Shrimp scissors

A scissors and scissor blade technology, applied in shrimp/lobster processing, crustacean processing, slaughtering, etc., can solve problems such as troublesome operation and low efficiency, and achieve the effect of convenient removal of shrimp line and shrimp head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

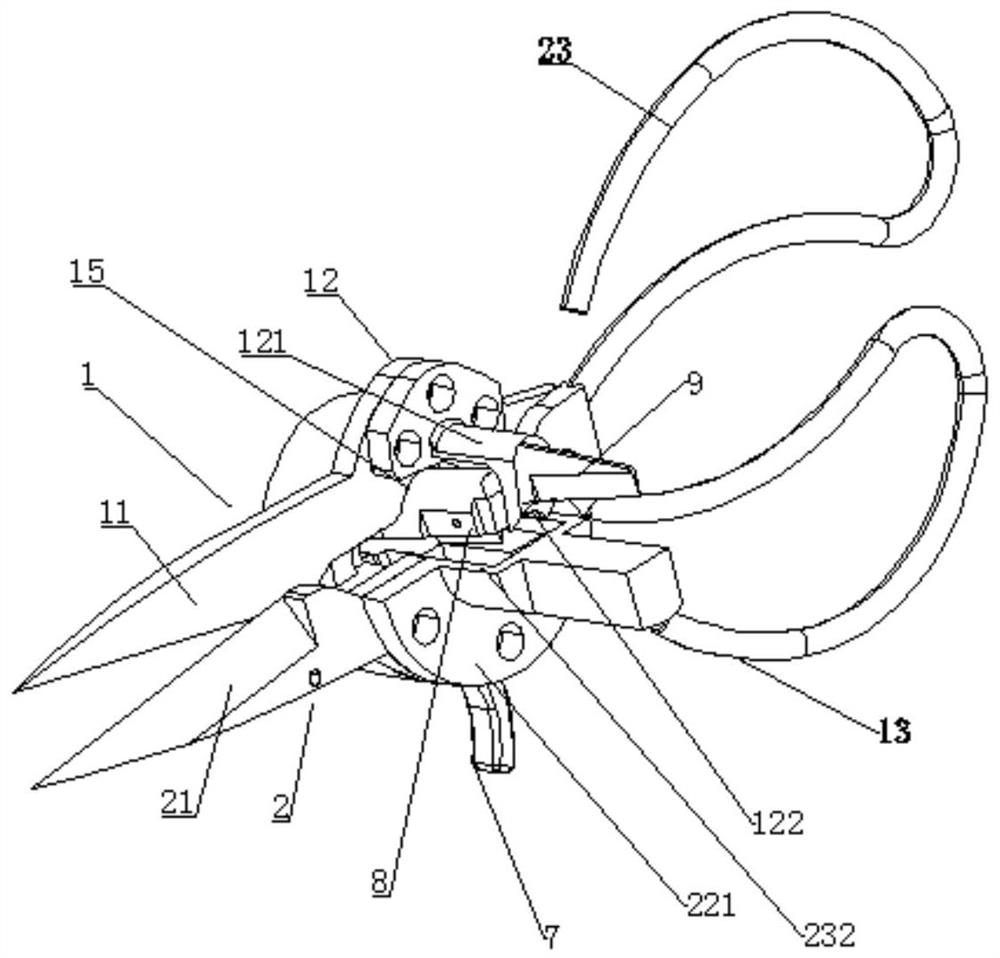

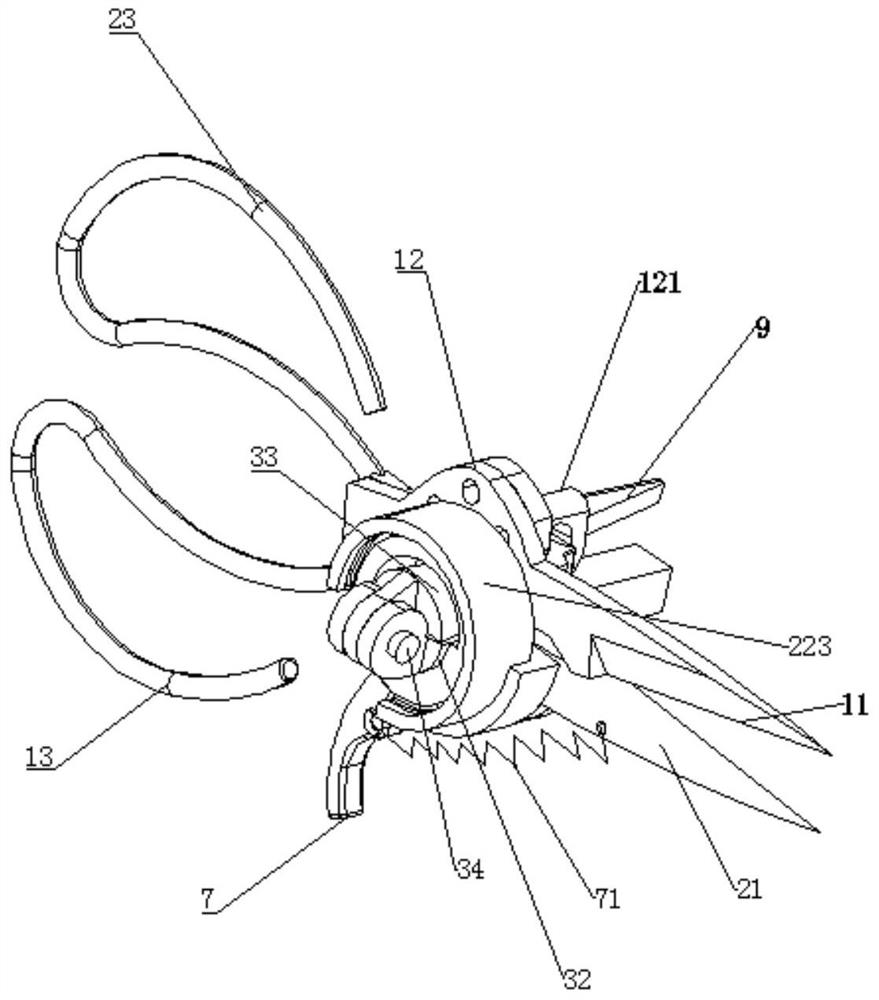

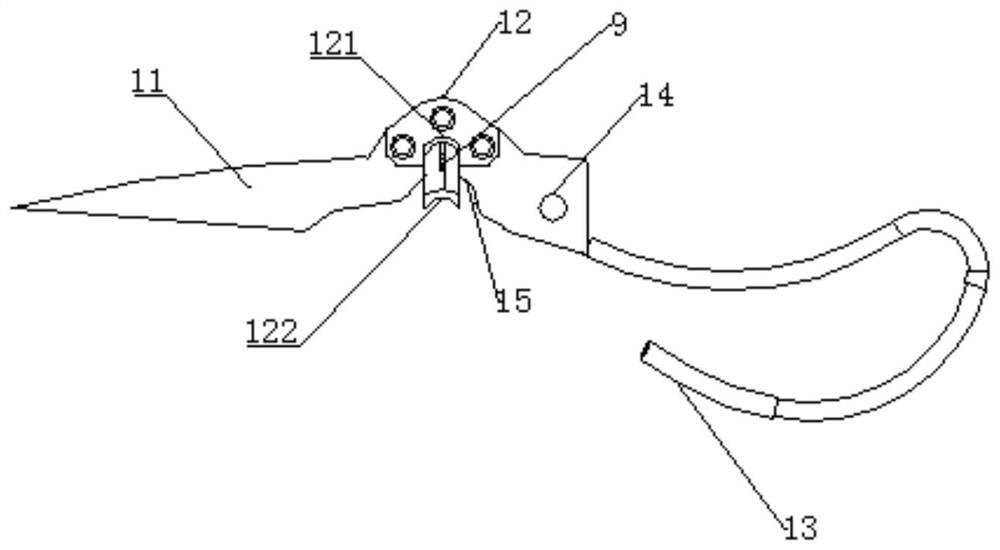

[0040] Such as figure 1 — Figure 15 Shown, a kind of shrimp scissors, comprises upper scissors blade 1, lower scissors blade 2 and the first installation pin shaft, and described upper scissors blade 1 includes upper scissors front blade portion 11, upper scissors mounting portion 12 and upper scissors rear handle portion 13. An upper installation hole 14 is provided between the upper scissors installation part 12 and the upper scissors rear handle part 13; the lower scissors blade 2 includes the lower scissors front blade part 21, the lower scissors installation part 22 and the lower scissors rear handle part 23. A lower installation hole 24 is provided between the lower scissors installation part 22 and the lower scissors rear handle part 23, and the upper scissors blade 1 and the lower scissors blade 2 pass through the upper installation hole through the first installation pin 14 and the lower mounting hole 24 are hinged together, and the left surface of the upper scissor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com