Patents

Literature

36results about How to "Guaranteed preprocessing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

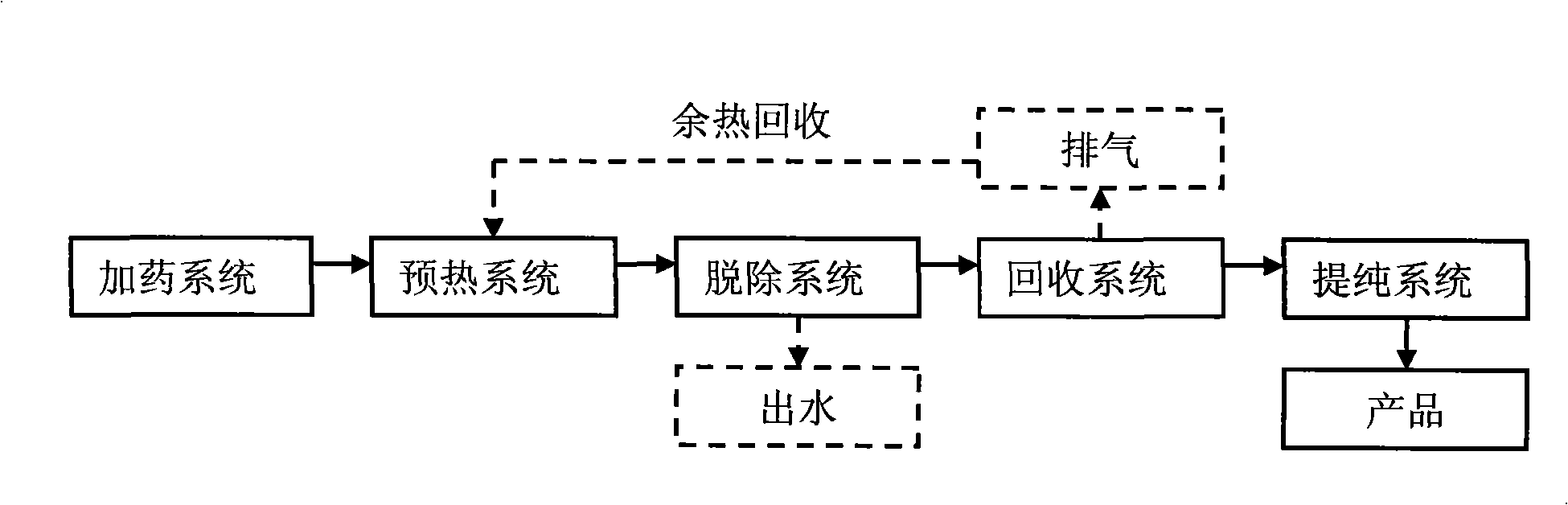

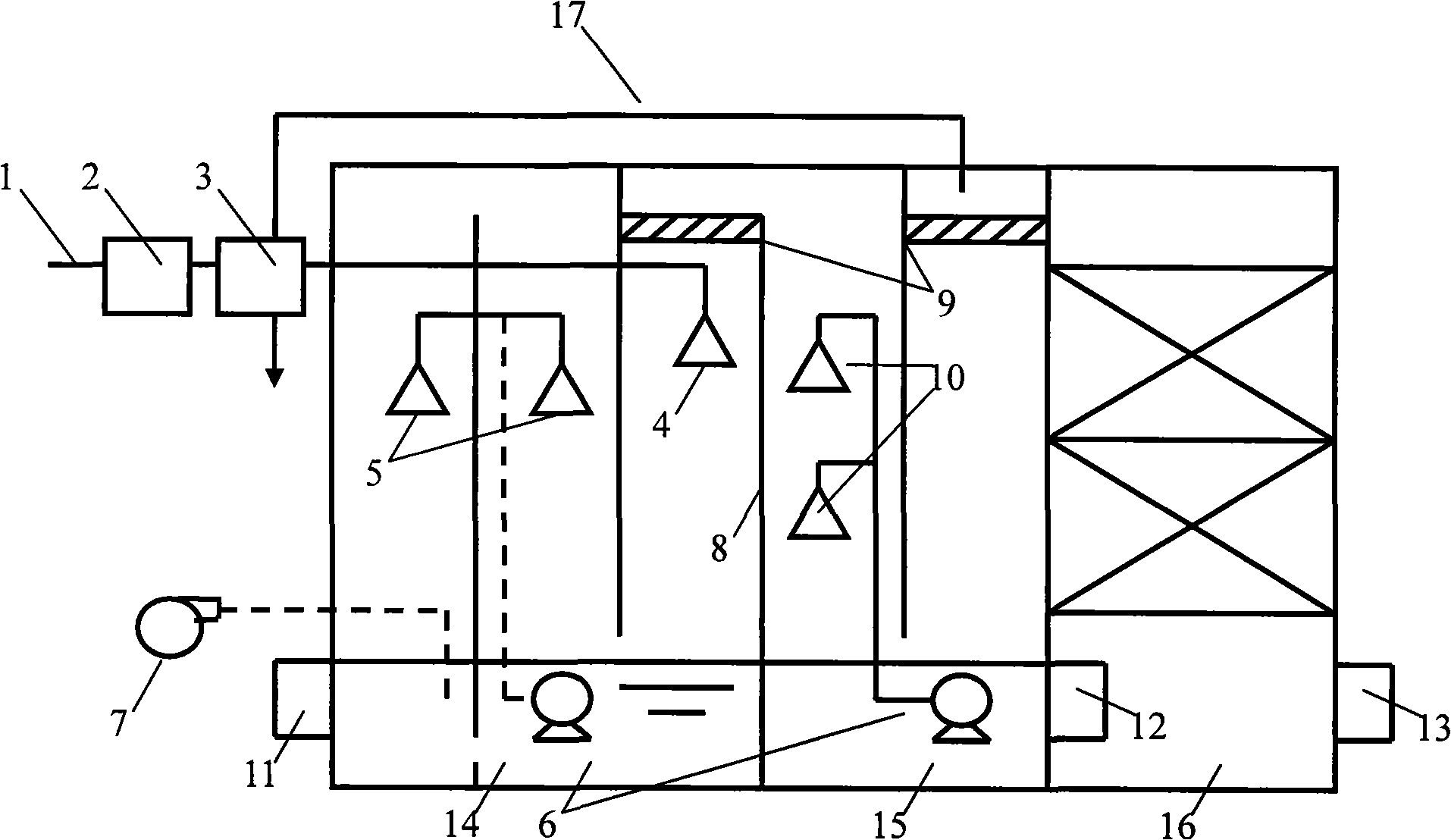

Treatment method and apparatus for recycling ammonia nitrogen wastewater

InactiveCN101318752AReduce dosageGuaranteed preprocessing effectMultistage water/sewage treatmentWater/sewage treatment by heatingResource utilizationSewage

The invention relates to a method and a device for recycling treatment of ammonia nitrogen wastewater. The use method combining the device comprises the following steps that: a PH value of ammonia nitrogen wastewater is adjusted in an automatic medicine addition device; the ammonia nitrogen wastewater is preheated in a preheater, evenly distributed by a spraying device in a removal working section and collected in a bottom liquid storage zone; after ammonia is blown off by adopting forced-air blast, the ammonia in the wastewater is repeatedly removed by a circulating spraying system, purified and discharged from an effluent weir; ammonia-containing waste gas is filtered by a demisting device and subject to multilevel spraying and absorption so as to reclaim an ammonia crude product; and the purified gas is exhausted from the top part. The method and the device for recycling treatment of the ammonia nitrogen wastewater are suitable for ammonia nitrogen wastewater produced in the process of various industrial and agricultural productions, the treatment of domestic sewage and the resource utilization of materials, reclaim useful substances as possible while treating wastewater, reduce the cost for pollutant treatment and the emission of the pollutants and improve economical benefit while protecting environment.

Owner:ZHEJIANG UNIV

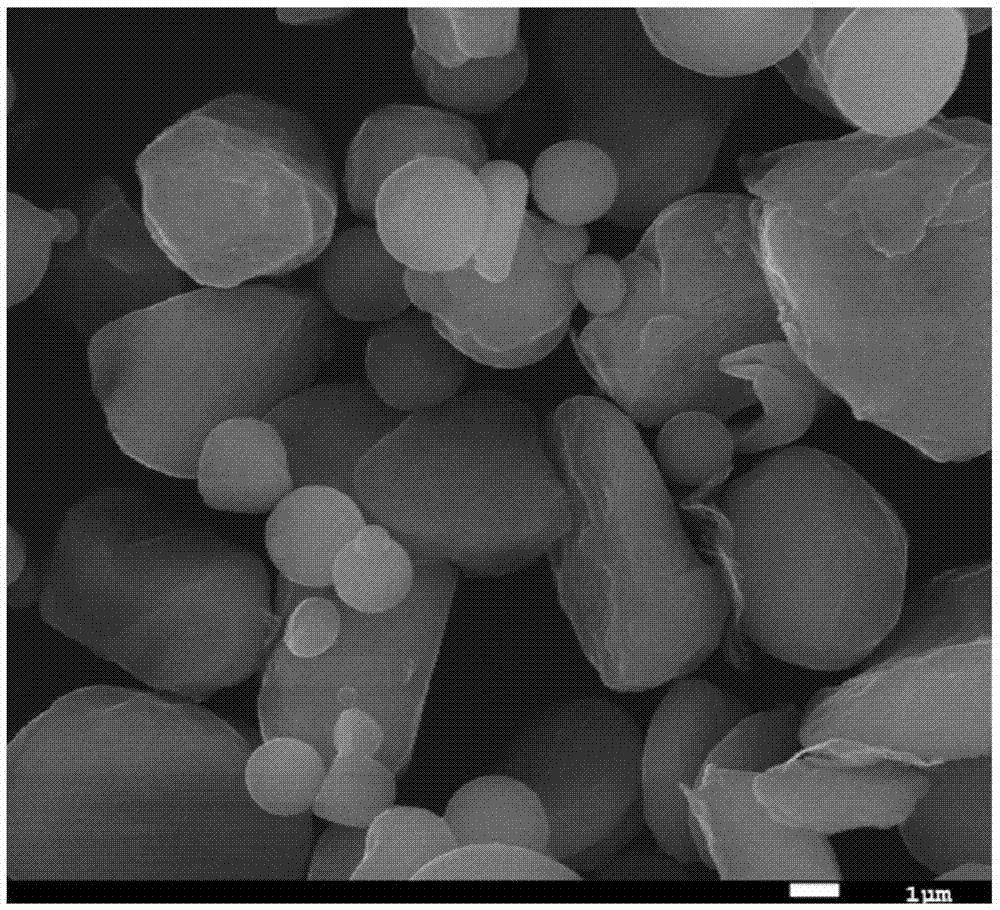

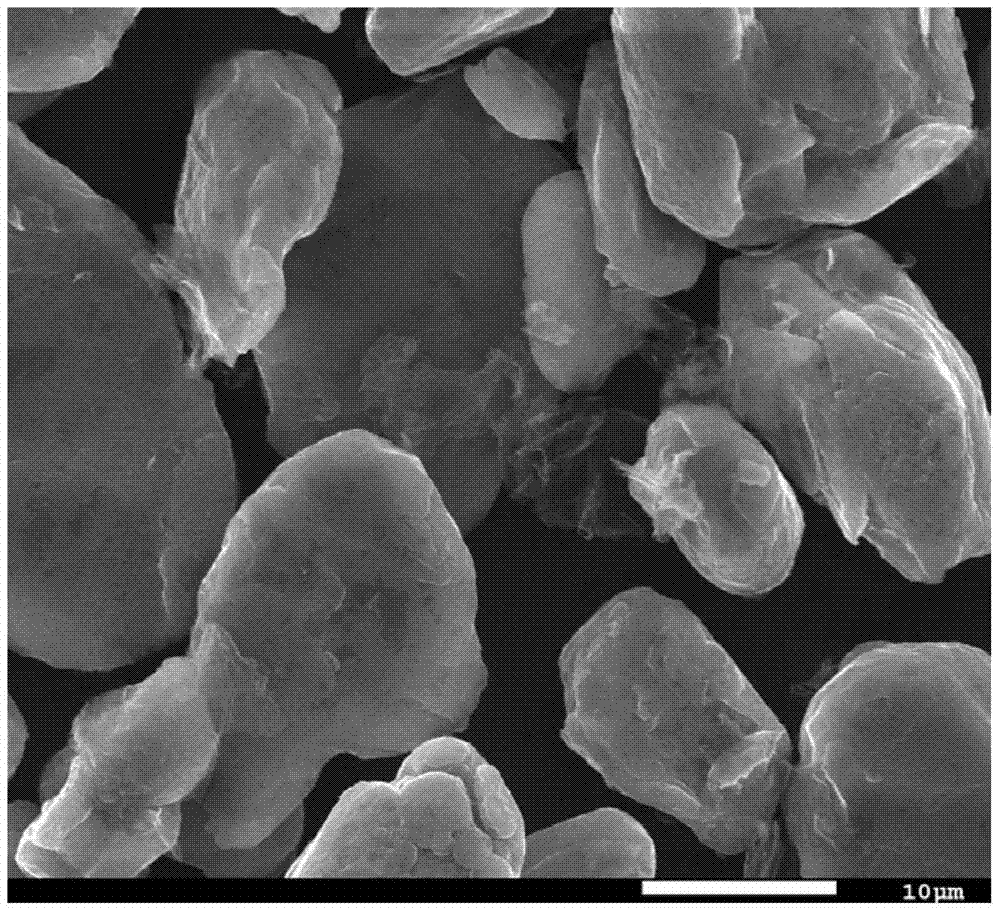

Preparation method for composite powder of graphene and metal aluminum powder

InactiveCN106914611AImproved reunion statusGuaranteed preprocessing effectAluminium powderSpherical shaped

The invention relates to a preparation method for composite powder of graphene and metal aluminum powder, and belongs to the field of nanosheet structure reinforced metal base composite materials. The preparation method comprises the following steps of: taking grapheme and metal aluminum powder as raw materials, and performing pre-dispersing through a mechanical stirring method, an ultrasonic vibrating method and a chemical reagent dispersing method; and then, preparing the composite powder by ball-milling, wherein the composite powder comprises the following components in percentage by weight: 0.3 wt.%-8.5wt.% of graphene and 91.5wt.%-99.7wt.% of aluminum powder. According to the preparation method, aluminum powder generates the laminarization effect, so that the morphology of the aluminum powder is changed into a cake shape or an ellipsoid shape from a spherical shape, dimension deformation percentage of the aluminum powder ranges from (-)200% to 200%, and graphene is uniformly distributed in aluminum powder. The obtained composite powder is low in impurity content, has moisture content lower than 0.01wt.%, and realizes kilogram-level composite powder preparation; and the preparation method is nontoxic and safe.

Owner:GRIMAT ENG INST CO LTD

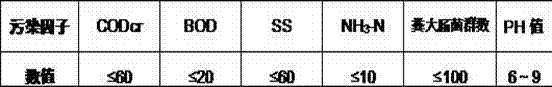

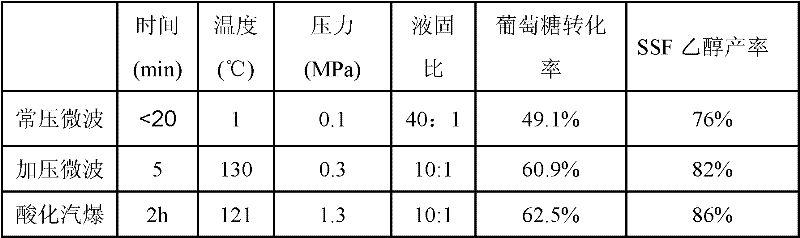

Method for performing lignocelluloses raw material high-temperature diluted acid pretreatment by using extremely small amount of water

InactiveCN102010882AWide range of raw materialsReduce the ratioBiofuelsFermentationCellulosePretreatment method

The invention provides a method for performing lignocelluloses raw material high-temperature diluted acid pretreatment by using extremely small amount of water, which comprises the following steps: (1) pre-treating a lignocelluloses raw material to remove impurities; (2) mixing the raw material with 0.2 to 10 weight percent acidic solution in an extremely high solid to liquid ratio, uniformly stirring, and standing at normal temperature to infiltrate the acidic solution into the lignocelluloses raw material completely, wherein the extremely high solid to liquid ratio is 1:2-3:1; and (3) filling the obtained raw material into a pretreatment reactor at a 100 percent material filling rate, heating the raw material to a required temperature and pressure directly by high-temperature steam, keeping the temperature and pressure for a certain period of time, relieving pressure, taking the material out and cooling. When the method is used, water consumption and energy consumption are reduced greatly on the premise of ensuring the pretreatment effect, zero discharge of sewage is realized, a pretreated lignocelluloses raw material with high solid content is obtained, and the perfect connection with a subsequent high-solid-content biological processing process is realized.

Owner:EAST CHINA UNIV OF SCI & TECH

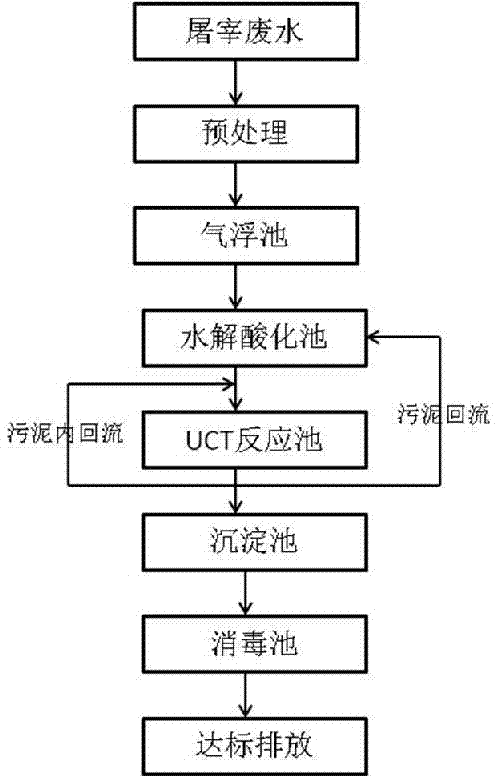

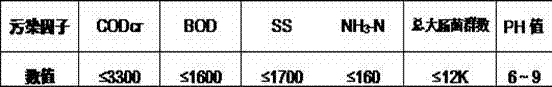

Process for treating slaughtering wastewater by using UCT

PendingCN106977040AReduce processing costsReduce volume loadWater treatment parameter controlTreatment involving filtrationNitrogen gasHydrolysis

The invention discloses a process for treating slaughtering wastewater by using UCT. The process comprises pretreatment, air floatation treatment, hydrolysis acidification treatment, UCT treatment, precipitation treatment and disinfection treatment. According to the process, slaughtering wastewater is pretreated, the pretreated slaughtering wastewater enters an air floatation pool through a lifting pump, and oil removing and residue removing are performed; in a hydrolysis acidification pool, the organic macromolecules in the wastewater are degraded into organic small molecules, and the nitro state nitrogen or nitroso state nitrogen is converted into nitrogen gas through a denitrification effect; the wastewater being subjected to hydrolysis acidification enters a UCT pool, aerobic bacteria are added under an aerobic condition, and the small molecule organic matters are oxidized into carbon dioxide and water while the ammonia nitrogen in the water is converted into nitrate nitrogen and nitrite nitrogen through a nitrification effect; and the wastewater treated by the UCT pool is subjected to sedimentation treatment and disinfection treatment, and the obtained treated wastewater meets the discharging standard. According to the present invention, the process has advantages of simple process, easy operation, easy maintenance, low comprehensive energy consumption, high efficiency, energy saving, and low running cost.

Owner:XIAMEN JULONG TENGWEI ENVIRONMENTAL ENG TECH CO LTD

Method for carrying out pressurization microwave pretreatment on lignocellulose

InactiveCN102220384AImprove securityReduce energy consumptionBiofuelsFermentationChemistryTreatment time

The invention provides a method for carrying out pressurization microwave pretreatment on lignocellulos, relates to a method for treating lignocellulose, and solves the problems of large water consumption, high cost and energy consumption as well as low conversion rate of reducing sugar of the existing methods for pretreating the lignocellulose. The method comprises the following steps of: obtaining and pulverizing lignocellulose which is dried to constant weight, adding distilled water and finally carrying out pressurization microwave treatment. The method achieves the purposes of shortening treatment time, reducing water consumption, cost and energy consumption during production, avoiding secondary pollution and being easily applicable to industry. The method achieves milder condition of pressurization microwave pretreatment in comparison with other pretreatment methods, low requirement on reaction temperature and pressure (reaction temperature: 110-150 DEG C, the pressure: 0.1-0.5 MPa), high safety, low energy consumption, no need of chemical reagent, short reaction time (only 2 to 15 min) and cost saving.

Owner:HARBIN INST OF TECH

Raw material microwave pre-treatment method for producing fuel alcohol

ActiveCN101168748AGuaranteed preprocessing effectSimple processBiofuelsLiquid carbonaceous fuelsPretreatment methodAlcohol production

The invention discloses a raw material microwave pretreatment method used for the production of fuel alcohol, and relates to a raw material pretreatment method before producing the fuel alcohol. The invention solves the disadvantages that the cost is too high, the energy consumption is too large, or the conditions are too severe, etc., and the problems that the production cycle is long, and secondary pollution is caused. The invention has the following steps: 10 g of matrix powder after water equilibrium is taken, and is filled with water according to a solid to liquid ratio of 1:30 to 50, andis put into a microwave treater, pretreatment is performed in the condition of 00 to 1000 W for 30 to 60 min, then wshing and filtering are performed, and the pretreatment is finished. Under the premise of ensuring the pretreatment effect, the invention simplifies the technical process, reduces the treatment time, reduces the production energy consumption and the cost, simultaneously does not cause secondary pollution, and is easy to realize industrial application. The optimal conditions of the invention are obtained by respectively optimizing the liquid to solid ratio, the heating time and the microwave power, and 49.1 percent of glucose conversion rate, 21.1 percent of xylose conversion rate, and 76 percent of theoretical ethyl alcohol yield rate are respectively abtained under the optimal conditions.

