Patents

Literature

41 results about "Evaporation Purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isolation of pure liquids by virtue of their different evaporation characteristics.

Solar water evaporation purification and decomposition device

ActiveCN107879405AAchieve fadeAchieve purificationGeneral water supply conservationSeawater treatmentWater desalinationEvaporation Purification

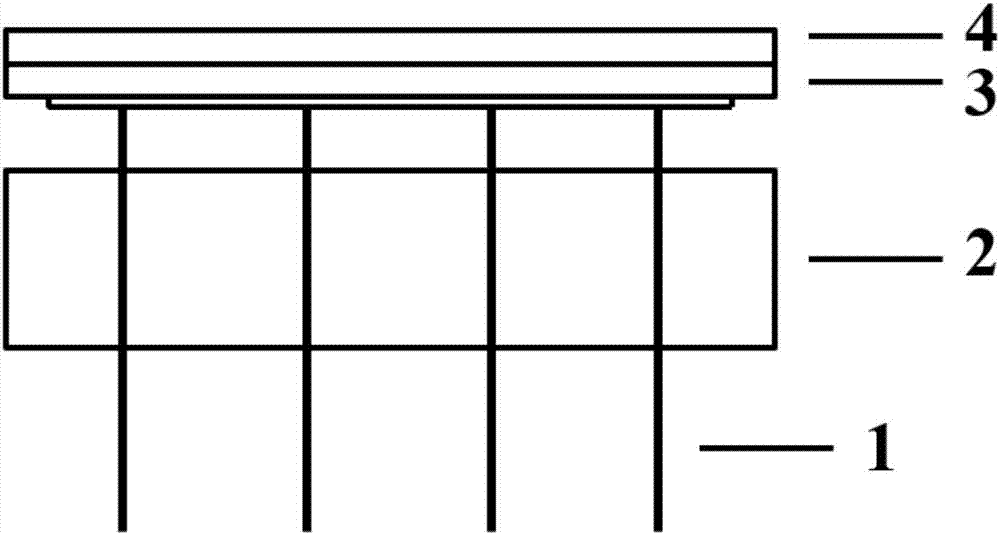

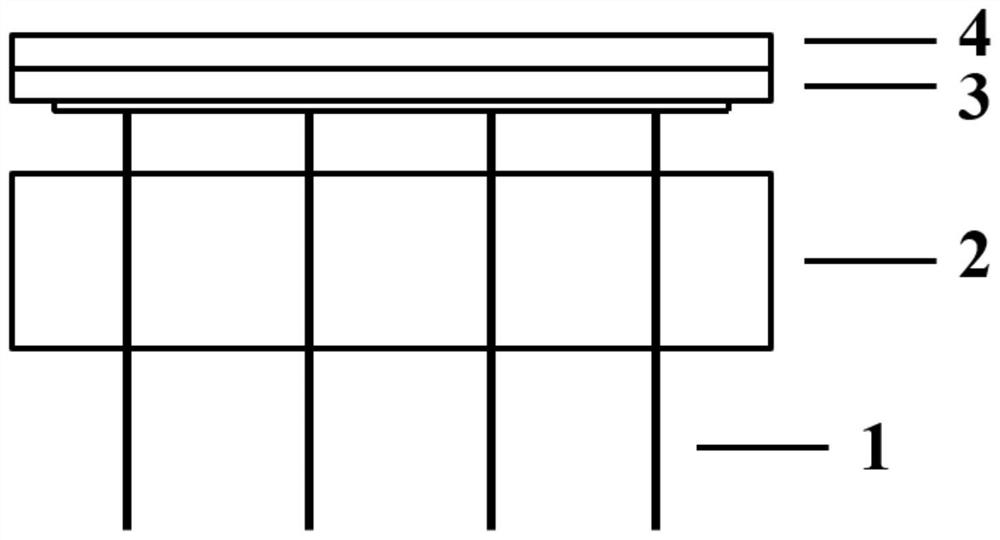

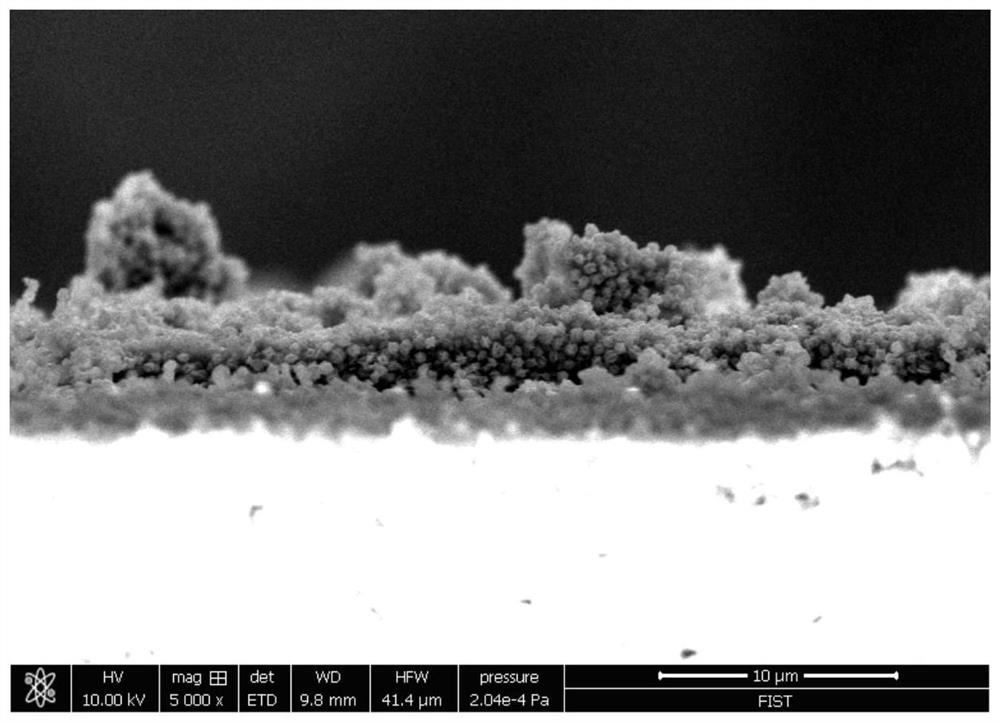

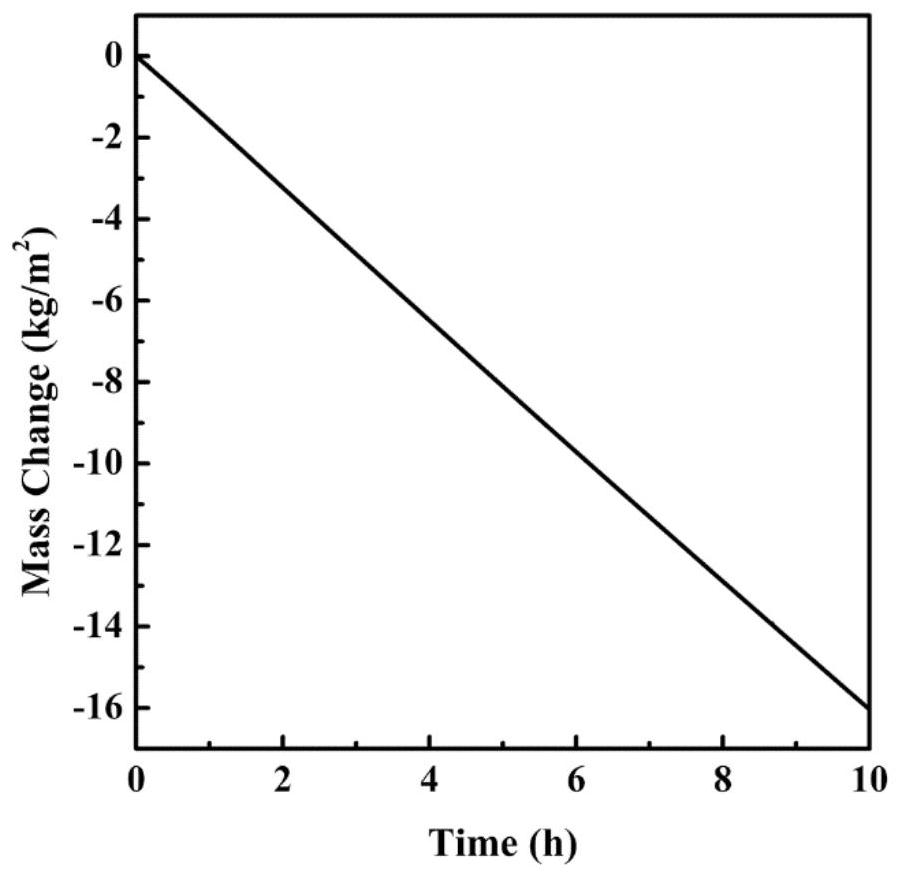

The invention discloses a solar water evaporation purification and decomposition device which comprises a water supply line, a float and heat insulation layer, an evaporation layer and a photothermalconversion and solute barrier layer which are connected in sequence from bottom to top. The water supply line enables water to pass through the float and heat insulation layer, and the water is pumpedinto the evaporation layer by virtue of a capillary action; solar energy absorbed by the photothermal conversion and solute barrier layer is converted into heat, and water is heated to be vaporized into water vapor from the evaporation layer; due to pore channel volatilization of the photothermal conversion and solute barrier layer, partial water vapor is decomposed to produce hydrogen and oxygen; since the photothermal conversion and solute barrier layer contains a hydrophobic part and is not infiltrated by water, the solar energy can directly heat a heat-absorbing material only, but not heat water, so that high photothermal conversion efficiency is realized; and meanwhile, the solute in the water is prevented from being separated out on the membrane, and sea water desalination, sewage purification and water decomposition can be realized. Due to the design of a hydrophilic / hydrophobic double-layer evaporation structure, the solar water evaporation purification and decomposition device with high photothermal conversion efficiency and high stability is obtained.

