Preparation method for composite powder of graphene and metal aluminum powder

A technology of composite powder and metal aluminum powder, which is applied in the field of nanosheet structure reinforced metal matrix composite materials, can solve the problems of graphene microstructure damage, damage to graphene structure state, and reduce the intrinsic properties of graphene, so as to achieve low toxicity, Toxicity-safe, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

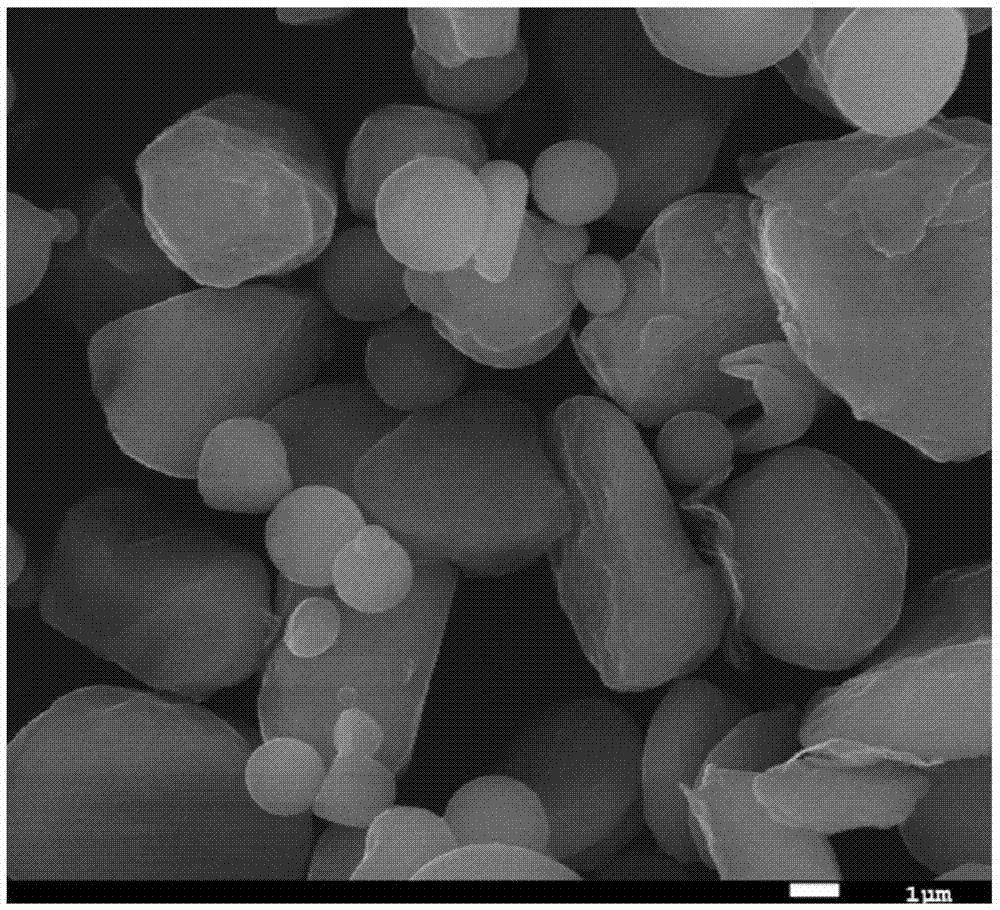

[0050] Follow the specific steps described above to operate. The graphene content is 0.3 wt.%, and the aluminum powder content is 99.7 wt.%. The thickness of the graphene sheet is between 3 and 18 layers, the average particle size of the aluminum powder is selected to be about 15 μm, and the purity is 99.8 wt.%. In the pre-dispersion process, 0.3 g of graphene was added, the amount of anhydrous ethanol was 100 mL, the stirring speed was 20 r / min, the ultrasonic vibration frequency was 60 Hz, the action time was 20 min, and the solution temperature was room temperature 20 °C. In the ball milling process, the ratio of ball to material is 4:1, the ball milling time is 0.5h, and the speed of the ball mill is 200r / min. The drying temperature is 90°C, the time is 64 hours, and the vacuum degree at the end of drying is 4×10 -2 Pa.

