Treatment method and apparatus for recycling ammonia nitrogen wastewater

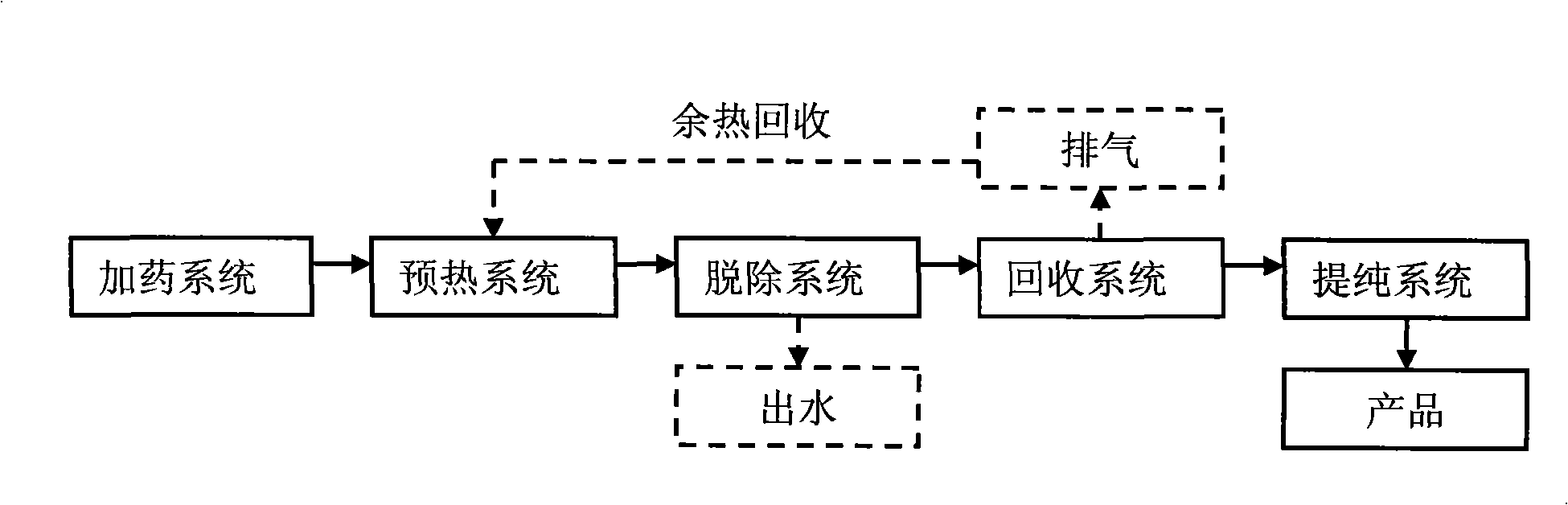

An ammonia nitrogen wastewater and treatment device technology, which is applied in water/sewage multi-stage treatment, heating water/sewage treatment, degassed water/sewage treatment, etc. problems such as low controllability and low adaptability, to achieve the effect of ensuring the pretreatment effect, saving the dosage of chemicals, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