Owner:江苏哈宜环保研究院有限公司

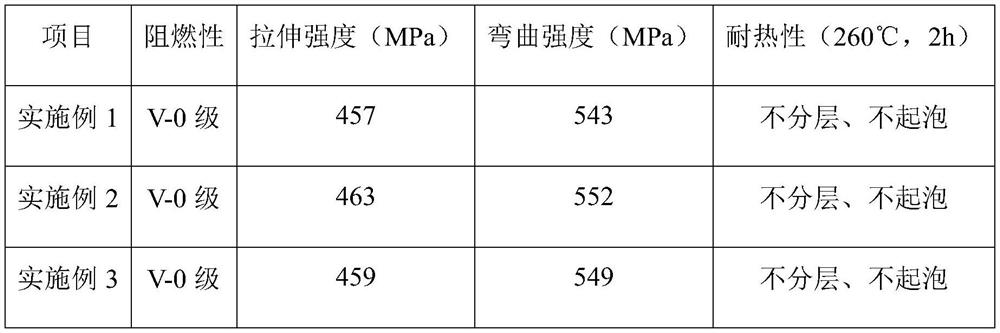

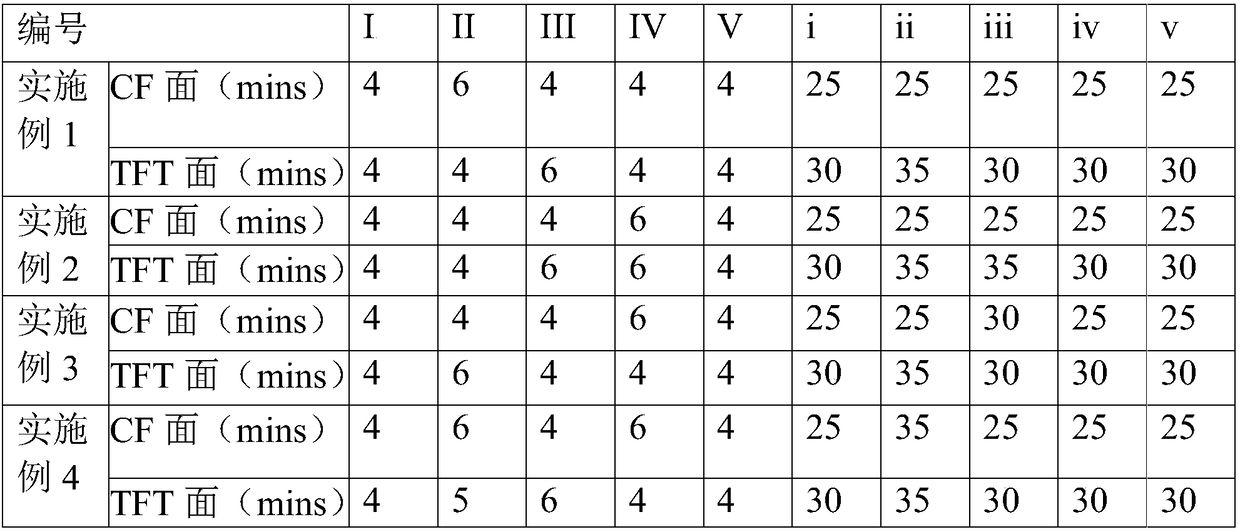

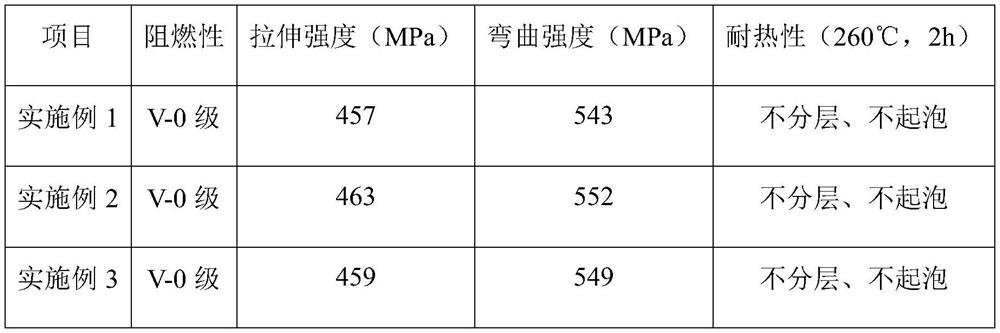

Glass fiber cloth reinforced insulating molded board and preparation method thereof

ActiveCN113150331AGood mechanical propertiesImprove high temperature resistanceGlass fiberPolymer science

The invention discloses a glass fiber cloth reinforced insulating molded board and a preparation method thereof. The glass fiber cloth reinforced insulating molded board comprises reinforcing material glass fiber cloth and glue solution coated on two sides of the glass fiber cloth; in order to improve cohesiveness and permeability between the glue solution and the reinforcing material glass fiber cloth, when alkali-free glass fiber cloth is impregnated, the modified silane coupling agent, the citric acid and the sodium hypophosphite are added and mixed, and due to the introduction of the modified silane coupling agent and the mutual synergistic effect of the components such as the citric acid and the sodium hypophosphite, the high temperature resistance and the flame retardance of the glass fiber cloth can be effectively improved; the molded board prepared by the invention not only has excellent mechanical properties, but also has excellent high-temperature resistance and flame retardance due to modification of the flame retardant and modification treatment of the silane coupling agent, can be suitable for various environmental applications, and has higher practicability.

