Corn straw dilute acid pretreatment method for reducing corrosion degree of reactor

A corn stalk and pretreatment technology, applied in fermentation and other directions, can solve problems such as corrosion and heavy sewage treatment burden, and achieve the effects of reducing corrosion, reducing equipment investment, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

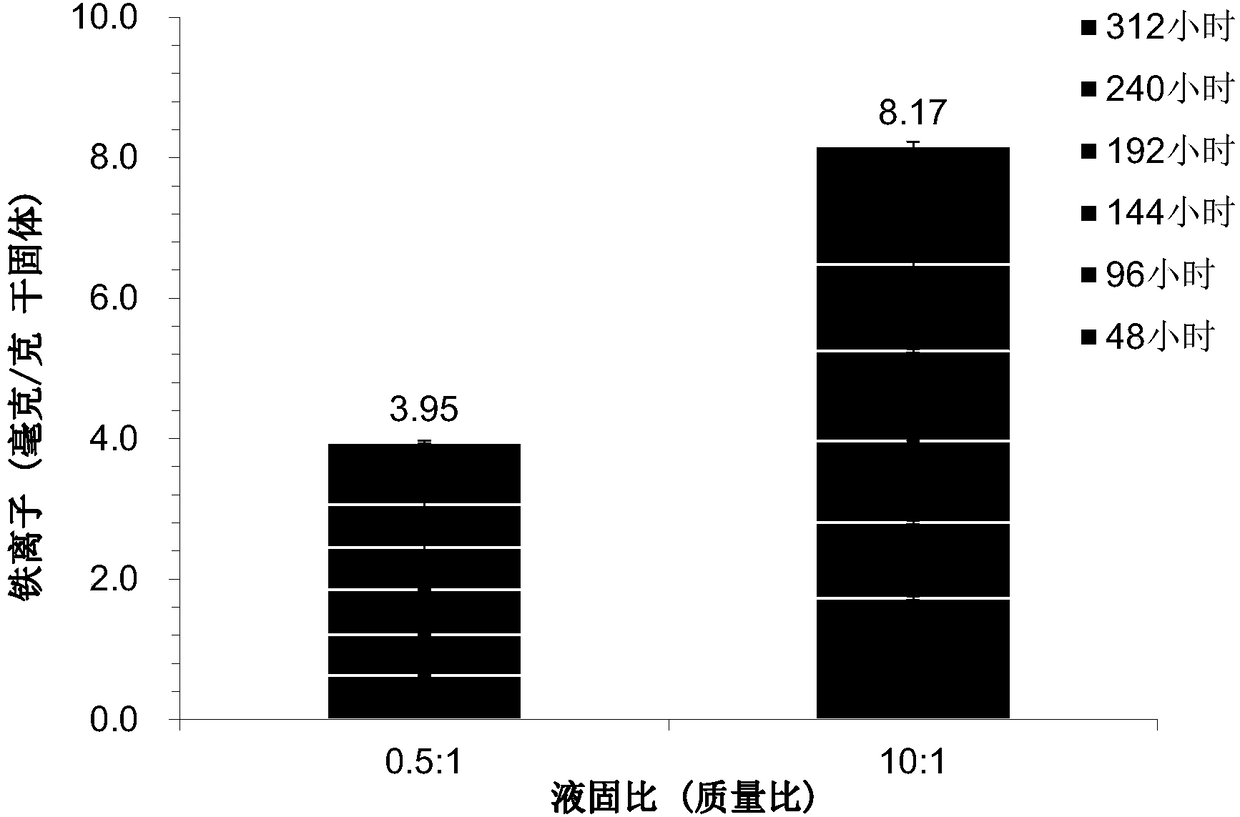

Embodiment 1

[0019] Mix 10 g of dilute sulfuric acid solution (the mass fraction of sulfuric acid is 0.25%) with 1 g of dry corn stalks (liquid-solid ratio is 10:1) after dedusting coarse powder, and then put them into a cylindrical reactor processed by 304 stainless steel. The dosage is 25mg / g dry corn stover. After sealing, place it in a muffle furnace for high-temperature pretreatment reaction, the reaction condition is 175°C, keep it for 12 hours after the temperature rises to 175°C, take out the pretreatment slurry from the steel pipe without washing, repeat the above process, and the number of cycles is 26 times . The pretreatment slurry obtained each time is suction-filtered, and the liquid part is measured with a phenanthroline spectrophotometer for iron ion concentration and the results of 26 times are accumulated, and the iron ion concentration produced is 8.17mg / g dry solid. Under the above pretreatment conditions, the retention time was adjusted to 90 minutes, and the enzymati...

Embodiment 2

[0021] 0.5g of dilute sulfuric acid solution (the mass fraction of sulfuric acid is 5%) and 1g of dry corn stalks after dedusting coarse powder (liquid-solid ratio is 0.5:1) are mixed evenly and loaded into a cylindrical reactor processed by 304 stainless steel. The dosage of sulfuric acid is 25mg / g dry corn stover. After sealing, put it in a muffle furnace for high-temperature pretreatment reaction. The reaction condition is 175°C. After the temperature rises to 175°C, keep it for 12 hours. Take out the pretreated material from the steel pipe and do not wash it. Repeat the above process, and the number of cycles is 26 times. . The pretreatment material obtained each time is suction filtered after being diluted, and the liquid part is measured by the phenanthroline spectrophotometer for iron ion concentration and the results of 26 times are accumulated, and the iron ion concentration produced is 3.95mg / g dry solid. Under the above pretreatment conditions, the retention time w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com