A gas oxidation combustion utilization method based on desulfurization and dehydration pretreatment

A pretreatment and gas technology, applied in the direction of combustion methods, chemical instruments and methods, combustion types, etc., can solve the unsatisfactory dehydration effect of mechanical dehydrators and affect the efficiency of heat energy utilization (power generation efficiency, refrigeration efficiency or heating efficiency, reduction Problems such as the heat output of the regenerative oxidation device, to achieve the effects of convenient, reliable and efficient treatment, improved combustion efficiency, sufficient and reliable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

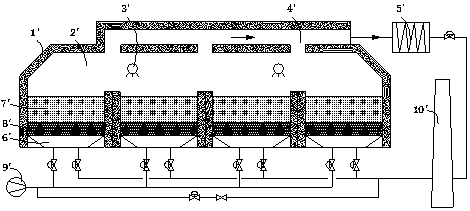

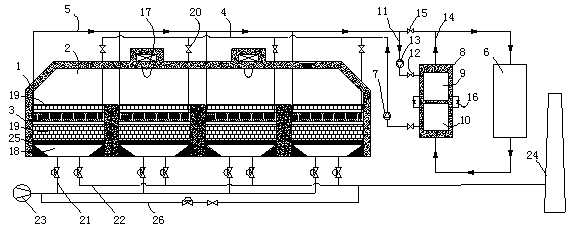

Image

Examples

Embodiment approach

[0038] Embodiment, a gas oxidative combustion utilization method based on desulfurization and dehydration pretreatment, including the step of oxidative combustion of gas by means of a gas oxidative combustion device. Set the moisture sorbent filler and / or the sulfur sorbent filler, and switch the direction of the inlet and outlet of the air inlet channel and the outlet channel according to a fixed time interval, so that the inlet channel relies on the moisture sorbent filler and / or the sulfur sorbent filler Realize the adsorption treatment of moisture and / or sulfur in the intake air, and at the same time make the moisture adsorbent packing and / or sulfur adsorbent packing adsorb moisture and / or the sulfur adsorbent packing in the last cycle time period by relying on the waste heat temperature of the outlet gas in the air outlet channel Or sulfur desorption treatment.

[0039] In this way, the moisture and sulfur contained in the intake air can be adsorbed and treated by the ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com