Owner:HUIZHOU ZONGSHENG ELECTRONICS MATERIAL CO LTD

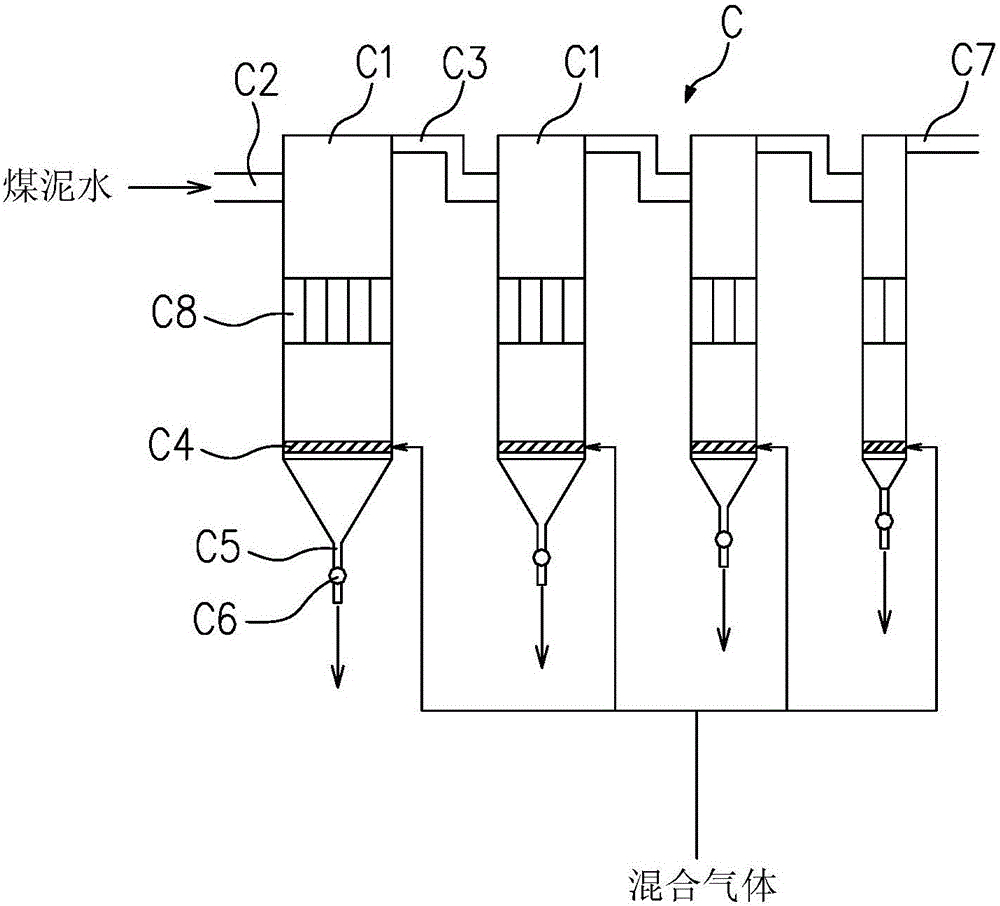

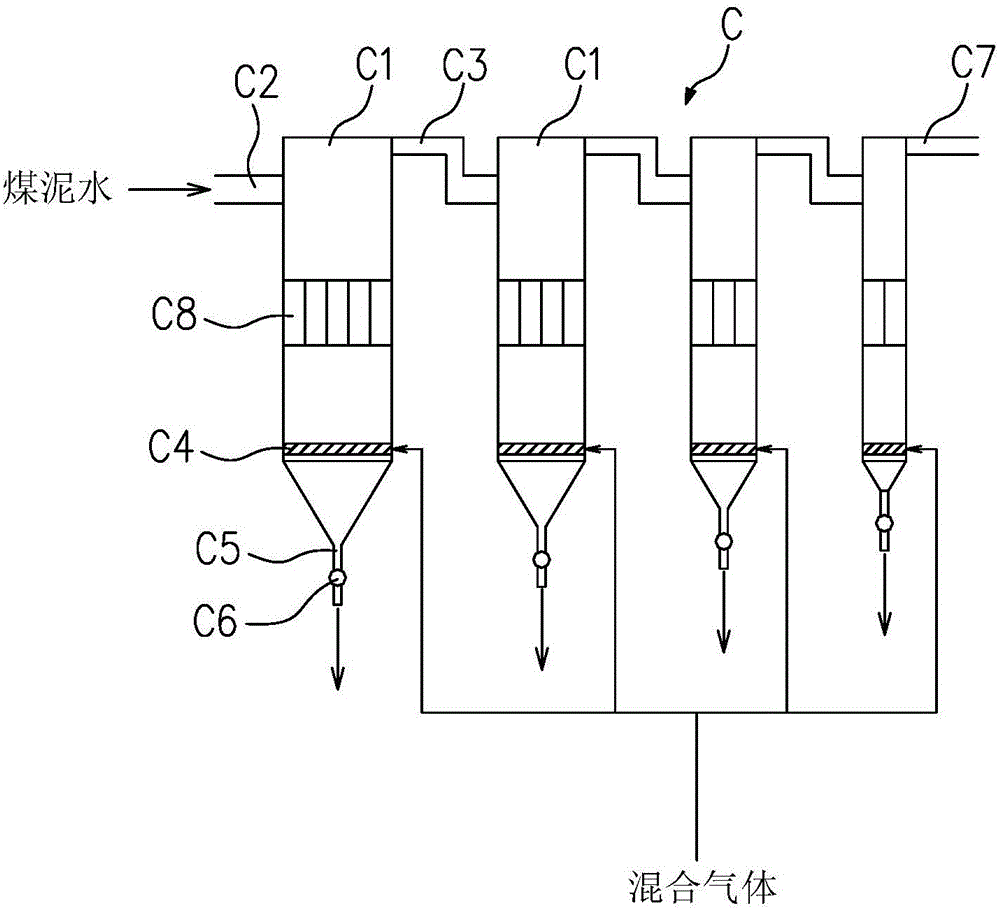

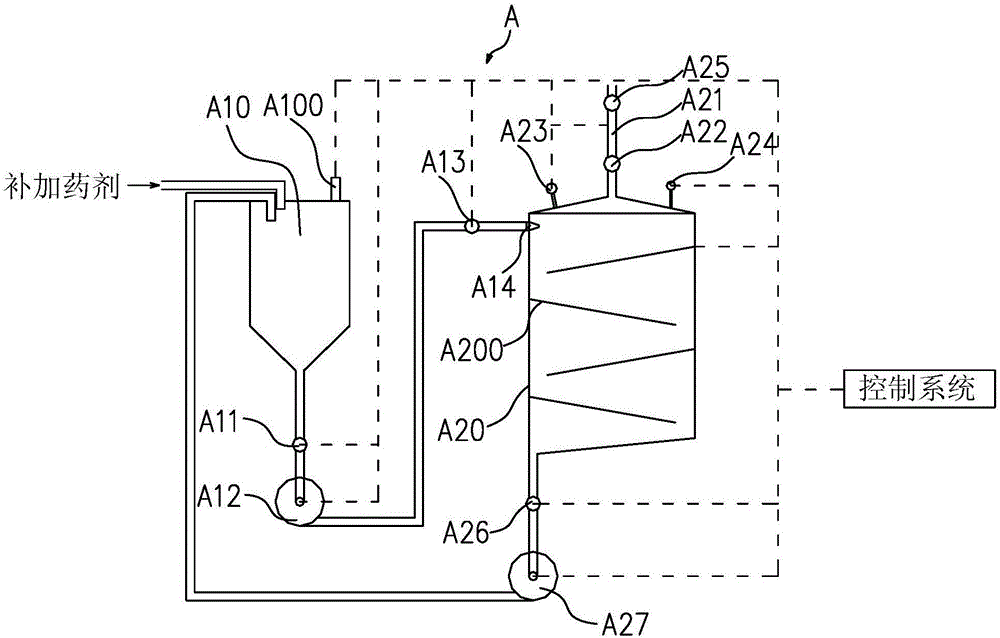

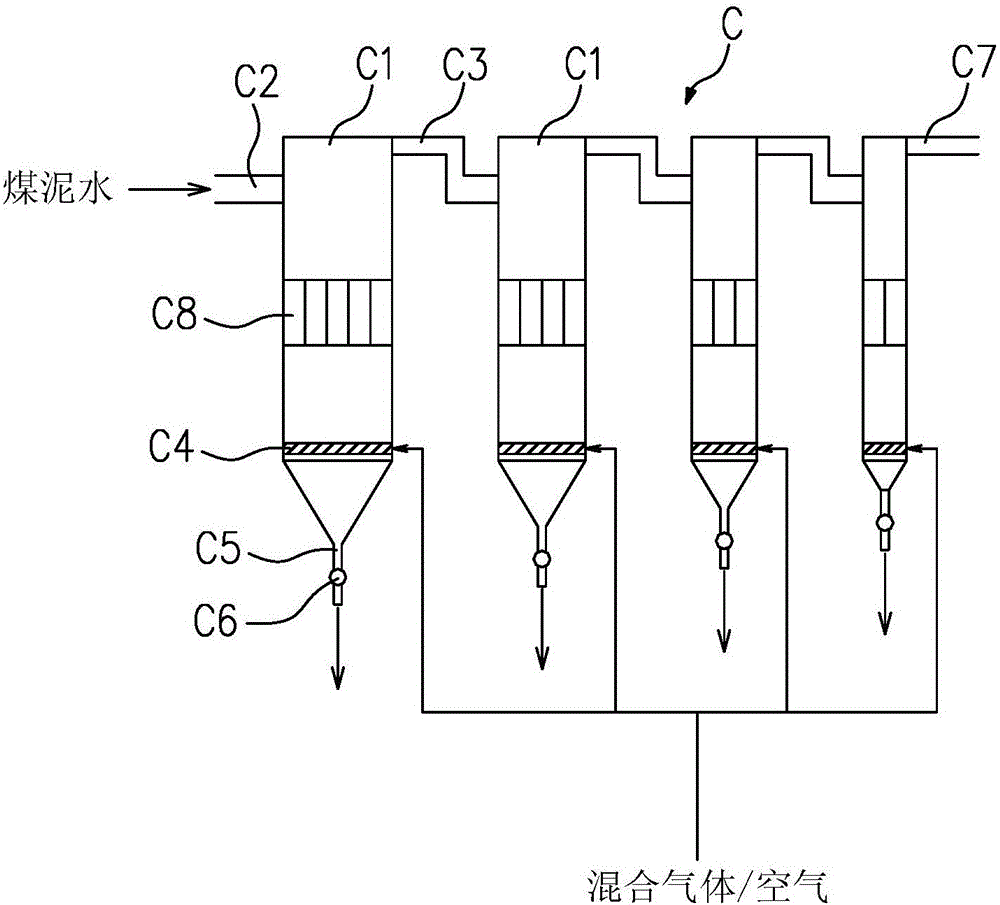

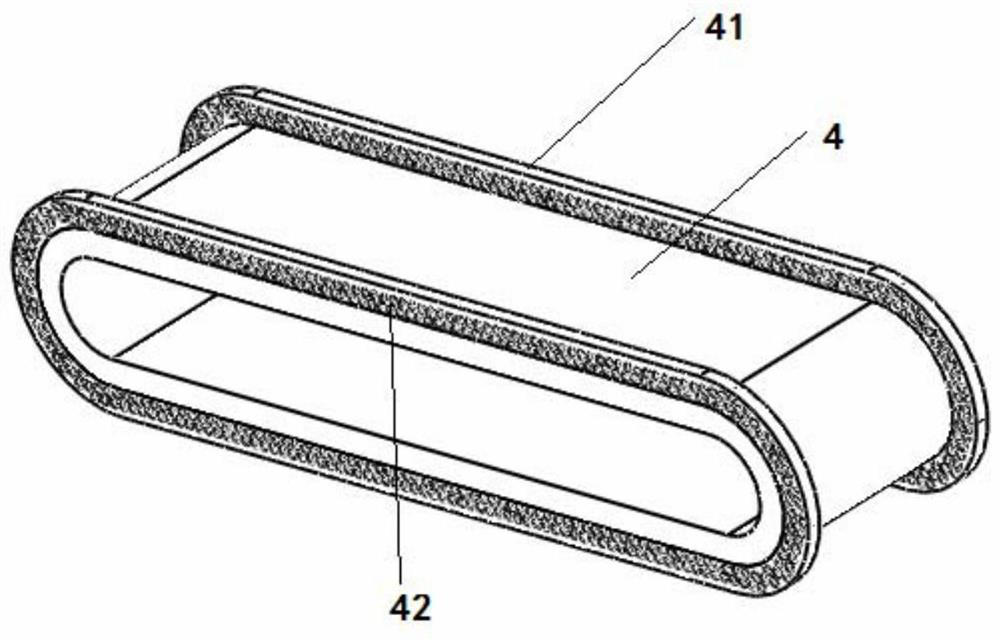

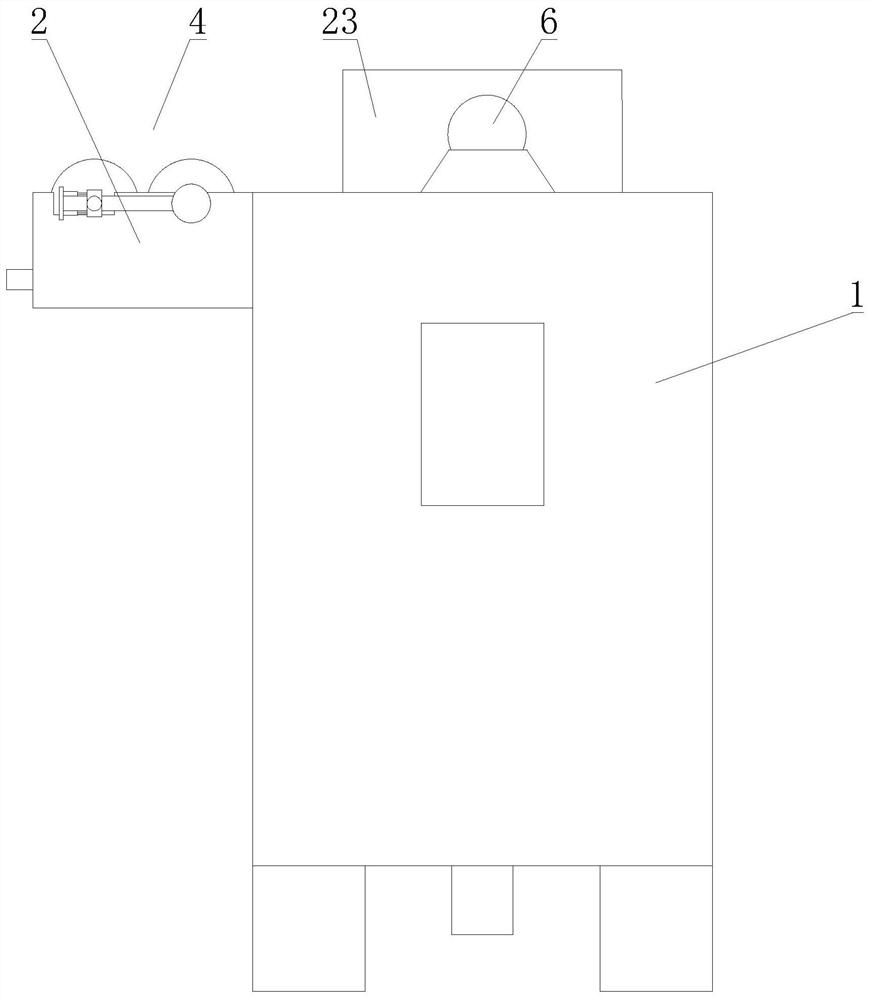

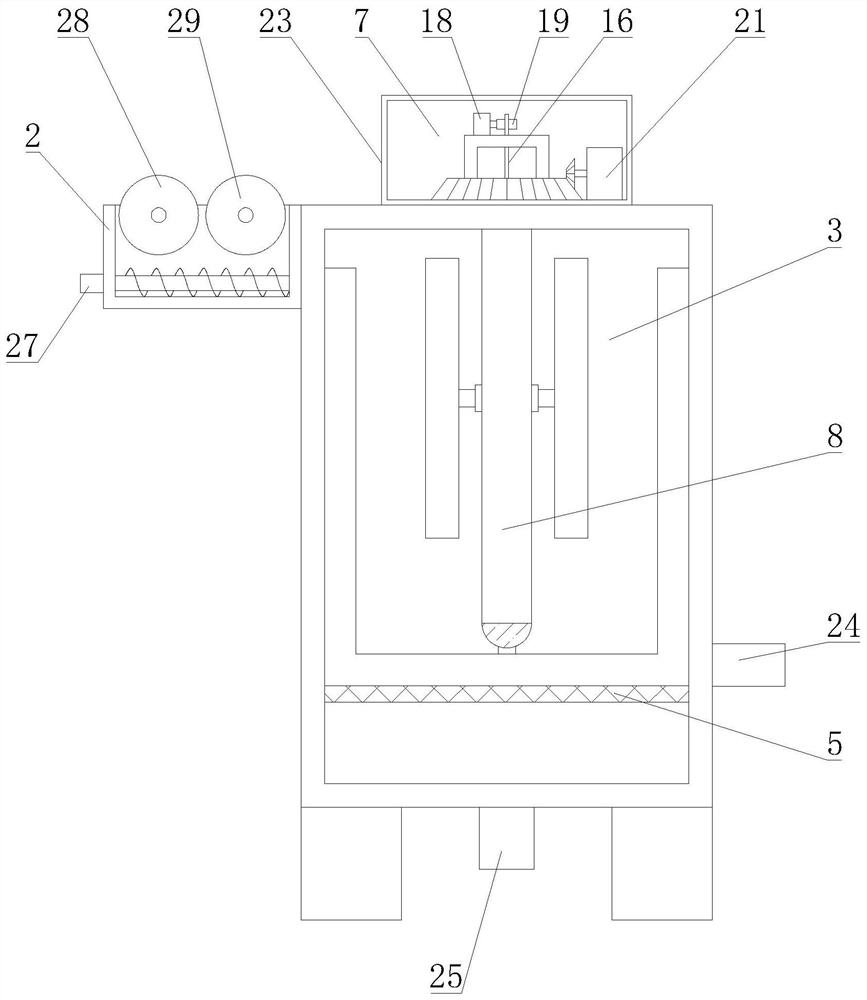

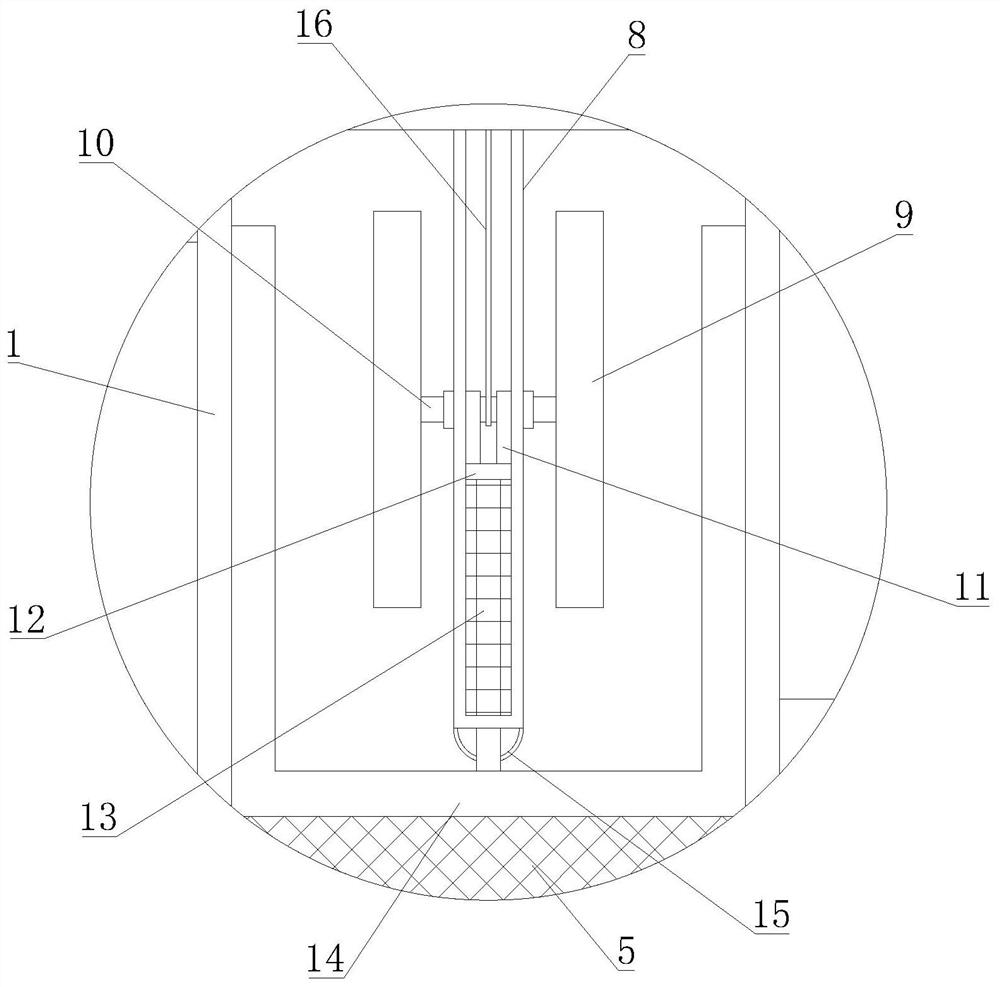

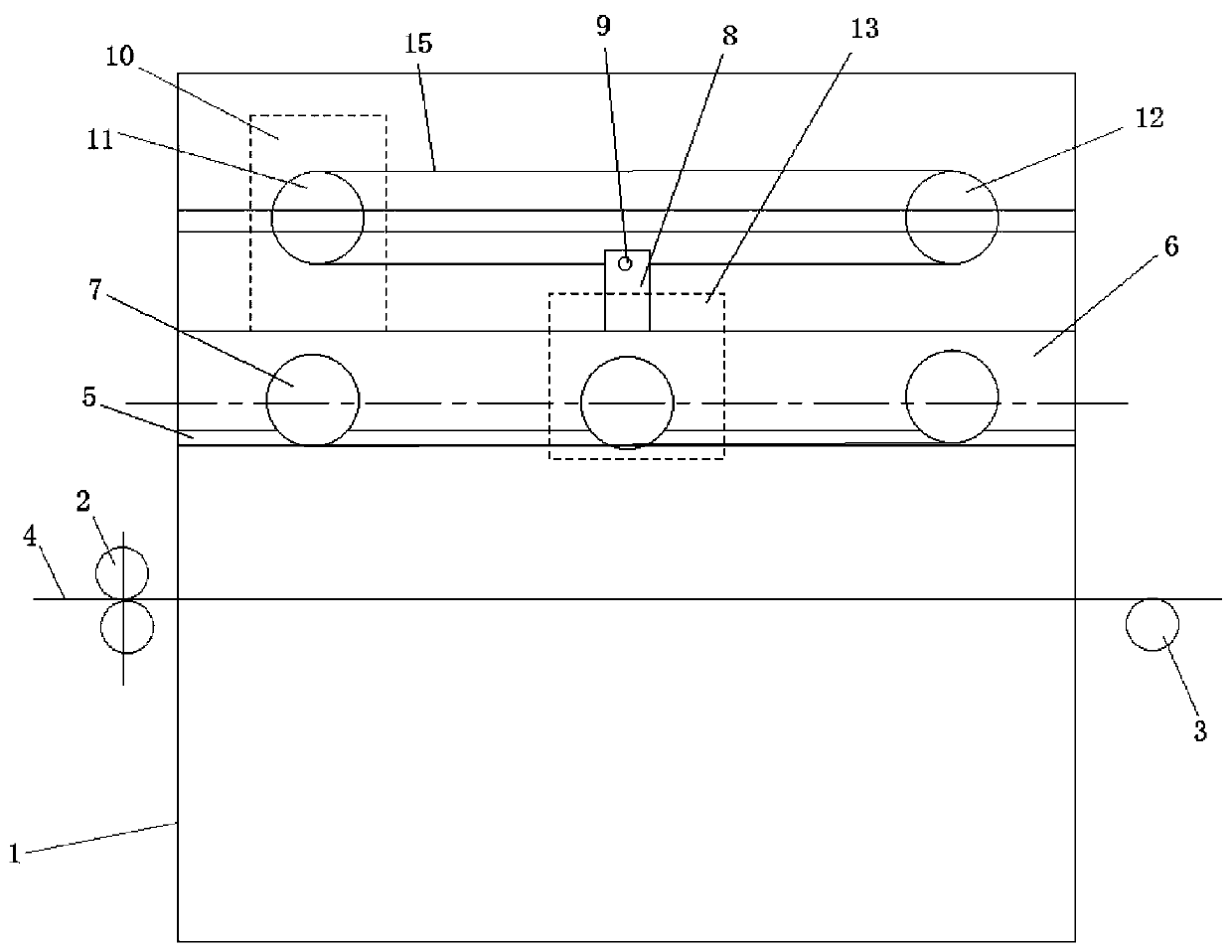

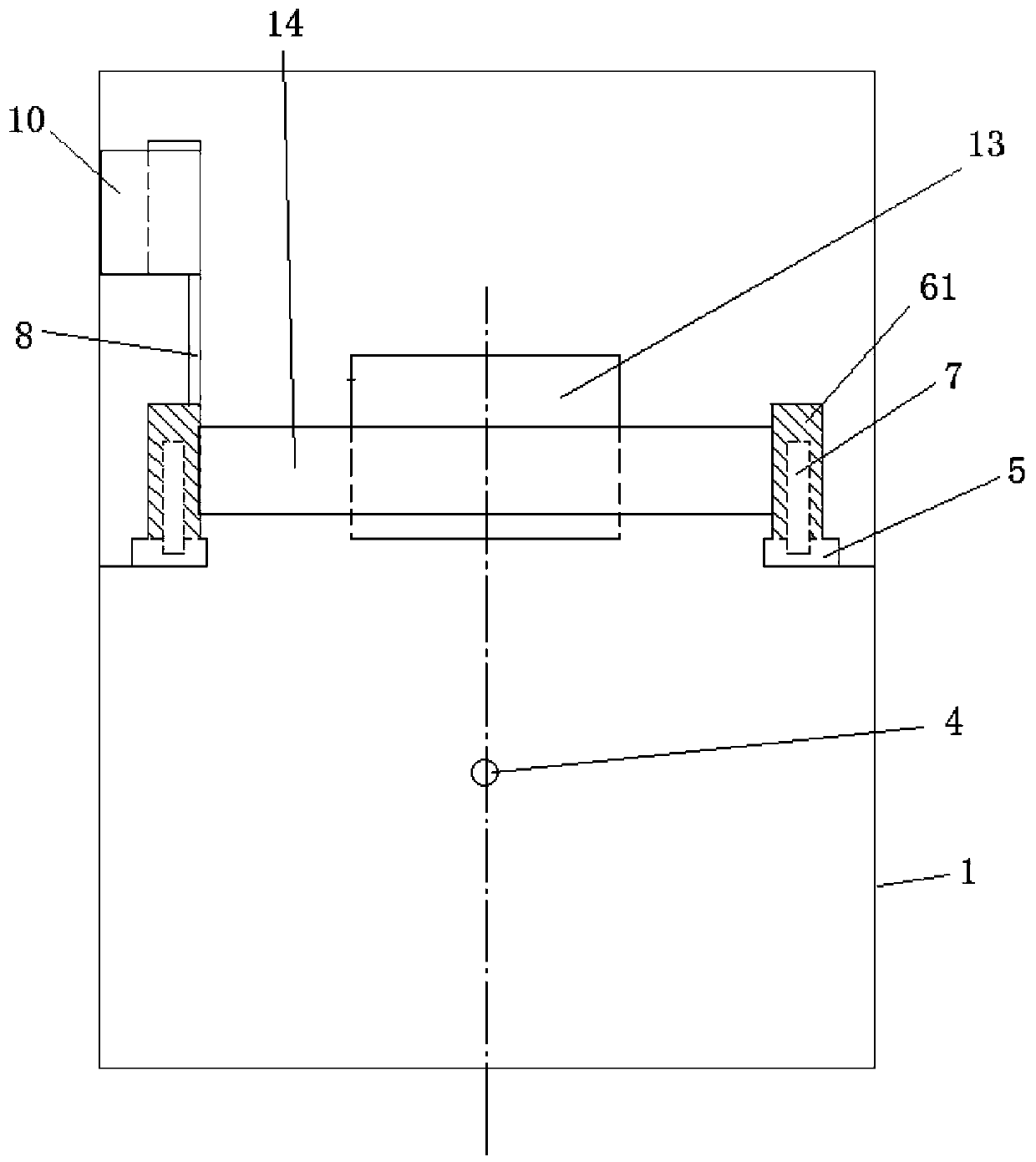

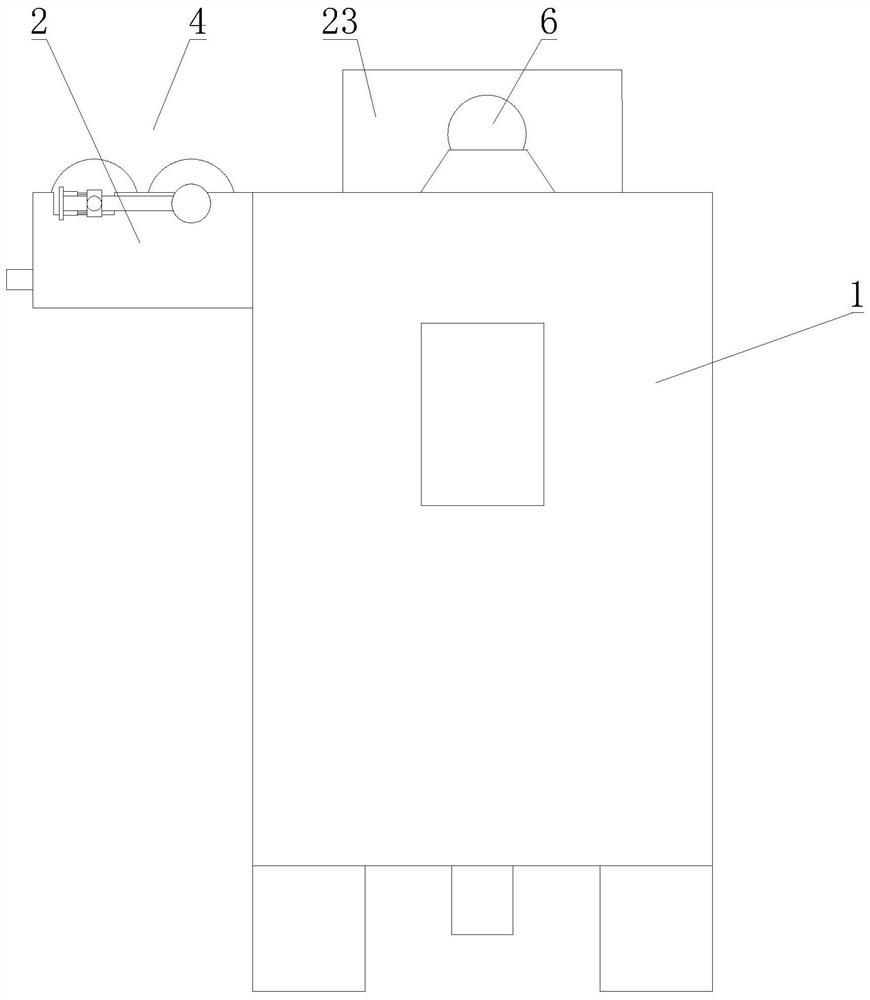

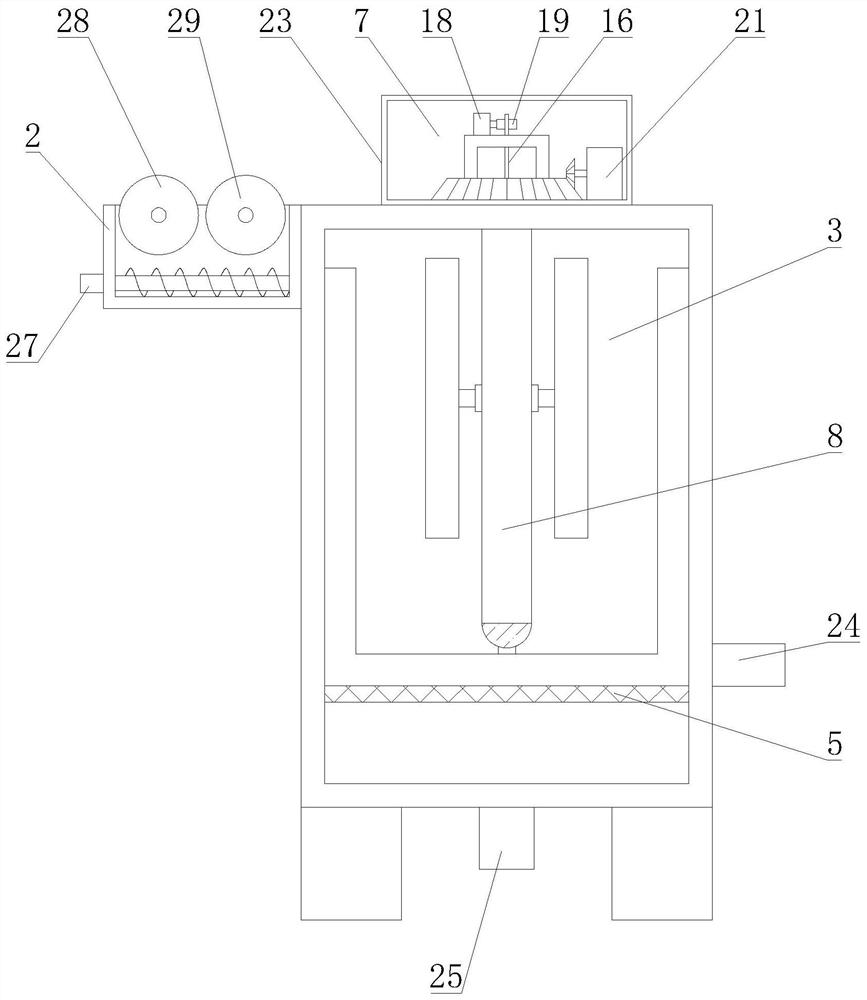

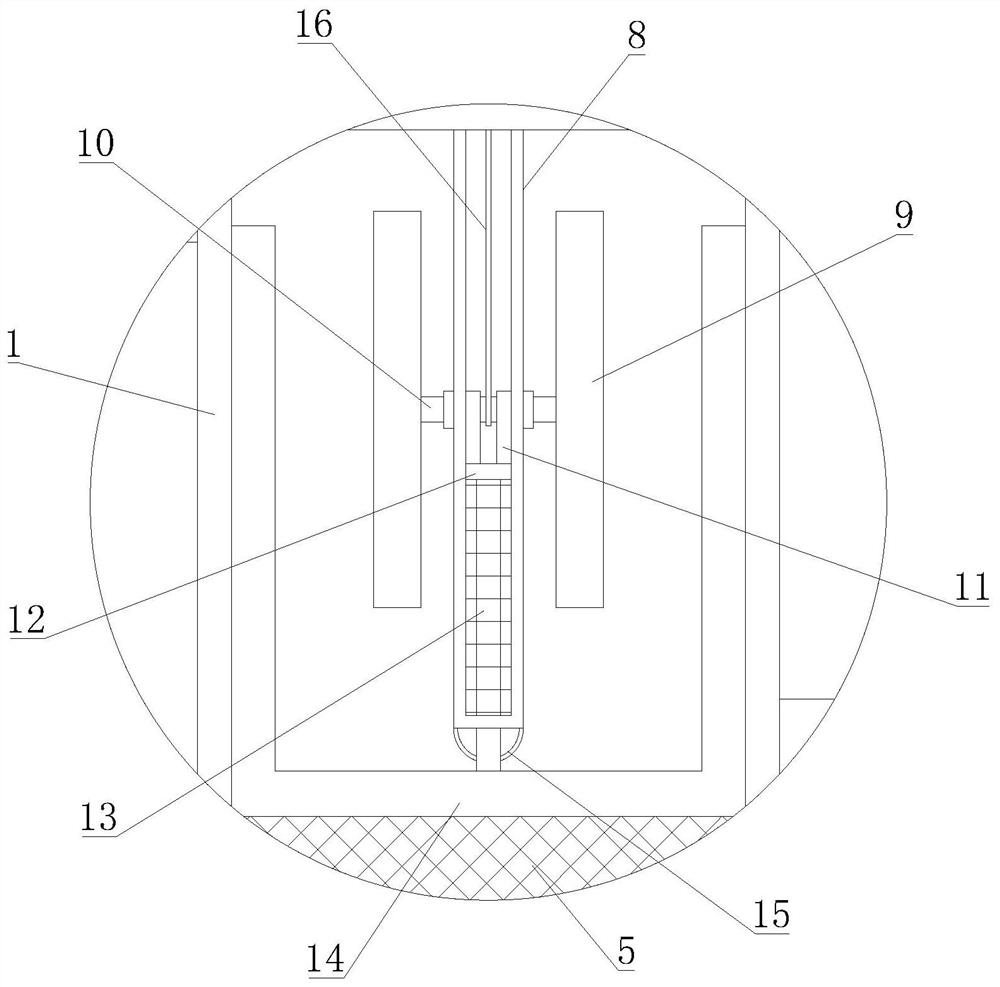

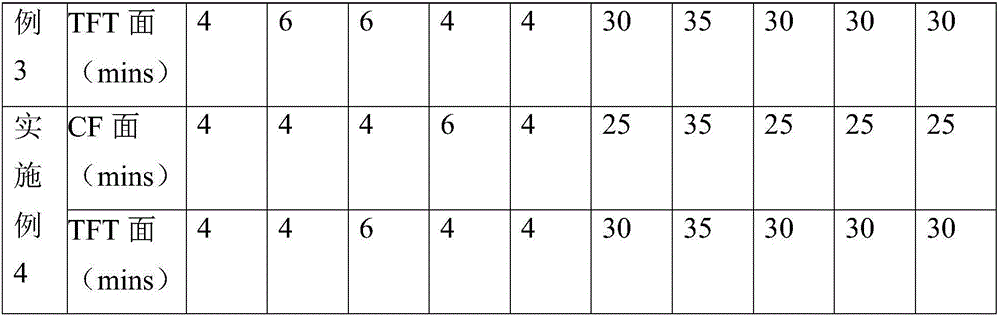

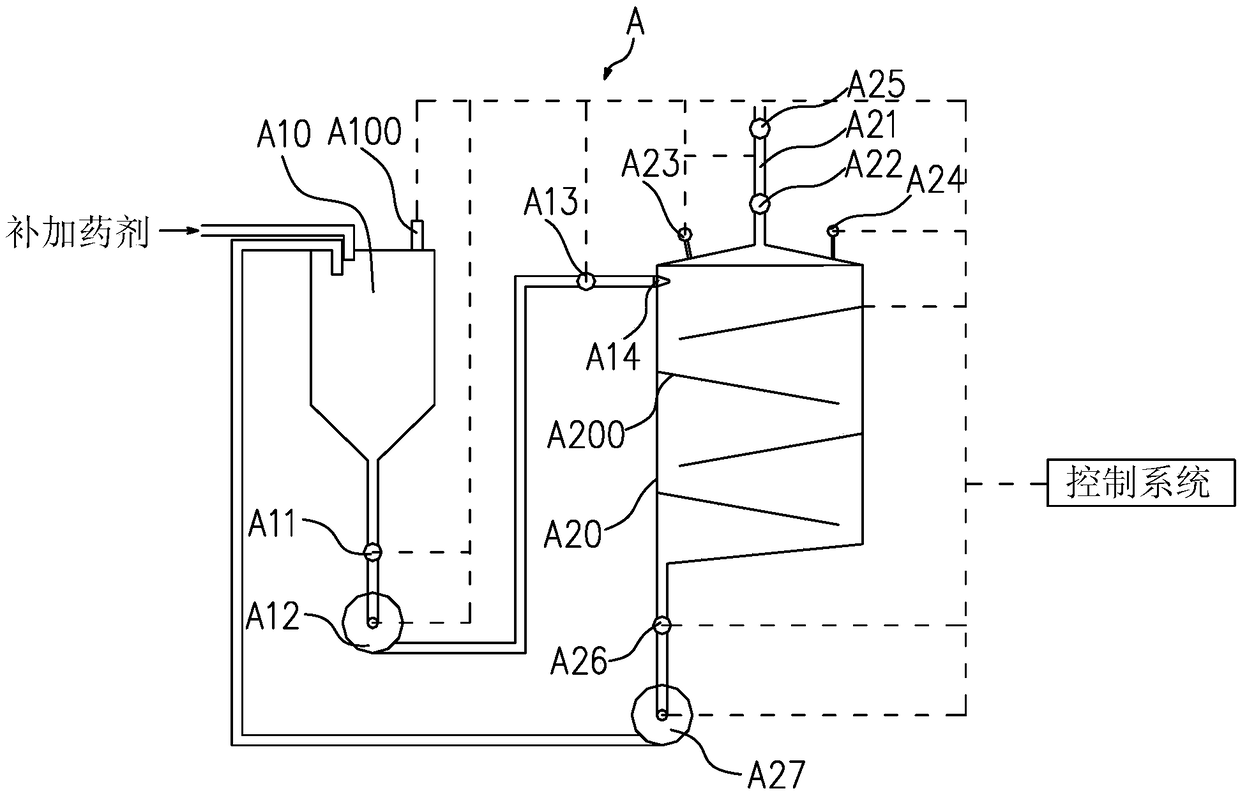

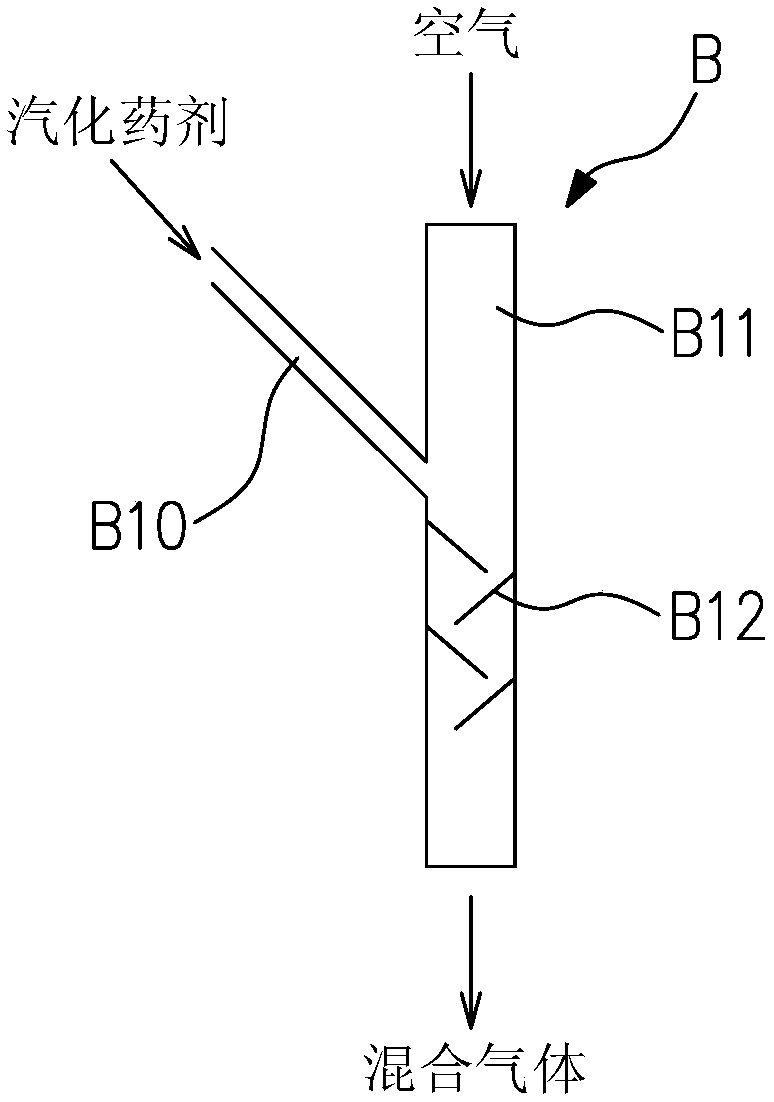

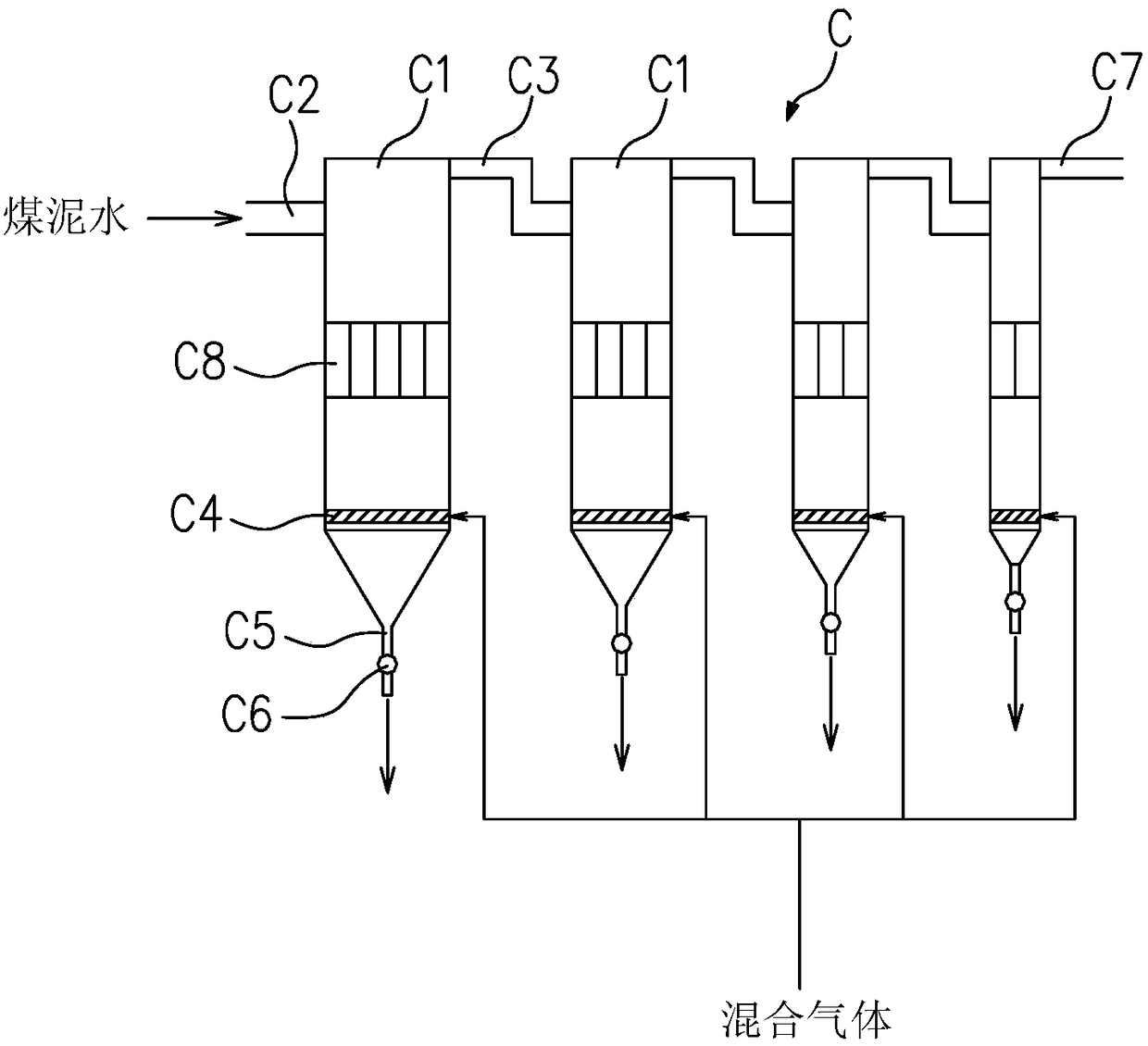

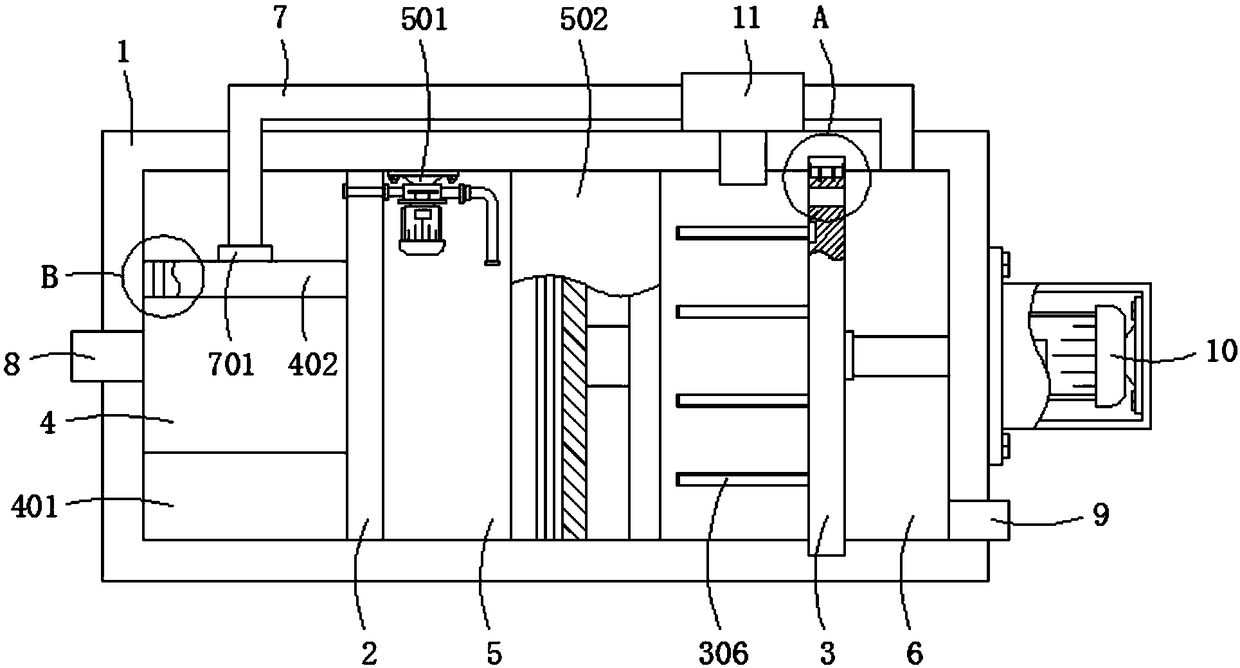

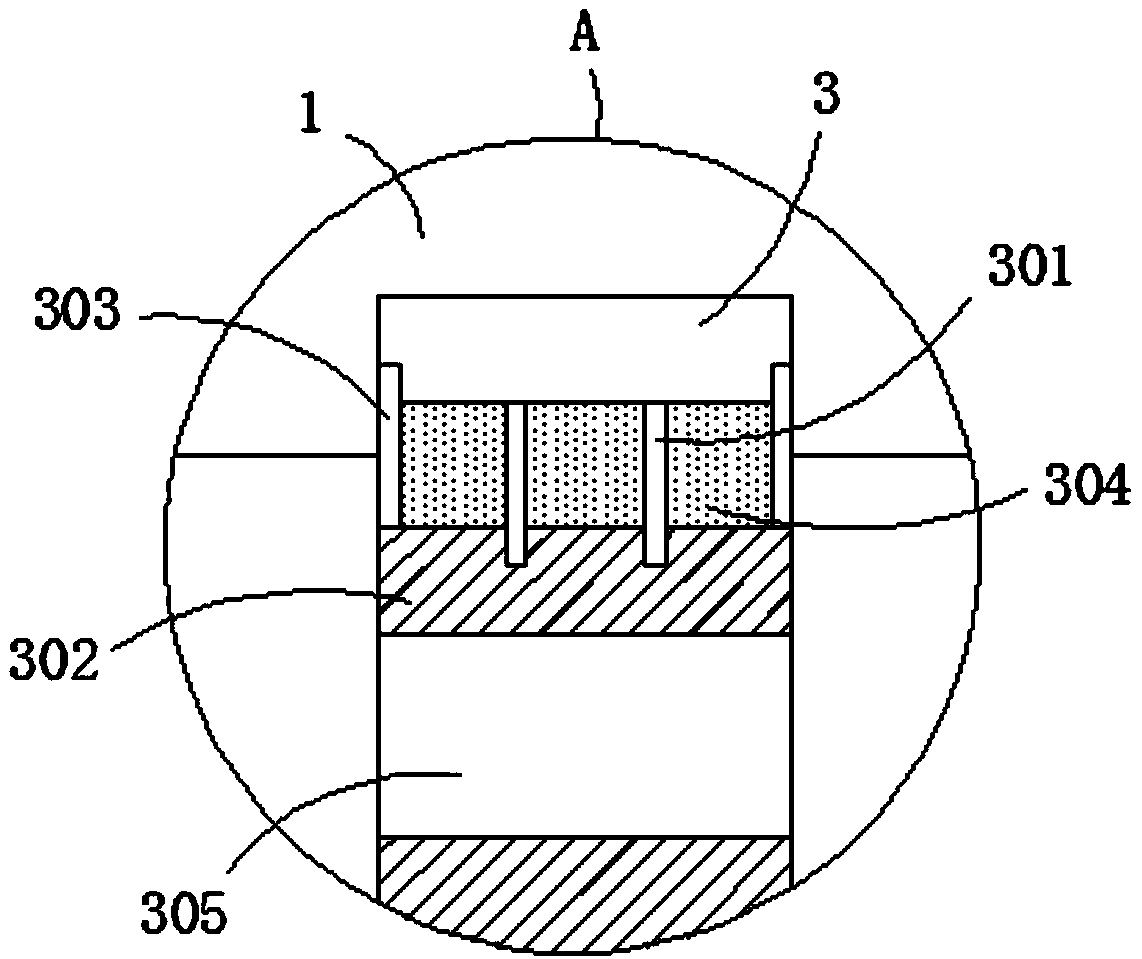

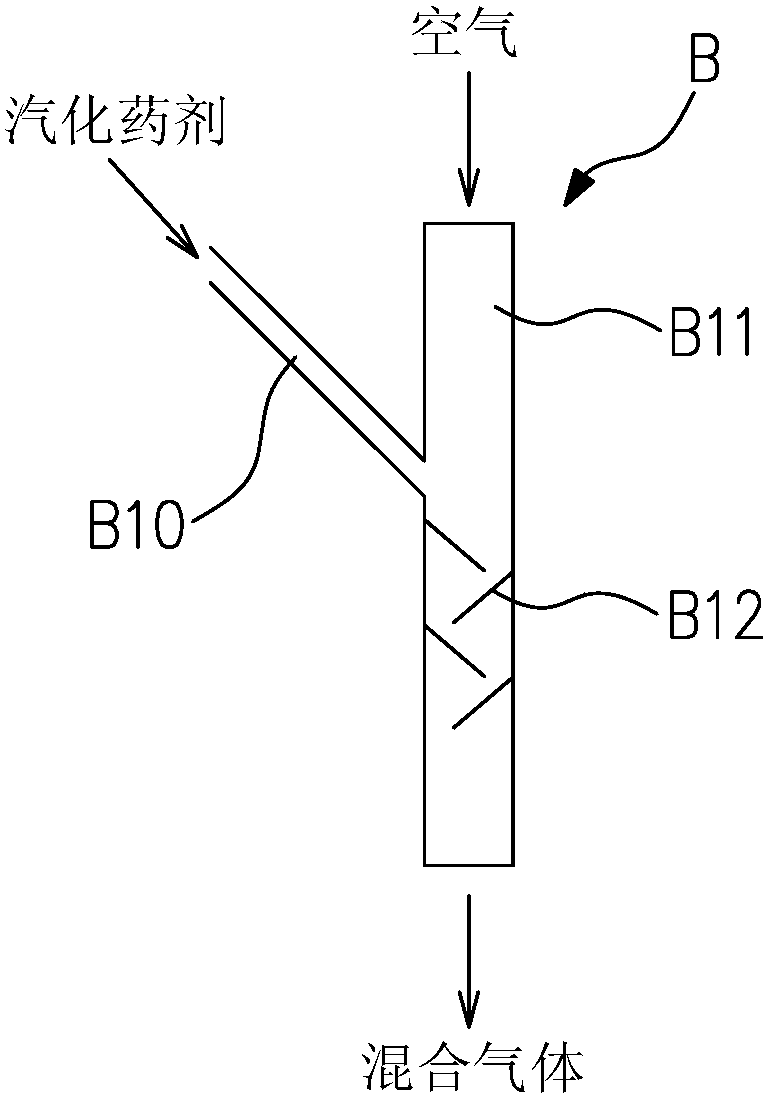

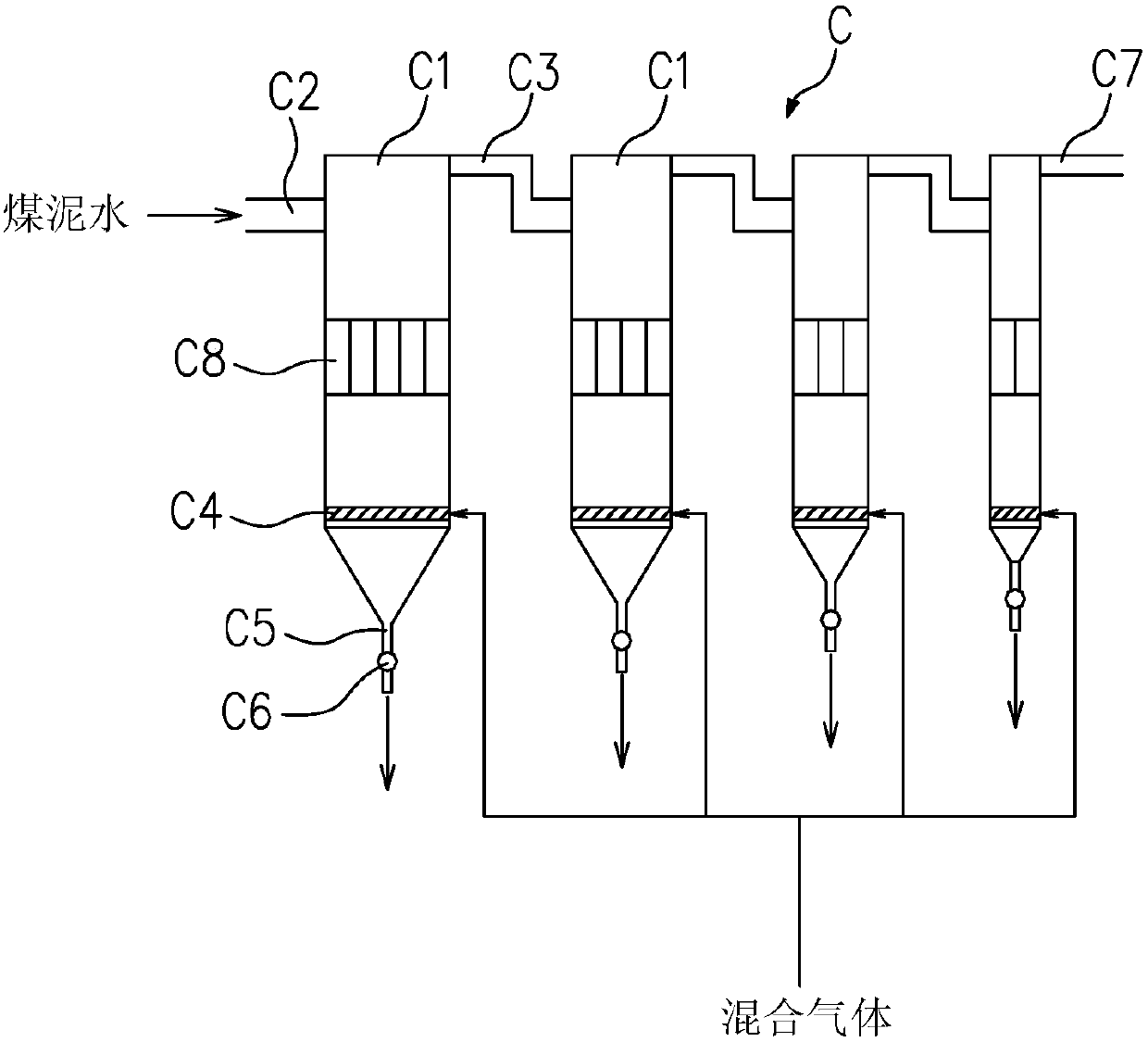

Slime water flotation device and technology

The invention discloses a slime water flotation device and technology. The slime water flotation device comprises a chemical pre-vaporization device, a chemical and air mixing device, a slime water pre-classifying device and flotation equipment. A vaporization chemical of the chemical pre-vaporization device is output to the chemical and air mixing device, the output end of the chemical and air mixing device communicates with the slime water pre-classifying device, and after being subjected to classifying flotation, the vaporization chemical flows into the flotation equipment. The flotation technology comprises the steps that firstly, the chemical is subjected to pre-vaporization and mixing, wherein a collecting agent and a foaming agent in a flotation chemical are subjected to pre-vaporization, and then the vaporization chemical and air are sufficiently mixed to form mixed gas; and secondly, slime water is subjected to pre-classifying and flotation, wherein the mixed gas is led into the slime water pre-classifying device to be subjected to classifying flotation. The slime water flotation device is simple in structure and stable in running, the contact area of the chemical and slime water is sufficiently increased, the slime water pretreatment effect is effectively improved, and the slime water classifying effect can be improved.