Owner:XI AN JIAOTONG UNIV

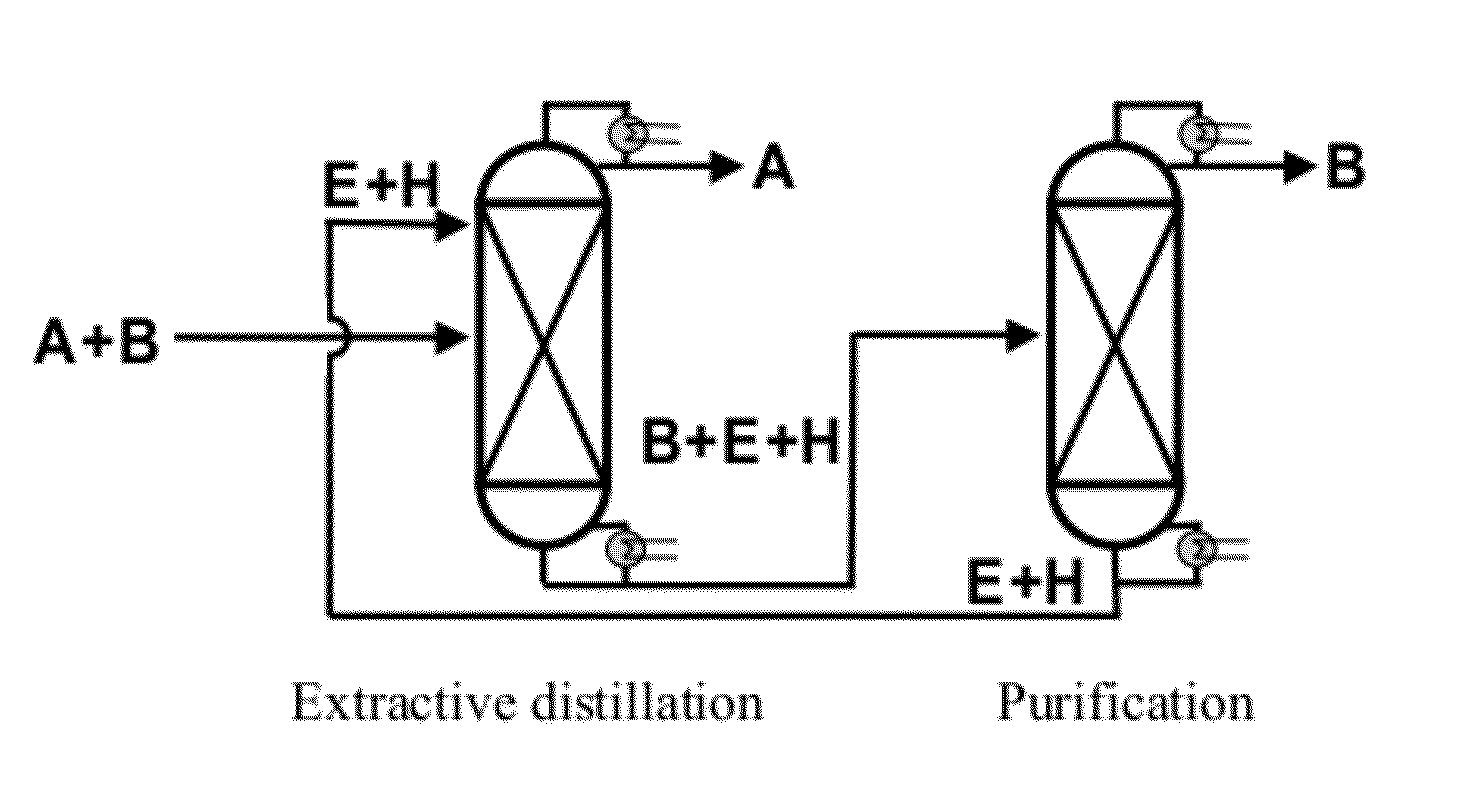

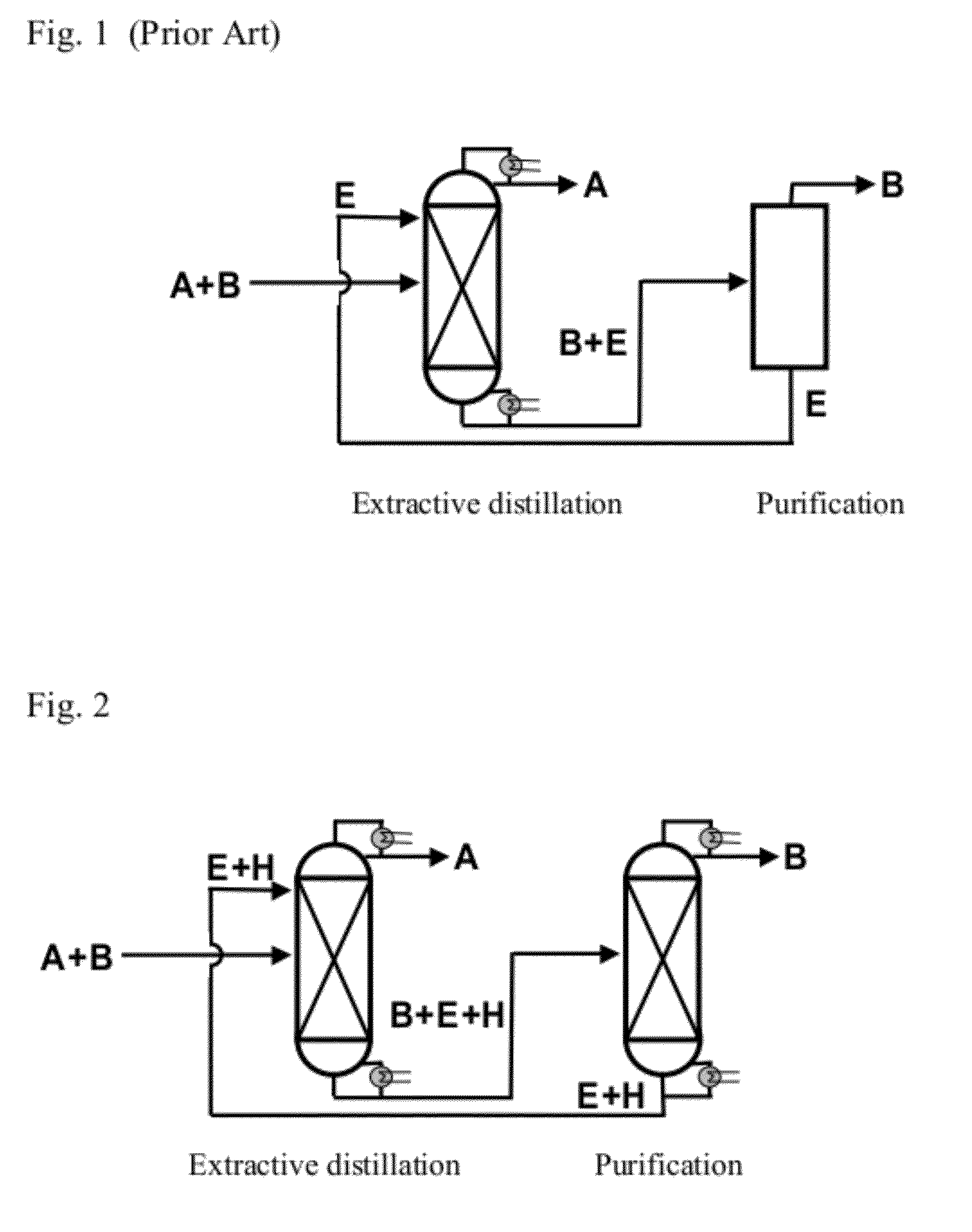

Method for the distillative purification of slow-evaporating fluids

InactiveUS8277615B2Readily componentLow costGroup 5/15 element organic compoundsDistillation purification/separationEvaporation PurificationChemical reaction

Owner:BAYER INTELLECTUAL PROPERTY GMBH

Method for refining pure metal

InactiveCN101570823AEasy accessHigh purityPhotography auxillary processesProcess efficiency improvementEvaporation PurificationBoiling point

The invention discloses a method for refining pure metal, which comprises the following steps: firstly, performing preliminary purification on crude metal by adopting an electrolytic method; and secondly, performing evaporation purification on the metal after the preliminary purification in a special device. The evaporation purification comprises the following steps: vacuumizing a purification furnace first, and introducing liquid metal into a purification crucible in the purification furnace through a pipeline and a stop valve by using the air pressure difference between the purification furnace and a heating furnace; controlling the temperature and the vacuum degree in the purification furnace to evaporate, volatilize and remove low-boiling impurity elements first; and then controlling the temperature of the furnace to evaporate and volatilize the desired metal to further obtain the purified metal through condensation and collection. The method has simple purification process and good purification effect, and can be widely applied to purifying metals and nonmetals.

Owner:贾宏志

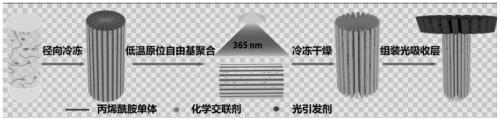

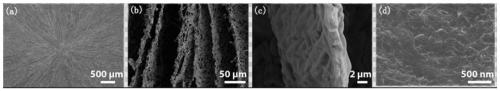

Double-layer aerogel as well as preparation method and application thereof as solar evaporator

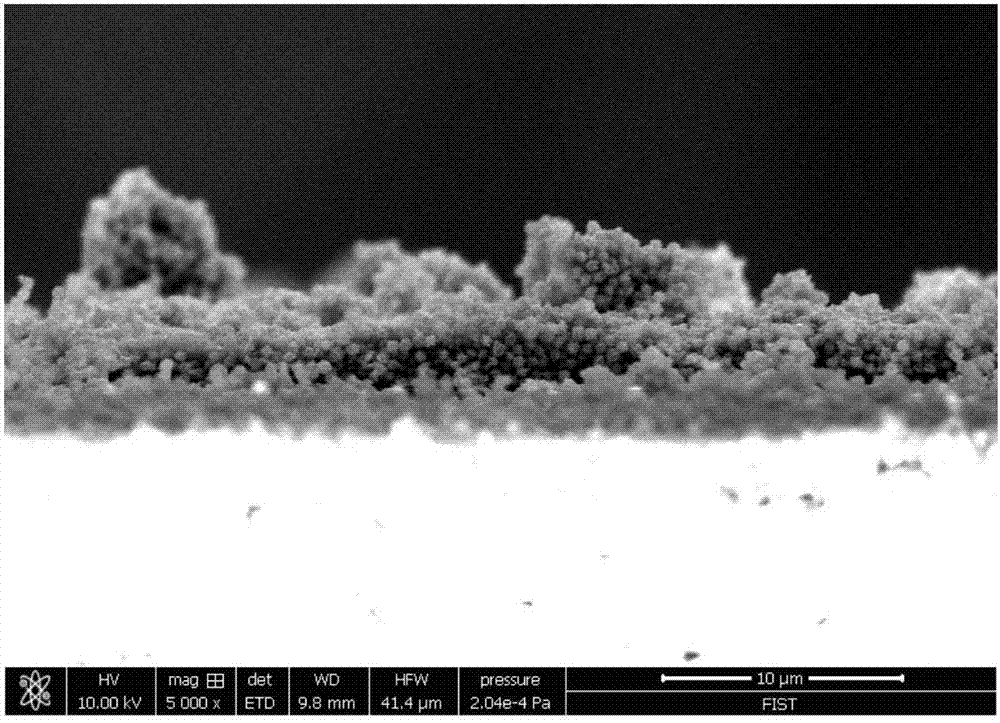

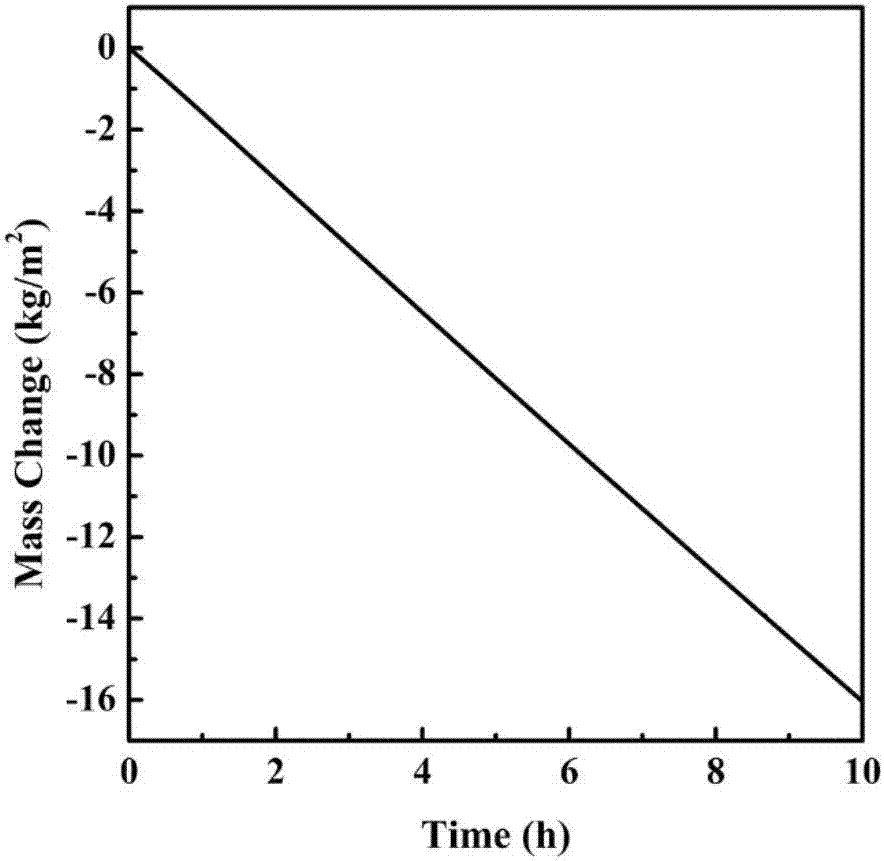

ActiveCN110218277ARealize the purpose of long-distance directional transport waterEasy to makeHeat exchange apparatusEvaporation PurificationFreeze-drying

The invention discloses a double-layer aerogel as well as a preparation method and application thereof as a solar evaporator. The double-layer aerogel consists of a lower layer of a polyacrylamide aerogel and an upper layer of a polyacrylamide-carbon nanotube composite aerogel, wherein the polyacrylamide aerogel is used as a water supply layer and is of a radial classified porous structure; the polyacrylamide-carbon nanotube composite aerogel is used as a light absorption layer; the polyacrylamide aerogel of the radial classified porous structure is mainly prepared by preparing a solution, carrying out radial freezing, carrying out low-temperature ultraviolet radiation cross-linking, and by carrying out freeze drying and pretreatment; and the polyacrylamide-carbon nanotube composite aerogel is mainly prepared by preparing a carbon nanotube dispersion, supporting a layer of arbon nanotubes at the top of the aerogel, and by carrying out freeze drying. In addition, when the double-layer aerogel disclosed by the invention is used as an evaporator, the lower layer of the water supply layer is used for providing water to the upper layer of the light absorption layer, solar energy absorbed by the upper layer of the light absorption layer is converted into heat energy for evaporating the water, then power is provided for water conveying in capillary channels in the lower layer of the water supply layer, and water evaporation purification is achieved.

