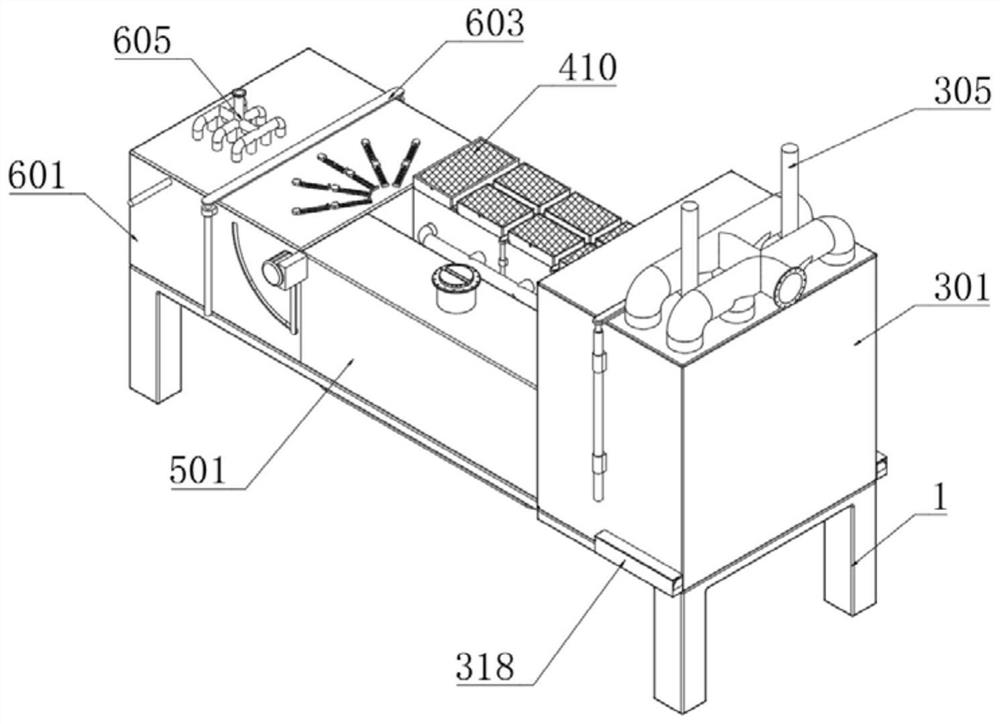

[0047] Example: such as Figure 1-15 As shown, the present invention provides a technical solution, a vertical intelligent multi-directional electrostatic painting method, comprising the following steps:

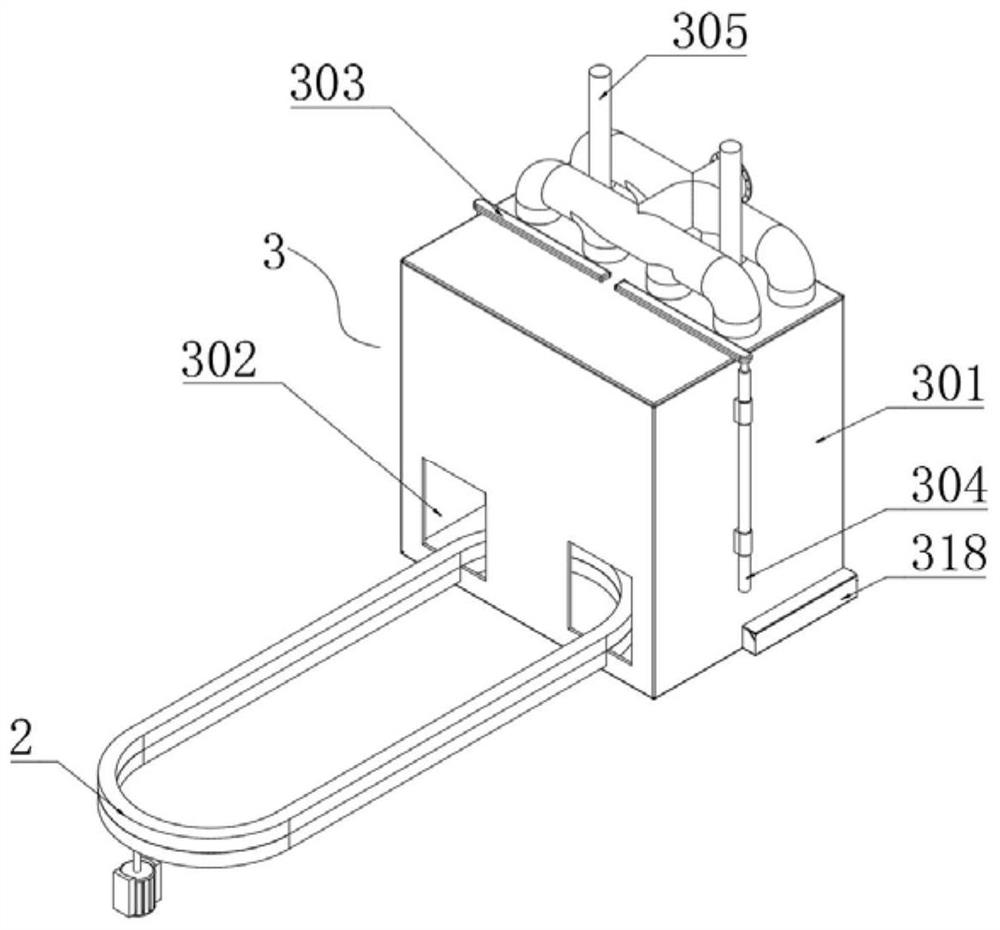

[0048] S1: Product preheating: it is supported by the support frame 1, and the internal heat is supplied through the intake pipe 502, and the angle of the flow-limiting disc 507 is controlled by the adjusting electromagnet 508, so as to facilitate the control of the gas flow rate and ensure the heat exchange time ;

[0049] S2: Product rotation: The product is supported by the limiting inner hole rod 307 and the fixed support plate 312, and the gap difference between the air inlet and outlet is used by the accelerating fan 317 and the air inlet box 318, so that the airflow always flows at an angle, driving The product is rotated;

[0050] S3: Electrostatic spraying: Spray the rotating products through the internal electrostatic spraying gun;

[0051] S4: Paint drying: Hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com