Ionic liquid microemulsion and its preparation method and use

A technology of ionic liquid and microemulsion, which is applied in the direction of mixing methods, chemical instruments and methods, and dissolution, can solve the problems of high viscosity of ionic liquids, low accessibility and low permeability of fiber raw materials, and improve the efficiency of enzymatic hydrolysis and saccharification. The effect of improving pretreatment efficiency and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] With hydrophilic ionic liquid [BMIM]Cl as the main body, lipophilic ionic liquid [BMIM]PF 6 As the core, the cationic surfactant CTAB (cetyltrimethylammonium bromide) and the co-surfactant n-butanol are used as the mixed interfacial film to form [BMIM]PF 6 / [BMIM]Cl type ionic liquid microemulsion, its preparation method is as follows:

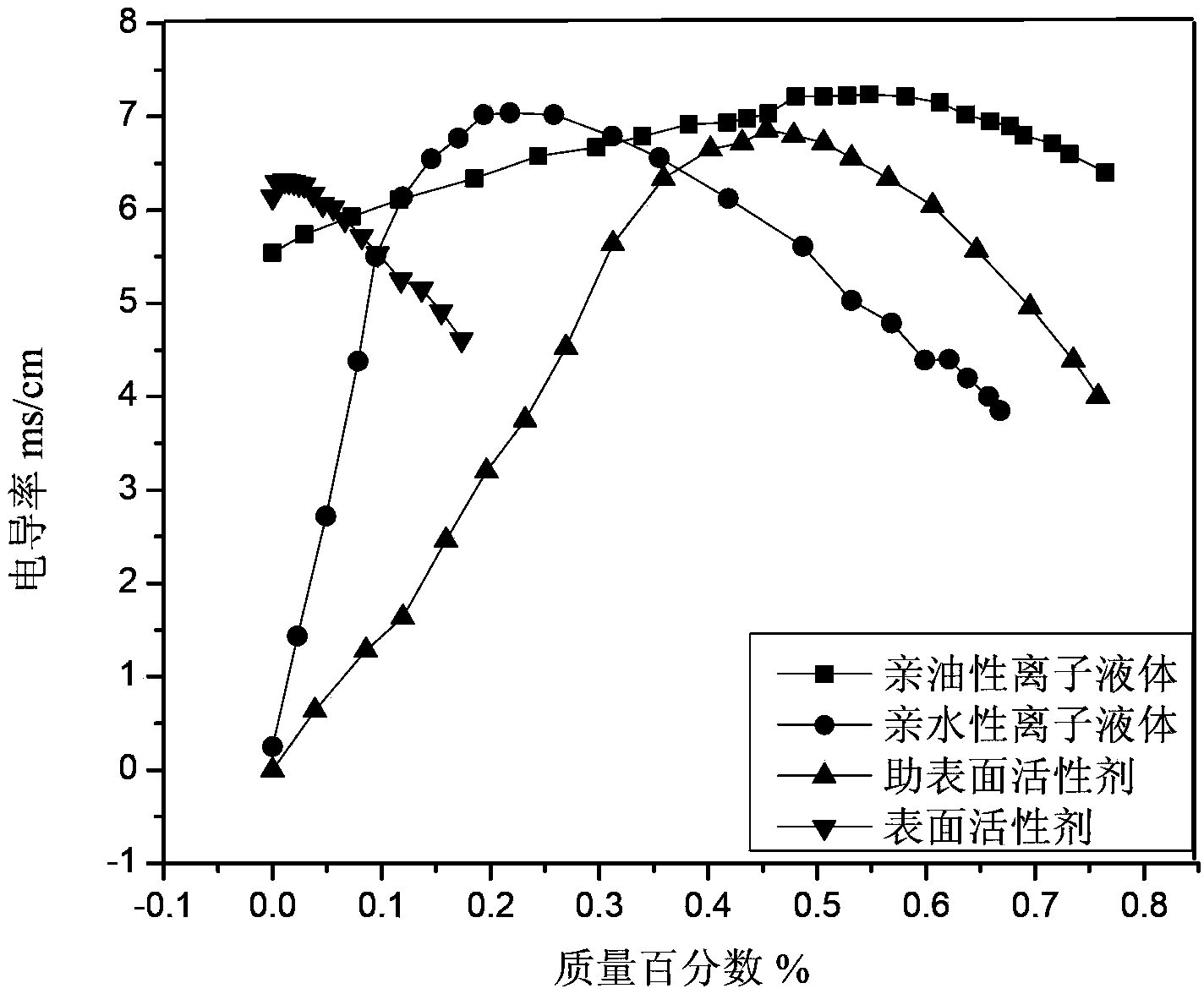

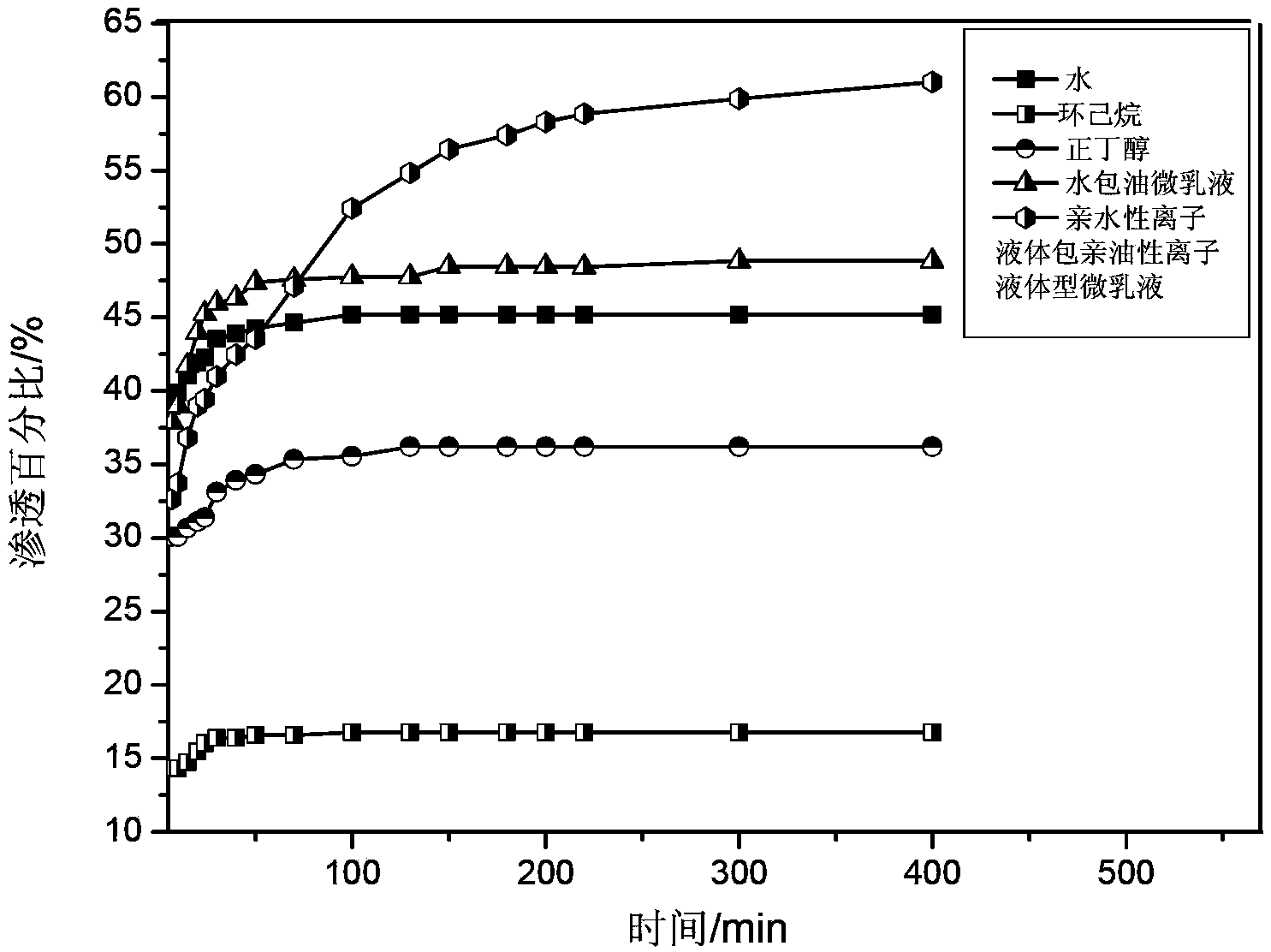

[0030] Add the four components of the microemulsion according to the mass ratio m (surfactant): m (co-surfactant): m (hydrophilic ionic liquid): m (lipophilic ionic liquid) = 1:6:8:4 In a transparent glass reaction container, after adding a magnetic stirrer, place the container in a magnetic stirring constant temperature water bath, set the temperature at 40°C, and stir at a speed of 300r / min for 20min until the system is clear and transparent and centrifuged at a high speed of 30000r / min for 5min. layered. After the ionic liquid microemulsion is prepared, it is placed in a grinding bottle for later use. At the same time, the electri...

Embodiment 2