Owner:ZHEJIANG SCI-TECH UNIV

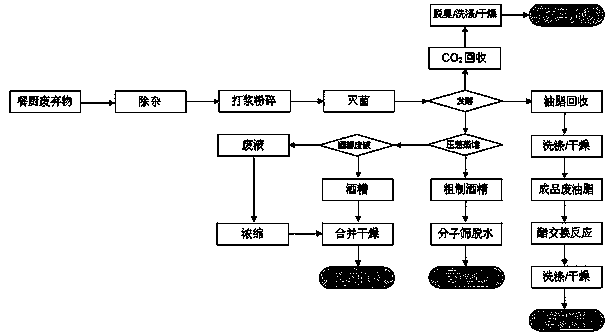

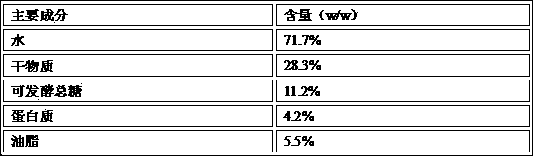

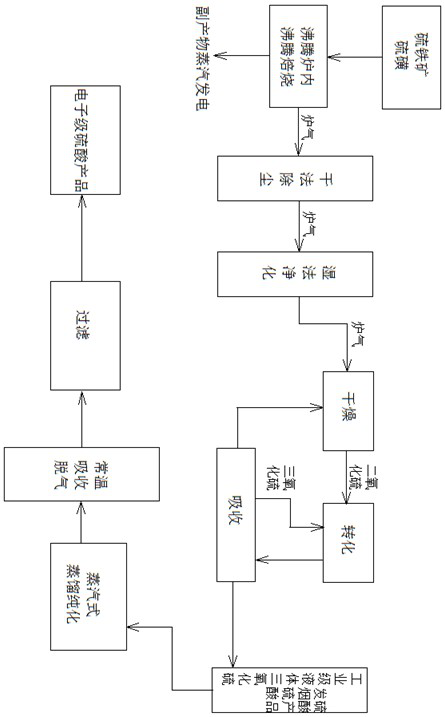

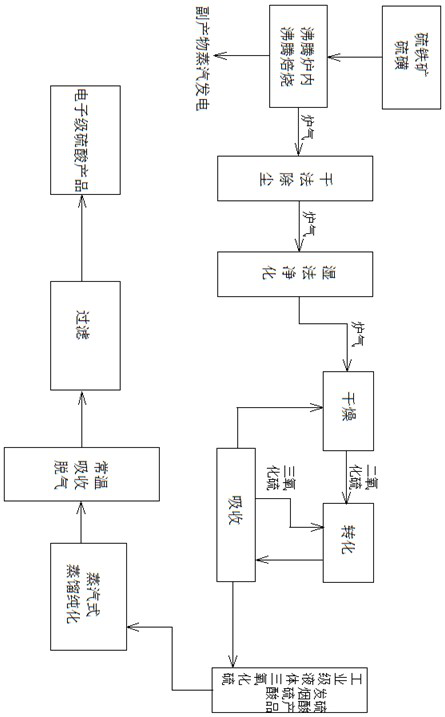

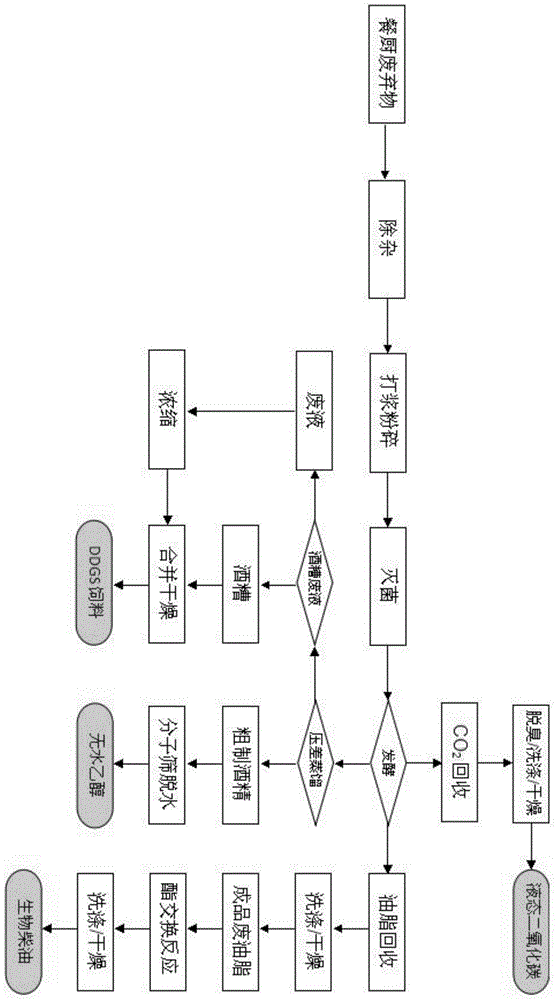

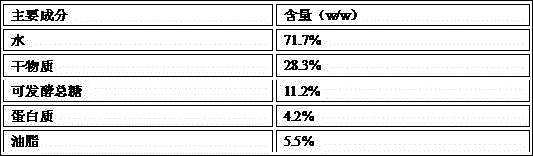

Kitchen waste treatment process with reclamation, harmlessness and reduction

ActiveCN103962365AResourcefulEfficient resource utilizationFatty oils/acids recovery from wasteFatty acid esterificationCelluloseEvaporation Purification

The invention relates to the field of kitchen waste treatment, and particularly discloses a kitchen waste treatment process with reclamation, harmlessness and reduction. In the aspect of reclamation, the composition of nutrient ingredients of kitchen waste is fully taken into account, and main ingredients such as starch, free sugar, oil and fat, proteins, cellulose and inorganic salt are collected in classification and converted as much as possible; in the aspect of harmlessness, pollution and hazards possibly caused by kitchen waste are fully taken into account for a plurality of technical improvements; in the aspect of reduction, firstly, no water is added in the pretreatment stage, then various products and byproducts such as carbon dioxide, oil and fat, ethyl alcohol, vinasse and vinasse waste fluid are gradually separated in the technical process so as to fulfill the purpose of full reduction, and remaining water is recycled after evaporation purification, so that the reduction effect is obvious. The kitchen waste treatment process disclosed by the invention has environment-friendly and low-carbon effects.

Owner:GUANGDONG RECYCLEAN LOW CARBON TECH CO LTD

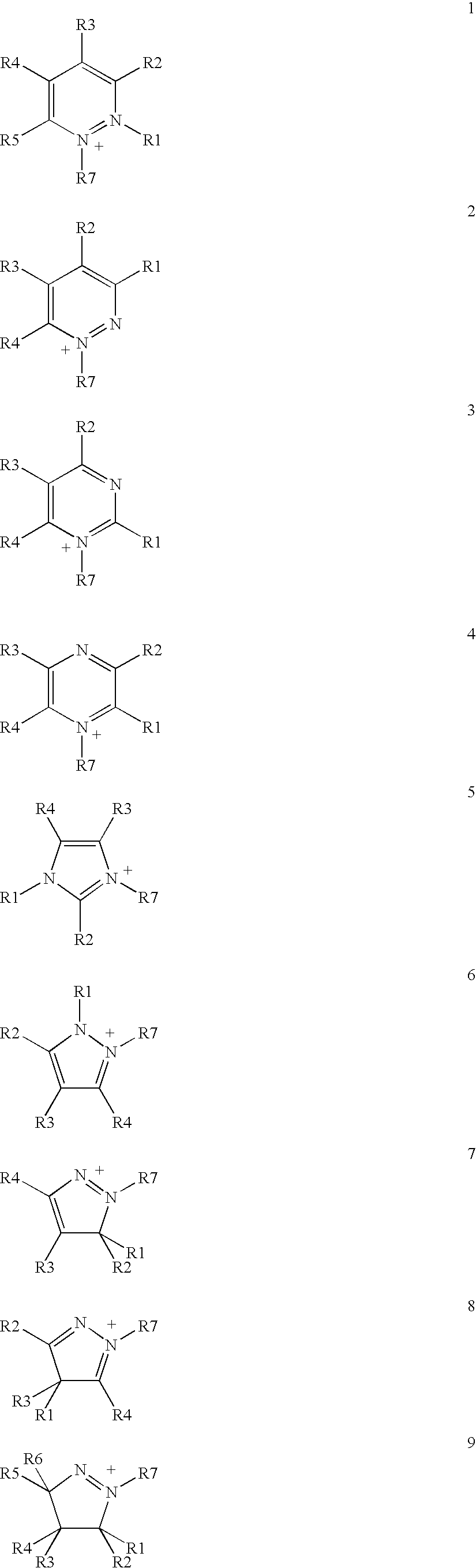

Method for preparing carbonyl sulfide removal ionic liquid mixtures

PendingCN108325338AEfficient removalImprove solubilityProductsGas treatmentEvaporation PurificationAlcohol

The invention relates to a method for preparing carbonyl sulfide removal ionic liquid mixtures. The method particularly includes dropwise adding halogenated hydrocarbon compounds B into nitrogen-containing organic compounds A under the constant pressures, carrying out sufficient reaction, and then carrying out vacuum rotary evaporation purification, washing and drying to obtain C+X- ionic liquid;mixing alcohol amine solution, the prepared ionic liquid, absorption reinforcing agents and water with one another to obtain the carbonyl sulfide removal ionic liquid mixtures. A molar ratio of the nitrogen-containing organic compounds A to the halogenated hydrocarbon compounds B is 1:1-1:3. C+ of the C+X- ionic liquid represents nitrogen-containing cations, and X- of the C+X- ionic liquid represents halogen anions. The carbonyl sulfide removal ionic liquid mixtures comprises, by weight, 10wt%-30wt% of ionic liquid, 10wt%-50wt% of alcohol amine solution, 15wt%-50wt% of absorption reinforcing agents and the balance water. The method has the advantage that the carbonyl sulfide removal rate of the carbonyl sulfide removal ionic liquid mixtures prepared by the aid of the method can reach 80%-99.5%.

Owner:NORTHEAST GASOLINEEUM UNIV

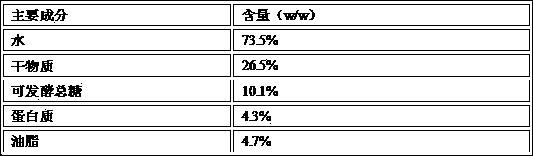

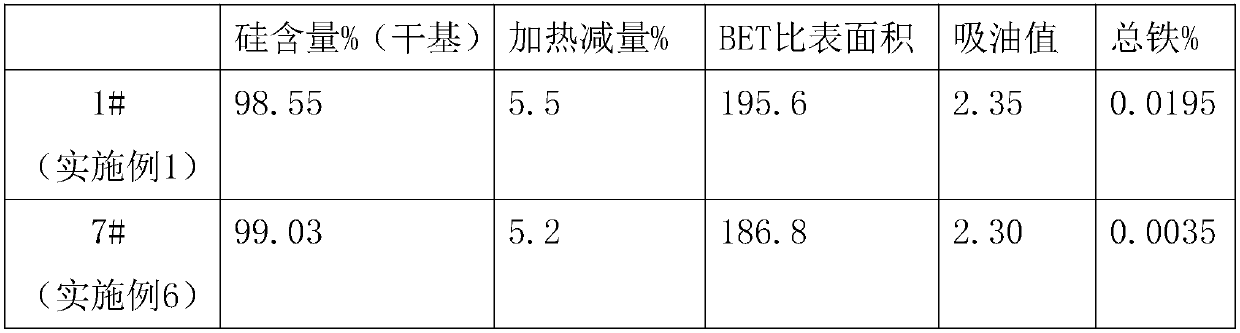

Green and environment-friendly white carbon black and caustic soda circulation combined production method

ActiveCN109678164AReduce manufacturing costHigh economic valueSilicaElectrolysis componentsEvaporation PurificationElectrolysis

The invention discloses a green and environment-friendly white carbon black and caustic soda circulation combined production method. The method comprises the following steps: (1), performing a reaction on sodium silicate and hydrochloric acid to obtain a silica precipitation filter cake and a sodium chloride solution; (2), washing and slurrying the silica precipitation filter cake, and performingdrying, crushing and packaging to obtain a finished white carbon black product; (3), treating the sodium chloride solution by an RO membrane twice to obtain a sodium chloride solution with concentration of 12%; (4), performing multi-effect evaporation purification on the sodium chloride solution with concentration of 12% to obtain a sodium chloride solution with concentration of 36%; (5), electrolyzing the sodium chloride solution with concentration of 36% to obtain sodium hydroxide, hydrogen and chlorine, and illuminating hydrogen and chlorine to obtain hydrochloric acid; (6), adding quartz sand to sodium hydroxide for a reaction to generate sodium silicate; (7), adding hydrochloric acid to sodium silicate to prepare white carbon black again. By combined production and recycling, zero emission of water can be basically realized, production cost and environmental protection cost are greatly reduced, and the method is a good method for industrial production of the white carbon black.

