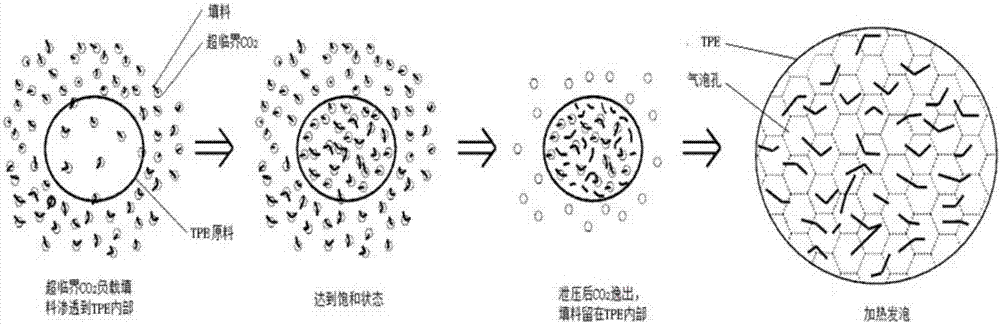

Process for forming thermoplastic elastomer/filler composite foam material

A thermoplastic elastomer and compound foaming technology, which is applied in the field of composite materials, can solve the problems of poor dispersion of fillers, and achieve the effects of good dispersion, excellent overall performance, and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Put the polyurethane elastomer and disperse dye Disperse Red 343 in the autoclave body, feed carbon dioxide and pressurize to make the pressure reach 30Mpa and the temperature is 60°C. At this time, the carbon dioxide is in a supercritical state. In this state, pressurize and infiltrate for 3 hours, and control the process to release the pressure slowly so that the dispersible filler in the base material does not mix with CO 2 Discharged and evenly dispersed in the polyurethane elastomer. After pressure relief, the polyurethane elastomer / dyed filler was foamed at 100° C. for 10 minutes to obtain a dyed polyurethane elastomer foam material. Put the dyed polyurethane elastomer foam material into the mold cavity heated to 150°C from the material gun, and then feed high-pressure steam with a steam pressure of 0.3MPa. At this time, close the condensate valve on one side, open the steam inlet valve, and at the same time , so that the steam inlet valve on the opposite side is...

Embodiment 2

[0028] Put the polyurethane elastomer and disperse dye Disperse Red 343 in the autoclave body, feed carbon dioxide and pressurize to make the pressure reach 30Mpa and the temperature is 60°C. At this time, the carbon dioxide is in a supercritical state. In this state, pressurize and infiltrate for 3 hours, and control the process to release the pressure slowly so that the dispersible filler in the base material does not mix with CO 2 Discharged and evenly dispersed in the polyurethane elastomer. After pressure relief, the polyurethane elastomer / dyed filler was foamed at 120° C. for 6 minutes to obtain a dyed polyurethane elastomer foam material. Put the dyed polyurethane elastomer foam material into the mold cavity heated to 150°C from the material gun, and then feed high-pressure steam with a steam pressure of 0.3MPa. At this time, close the condensate valve on one side, open the steam inlet valve, and at the same time , so that the steam inlet valve on the opposite side is ...

Embodiment 3

[0032] The polyurethane elastomer and the dispersive filler graphene are placed in the autoclave body, and carbon dioxide is introduced and pressurized, so that the pressure reaches 40Mpa and the temperature is 55°C, and the carbon dioxide is in a supercritical state at this time. In this state, keep the pressure and infiltrate for 4 hours, and control the process to release the pressure slowly, so that the dispersed filler graphene in the base material will not be mixed with CO 2Discharged and evenly dispersed in the polyurethane elastomer. After the pressure relief, the polyurethane elastomer / graphene was foamed at 110°C for 2 minutes to obtain a polyurethane elastomer / graphene foam material. Put the foaming material into the mold cavity heated to 170°C from the material gun, and then feed high-pressure steam with a steam pressure of 0.4 MPa. At this time, close the condensate valve on one side and open the steam inlet valve. The steam inlet valve is closed and the condensa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com