Owner:ANHUI UNIV OF SCI & TECH

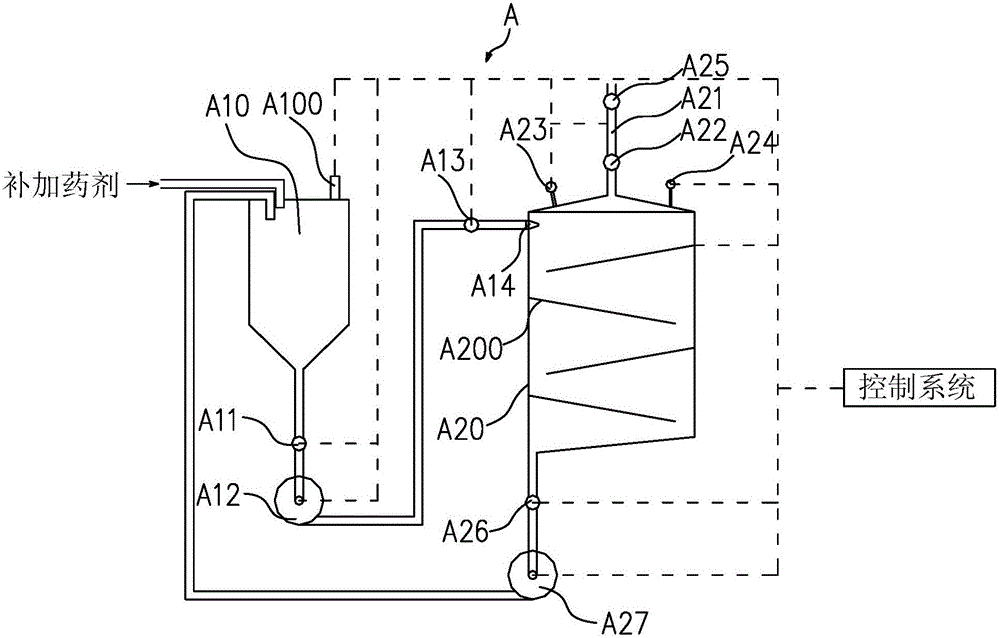

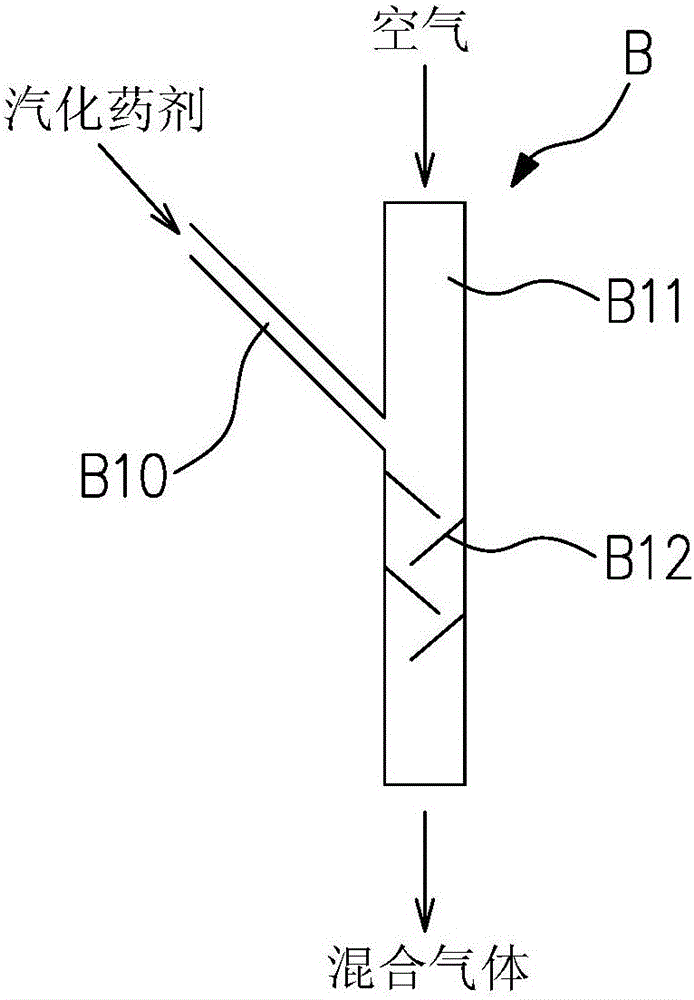

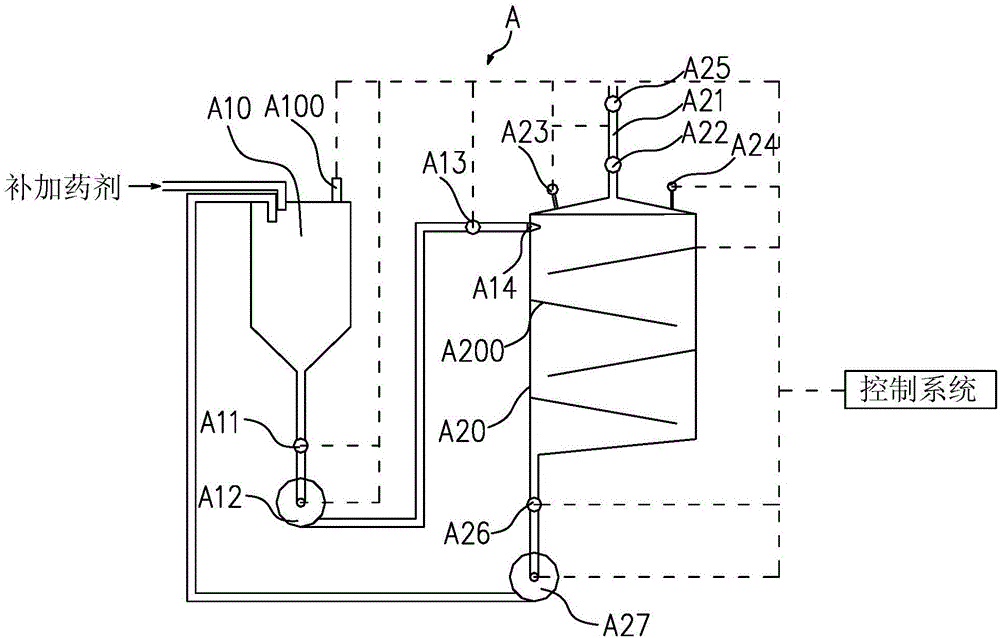

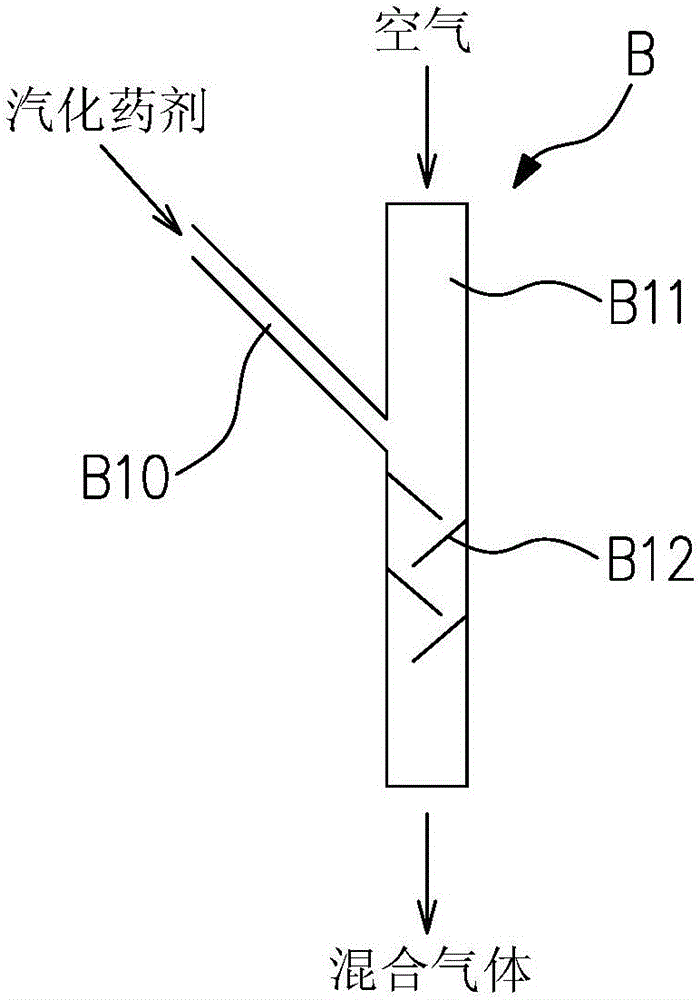

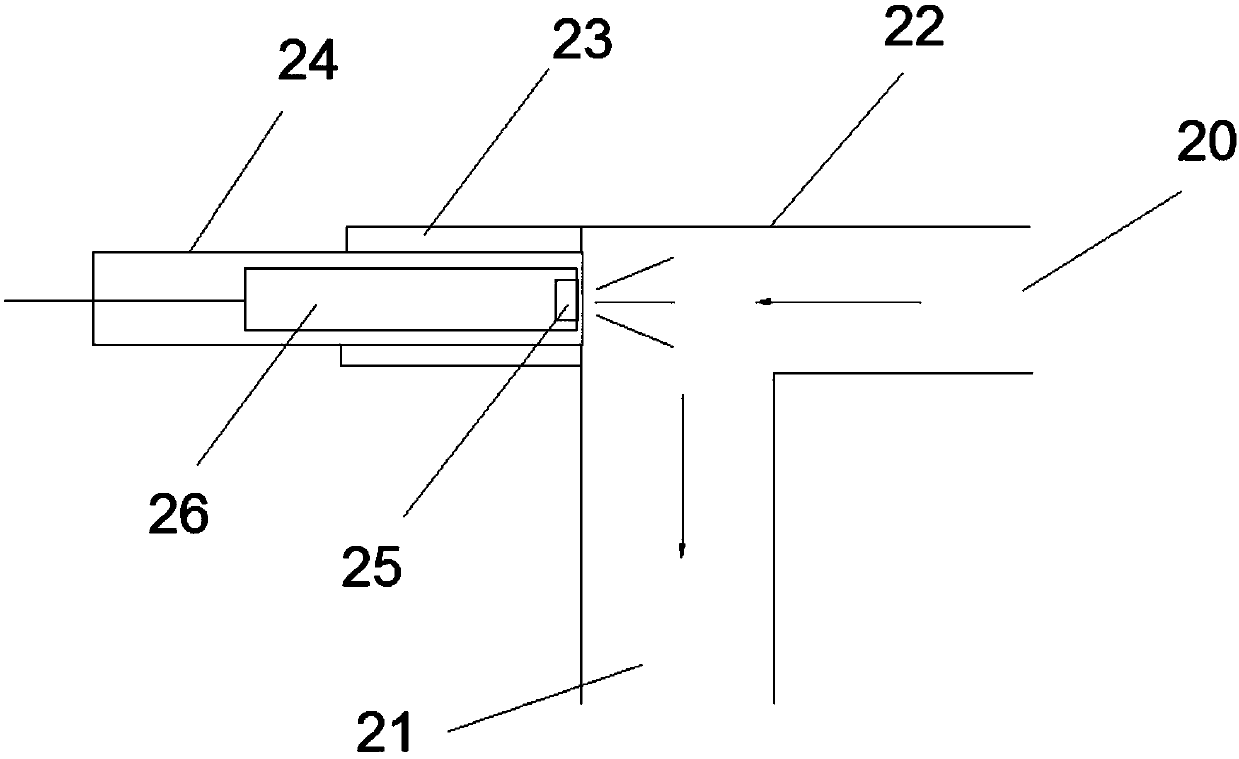

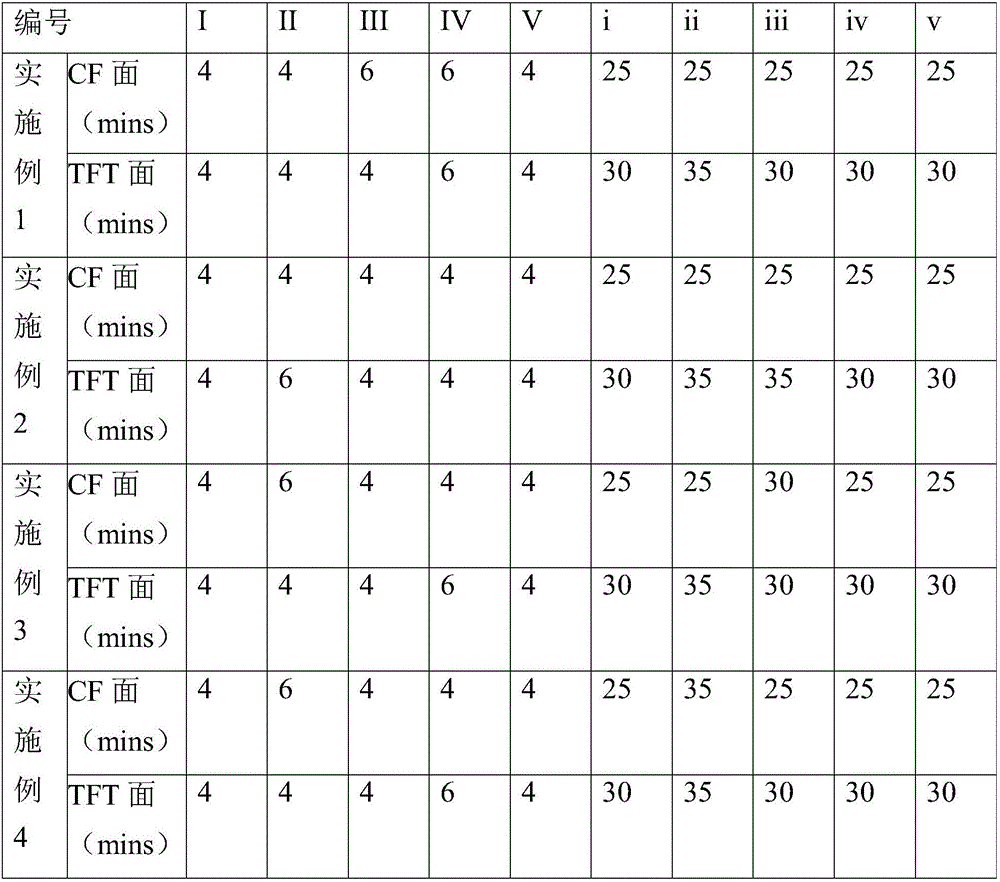

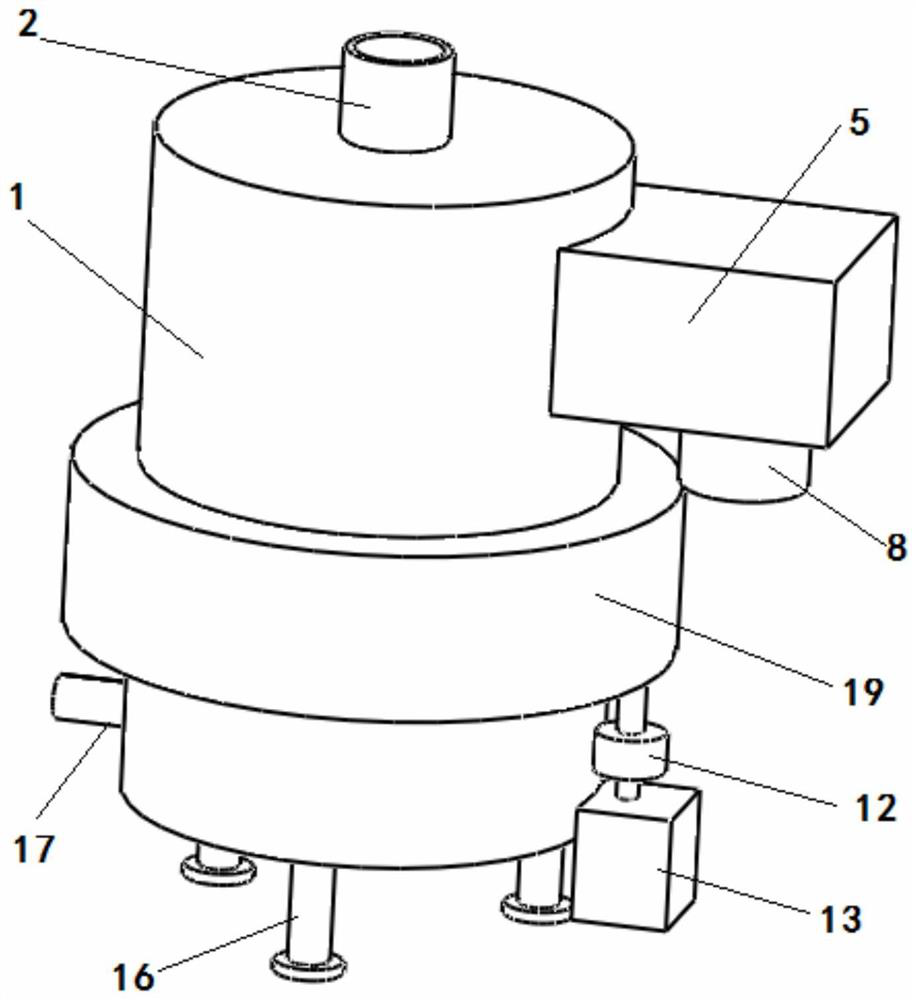

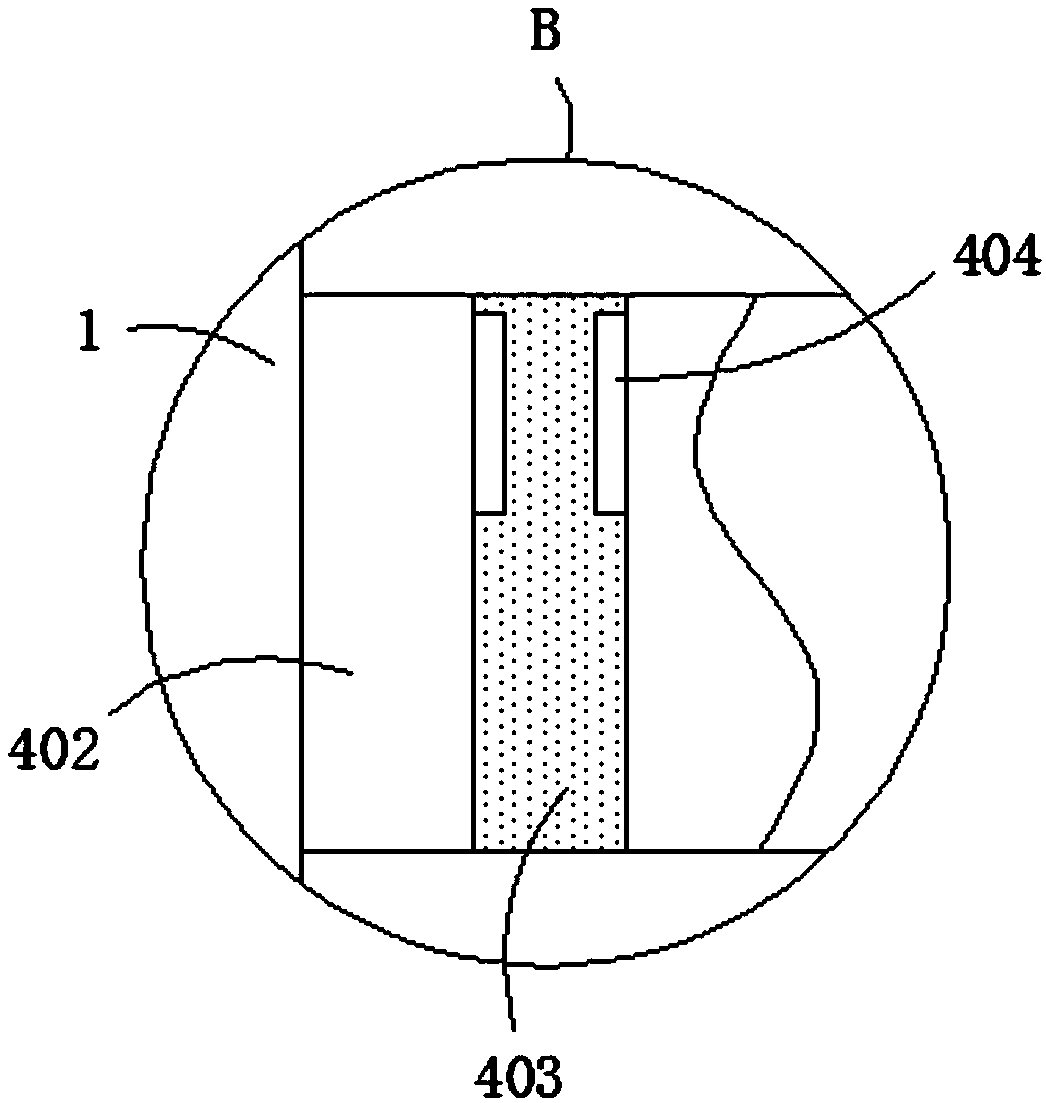

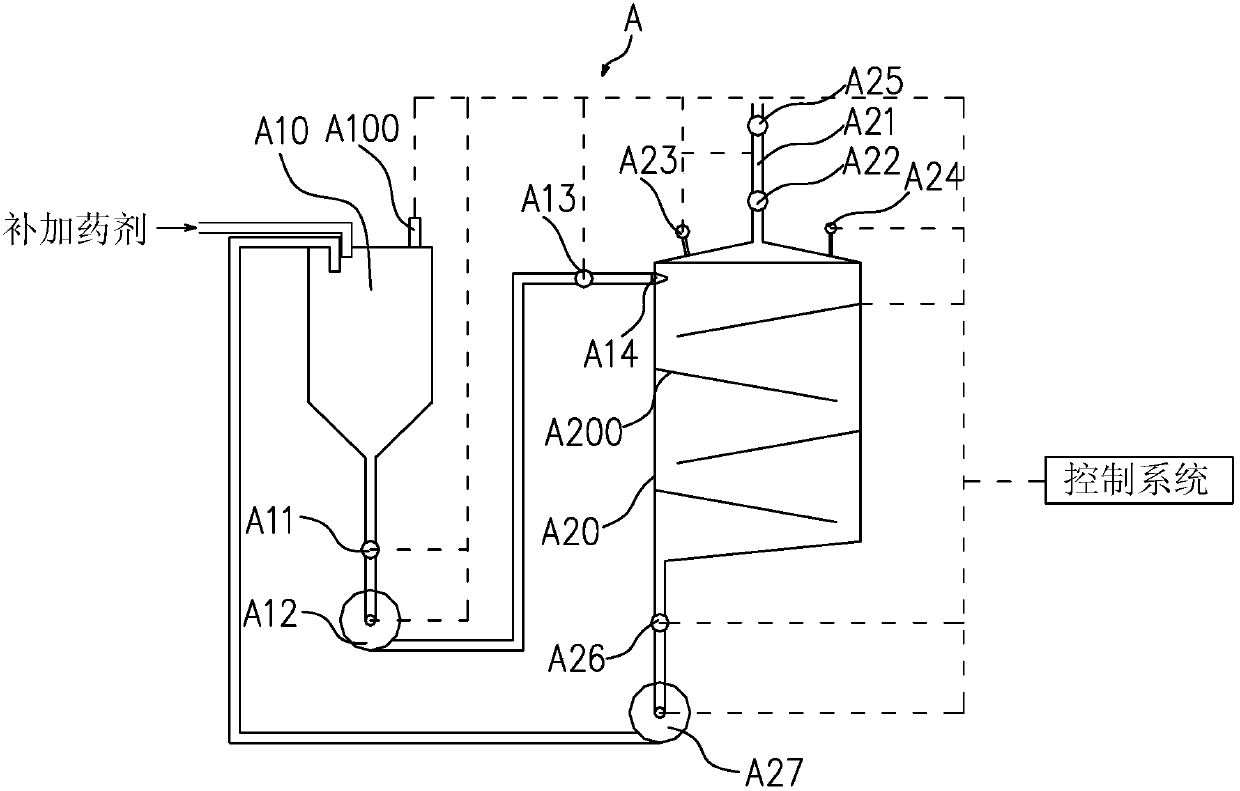

Coal slime water flotation reagent vaporizing device and vaporizing method thereof

ActiveCN105728201ASimple structural designIncrease contact areaFlotationElectric heatingControl system

The invention discloses a coal slime water flotation reagent vaporizing device and a vaporizing method thereof. The coal slime water flotation reagent vaporizing device comprises a reagent barrel, wherein the reagent barrel communicates with a vaporizing container through an electric control valve I, a high pressure pump, an electric control valve II and a spray nozzle; the part, at the upper end of the container, of the vaporizing container is connected to an electric heating tube; an electric control valve III used for collecting the vaporizing reagent is arranged on the electric heating tube; a temperature monitoring device and a pressure monitoring device for monitoring the temperature and the pressure of the inner part of the container are arranged on the vaporizing container; and the vaporizing container is further connected with a vacuum-pumping pipeline which communicates with the reagent barrel. The vaporizing container comprises a plurality of electric heating plates which are arranged on the inner part of the container, wherein the heating temperature of the electric heating plates is gradually increased from top to bottom; and the part, at the outlet of the electric control valve III, of the electric heating tube is further provided with a flow monitoring device. The device is further provided with a control system which is electrically connected to the monitoring devices, the electric control valve, the electric heating tube, the high pressure pump, the vacuum pump and the electric heating plate. The device is simple in structure, and is stable to operate, and the contact area of the reagent and coal slime water is sufficiently increased.