Owner:江西双龙硅材料科技有限公司

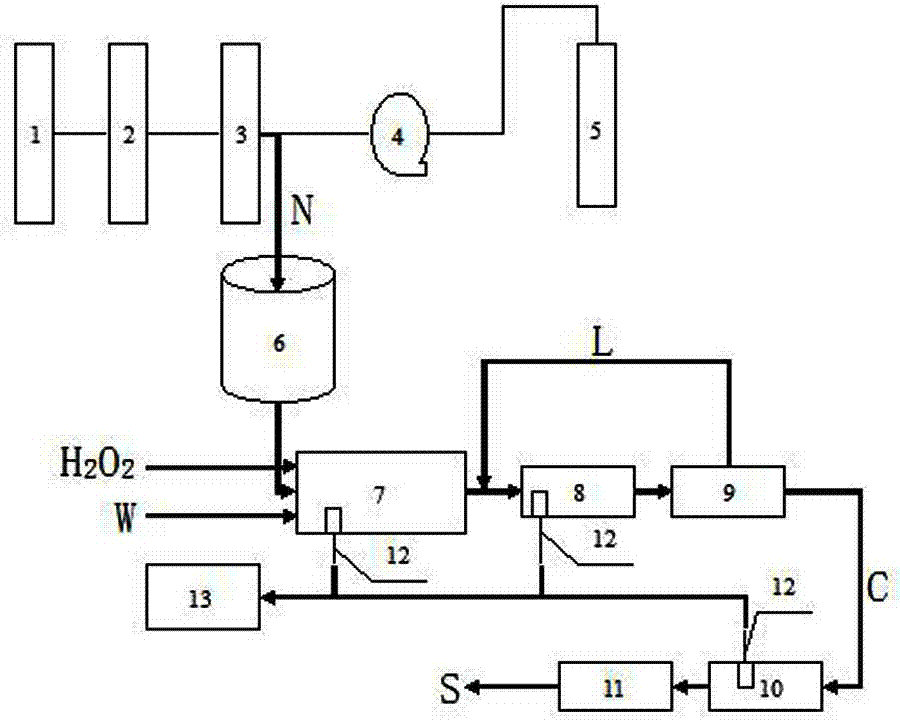

Production method of electronic-grade sulfuric acid

ActiveCN112320768ATake advantage ofIncrease profitEvaporator accessoriesDispersed particle separationEvaporation PurificationOleum

The invention discloses a production method of electronic-grade sulfuric acid, and belongs to the technical field of electronic chemical production. The production method comprises the steps of normal-temperature absorption and conversion, negative-pressure low-temperature evaporation, low-temperature absorption and heating degassing, sulfur trioxide in furnace gas is absorbed by concentrated sulfuric acid to obtain fuming sulfuric acid through normal-temperature absorption and conversion, and then the fuming sulfuric acid is oxidized and converted by a hydrogen peroxide aqueous solution; thenegative-pressure low-temperature evaporation is to evaporate sulfur trioxide gas under the condition that liquid is not boiled by an evaporation purification device under the condition that low-temperature hot water with the temperature lower than 50 DEG C is used as a heating medium; the low-temperature absorption is that ultrapure water or ultrapure sulfuric acid is used for absorption at a lowtemperature the temperature-increasing degassing is a process of removing gas in the liquid at a temperature slightly higher than the normal temperature. According to the production method, high-quality electronic-grade sulfuric acid can be obtained, and the operation safety is ensured while the yield and the efficiency are ensured.

Owner:LIANSHI NEW MATERIAL CORP LTD

Method for producing urea peroxide

ActiveCN104725281AReduce granulationReduce packaging linksUrea derivatives preparationOrganic compound preparationEvaporation PurificationPolyethylene glycol

The invention provides a method for producing urea peroxide. The method comprises the following steps: introducing molten urine into a dissolving tank after urine from a urea synthesizing tower is subjected to primary and secondary evaporation purification, and preparing a urea saturated solution from the urine; then, adding into a tubular reactor by virtue of a metering pump, and simultaneously adding hydrogen peroxide having concentration of 30 percent or above and a stabilizing agent which is 1-2 percent of the mass of urea into the reactor, wherein the stabilizing agent is prepared by mixing monopotassium phosphate and polyethylene glycol in a ratio of 1:1; reacting the urea, hydrogen peroxide and the stabilizing agent in the tubular reactor to generate a urea peroxide solution; cooling the solution by virtue of a cooler, and separating out the urea peroxide crystal, centrifuging the mixed liquid by virtue of a centrifugal machine to remove urea peroxide mother liquor; drying the urea peroxide crystal in a drier to prepare a urea peroxide product, packaging and warehousing. According to the method, urea and urea peroxide can be co-produced, continuous production can be realized, yield can be greatly improved, product stability is high, and raw material cost can be reduced.

Owner:SICHUAN MEIFENG CHEM IND

Method for recycling potassium chloride electrogalvanizing waste bath solution by normal-temperature evaporation method

PendingCN112499862AAvoid pollutionLess investmentZinc halidesTreatment involving filtrationActivated carbonActivated charcoal powder

The invention provides a method for recycling potassium chloride electrogalvanizing waste bath solution by a normal-temperature evaporation method. The method comprises the following steps: 1, pretreating a bath solution, specifically adding 5-10ml / L of hydrogen peroxide, conducting mechanical stirring for 30 minutes, conducting heating to 60-70 DEG C, keeping the temperature for 2-4 hours, adding2-5g / L of activated carbon powder, conducting mechanical stirring for 30 minutes, conducting standing for 4-8 hours, and conducting filtering to a clear state; and 2, pumping the pretreated bath solution into natural evaporation equipment by using a pump, and carrying out evaporation purification, wherein the natural evaporation equipment is formed by connecting platforms in parallel and in series, the platforms are formed by paving a plurality of soft PVC plates on flat ground or a tray formed by iron plates, pipelines and pumps are used for connection, and the natural evaporation equipmentis similar to a seawater salt drying device. According to the method for recycling the potassium chloride electrogalvanizing waste tank liquid through the normal-temperature evaporation method, the generated potassium chloride electrogalvanizing waste liquid is completely recycled, environmental pollution is avoided, investment is small, and the operation cost is low.

Owner:杨耀东

Continuous preparation method of ultra-clean high-purity hydrogen peroxide

PendingCN113526470AHigh purityEasy to usePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesEvaporation PurificationDivinylbenzene

The invention discloses a continuous preparation method of ultra-clean high-purity hydrogen peroxide, which comprises the following operation steps: selecting a certain amount of industrial-grade hydrogen peroxide, a certain amount of styrene monomer, a certain amount of divinylbenzene monomer, a certain amount of toluene organic solvent and a certain amount of filler; preparing the styrene monomer, the divinylbenzene monomer, the toluene organic solvent and the filler into a porous resin adsorption material body through a suspension copolymerization method,enabling industrial-grade hydrogen peroxide to sequentially pass through the porous resin adsorption material body, a cation exchange column and an anion exchange column at the flow speed of 280-460 L / H and then filtering circularly by a 0.1-micron filter element, and obtaining primarily purified hydrogen peroxide. According to the continuous preparation method of the ultra-clean high-purity hydrogen peroxide, feeding operation can be carried out in a pumping mode, the feeding amount is convenient to control, continuous preparation operation can be carried out, the preparation efficiency is improved, constant-temperature evaporation purification treatment is carried out under the low-temperature condition, the purity of hydrogen dioxide is improved, and the using effect is more excellent.

Owner:SUZHOU CRYSTAL CLEAR CHEMICAL CO LTD

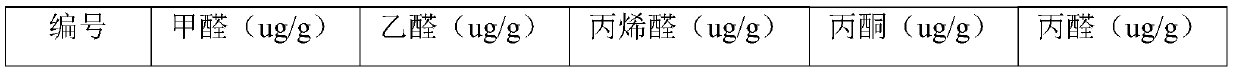

Method for reducing content of volatile organic compounds in polyether polyol

The invention belongs to the technical field of chemical synthesis, and particularly relates to a method for reducing the content of volatile organic compounds in polyether polyol. The method comprises the steps: adding polyether polyol to be treated into a reaction kettle, carrying out nitrogen replacement, stirring, heating, adding an aldehyde removal agent into the reaction kettle under the protection of nitrogen, carrying out nitrogen replacement after the addition is finished, continuously stirring for 10-120 minutes, respectively adding pure water and a refined adsorbent, stirring, drying, and filtering to obtain the finished product, wherein the aldehyde removing agent is composed of an aldehyde removing agent A, an aldehyde removing agent B and an auxiliary agent C, the addition amount of the aldehyde removing agent is 0.001-0.05% of the mass of the polyether polyol to be treated, and the mass ratio of the aldehyde removing agent A to the aldehyde removing agent B to the auxiliary agent C is 1:1:1-1:5:50. According to the method, aldehyde ketone substances in the polyether polyol to be treated are directly oxidized and decomposed into small molecular substances or removed through esterification reaction by a chemical reaction method, and the volatile organic compounds can be effectively removed through nitrogen bubbling evaporation purification and physical adsorption.

Owner:SHANDONG BLUSR DONGDA CHEM

Preparation method of tara modified zirconium complex tanning agent and tanning agent prepared by preparation method

ActiveCN106755632ATanningGood shrinkage temperatureTanning treatmentEvaporation PurificationAqueous sodium hydroxide

The invention relates to a preparation method of a tara modified zirconium complex tanning agent. The preparation method of the tara modified zirconium complex tanning agent comprises the following processing steps: one, a tanning extract is dissolved in water and tara initial mixed liquor is obtained; two, the tara initial mixed liquor obtained in the step one is centrifuged, and supernatant is obtained; three, the supernatant in the step two is subjected to rotary evaporation purification; four, a solution in the step three is transferred to a reaction kettle, a sodium hydroxide aqueous solution is added, a pH value of the solution is adjusted to be greater than 7, heat preservation is carried out for half an hour, then a hydrogen peroxide solution is added, and the solution is kept in an alkaline environment; five, under ordinary pressure, temperature reaction happens, then cooling to room temperature is carried out; and six, a pH value of the solution is adjusted with dilute sulphuric acid, a tetravalent zirconium salt aqueous solution is added, heating-up is carried out, then cooling and discharge are carried out, and a required product is obtained. With the adoption of the technical scheme, the prepared tara modified zirconium complex tanning agent is good in comprehensive performance, is environmental-friendly, and has the advantages of retaining the tanning property of a zirconium metal tanning agent and the selective filling property of a tanning extract degraded product simultaneously, and the like, so that the problem that a chromium type tanning agent has pollution to the environment is solved.

