Preheating processing method and device for air conditioning unit compressor

A technology for compressor preheating and air-conditioning units, applied in space heating and ventilation, heating methods, mechanical equipment, etc., can solve the problems of low commissioning efficiency and high time cost, improve commissioning efficiency, save time and cost, avoid The effect of warm-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

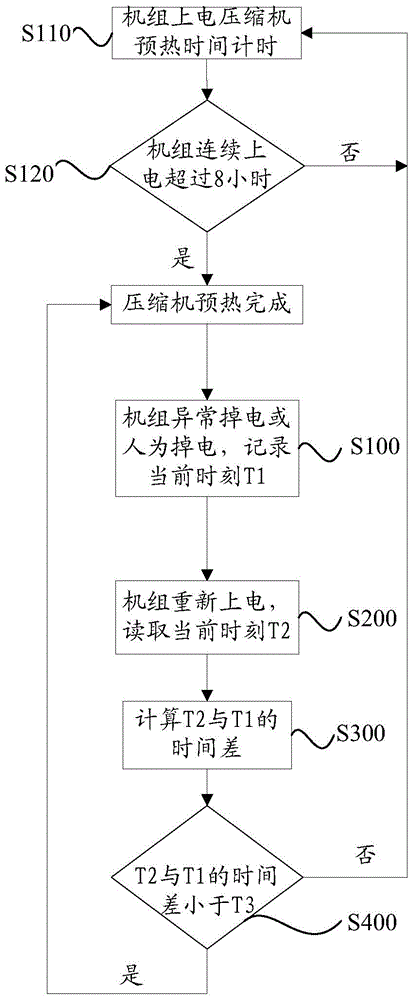

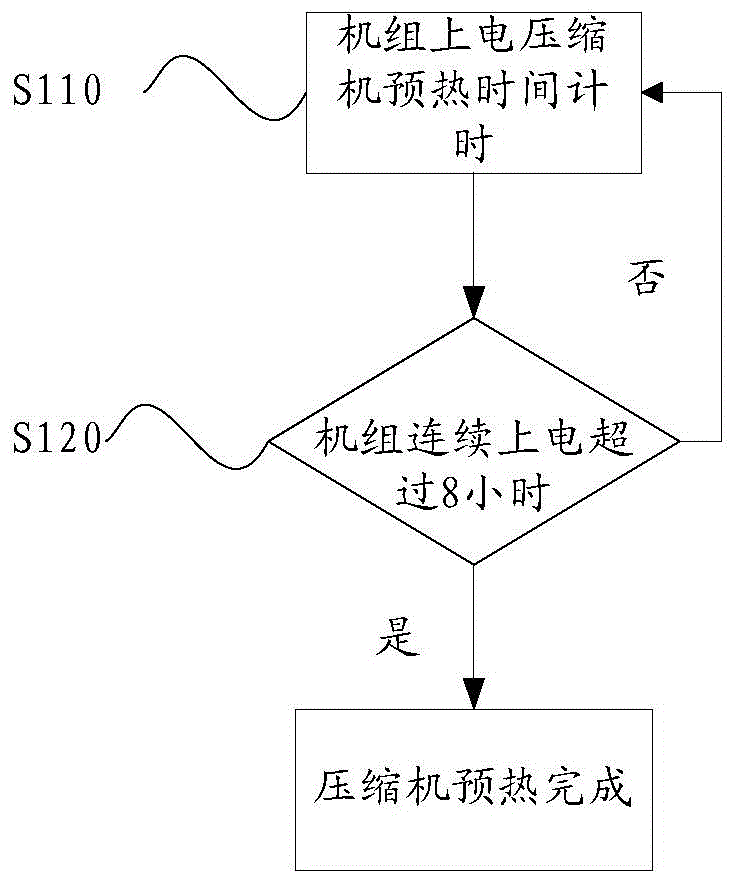

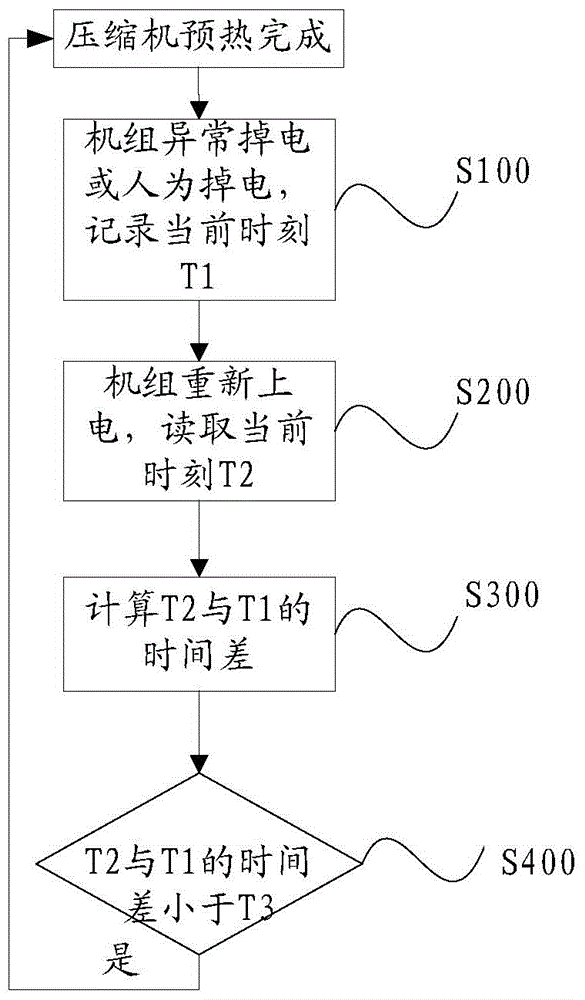

[0039] Such as figure 1 As shown, the method for preheating the compressor of the air-conditioning unit of the present invention, after the compressor is preheated, uses a time comparison method to determine whether the compressor needs to be preheated again after the compressor is abnormally or artificially powered off.

[0040] First turn on the power supply, the main control device connects the voltage to the compressor to preheat, record the current preheating time, and the main control device accumulates the preheating time of the compressor, and the duration of the compressor preheating when it is powered on After more than 8 hours, the preheating of the compressor is completed. After the preheating is completed, enter the debugging process of the compressor. If there is an abnormal power failure or artificial power failure during the debugging process, record the current power failure time T1. After the compressor solves the problem and powers on again, record it again....

Embodiment 2

[0057] Such as Figure 4 As shown, a processing device 100 for compressor preheating of an air-conditioning unit includes a first timing module 110 , a second timing module 120 , a time calculation unit 130 and a determination unit 140 .

[0058] in:

[0059] The first timing module 110 is used to record the power-off time T1 during power-off during the commissioning process after the air-conditioning unit is preheated for a preset preheating time;

[0060] The second timing module 120 is used to record the re-power-on time T2 when the power is turned on again after power-off;

[0061] The time calculation unit 130 is used to calculate the power-down time according to the power-off time T1 and the power-on time T2 again;

[0062] The determining unit 140 is configured to compare the power-off time with a preset warning time T3 and then determine the reheating mode of the compressor of the air conditioner unit.

[0063] After the air conditioner unit is powered off, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com