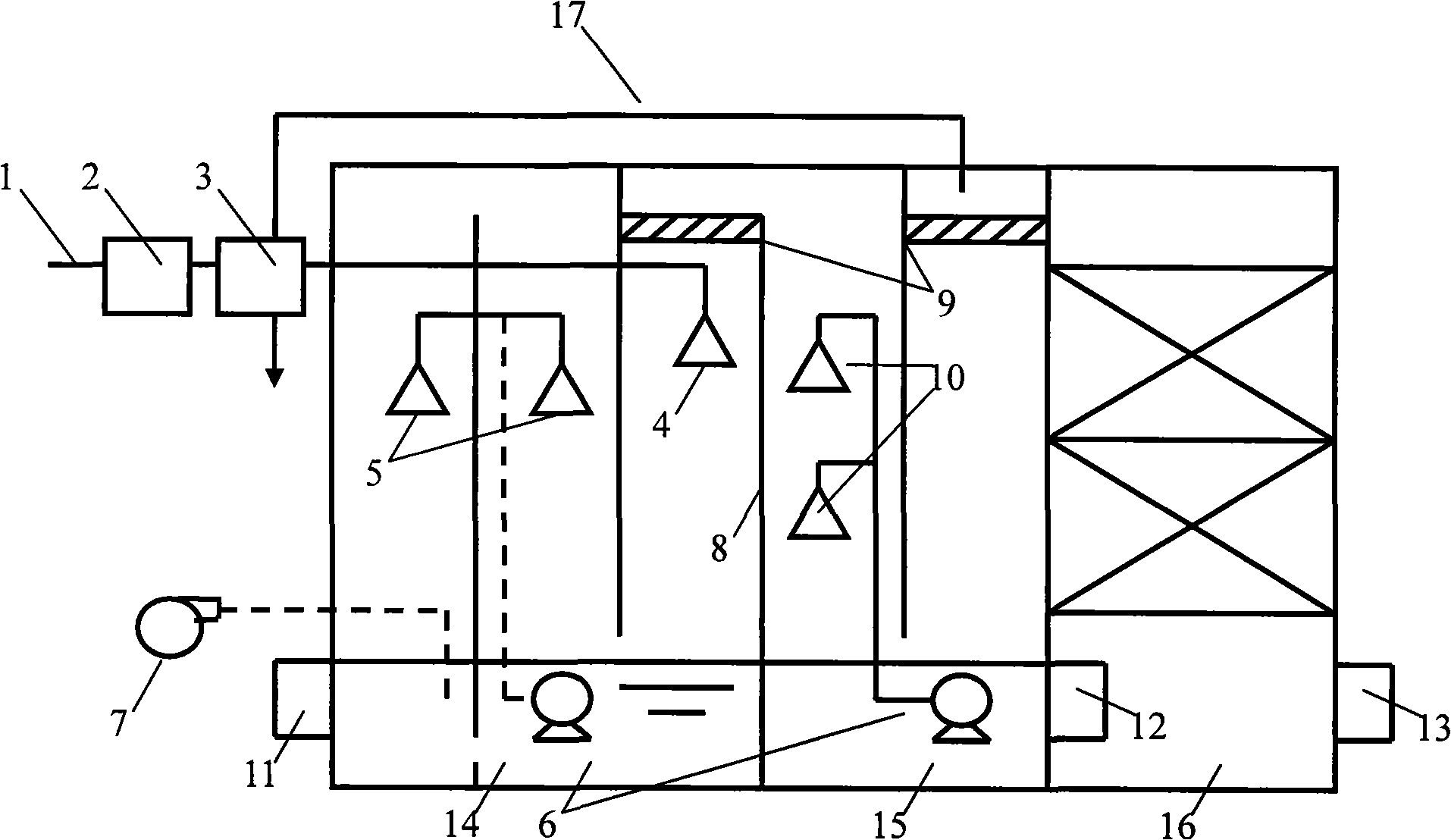

Examples

Embodiment 1

[0051] The ultra-high concentration ammonia nitrogen wastewater discharged by a metallurgical plant is about 350t / d, and the main pollutants in the wastewater are: pH 3-10, NH 3 -N6500~13500mg / L, SS 300mg / L, in addition, it also contains a certain amount of inorganic salts and a small amount of heavy metal ions. Utilize technique and equipment of the present invention to carry out the technological process of deammonification treatment as follows:

[0052] (1) Ultra-high concentration ammonia nitrogen wastewater first enters the automatic dosing system. The dosing system is divided into two parts: the first part is the heavy metal precipitation system. After adjusting the pH to close to neutral, the metering pump is used to add TMT heavy metal precipitant and PAC coagulation agent, mixed evenly in the pipeline mixer; the second part is the pH adjustment system, the KOH solution of 1-5mol / L is added by the metering pump, the pH value of the wastewater is adjusted to 12.0-13.8, ...

Embodiment 2

[0058] The discharge of high-concentration ammonia-nitrogen wastewater from a tanning enterprise is about 800t / d, and the wastewater quality is: pH 6-11, NH 3 -N 300~5000mg / L, also contains a certain amount of Cr 3+ and a very small amount of Cr 6+ . Utilize technique and equipment of the present invention to carry out the technological process of deammonification treatment as follows:

[0059] (1) High-concentration ammonia nitrogen wastewater enters the automatic dosing system first. The pH adjustment of the dosing system is divided into two sections: the first section is filled with saturated Ca(OH) by the quantitative dosing device 2 Solution, adjust the pH to 9.0-10.0 and precipitate Cr, and filter it out through the filter tank; in the second stage, add 10-30% NaOH solution by the metering pump to adjust the pH value of the wastewater to 12.5-13.5.

[0060] (2) High-concentration ammonia-nitrogen wastewater enters the steam heater after Cr removal and pH adjustment, ...

Embodiment 3

[0065] The discharge of ammonia nitrogen wastewater from a fertilizer factory is about 500t / d, and the wastewater quality is: pH5~8, NH 3 -N 800~1250mg / L, and also contains a small amount of phosphate. Utilize technique and equipment of the present invention to carry out the technological process of deammonification treatment as follows:

[0066] (1) Ammonia nitrogen wastewater enters the automatic dosing system first. The dosing system is divided into two sections: the first section is the phosphorus removal section, and the saturated Ca(OH) is added by the metering pump 2 solution, adjust the pH to 9.5-11.0, and filter out calcium phosphate with a filter membrane; in the second stage, add 0.5-2mol / L NaOH solution by a metering pump to adjust the pH value of the wastewater to 12.2-13.4.

[0067] (2) The ammonia nitrogen wastewater then enters the steam heating device (using waste steam in the factory) to raise the water temperature to 63.5-72.5°C. The steam heater is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com