Owner:WENZHOU UNIVERSITY

Umbilical region dropping liquid for eliminating dampness and reducing weight and preparation method thereof

InactiveCN113521143AAvoid side effectsImprove absorption rateMetabolism disorderPharmaceutical delivery mechanismEvaporation PurificationAllergy

The invention discloses an umbilical region dropping liquid for eliminating dampness and reducing weight and a preparation method thereof, and belongs to the technical field of dampness-eliminating and weight-reducing herbal extracting solutions. The Umbilical region dropping liquid comprise the following components: pericarpium citri reticulatae, poria cocos, lotus leaves, semen cassiae and the like. The preparation method comprises the steps of raw material crushing, ethanol soaking, ethanol percolation, evaporation purification, ultrasonic activation, blending and further activation. At present, oral weight-reducing medicines in the market can damage bodies to different degrees, external medicines also have allergy phenomena, and the dampness-clearing weight-reducing umbilical region dropping liquid have no side effects, are quickly absorbed, have good fat-reducing effects and are particularly suitable for abdominal weight loss.

Owner:辽宁乾源健康管理有限公司

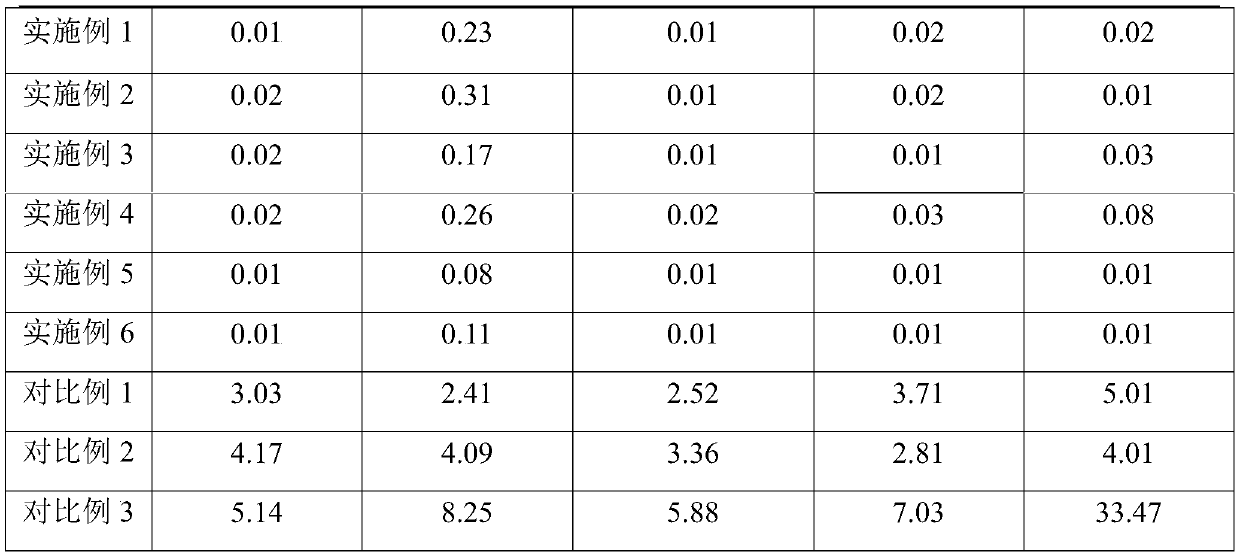

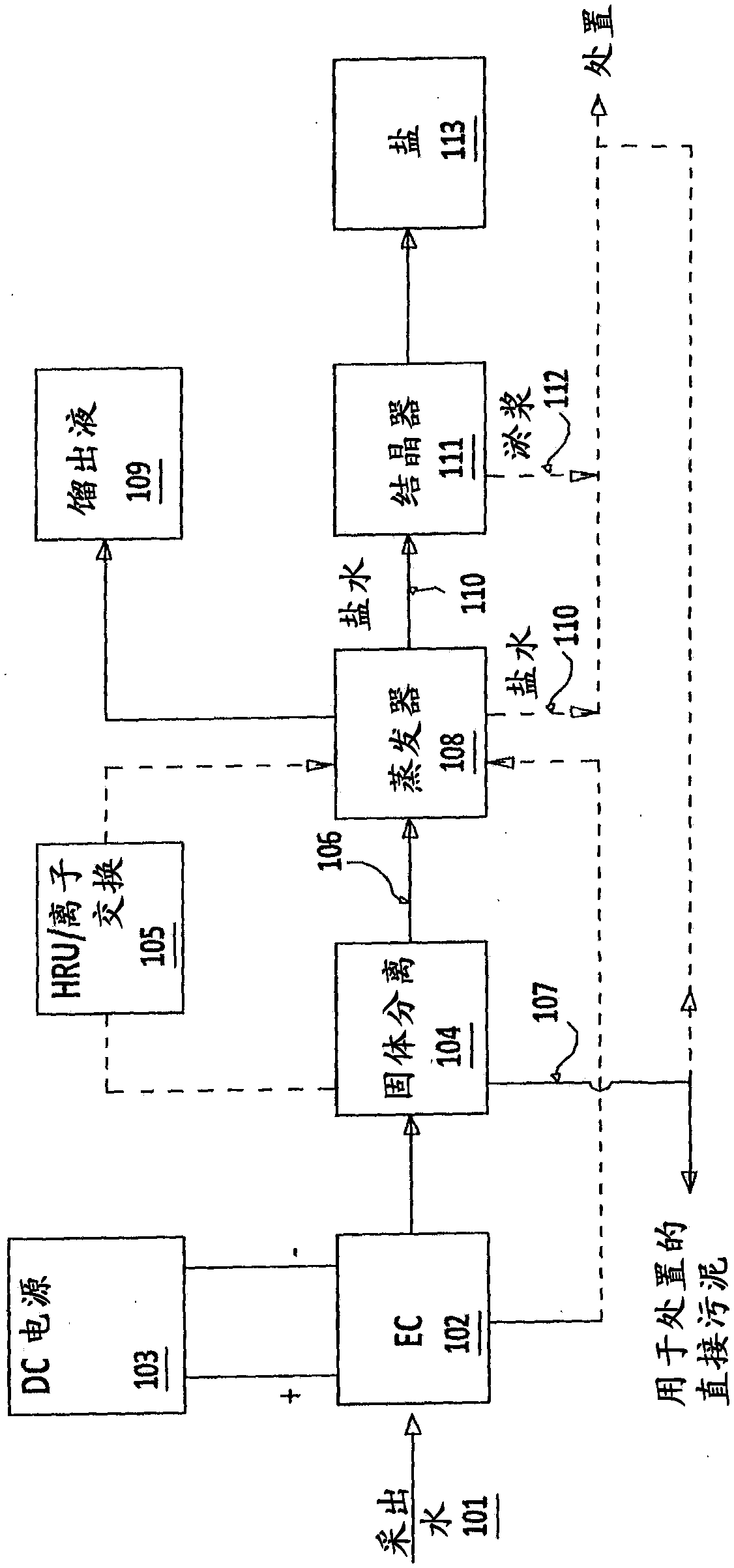

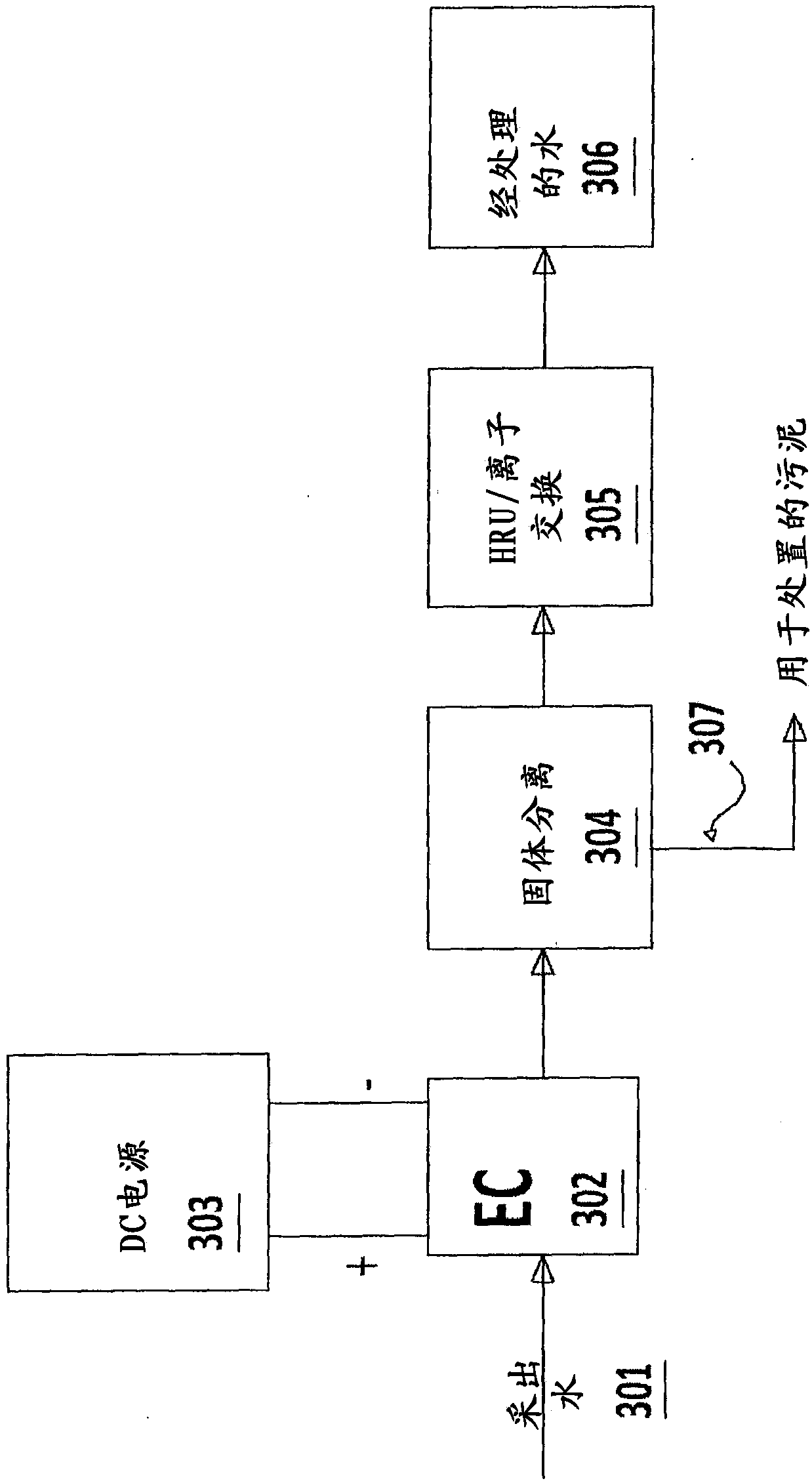

Water treatment process

InactiveCN108275820AContinuous removalContinuous electrocoagulation stepWaste water treatment from quariesWater contaminantsEvaporation PurificationElectrocoagulation

A process for enhanced removal of impurities from water by an enhanced multi-step electrocoagulation process including electrocoagulation, solids separation, hardness removal, crystallization, and, optionally, reverse osmosis and evaporative purification. Embodiments of the invention may remove multiple impurities at substantial savings in time, energy, and chemical use. Zero liquid discharge options are also reported.

