Glass fiber cloth reinforced insulating molded board and preparation method thereof

A glass fiber cloth, molding technology, applied in the field of molded boards, can solve the problems of high temperature resistance, mechanical properties can not meet actual needs, poor flame retardant performance, inconvenience, etc., to achieve excellent high temperature resistance, excellent mechanical properties, and reasonable process design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

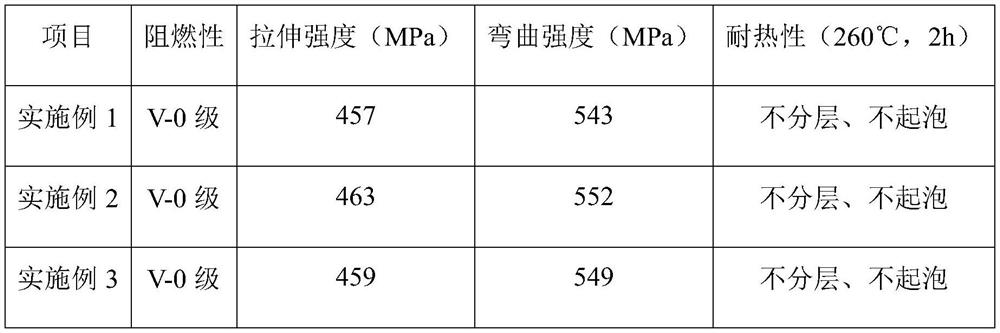

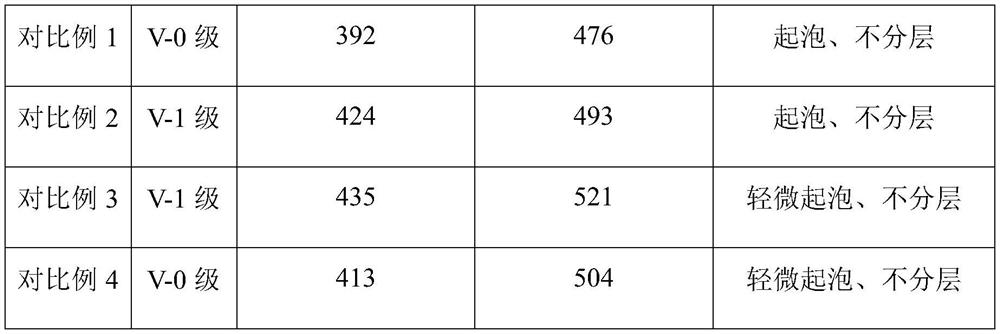

Examples

Embodiment 1

[0037] A preparation method of an insulating molded board reinforced by glass fiber cloth, comprising the following steps:

[0038] (1) Take 4-hydroxyphenylboronic acid and tetrahydrofuran, mix them evenly in an ice-water bath at 0°C, then add triethylamine and tetrahydrofuran solution of phenylphosphoryl dichloride, keep warm for 2 hours, then raise the temperature to 25°C, and continue the reaction for 10 hours , after the reaction is finished, it is filtered and washed, and dried in vacuum at 60°C for 24 hours to obtain a flame retardant;

[0039] (2) Take dichloromethane, phenylene anhydride, phenylacetylene and triethylamine, mix and stir for 20 minutes, react at 25°C for 9 hours, filter and wash with suction, and recrystallize to obtain material A;

[0040] Take material A, transfer it to acetone under a nitrogen atmosphere, add an aminosilane coupling agent, react at 25°C for 3 hours, remove the acetone, and obtain a modified silane coupling agent; the aminosilane coupl...

Embodiment 2

[0046] A preparation method of an insulating molded board reinforced by glass fiber cloth, comprising the following steps:

[0047] (1) Take 4-hydroxyphenylboronic acid and tetrahydrofuran, mix them evenly in an ice-water bath at 0°C, then add triethylamine and a tetrahydrofuran solution of phenylphosphoryl dichloride, keep the temperature for 2.5 hours, then raise the temperature to 27°C, and continue the reaction 9h, after the reaction was completed, it was filtered and washed with suction, and vacuum-dried at 65°C for 22h to obtain a flame retardant;

[0048] (2) Take dichloromethane, metaphthalic anhydride, phenylacetylene and triethylamine, mix and stir for 25 minutes, react at 28°C for 8.5 hours, wash with suction, and recrystallize to obtain material A;

[0049] Take material A, transfer it to acetone under nitrogen atmosphere, add aminosilane coupling agent, react at 28°C for 2.5h, remove acetone, and obtain modified silane coupling agent; the aminosilane coupling agen...

Embodiment 3

[0055] A preparation method of an insulating molded board reinforced by glass fiber cloth, comprising the following steps:

[0056] (1) Take 4-hydroxyphenylboronic acid and tetrahydrofuran, mix them evenly in an ice-water bath at 0°C, then add triethylamine and tetrahydrofuran solution of phenylphosphoryl dichloride, keep the temperature for 3 hours, then raise the temperature to 28°C, and continue the reaction for 8 hours , after the reaction is finished, it is filtered and washed, and vacuum-dried at 70° C. for 20 hours to obtain a flame retardant;

[0057] (2) Take dichloromethane, phenylene anhydride, phenylacetylene and triethylamine, mix and stir for 30 minutes, react at 30°C for 8 hours, filter and wash with suction, and recrystallize to obtain material A;

[0058] Take material A, transfer it to acetone under a nitrogen atmosphere, add an aminosilane coupling agent, react at 30°C for 2 hours, remove the acetone, and obtain a modified silane coupling agent; the aminosil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com