Standby control for machine tools

A technology for standby control and machine tools, applied in the field of machine tool control or machine tools, and can solve problems such as non-consideration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

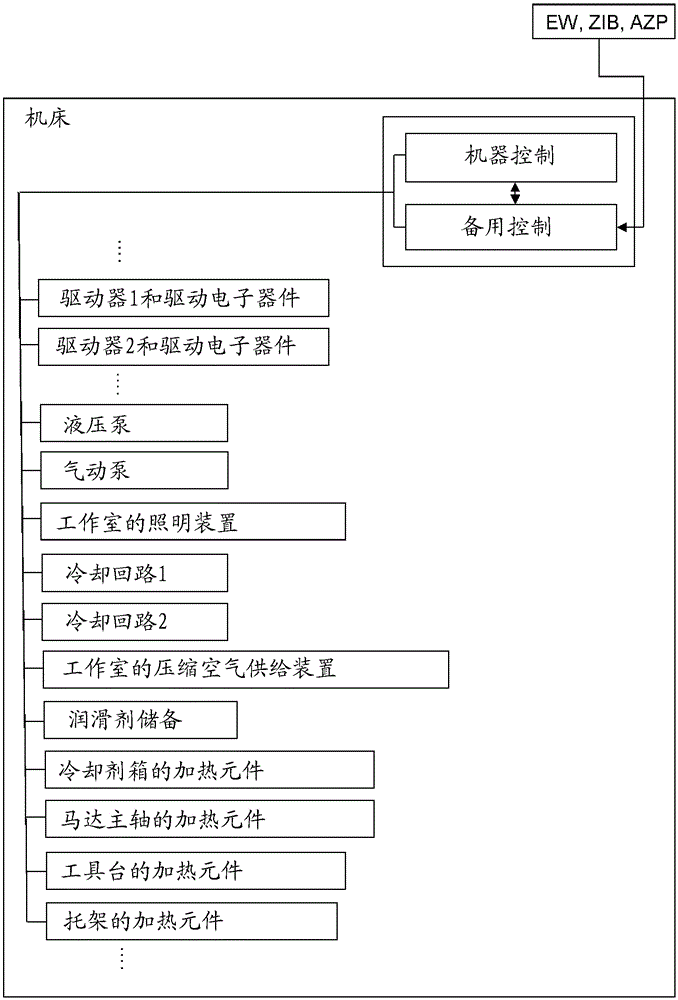

[0049] As shown by way of example in the figures, the standby control is part of the superordinate control system of the machine tool. Standby controls are also linked to normal machine tool controls. As shown in the attached figure, the backup control can be connected to many or individual power consuming components of the machine tool. These energy-consuming components are preferably elements / modules whose temperature or operation (eg in the case of fans) significantly or significantly affects the machining accuracy of the machine tool. The standby control according to the invention activates or deactivates the components given individually as required. In this way, standby control can affect the thermal state of the machine or critical machine areas during non-operational periods of the machine (or when standby mode is active) and ensure that the The desired machining accuracy of the machine tool (predetermined by entering the value EW) is retrieved in a precise manner. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com