Owner:AQUATECH INT LLC

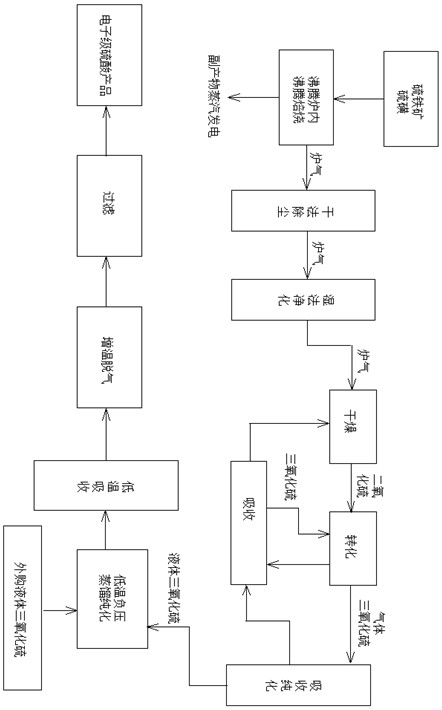

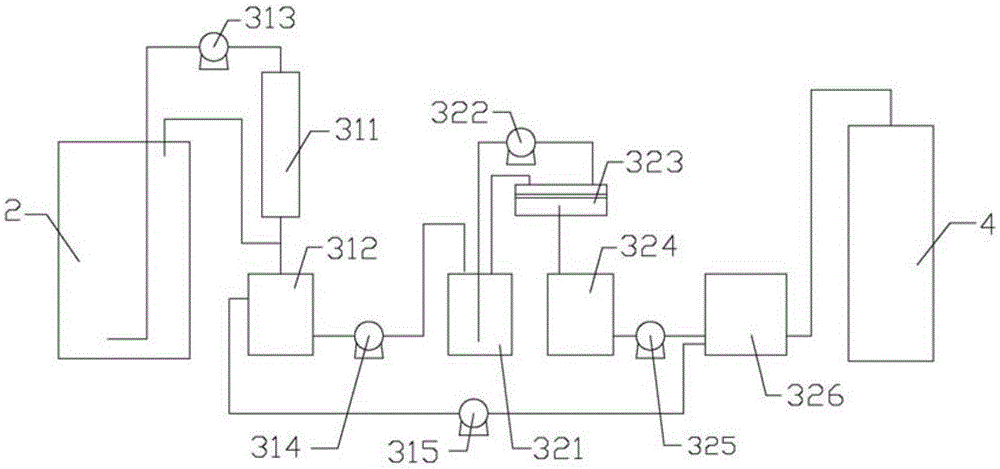

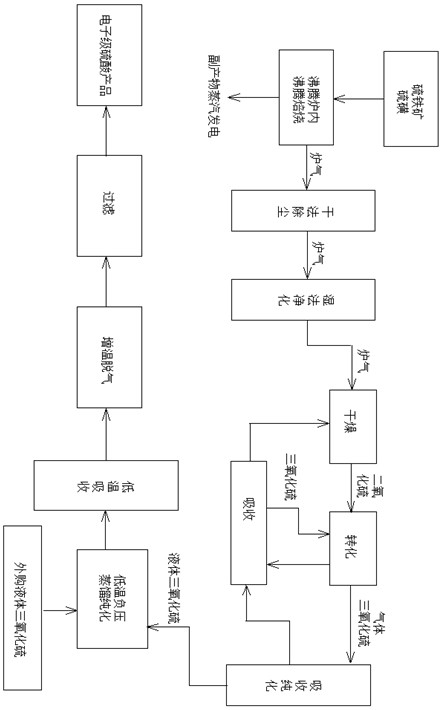

System and method for producing C5-C19 alkyl ketones

InactiveCN105567551AAchieve entryAchieve continuous productionBioreactor/fermenter combinationsBiological substance pretreatmentsEvaporation PurificationKetone

The invention relates to a system and method for producing C5-C19 alkyl ketones, belonging to the technical field of biochemical engineering. The system comprises a fermentation apparatus, a product separation and purification device and a chemical catalytic unit, wherein the fermentation apparatus is connected with the chemical catalytic unit through the product separation and purification device; and the product separation and purification device is composed of at least one of a gas stripping purification device, a pervaporation membrane purification device, an adsorptive purification device, a steam penetration purification device, a liquid-liquid extraction purification device, a centrifugal device, a multi-effect evaporation purification device and a rectification purification device. By using the system and method, industrial sugar-containing waste molasses or agricultural waste straws can be converted into C5-C19 long-chain alkyl ketones under the biological catalytic and chemical catalytic actions, and the C5-C19 long-chain alkyl ketones can be used as gasoline, diesel or aviation fuel directly or after being deoxidized.

Owner:DALIAN UNIV OF TECH

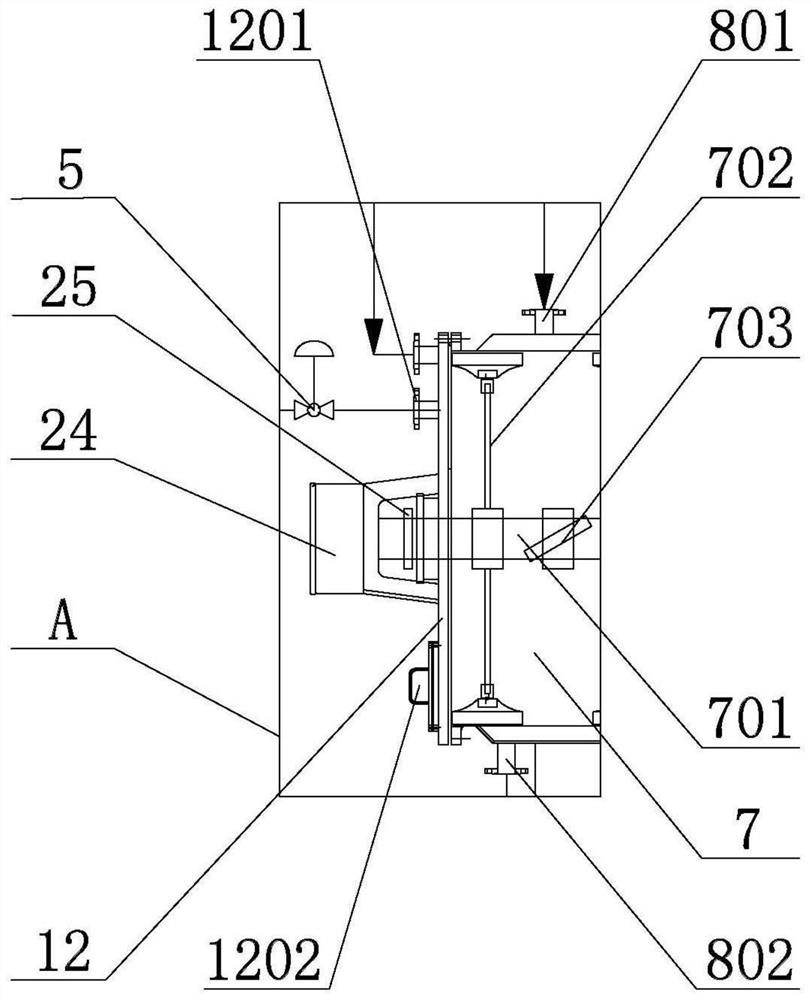

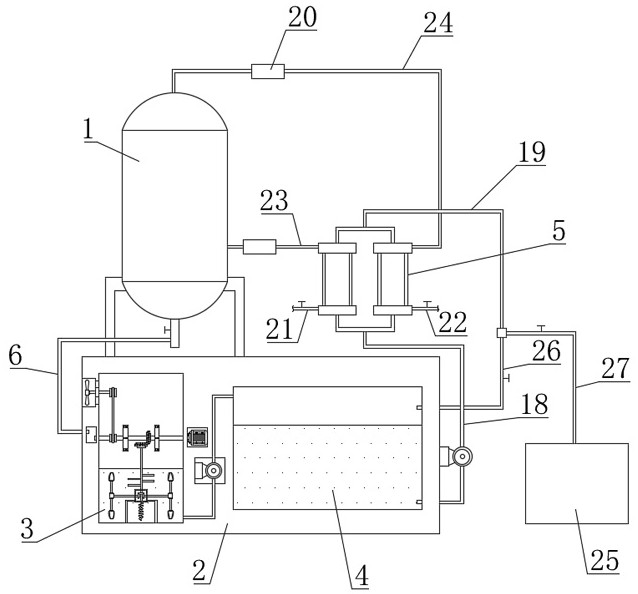

Automatic-cleaned high-concentration waste liquor drying device and use method therefor

PendingCN111977731AEfficient Drying Operation EfficiencyClean in timeSpecific water treatment objectivesHollow article cleaningEvaporation PurificationAutomatic control

The invention discloses an automatic-cleaned high-concentration waste liquor drying device and a use method therefor. The drying device comprises a charging unit, an evaporative crystallization unit,an evaporative purification unit, a vacuum unit and an automatic control unit which are sequentially connected, wherein the evaporative crystallization unit at least comprises a tubular shell body, anautorotatable main shaft is coaxially arranged inside the shell body, a group of combined scrapers which synchronously rotate along with the main shaft are arranged on the main shaft in an annular manner, the shell body and the evaporative purification unit communicate with a cleaning unit through pipelines, the cleaning unit at least comprises a cleaning water tank and a cleaning centrifugal pump, the cleaning water tank is at least connected with one dosing tank, and the automatic control unit can control the cleaning unit to automatically start up the cleaning water tank and / or the dosingtank for clean water cleaning and / or agent cleaning. According to the automatic-cleaned high-concentration waste liquor drying device and the use method therefor, disassembly-free online cleaning canbe carried out by using clean water or preparing a detergent, and thus, the evaporative crystallization unit and the evaporative purification unit can maintain efficient drying operating efficiency.