[0051] The deformation of the composite powder aluminum powder prepared by the above process is about -40%, the graphene is well dispersed, and the al...

Embodiment 2

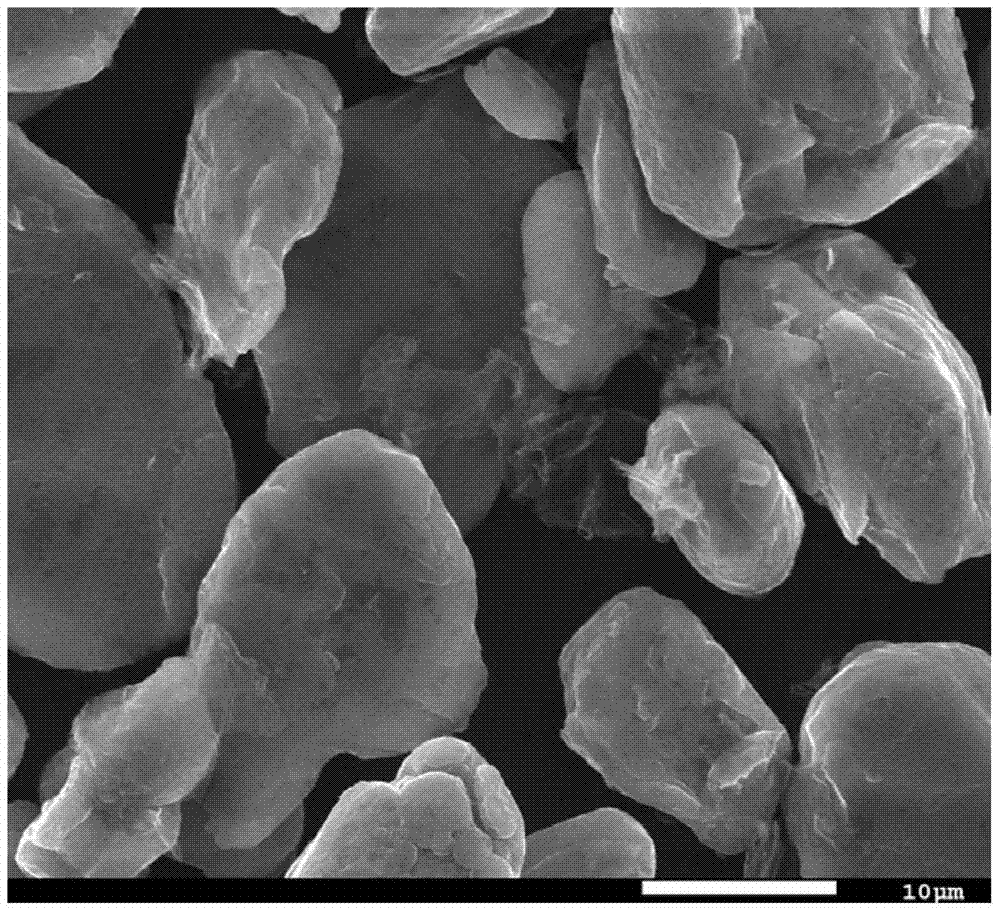

[0053] The graphene content is 8.5 wt.%, and the aluminum powder content is 91.5 wt.%. The thickness of the graphene sheet is between 3 and 18 layers, the average particle size of the aluminum powder is selected to be about 55 μm, and the purity is 99.8 wt.%. In the pre-dispersion process, 8.5 g of graphene was added, the amount of anhydrous ethanol was 1000 mL, the stirring speed was 120 r / min, the ultrasonic vibration frequency was 120 Hz, the action time was 360 min, and the solution temperature was room temperature 25 °C. In the ball milling process, the ball-to-material ratio is 50:1, the ball milling time is 50h, and the ball mill rotating speed is 40r / min. The drying temperature is 240°C, the time is 8 hours, and the vacuum degree at the end of drying is 4.5×10 -2 Pa.

[0054] The deformation amount of the composite powder aluminum powder prepared by the above process is about -70%, the graphene is well dispersed, and the flake effect of the aluminum powder is larger ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com