Owner:ANHUI UNIV OF SCI & TECH

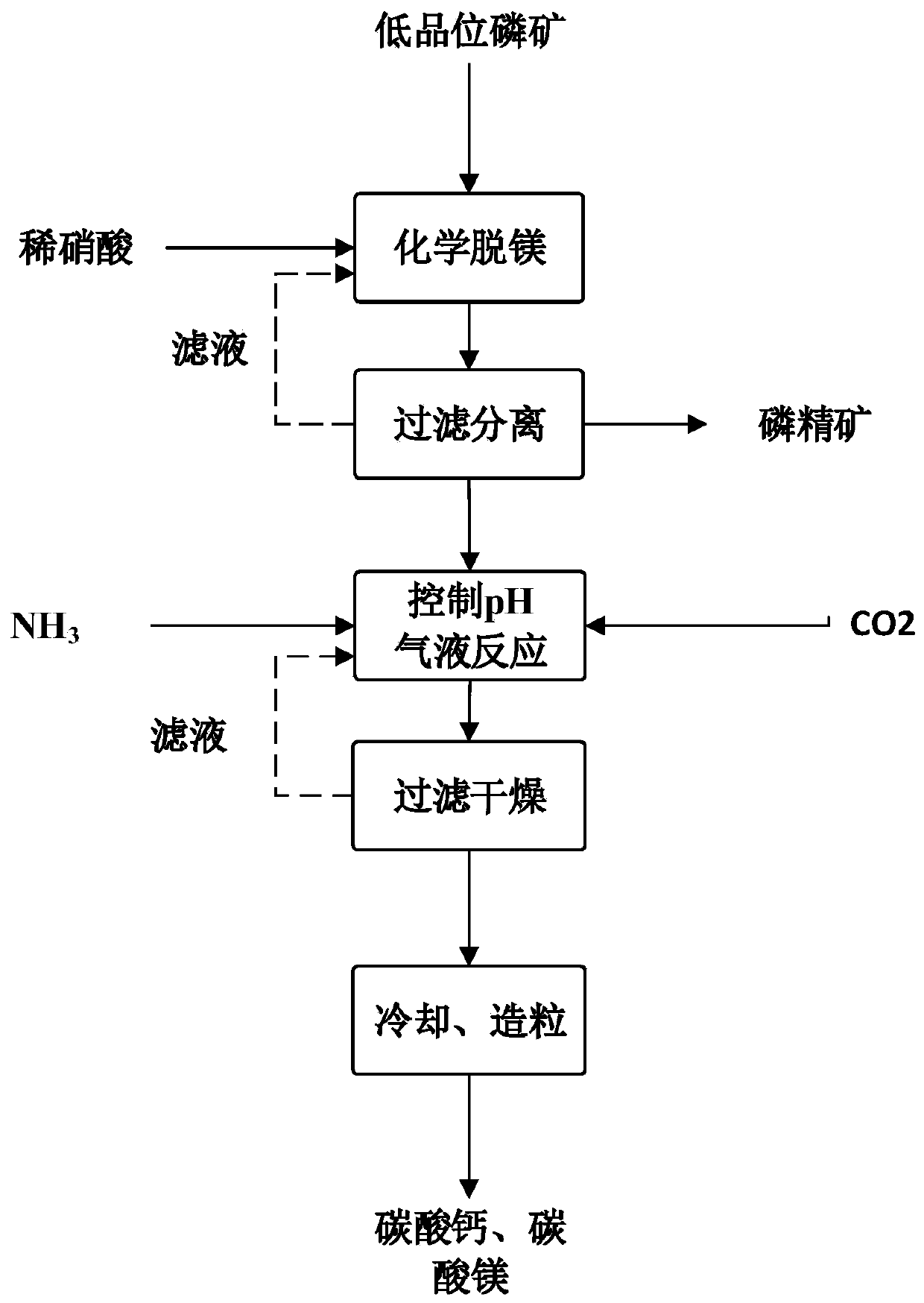

Method for magnesium removal of phosphate rock and co-production of magnesium carbonate and calcium carbonate

PendingCN110255591AReduce loss rateReduce energy consumptionCalcium/strontium/barium carbonatesMagnesium carbonatesChemical industryPhosphorite

The invention belongs to the field of phosphorus chemical industry, and concretely relates to a method for magnesium removal of phosphate rock and co-production of magnesium carbonate and calcium carbonate. The method for the magnesium removal of the phosphate rock and the co-production of the magnesium carbonate and the calcium carbonate includes the following steps: A, adding a nitric acid solution into phosphate rock slurry, controlling the pH of a reaction system to be 2-4 and a liquid-solid ratio be 2-4:1, and obtaining the phosphate plasm after a reaction is completed, wherein the phosphorus rock slurry is obtained by mixing phosphate rock powder and water; B, carrying out solid-liquid separation on the phosphate rock plasm obtained in the step A to obtain solid-phase a and a magnesium-containing solution b, and washing and drying the solid-phase a to obtain low-magnesium concentrate; and C introducing NH3 and CO2 into the magnesium-containing solution b to obtain the calcium carbonate and the magnesium carbonate. The method of the invention realizes the magnesium removal of the phosphate rock and the co-production of the magnesium carbonate and the calcium carbonate.

Owner:SICHUAN UNIV

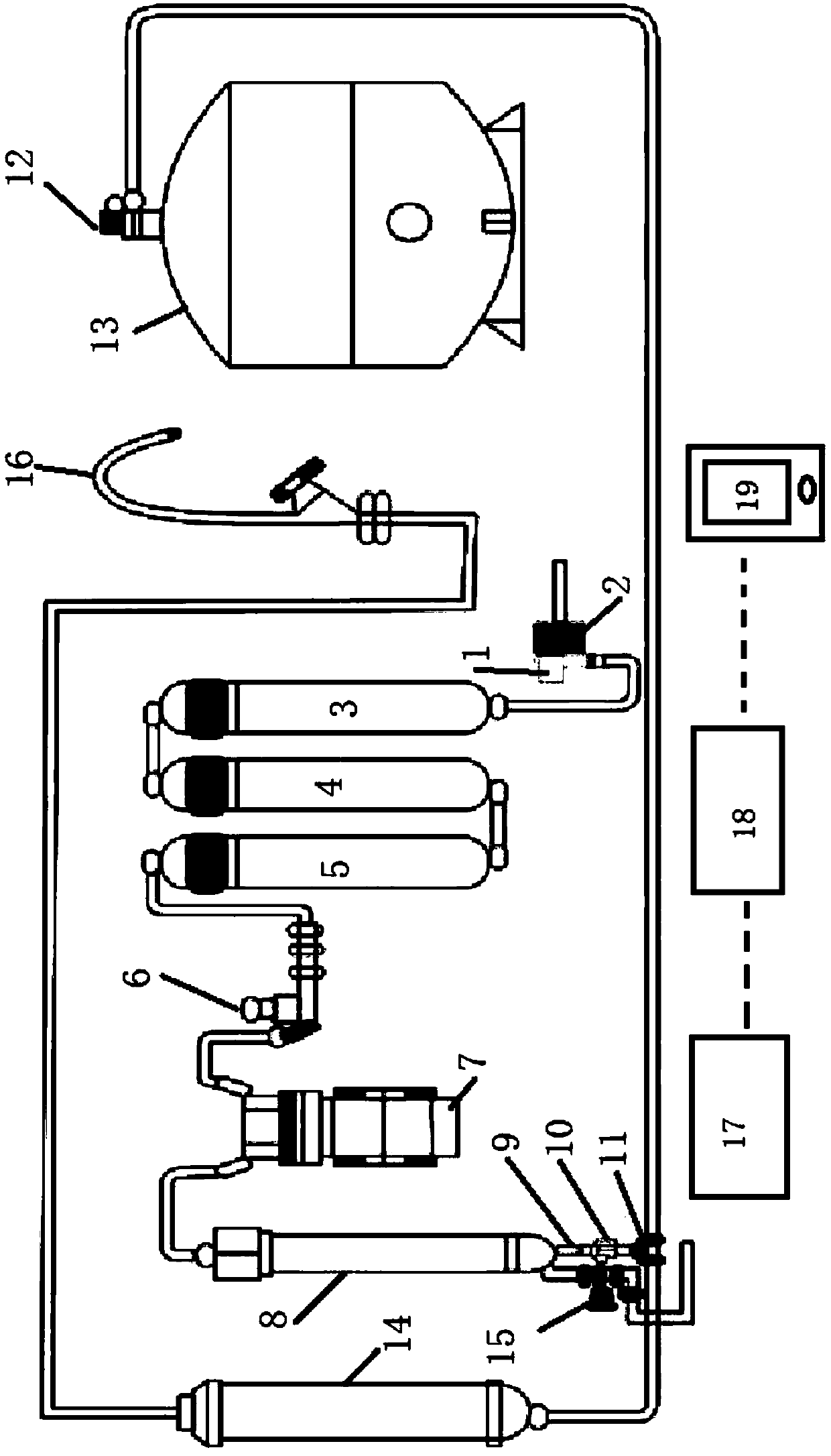

Intelligent water purifying system and method thereof

InactiveCN107758948AAchieve emissionsSmart Judgment UsageWater/sewage treatment by irradiationTransmission systemsInlet valveSewage

The invention discloses an intelligent water purifying system. The intelligent water purifying system is characterized by comprising a water inlet three-way joint (1), a water inlet valve (2), first-stage PP cotton (3), granular activated carbon (4), compressed activated carbon (5), a water inlet electromagnetic valve (6), a booster pump (7), a fourth-stage RO membrane (8), a check valve (9), a high-pressure switch (10), an LED deep ultraviolet water sterilizer (11), a pressure barrel switch (12), a pressure barrel (13), a post filter (14), a water outlet faucet (16), a controller mainboard (17), a server (18) and a mobile phone (19). The intelligent water purifying system disclosed by the invention can be connected with APP software of a user terminal in real time to realize automatic flushing and automatic drainage, intelligently identity remaining service time of a filter element of the intelligent water purifying system, and intelligently remind a user to replace the filter elementin good time.

Owner:南京新高生物科技有限公司 +1

Dry dilute acid pretreatment method for lignocellulose raw material by using low-pressure steam heating

PendingCN108690859AHigh steam intake rateGuaranteed preprocessing effectFermentationCellulosePretreatment method

The invention discloses a dry dilute acid pretreatment method for a lignocellulose raw material by using low-pressure steam heating. The method concretely comprises the following steps: (1) preprocessing the lignocellulose raw material; (2) carrying out dry dilute acid pretreatment on the lignocellulose raw material obtained in step (1), wherein the heating steam in the pretreatment step is low-pressure saturated vapor with the pressure being 1.0-2.1 MPa; and (3) subsequently biologically processing the pretreated lignocellulose raw material obtained in step (2). The method has the following advantages: the dry dilute acid pretreatment using low-pressure steam heating ensures the pretreatment effect; the pressure of the heating steam is low, so the device investment of a steam boiler is greatly reduced; and additionally, the low-pressure steam has a high steam feeding rate, so mixing and heat transfer in the pretreatment process are enhanced, and inhibitors generated in the pretreatment process are effectively reduced. The dry dilute acid pretreatment using the low-pressure steam heating lays a foundation for a small distributed pretreatment-large centralized biological refining mode.

Owner:SHANXI SYNTHETIC BIOLOGY INST CO LTD

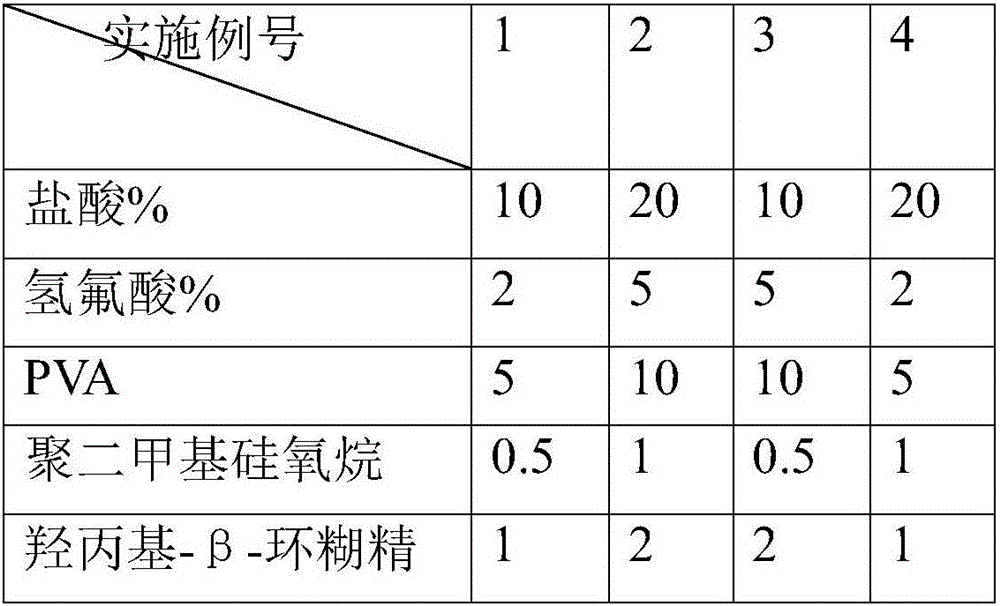

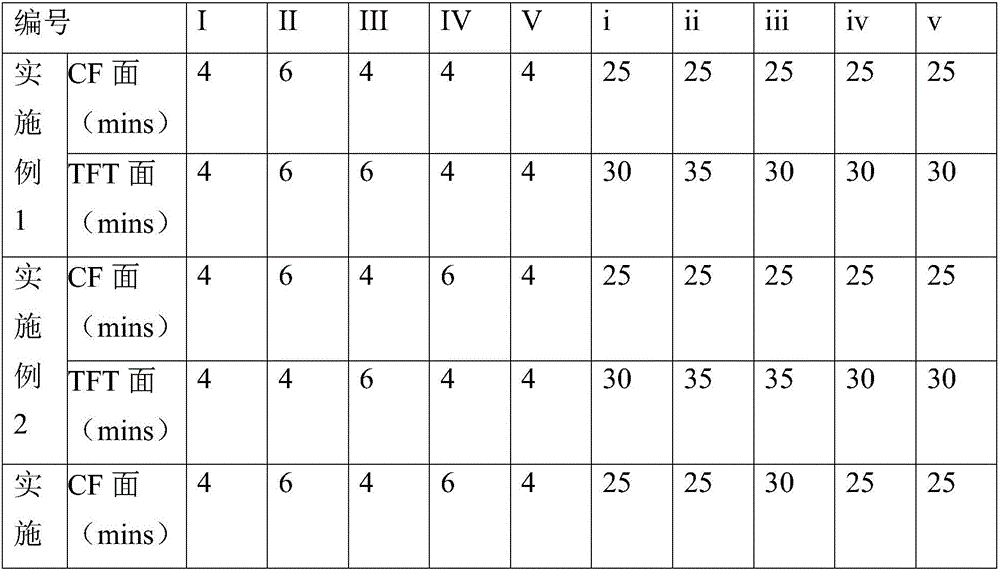

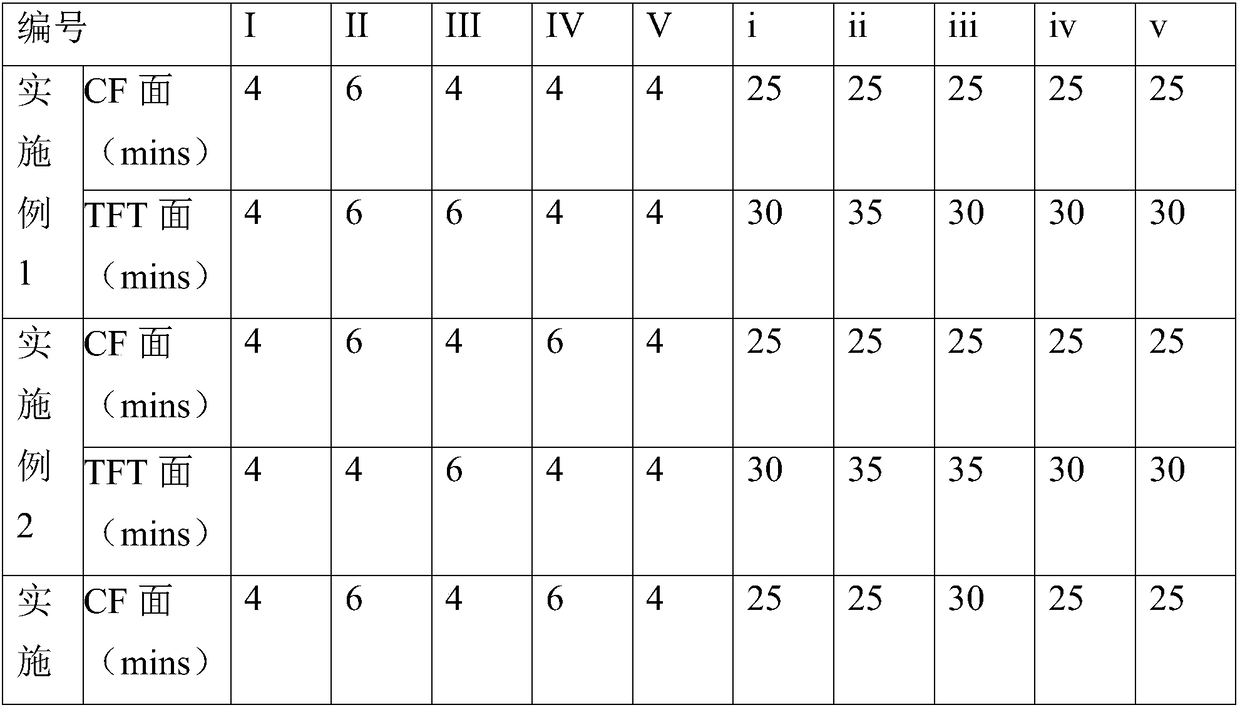

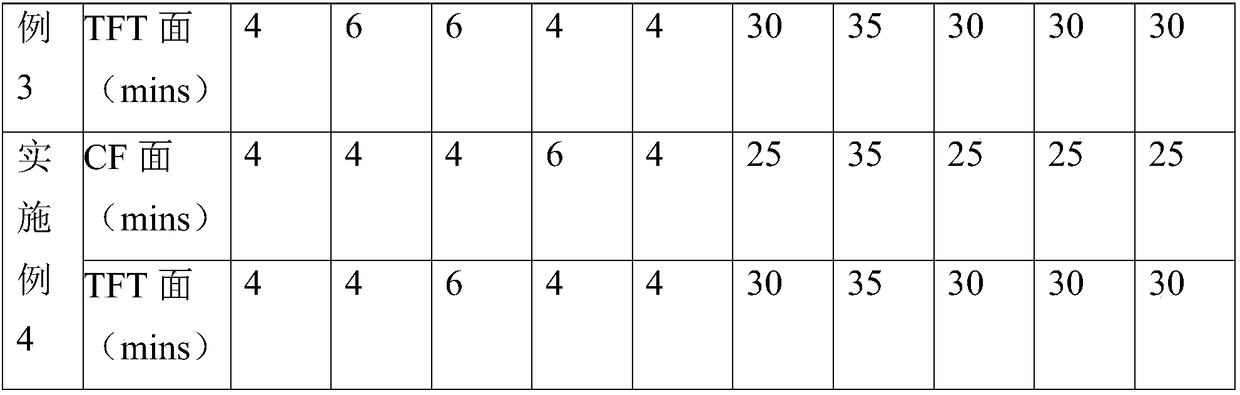

Pretreatment fluid for TFT glass substrate thinning process

A pretreatment fluid for a TFT glass substrate thinning process is characterized by being prepared from, by mass, 10-20% of hydrochloric acid (HCl), 2%-5% of hydrofluoric acid (HF), 5-10% of polyvinyl alcohol (PVA), 0.5-1% of polydimethylsiloxane, 1-2% of hydroxypropyl-beta-cyclodextrin and the balance water.

Owner:天津美泰真空技术有限公司

Slime water microbubble classifying and desliming device

ActiveCN105772239AReduce collisionIncrease collisionReversed direction vortexFlotationEngineeringNet shape

The invention discloses a slime water microbubble classifying and desliming device. The device comprises multiple cylinders which are connected in series. The upper end of the first cylinder is provided with a feeding pipe in the tangential direction. The multiple cylinders are connected through connecting pipes at the top ends. The top end of the final-stage cylinder is provided with a discharging pipe in the tangential direction. The lower end of any cylinder is provided with a bubble generation device. The bottom end of the lower side of each bubble generation device is connected with a bottom flowing pipe and a discharging valve. The head ends of the connecting pipes between the cylinders are arranged in the flowing-out direction of slime water, and the tail ends of the connecting pipes between the cylinders are arranged in the flowing-in direction of the slime water. The bubble generation devices are arranged to be multiple hollow pipes which are interwoven in a net shape and communicate with one another, and air holes are evenly distributed in the upward faces of the hollow pipes. The diameters of the cylinders are gradually reduced from the first stage to the final stage. The slime water microbubble classifying and desliming device is simple in structure, stable in running and capable of ensuring the slime water treatment efficiency and meanwhile ensuring the slime water treatment effect.