Owner:常州乐研分离技术有限公司

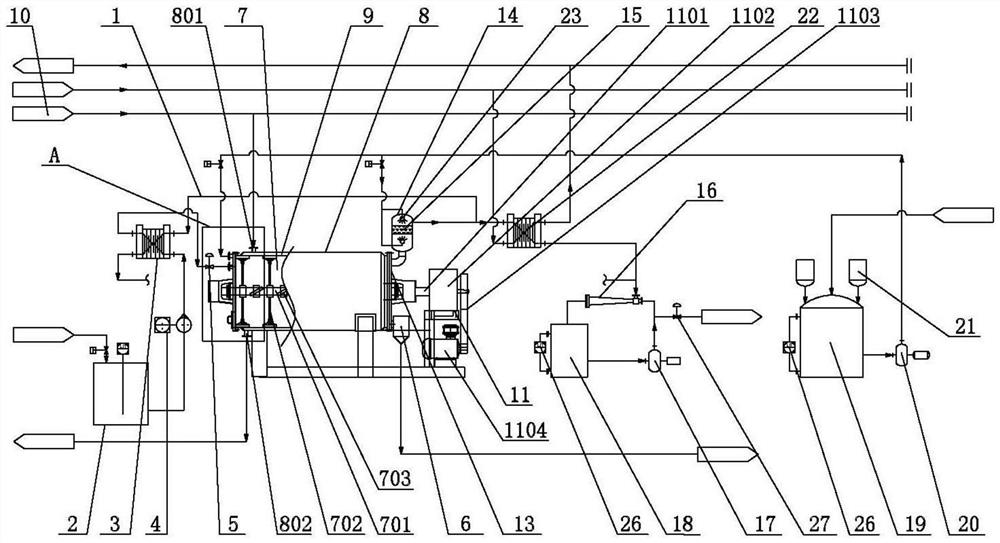

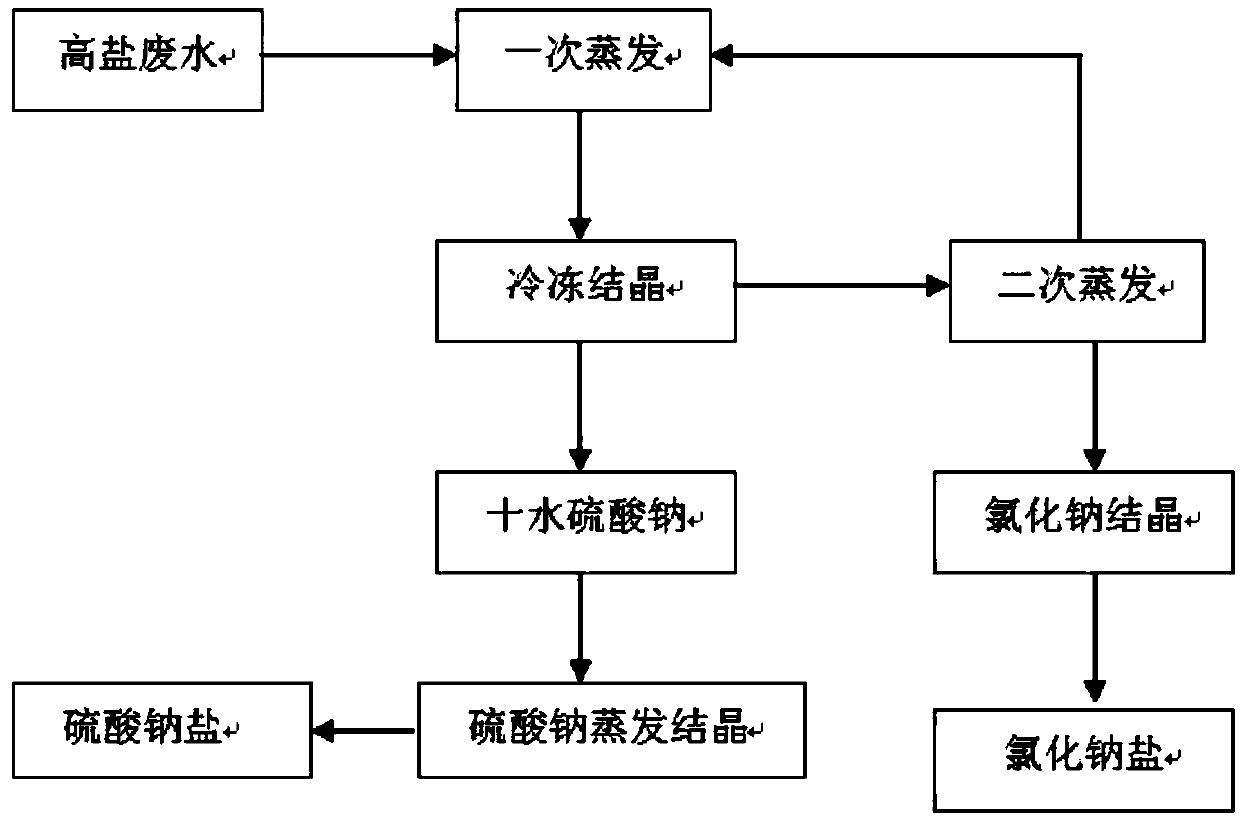

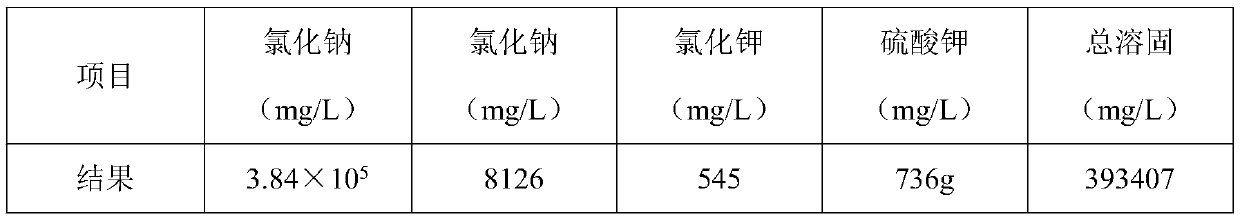

Salt separation evaporation crystallization and purification method

InactiveCN110152340AGuaranteed puritySalt realizationAlkali metal sulfite/sulfate purificationSolution crystallizationEvaporation PurificationPurification methods

The invention discloses a salt separation evaporation crystallization and purification method, which comprises four steps of primary evaporation, freezing crystallization, evaporation purification andsecondary evaporation. The method realizes the salt separation of sodium sulfate and sodium chloride from printing and dyeing high-salt waste water, and ensures the purity of the sodium sulfate and the sodium chloride, wherein the purity of the sodium sulfate is more than or equal to 99%, the purity of the sodium chloride is more than or equal to 98%, and the produced salts can be reused in industrial production, finally no waste water and solid waste are discharged, and true zero emission is realized.