[0035] Add the four components of the microemulsion according to the mass ratio m (surfactant): m (co-surfactant): m (hydrophilic ionic liquid): m (lipophilic ionic liquid) = 1:10:12:4 In a transparent glass reaction container, after adding a magnetic stirrer, place the container in a magnetic stirring constant temperature water bath, set the temperature at 50°C, and stir at a speed of 300r / min for 20min until the system is clear and transparent and centrifuged at a high speed of 30000r / min for 5min. layered. After the ionic liquid microemulsion is prepared, it is placed in a grinding bottle for later use. At the same time, the electrical conductivity and wood permeability of the configured ionic liquid microemulsion were characterized and tested.

[0036] The prepared ionic liquid microemulsion and 80 mesh masson pine wood powder (water content 7%) are added in the round bottom flask with condensing system according to the liquid-solid ratio 30:1ml / g (wood powder is calculat...

Embodiment 3

[0040]Add the four components of the microemulsion according to the mass ratio m (surfactant): m (co-surfactant): m (hydrophilic ionic liquid): m (lipophilic ionic liquid) = 1:14:12:6 In a transparent glass reaction container, after adding a magnetic stirrer, place the container in a magnetic stirring constant temperature water bath, set the temperature at 50°C, and stir at a speed of 300r / min for 20min until the system is clear and transparent and centrifuged at a high speed of 30000r / min for 5min. layered. After the ionic liquid microemulsion is prepared, it is placed in a grinding bottle for later use. At the same time, the electrical conductivity and wood permeability of the configured ionic liquid microemulsion were characterized and tested.

[0041] The prepared ionic liquid microemulsion and 80 mesh masson pine wood powder (water content 7%) are added in the round bottom flask with condensing system according to the liquid-solid ratio 25:1ml / g (wood powder is calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com