Owner:ANHUI UNIV OF SCI & TECH

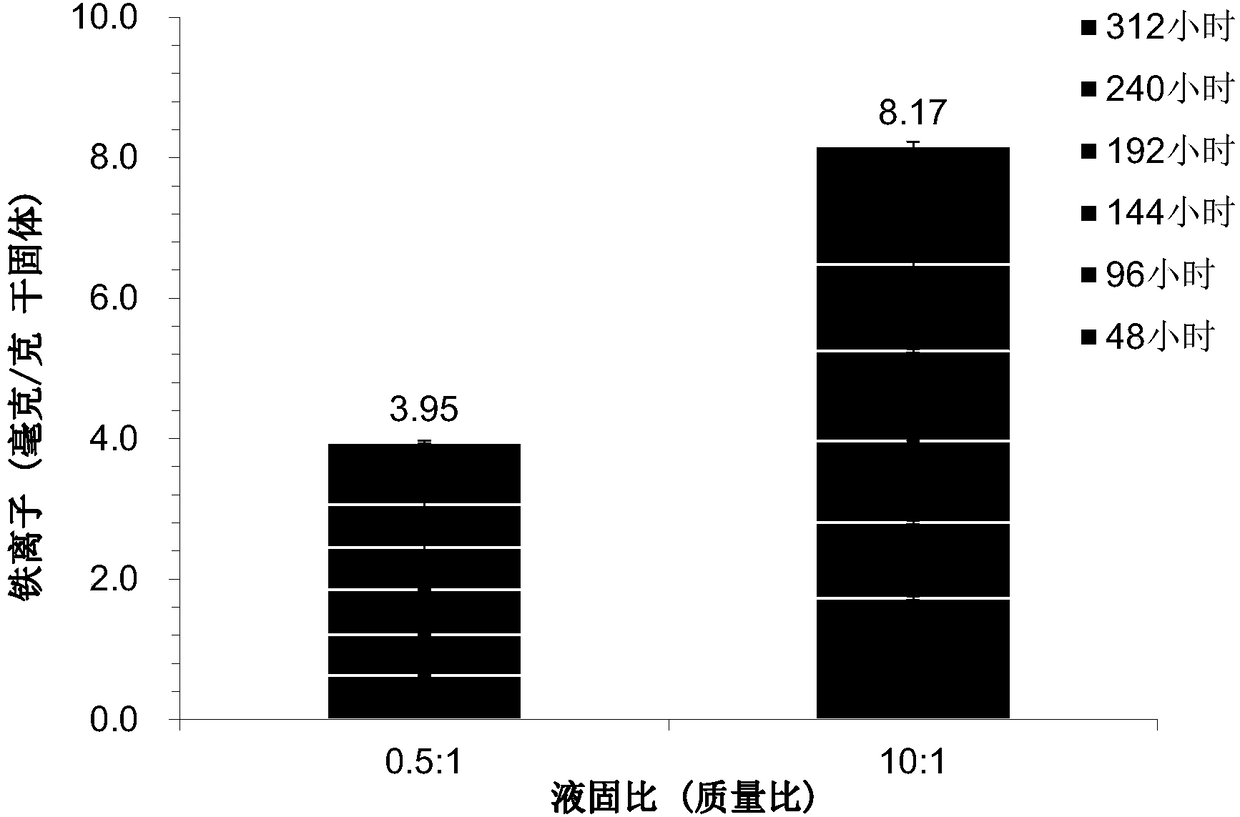

Corn straw dilute acid pretreatment method for reducing corrosion degree of reactor

The invention discloses a corn straw dilute acid pretreatment method for reducing the corrosion degree of a reactor. The preparation method comprises the concrete steps: (1) mixing dilute sulfuric acid with corn straw after dedusting and smashing in a low liquid-solid ratio evenly, making the dilute sulfuric acid solution completely absorbed by the corn straw and making no free dilute acid exist;(2) adding the corn straw of the step (1) into a pretreatment reactor with a built-in stirring device, and pretreating; and (3) using the pre-treated corn straw obtained by the step (2) in a subsequent biological processing process. The pretreatment method has the advantages that the dilute acid pretreatment process with low liquid-solid ratio (the mass ratio of the dilute sulfuric acid solution to the corn straw solid) achieves good pretreatment effect, meanwhile, the corrosion to a reactor material in the pretreatment process is greatly reduced by the absence of a free acidic solution, the service life of the reactor is prolonged and the economy of the biorefinery process is improved.

Owner:SHANXI SYNTHETIC BIOLOGY INST CO LTD

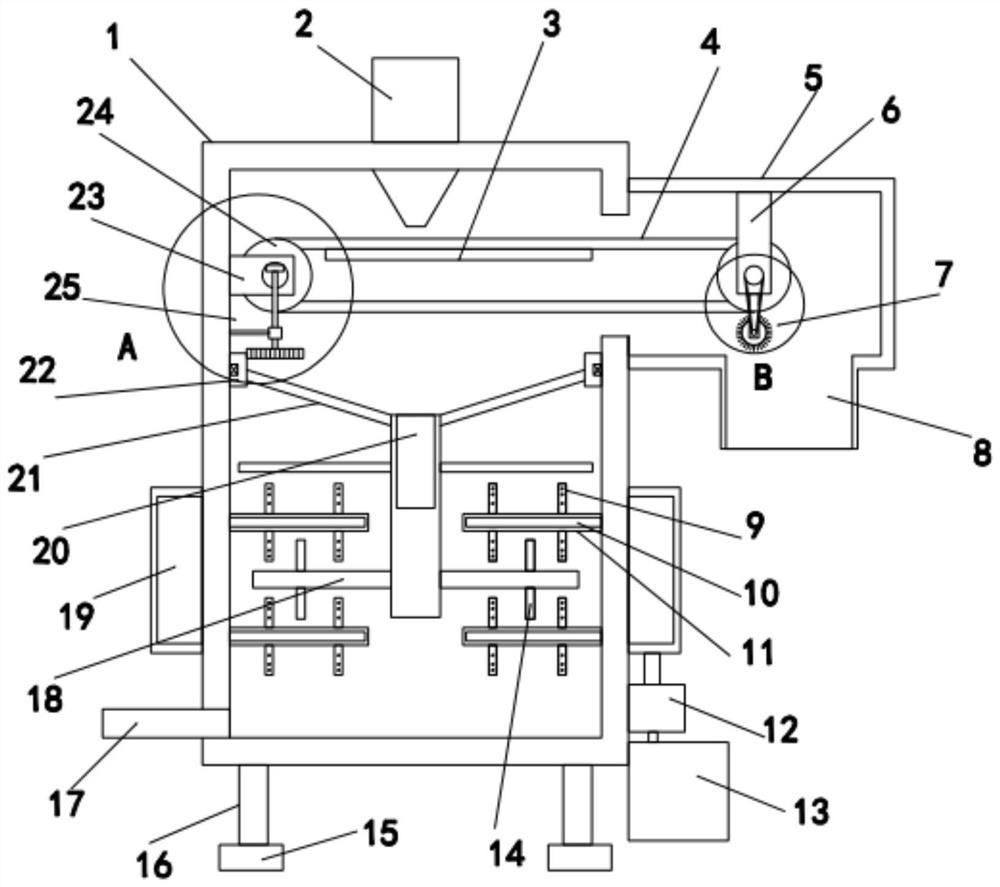

Energy-saving and environment-friendly chemical industry sewage intelligent treatment device and method

InactiveCN111960604AGuaranteed purification effectTimely collectionSpecific water treatment objectivesTreatment involving filtrationChemical industrySewage

The invention discloses an energy-saving and environment-friendly chemical industry sewage intelligent treatment device and method. The energy-saving and environment-friendly chemical industry sewageintelligent treatment device comprises a box body, a water inlet pipe for introducing sewage is arranged in the middle of the upper end of the box body, and a pretreatment mechanism for removing large-particle impurities and metal impurities in the sewage is arranged in the box body; the pretreatment mechanism comprises a collecting box arranged at the right side of the box body; a conveying beltis horizontally arranged between the collecting box and the box body; conveying rollers are arranged at two ends of the conveying belt; a baffle plate is arranged on the side face of the conveying belt; and the baffle plate is provided with a filter port and a filter screen surface arranged at the filter port. The sewage treatment device is designed for overcoming the defects of an existing device, large-particle impurities and metal blocks in sewage can be removed in advance, the removed impurities can be collected away in time, and the later-period pretreatment effect is guaranteed; and in addition, sufficient mixing of the sewage and chemicals is guaranteed, the sewage purification effect is guaranteed, and practicability is high.

Owner:江康(上海)科技有限公司

Rapid raw material mixing and filtering device for cosmetic production

ActiveCN112090484AImprove efficiency and effectivenessImprove mixing efficiencySievingScreeningProcess engineeringManufacturing engineering

A rapid raw material mixing and filtering device for cosmetic production comprises a shell, a feeding hopper, a mixing assembly, a crushing assembly, a filter screen, a pressurizer and a driving assembly. The feeding hopper is arranged on one side of the shell; the crushing assembly is arranged on the feeding hopper; the mixing assembly driven by the driving assembly is arranged in the shell; thefilter screen is arranged at the lower end of the mixing assembly; the pressurizer is arranged on the shell; and a controller is arranged on the shell. The crushing assembly is arranged, so that the position of a moving roller is conveniently controlled according to the size of raw materials and processing requirements, the pretreatment effect of the raw materials is ensured, and the subsequent processing efficiency and effect are improved. The mixing assembly and the driving assembly are arranged to be matched, a stirring paddle mixes raw materials in the center of the shell, a scraper blademixes the raw materials on the periphery of the shell and scrapes off the raw materials adhering to the inner wall of the shell at the same time, the raw material mixing efficiency is high, and the effect is good. The pressurizer is arranged to accelerate the filtering and discharging speed.

Owner:上海虹久企业发展有限公司

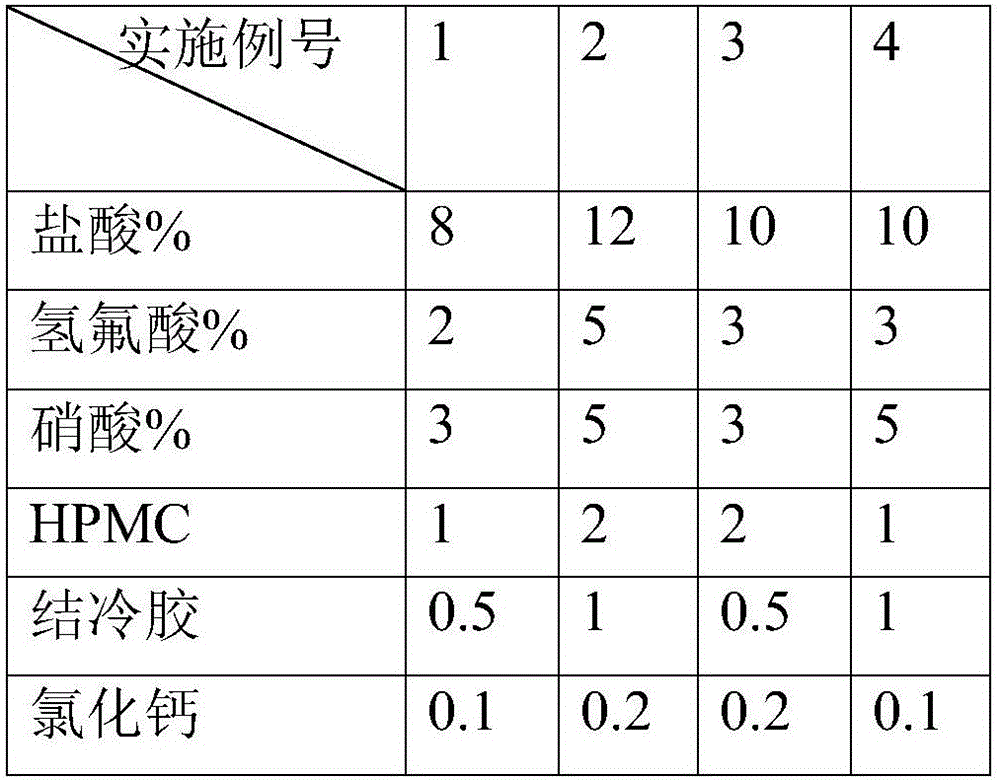

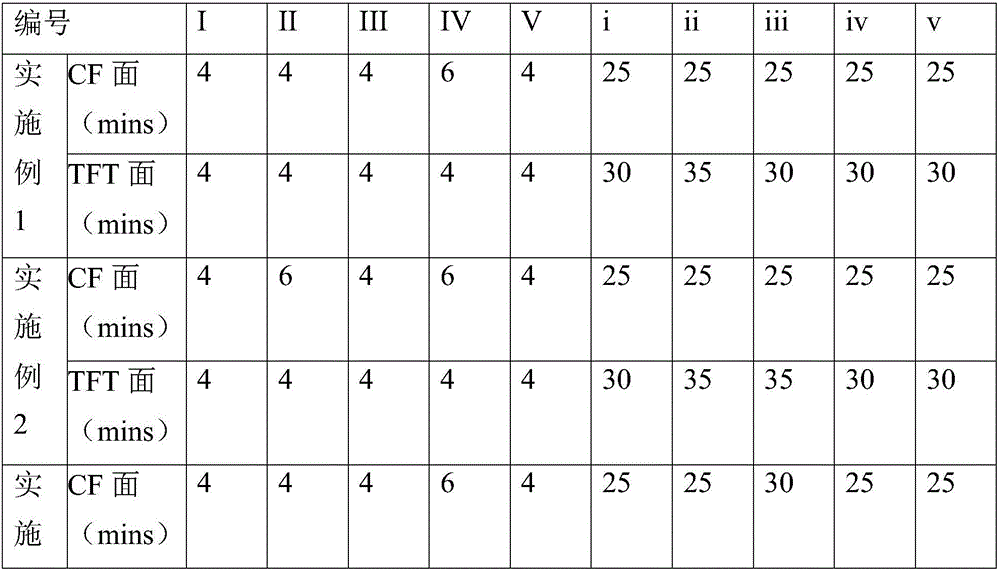

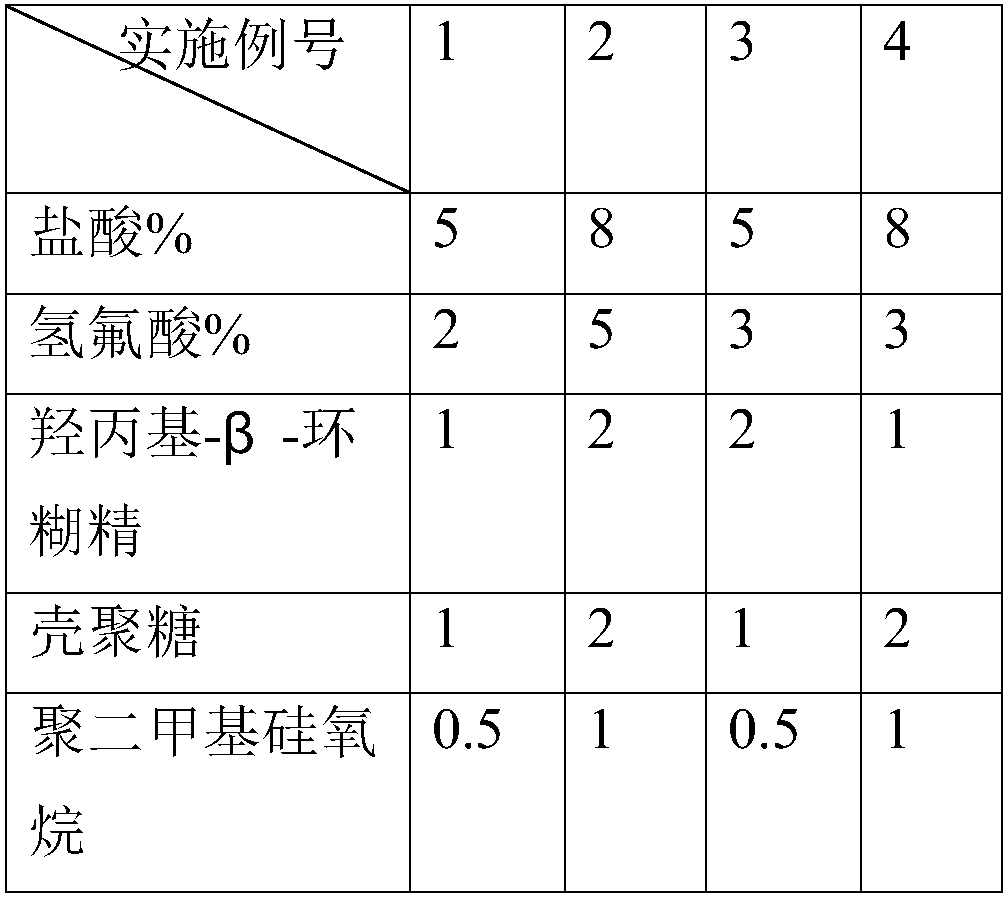

TFT glass substrate thinning process pretreatment agent

Disclosed is a TFT (thin film transistor) glass substrate thinning process pretreatment agent. The TFT glass substrate thinning process pretreatment agent is prepared from the following components based on mass percentage: 8-12% of hydrochloric acid (HCl), 3-5% of nitric acid, 2-5% of hydrofluoric acid (HF), 5-6% of hydroxypropyl methyl cellulose (HPMC), 2-3% of gellan gum and the balance of water.

Owner:SHENZHEN HONGSHENGKAI TECH LTD

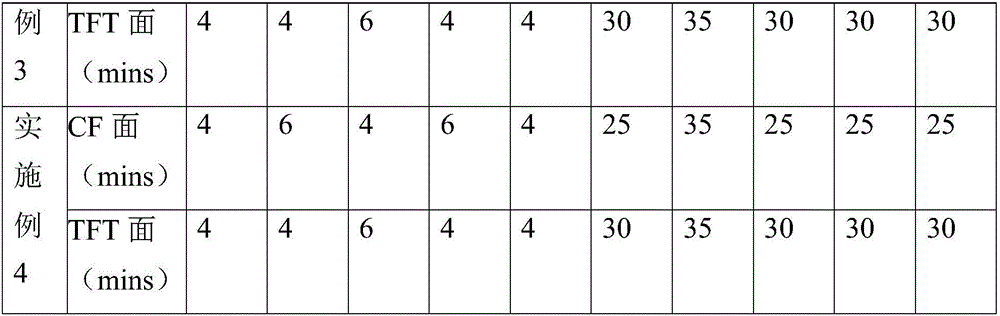

Composition for surface treatment of liquid crystal display glass substrate

The invention relates to a composition for processing the surface of a glass substrate of a liquid crystal display. The composition contains the following components in percentage by mass: 5%-8% of hydrochloric acid (HCl), 2%-5% of hydrofluoric acid (HF), 1%-2% of chitosan, 0.5%-1% of polydimethylsiloxane, 0.5%-1% of hydroxypropyl-beta-cyclodextrin and the balance of water.

Owner:赫得纳米科技(黄石)有限公司

A glass fiber cloth reinforced insulating molded board and its preparation method

ActiveCN113150331BImprove high temperature resistanceImprove flame retardant performanceGlass fiberPolymer science

The invention discloses a glass fiber cloth-reinforced insulating molded board and a preparation method thereof. Adhesiveness and permeability, when the alkali-free glass fiber cloth is impregnated, this application adds modified silane coupling agent, citric acid, sodium hypophosphite to mix, the introduction of modified silane coupling agent, citric acid, sodium hypophosphite The synergistic effect of the components can effectively improve the high temperature resistance and flame retardancy of the glass fiber cloth; the molded plate prepared by the present invention not only has excellent mechanical properties, but also due to the modification of the flame retardant, the silane coupling agent Modified treatment, the molded plate has excellent high temperature resistance, flame retardancy, can be applied to a variety of environmental uses, and has high practicability.

Owner:广东纵胜新材料股份有限公司

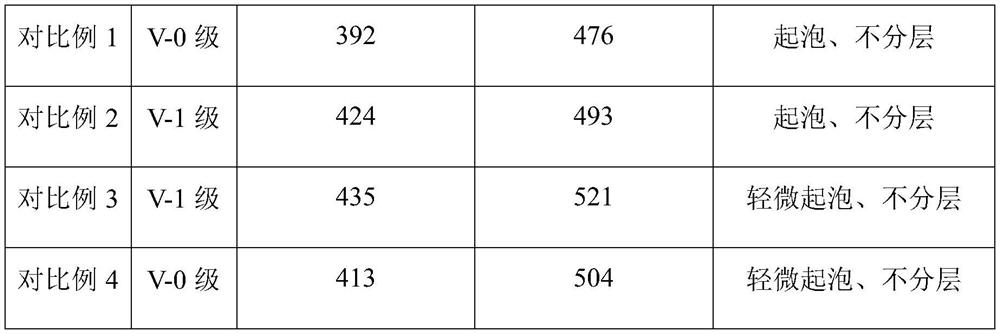

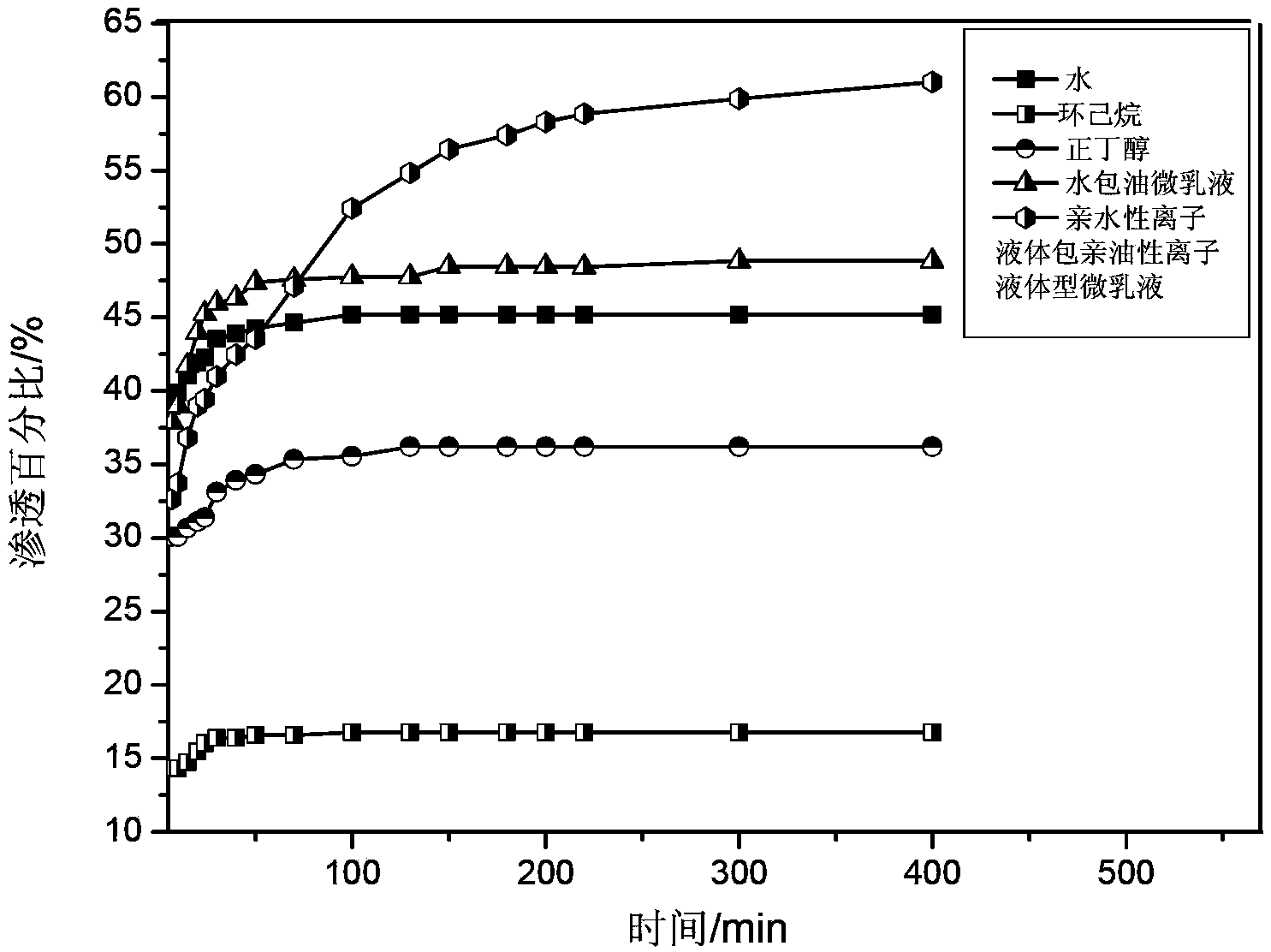

Ionic liquid microemulsion and its preparation method and use

The invention discloses an ionic liquid microemulsion and its preparation method and use. The ionic liquid microemulsion is a [BMIM]PF6 / [BMIM]Cl type ionic liquid microemulsion composed of a hydrophilic ionic liquid [BMIM]Cl as a main body, a lipophilic ionic liquid [BMIM]PF6 as a core, and a cationic surface active agent CTAB and a cosurfactant n-butanol as a mixed interfacial film. The preparation method comprises the following steps of adding the four components of the microemulsion into a reaction container, after adding a magnetic stirrer, putting the container into a magnetic stirring constant-temperature water bath kettle, keeping the temperature between 40 and 60 DEG C, and carrying out stirring until the system is clear and transparent and is not layered after being centrifugation at a high rate of 30000r / min for 5min. The ionic liquid microemulsion can be used for pre-treatment on wood fiber biomass. The ionic liquid microemulsion can reduce ionic liquid system viscosity and improves permeability and accessibility of drugs into a biomass raw material.

