Electric wire identification printing pretreatment device

A pretreatment device and wire technology, applied in the direction of marking conductors/cables, etc., can solve the problems of inability to guarantee the clarity, blurred marks, etc., and achieve the effect of ensuring the pretreatment effect, improving the bonding strength, and ensuring the printing clarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

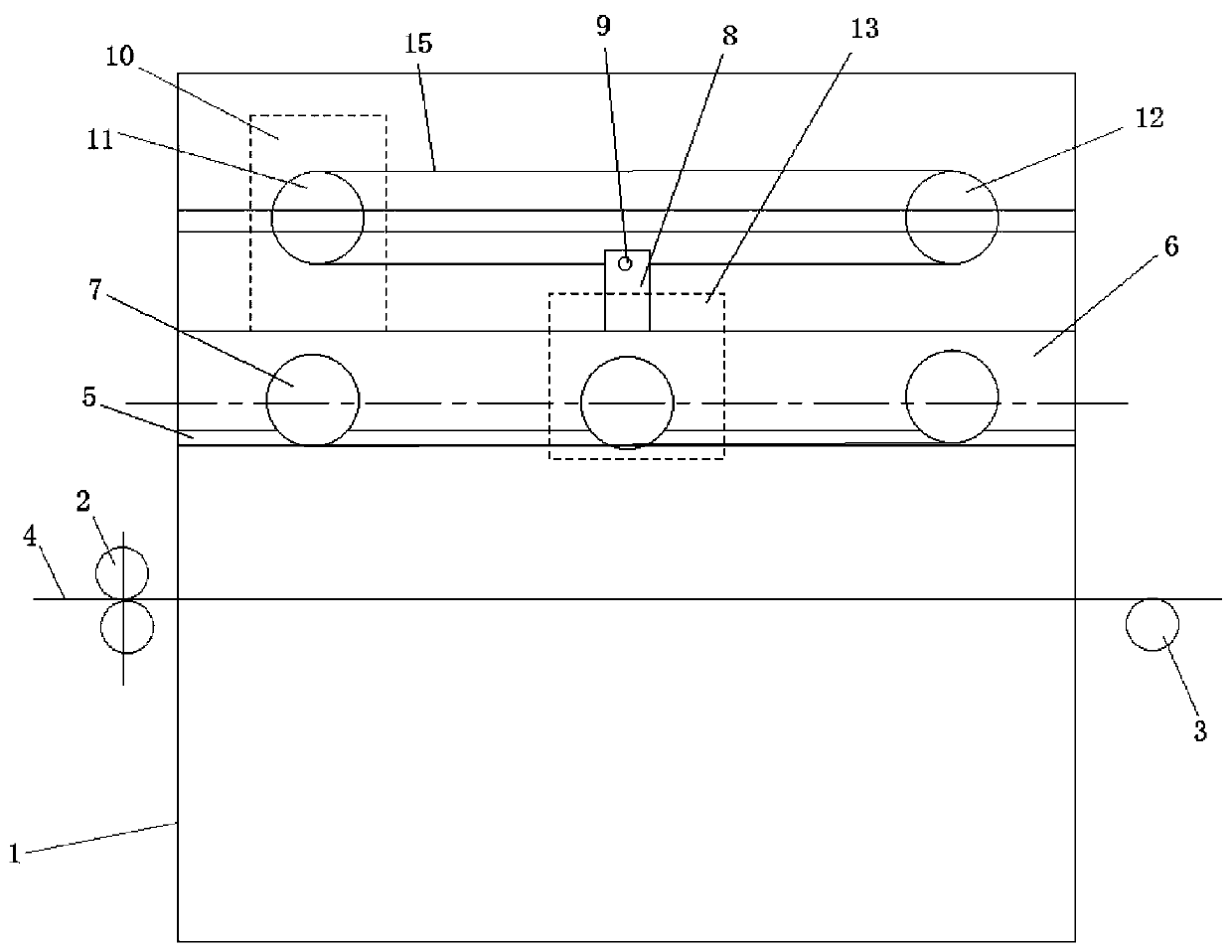

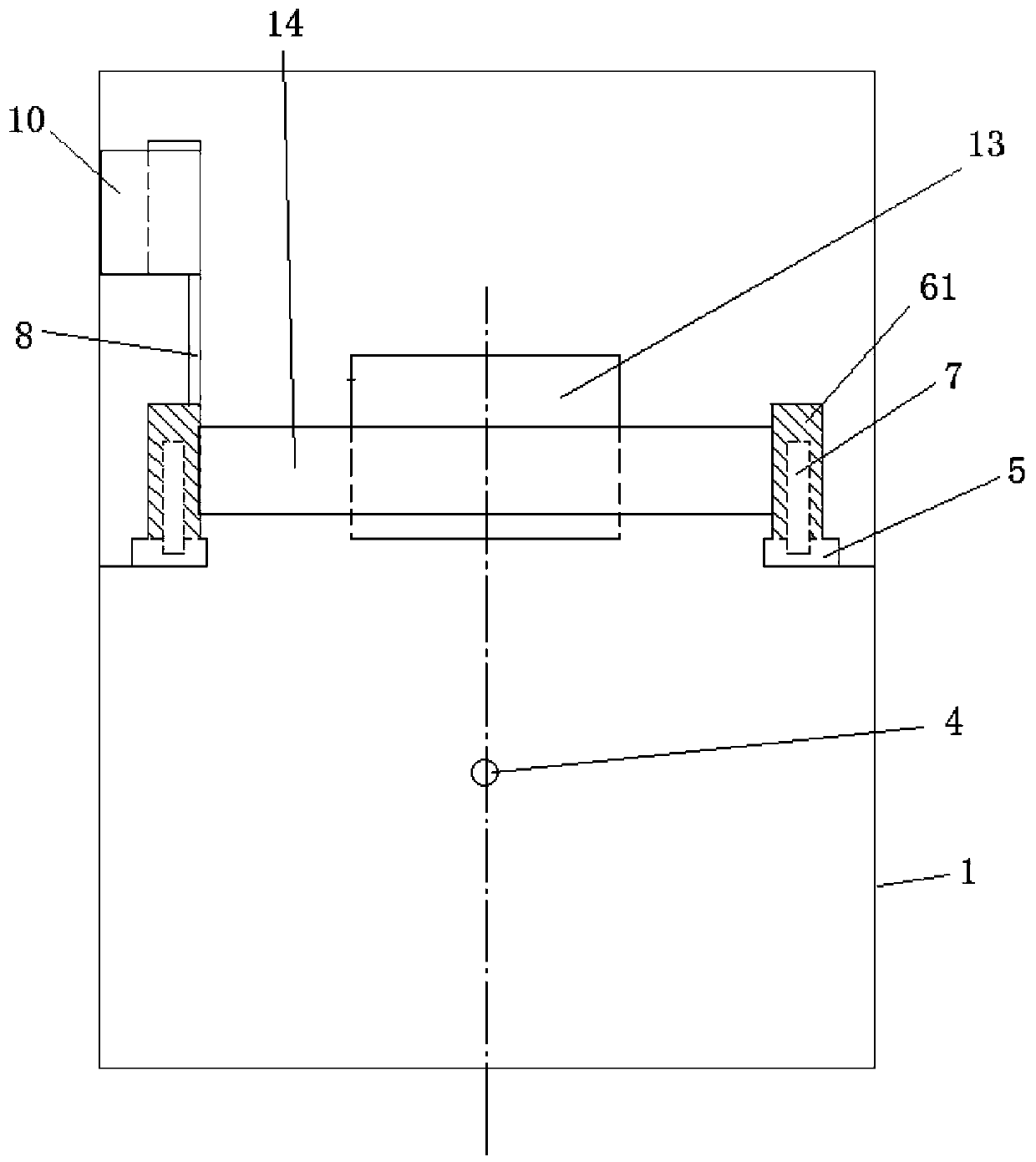

[0010] The present invention is specifically described below in conjunction with accompanying drawing, as shown in the figure, the present invention comprises closed cavity 1, the inlet and the outlet of electric wire are set in the described cavity, and electric wire 4 is driven from described traction pair wheel 2 and guide wheel 3 The inlet and outlet pass through the cavity; a guide rail 5 is set above the cavity, a slide bed 6 is set on the guide rail, rollers 7 of the slide bed are set on the guide rail 5, a plasma spray gun 13 is set on the slide bed 6, and the plasma spray gun faces Electric wire; connecting rod 8 is set on the slide bed, and a through hole is set at the upper end of the connecting rod, and the through hole is sleeved on the positioning pin 9 on the belt 15; the two ends of the belt are respectively driving pulley 11 and driven pulley 12, and the driving pulley The wheel 11 is driven to rotate by the output shaft of the servo motor 10; the direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com