Method for carrying out pressurization microwave pretreatment on lignocellulose

A technology of lignocellulose and microwave treatment, applied in biofuels, fermentation, etc., can solve the problems of low conversion rate of reducing sugar, large water consumption, high energy consumption, etc., and achieve short reaction time, cost saving, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

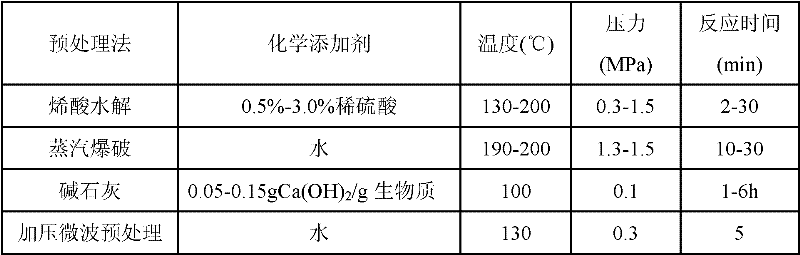

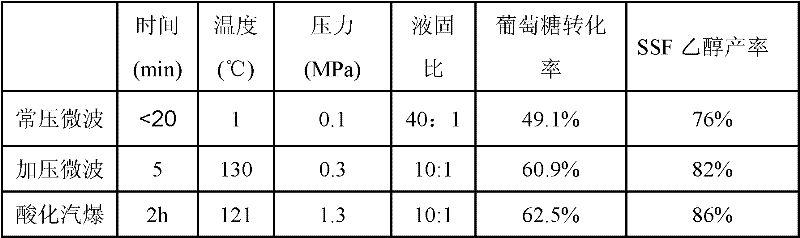

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific Embodiment 1: The method for pressurized microwave pretreatment of lignocellulose in this embodiment is carried out according to the following process: take 4 to 6 g of lignocellulose that has been dried to constant weight, grind it into powder of 10 to 40 mesh, and then Add distilled water at 1:5-20, and pressurize microwave treatment for 2-15 minutes at a temperature of 110-150°C to complete pressurized microwave pretreatment of lignocellulose; the pressure used for pressurized microwave treatment is 0.1-0.5MPa, The microwave frequency used was 450 MHz.

[0015] The type of microwave processor used in the microwave pretreatment in this embodiment is the Mars5 high-throughput closed microwave digestion system (microwave digestion instrument) produced by the American CEM company, and the microwave frequency is 450 MHz.

[0016] In this embodiment, after the pressurized microwave treatment, washing and filtering are not required.

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the lignocellulose is one or a combination of sugarcane, rice husk, and straw. Other steps and parameters are the same as those in Embodiment 1.

[0018] In this embodiment, when the lignocellulose is a mixture, each component is mixed in any proportion.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that 4 g of lignocellulose dried to constant weight is taken, crushed into 10-mesh powder, and then distilled water is added at a solid-to-liquid ratio of 1:5. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com