Owner:SOUTH CHINA UNIV OF TECH

Electric wire identification printing pretreatment device

InactiveCN110931180AHigh bonding strengthGuaranteed printing clarityConductor/cable markingDrive wheelEngineering

The invention discloses an electric wire identification printing pretreatment device which comprises a closed cavity, an inlet and an outlet of an electric wire are formed in the cavity, and the electric wire is driven by a traction pair wheel and a guide wheel to penetrate through the cavity from the inlet and the outlet; a guide rail is arranged above the cavity, a sliding bed is arranged on theguide rail, rollers of the sliding bed are arranged on the guide rail, a plasma spray gun is arranged on the sliding bed, and the plasma spray gun faces the electric wire; a connecting rod is arranged on the sliding bed, a through hole is formed in the upper end of the connecting rod, and a positioning pin on the belt is sleeved with the through hole; a driving wheel and a driven wheel are arranged at the two ends of the belt respectively, and the driving wheel is driven by an output shaft of a servo motor to rotate. The direction of the guide rail is parallel to the axial direction of the wire. The method has the advantages that the treatment time of the plasma spray gun on the insulating layer of the electric wire is adjusted through the relative speed of the plasma spray gun and the electric wire, and then the pretreatment effect is guaranteed.

Owner:沈阳盛隆电线电缆有限公司

Raw material microwave pre-treatment method for producing fuel alcohol

InactiveCN101168748BGuaranteed preprocessing effectSimple processBiofuelsLiquid carbonaceous fuelsPretreatment methodAlcohol production

The invention discloses a raw material microwave pretreatment method used for the production of fuel alcohol, and relates to a raw material pretreatment method before producing the fuel alcohol. The invention solves the disadvantages that the cost is too high, the energy consumption is too large, or the conditions are too severe, etc., and the problems that the production cycle is long, and secondary pollution is caused. The invention has the following steps: 10 g of matrix powder after water equilibrium is taken, and is filled with water according to a solid to liquid ratio of 1:30 to 50, andis put into a microwave treater, pretreatment is performed in the condition of 00 to 1000 W for 30 to 60 min, then wshing and filtering are performed, and the pretreatment is finished. Under the premise of ensuring the pretreatment effect, the invention simplifies the technical process, reduces the treatment time, reduces the production energy consumption and the cost, simultaneously does not cause secondary pollution, and is easy to realize industrial application. The optimal conditions of the invention are obtained by respectively optimizing the liquid to solid ratio, the heating time and the microwave power, and 49.1 percent of glucose conversion rate, 21.1 percent of xylose conversion rate, and 76 percent of theoretical ethyl alcohol yield rate are respectively abtained under the optimal conditions.

Owner:江苏哈宜环保研究院有限公司

A rapid mixing and filtering device for raw materials used in cosmetic production

ActiveCN112090484BGuaranteed preprocessing effectEasy to controlSievingScreeningProcess engineeringMechanical engineering

A rapid mixing and filtering device for raw materials used in cosmetic production, including a housing, a feeding hopper, a mixing assembly, a crushing assembly, a filter screen, a pressurizer, and a driving assembly; the feeding hopper is arranged on one side of the casing; the crushing assembly It is arranged on the feeding hopper; the mixing assembly driven by the drive assembly is arranged inside the casing; the filter screen is arranged at the lower end of the mixing assembly; the pressurizer is arranged on the casing; the casing is provided with a controller. The present invention is equipped with crushing components, which is convenient to control the position of the moving roller according to the size of raw materials and processing requirements, ensures the pretreatment effect of raw materials, and improves the efficiency and effect of subsequent processing; the mixing component and the driving component are set to cooperate, and the agitating paddle is aligned with the shell. The raw materials in the center are mixed, and the scraper mixes the raw materials on the periphery of the shell while scraping off the sticky raw materials on the inner wall of the shell.

Owner:上海虹久企业发展有限公司

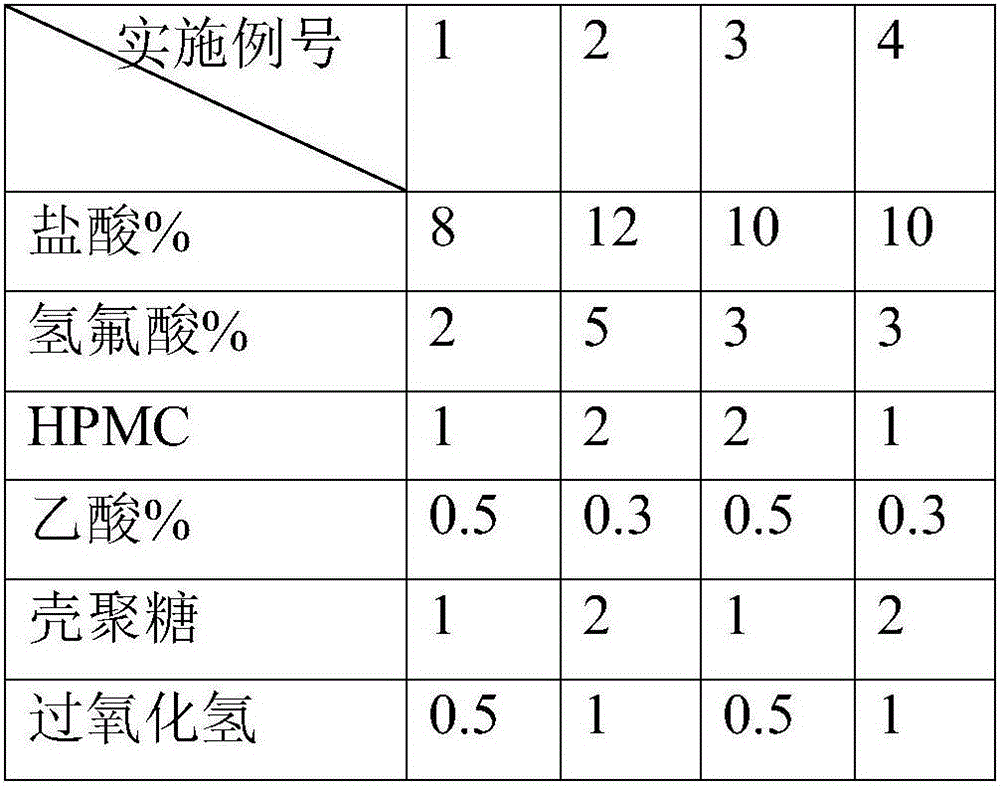

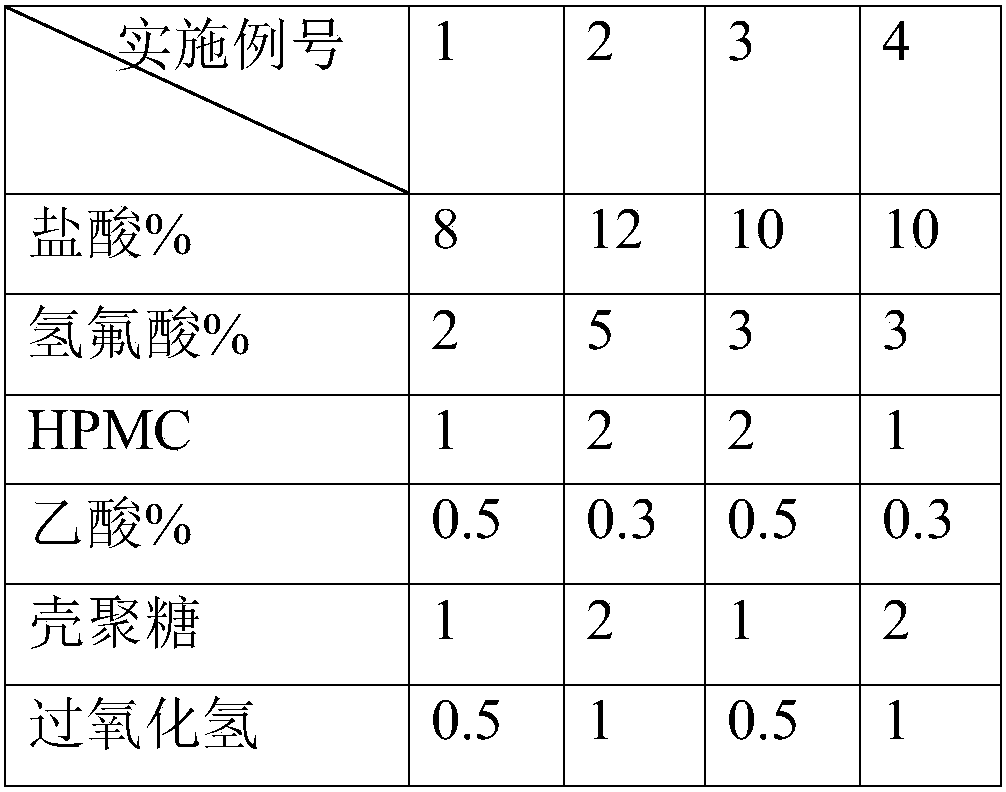

Pretreatment agent for liquid crystal display glass substrate thinning technology

The invention provides a pretreatment agent for liquid crystal display glass substrate thinning technology. The agent comprises the following components in percentages by mass: 8-12% of HCl, 2-5% of HF, 0.3-0.5% of acetic acid, 0.5-1% of hydrogen peroxide, 1-2% of hydroxypropyl methyl cellulose (HPMC), 1-2% of chitosan, and the balance being water.

Owner:重庆思昱兴电子材料有限公司

Coal slime water flotation agent vaporization device and vaporization method thereof

The invention discloses a coal slime water flotation reagent vaporizing device and a vaporizing method thereof. The coal slime water flotation reagent vaporizing device comprises a reagent barrel, wherein the reagent barrel communicates with a vaporizing container through an electric control valve I, a high pressure pump, an electric control valve II and a spray nozzle; the part, at the upper end of the container, of the vaporizing container is connected to an electric heating tube; an electric control valve III used for collecting the vaporizing reagent is arranged on the electric heating tube; a temperature monitoring device and a pressure monitoring device for monitoring the temperature and the pressure of the inner part of the container are arranged on the vaporizing container; and the vaporizing container is further connected with a vacuum-pumping pipeline which communicates with the reagent barrel. The vaporizing container comprises a plurality of electric heating plates which are arranged on the inner part of the container, wherein the heating temperature of the electric heating plates is gradually increased from top to bottom; and the part, at the outlet of the electric control valve III, of the electric heating tube is further provided with a flow monitoring device. The device is further provided with a control system which is electrically connected to the monitoring devices, the electric control valve, the electric heating tube, the high pressure pump, the vacuum pump and the electric heating plate. The device is simple in structure, and is stable to operate, and the contact area of the reagent and coal slime water is sufficiently increased.

Owner:ANHUI UNIV OF SCI & TECH

Liquid crystal display glass substrate thinning process pretreatment agent

The invention provides a pretreatment agent for liquid crystal display glass substrate thinning technology. The agent comprises the following components in percentages by mass: 8-12% of HCl, 2-5% of HF, 0.3-0.5% of acetic acid, 0.5-1% of hydrogen peroxide, 1-2% of hydroxypropyl methyl cellulose (HPMC), 1-2% of chitosan, and the balance being water.

Owner:重庆思昱兴电子材料有限公司

Organic wastewater treatment equipment

InactiveCN108658342AAchieve backwash effectAffect hydraulic conductivityFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationEngineeringLarge size

The invention discloses organic wastewater treatment equipment. The organic wastewater treatment equipment comprises an equipment body, wherein a sealing partition board and a fixed board are installed in the equipment body, the fixed board is located on one side of the sealing partition board, a rotating board is connected into the fixed board through a limiting sliding board in a sliding mode, the interior of the equipment body is divided into a negative pressure chamber, a treatment chamber and a flow dividing chamber by the sealing partition board and the fixed board, the treatment chamberis located between the negative pressure chamber and the flow dividing chamber, and a negative pressure return pipe is connected between the negative pressure chamber and the flow dividing chamber. The equipment is provided with a flow guiding board, flow guiding holes, back-washing shower nozzles, the negative pressure return pipe and a back-washing valve, when the equipment starts working, wastewater enters the negative pressure chamber through a water inlet, under the combined action of the negative pressure of the negative pressure chamber and a negative pressure pump, the wastewater runsthrough the flow guiding board, then enters the treatment chamber through the negative pressure pump, the plurality of micro flow guiding holes are formed in the flow guiding board, and thus particles in large size cannot pass through the flow guiding holes.

Owner:浙江格扬热工装备科技有限公司

A kind of coal slime water flotation device and technology

ActiveCN105689154BSimple structural designIncrease contact areaFlotationFoaming agentEnvironmental engineering

The invention discloses a slime water flotation device and technology. The slime water flotation device comprises a chemical pre-vaporization device, a chemical and air mixing device, a slime water pre-classifying device and flotation equipment. A vaporization chemical of the chemical pre-vaporization device is output to the chemical and air mixing device, the output end of the chemical and air mixing device communicates with the slime water pre-classifying device, and after being subjected to classifying flotation, the vaporization chemical flows into the flotation equipment. The flotation technology comprises the steps that firstly, the chemical is subjected to pre-vaporization and mixing, wherein a collecting agent and a foaming agent in a flotation chemical are subjected to pre-vaporization, and then the vaporization chemical and air are sufficiently mixed to form mixed gas; and secondly, slime water is subjected to pre-classifying and flotation, wherein the mixed gas is led into the slime water pre-classifying device to be subjected to classifying flotation. The slime water flotation device is simple in structure and stable in running, the contact area of the chemical and slime water is sufficiently increased, the slime water pretreatment effect is effectively improved, and the slime water classifying effect can be improved.

Owner:ANHUI UNIV OF SCI & TECH

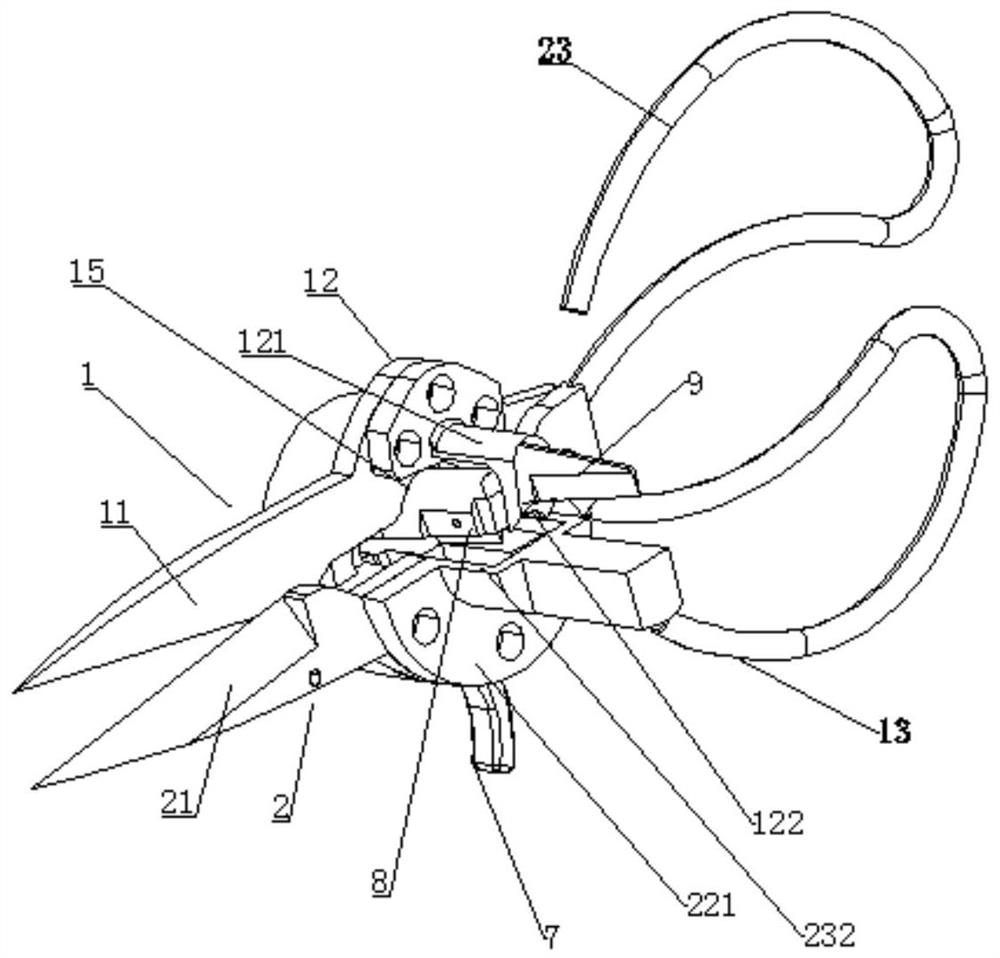

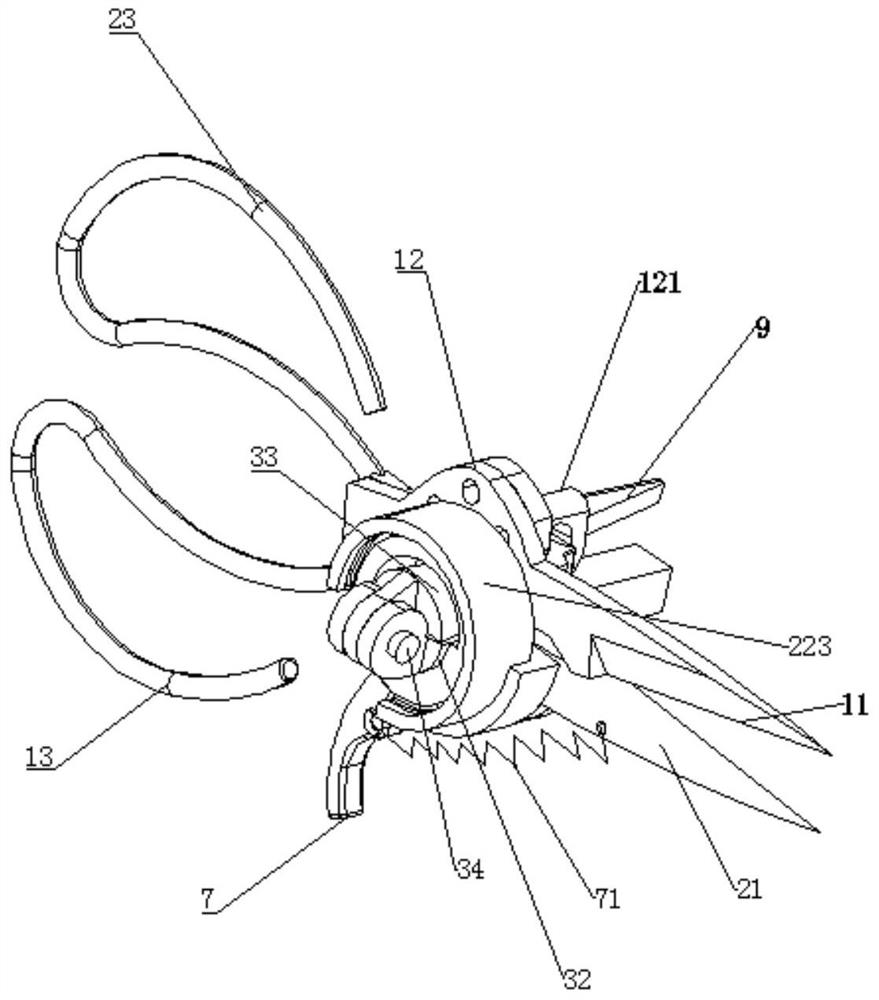

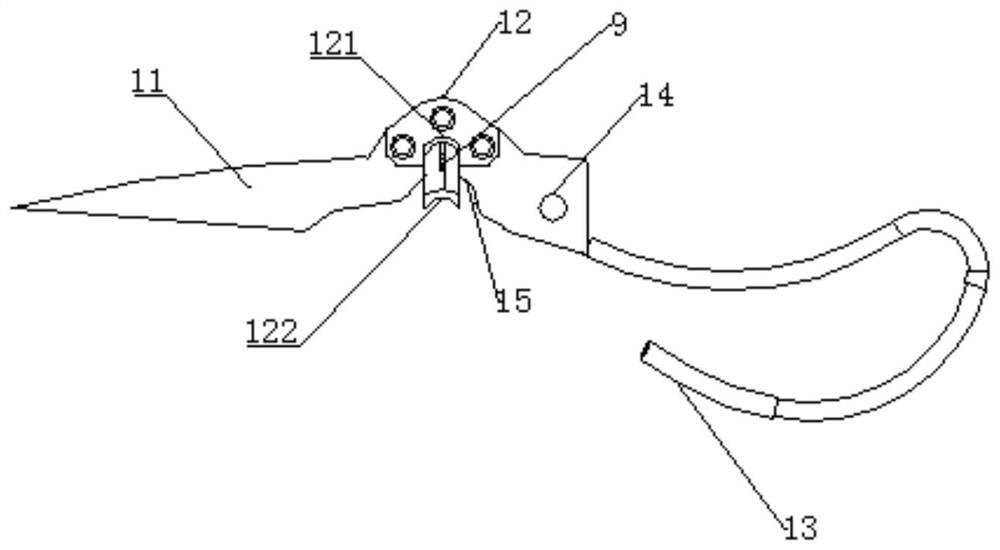

Shrimp scissors

PendingCN112868743AAvoid preprocessingGood removal effectShrimp/lobster processingAnimal scienceShrimp

The invention relates to the technical field of food processing, in particular to shrimp scissors which comprise an upper scissor part and a lower scissor part. An upper clamping support is fixed to an upper scissor mounting part, a lower clamping support is fixed to a lower scissor mounting part, and a right outer circular ring is fixed to the lower scissor part. The shrimp scissors also comprise an inner clamping rotating mechanism. When the shrimp scissors are in use, the upper clamping support and the lower clamping support are used for fixing the front portion of the shrimp tail, the inner clamping rotating mechanism is used for fixing the middle leaf portion of the shrimp tail, the mode is more stable compared with the mode that a shrimp body is held by hands, meanwhile, the inner clamping rotating mechanism is rotated, the middle leaf portion of the tail can be better twisted off, the middle leaf door and a shrimp digestive tract are connected into a whole, the shrimp digestive tract can be taken out more conveniently, operation is easy, the efficiency is improved, the pretreatment effect of crayfishes is ensured, and the problems that no available tool is available for removing crayfish digestive tracts at present, and the common method usually adopts manual treatment, so that the working efficiency is low, and the consumed time is long are solved.

Owner:龙泽良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com