TFT glass substrate thinning process pretreatment agent

A technology of glass substrate and pretreatment agent, which is applied in the field of TFT glass substrate etching pretreatment composition, can solve problems such as difficult disposal of waste liquid, and achieve the effects of reducing pits, improving pretreatment effect, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The TFT glass substrate thinning process pretreatment agent provided by the invention is prepared in the following way,

[0012] 1) Mix the prescribed amount of hydrochloric acid, nitric acid and hydrofluoric acid, add appropriate amount of water to dilute, add the prescribed amount of calcium chloride to dissolve,

[0013] 2) Dissolve the hydroxypropyl methylcellulose and gellan gum of the prescribed amount in an appropriate amount of water until completely dissolved;

[0014] 3) Slowly add the mixed solution obtained in step 1) into the mixed solution in step 2), make up the remaining amount of water, and then stir until the mixed solution is evenly mixed.

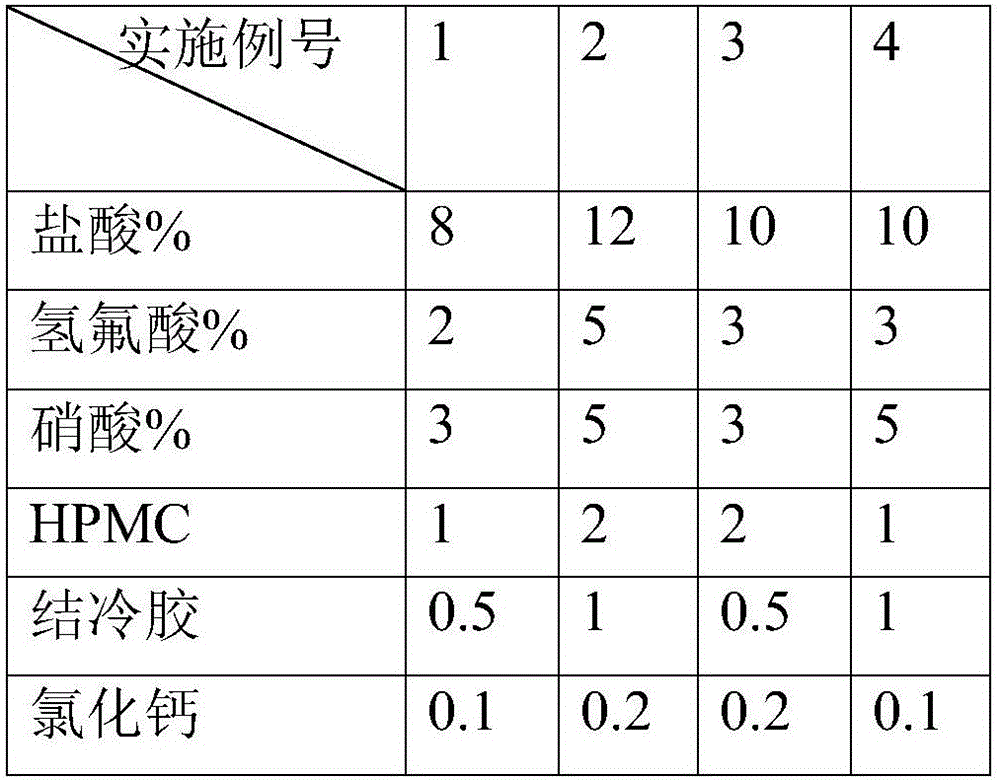

[0015] The formula of embodiment 1~4 sees the following table (mass percentage wt%)

[0016]

[0017] The gellan gum adopted in the present invention complies with GB 25535-2010 standard

[0018] The hydroxypropyl methylcellulose used in the present invention is produced by Anhui Shanhe Pharmaceutical Excipie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com