Owner:XINJIANG ENVIRONMENTAL ENG TECH

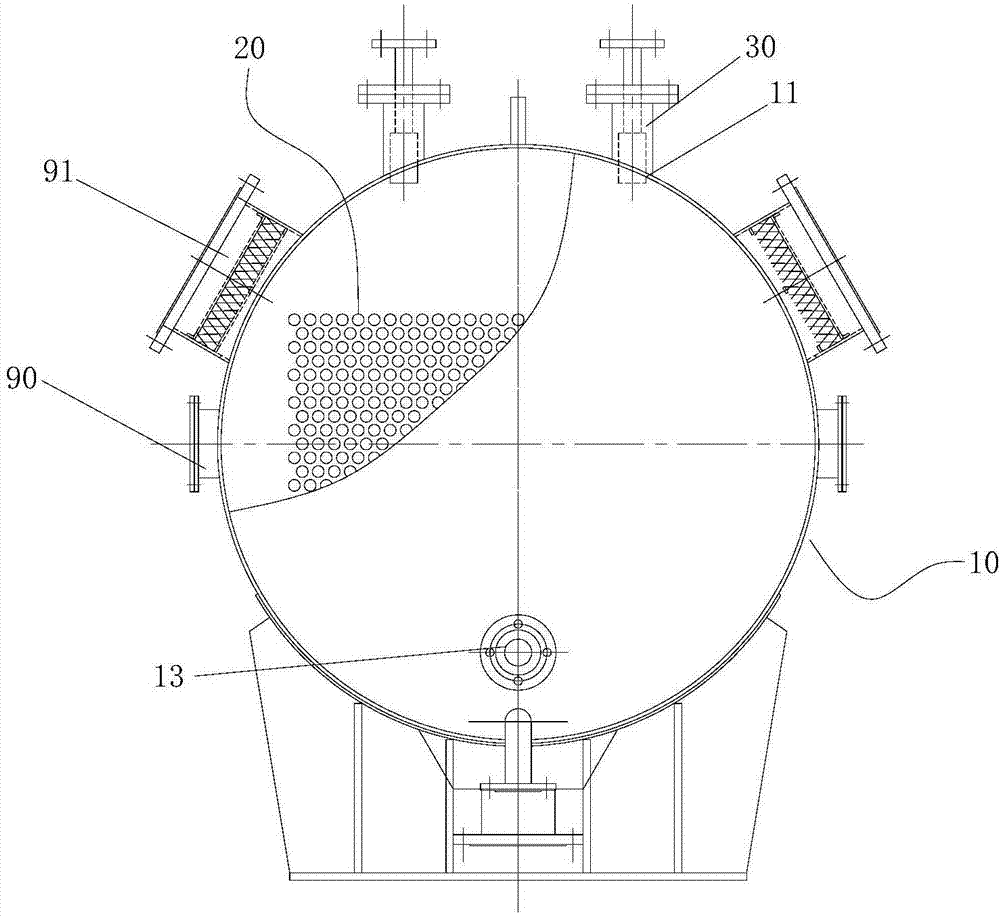

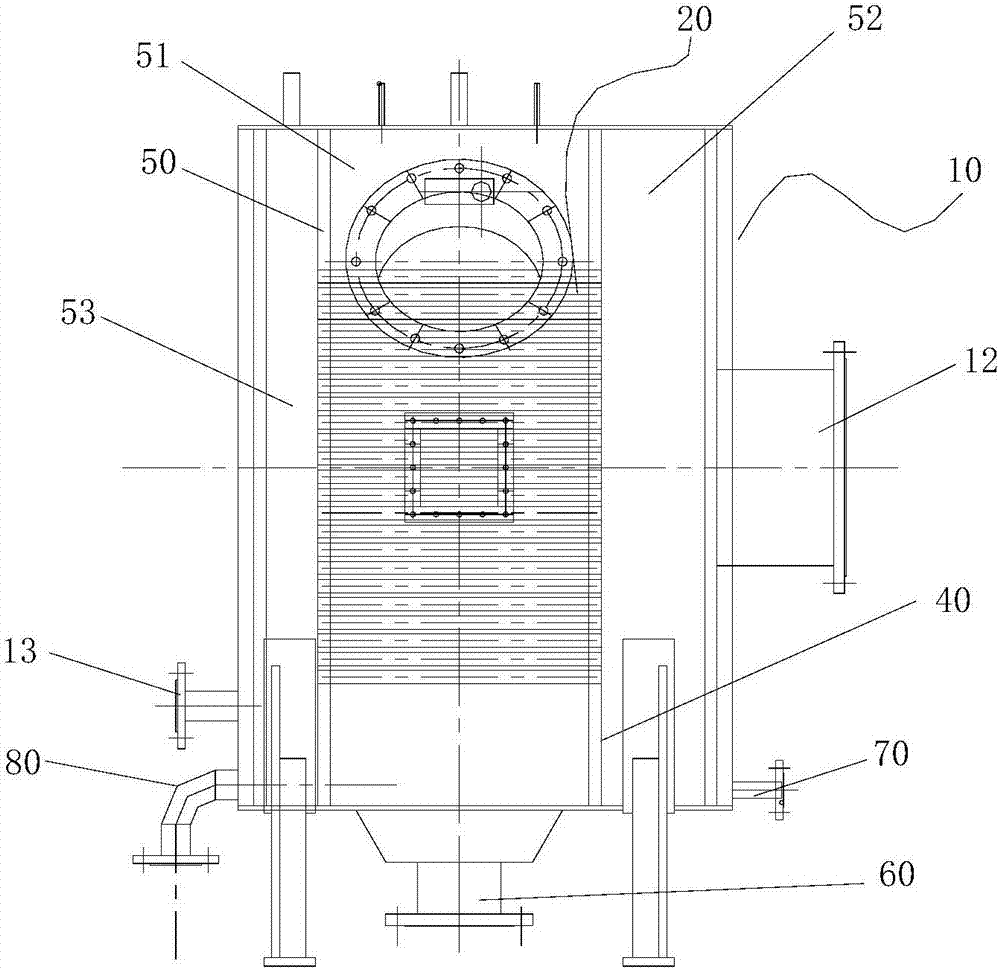

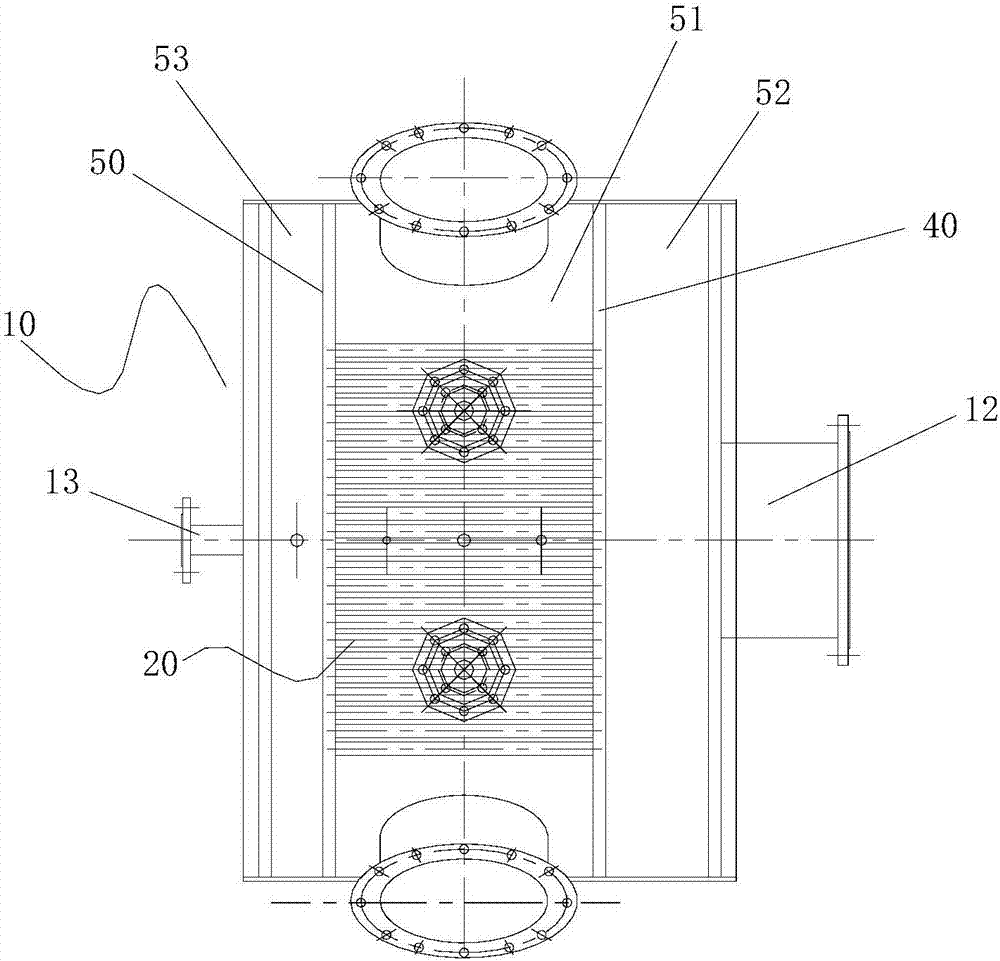

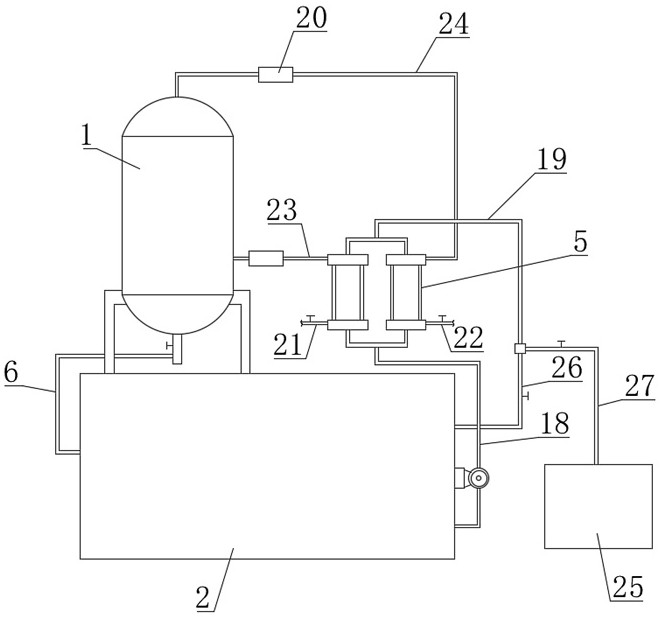

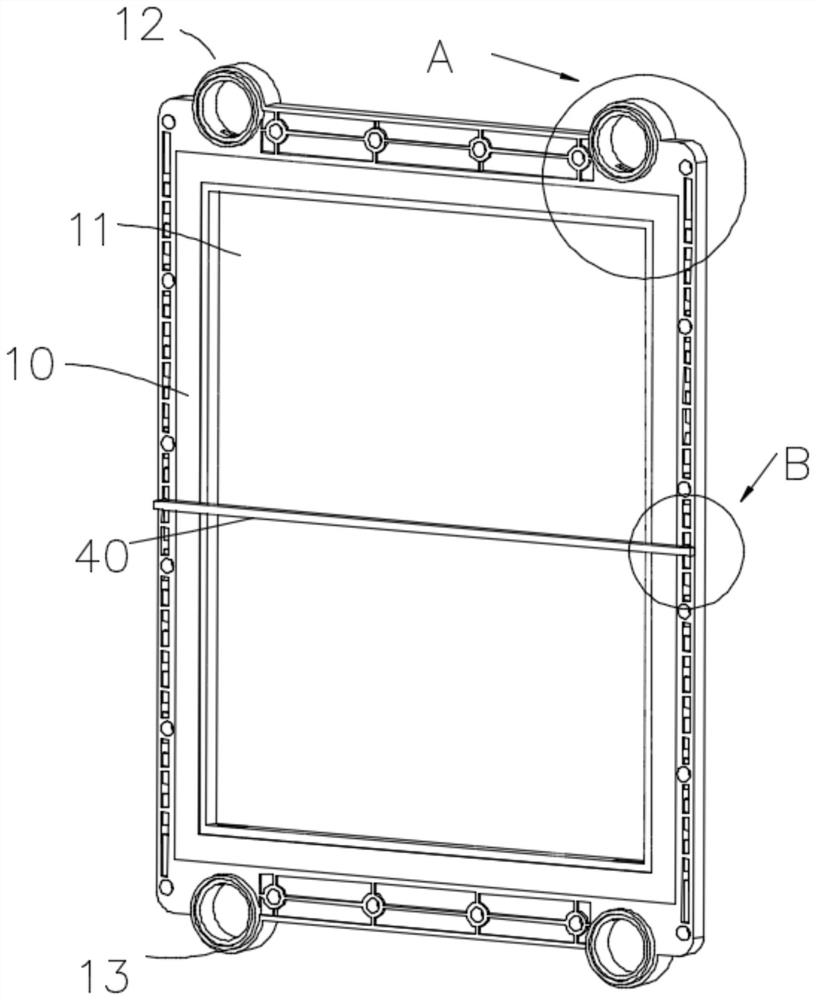

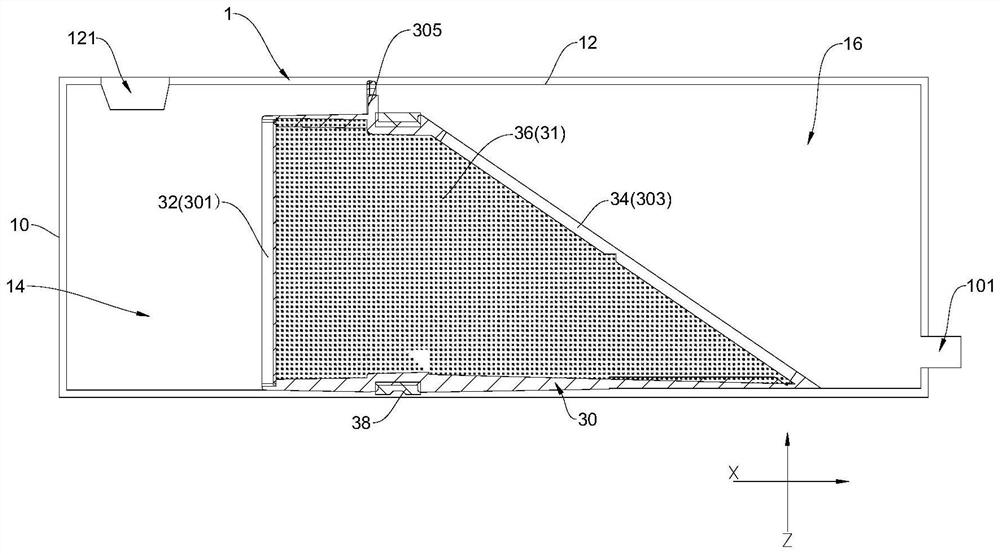

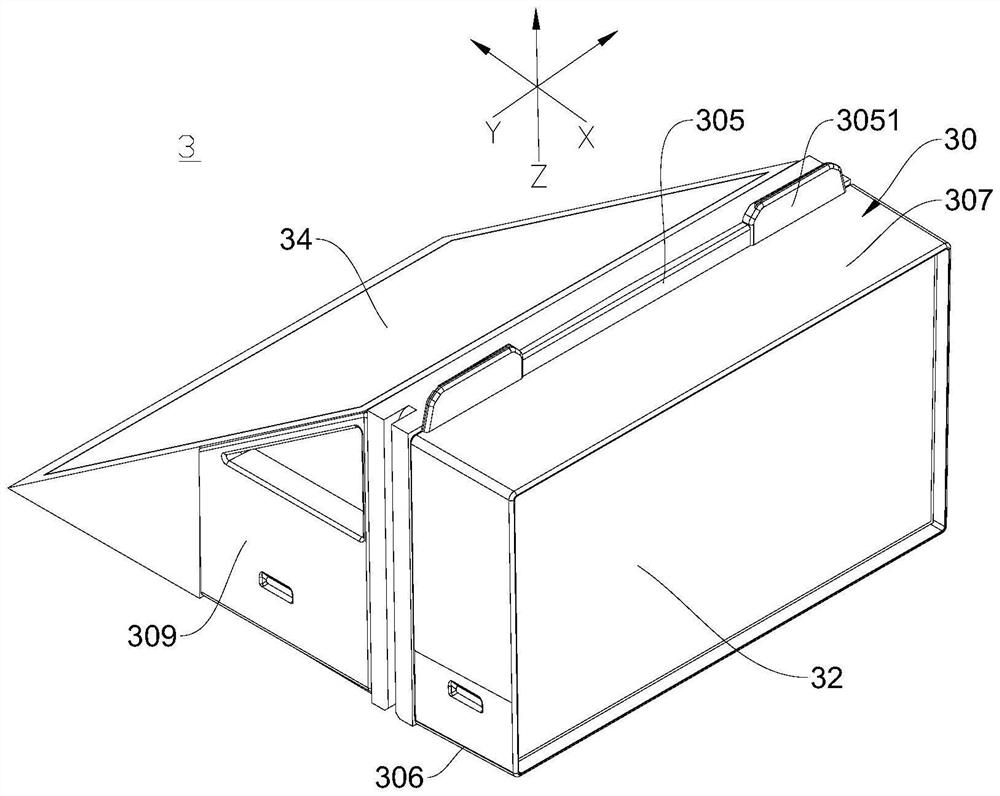

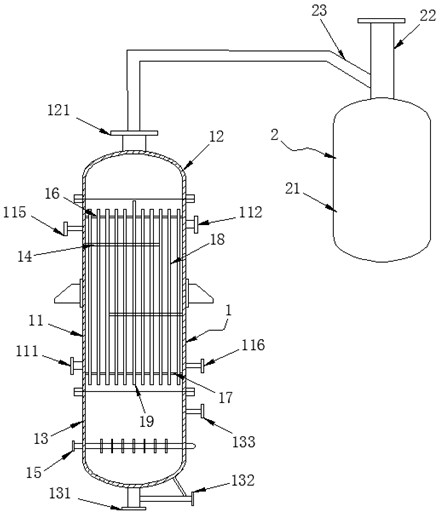

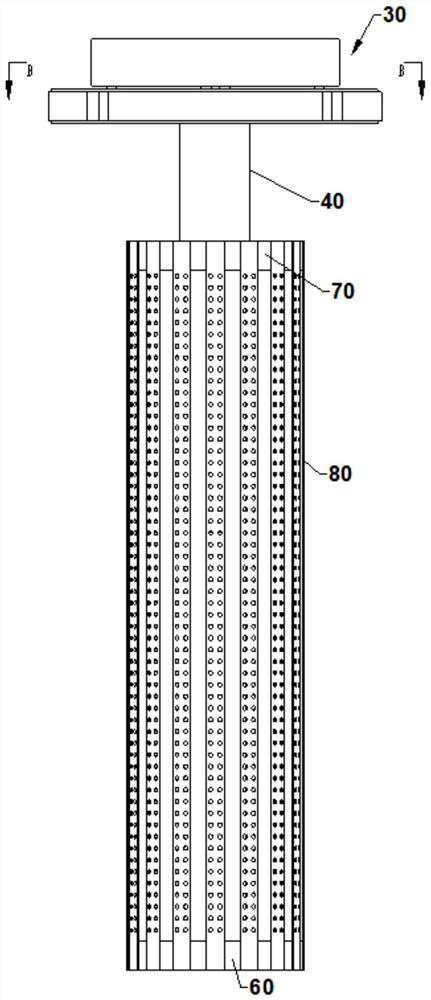

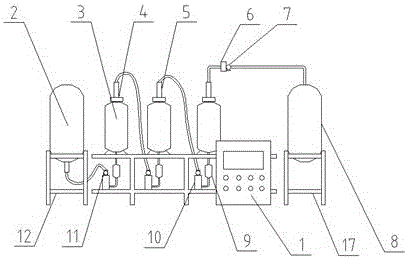

Evaporating purification device

PendingCN106865662AAvoid foulingImprove efficiencyGeneral water supply conservationWater/sewage treatment by heatingEvaporation PurificationThermodynamics

The invention provides an evaporating purification device. The evaporating purification device comprises a main body, a heat exchange part and a liquid distribution part, wherein the interior of the main body is provided with an accommodation space; a waste liquid inlet is arranged on the main body; the waste liquid inlet communicates with the upper part of the accommodation space; the heat exchange part is arranged inside the accommodation space and used for supplying heat for a waste liquid in the accommodation space; and the liquid distribution part is arranged at the waste liquid inlet and used for uniform liquid distribution. When the evaporating purification device works, the waste liquid enters the accommodation space from the waste liquid inlet, and uniform liquid distribution is realized through the liquid distribution part arranged at the waste liquid inlet, so the waste liquid uniformly contacts with the heat exchange part and is evaporated in real time; the phenomenon of scaling of partial positions of the heat exchange part due to nonuniform liquid distribution is effectively avoided; and the efficiency of purifying wastewater is improved.

Owner:CHINA ENFI ENGINEERING CORPORATION

Processing device for producing propylene glycol and use method thereof

InactiveCN113499745AShorten the heating timeStable temperatureEvaporator accessoriesPreparation by OH group eliminationEvaporation PurificationGlycerol

The invention belongs to the technical field of propylene glycol production, and aims to solve the problems of low synthesis efficiency, incapability of integrating synthesis and dehydration operation of propylene glycol and poor use effect due to the fact that heating of hydrogen and a glycerol solution needs a certain time in the conventional propylene glycol processing device. In particular, the invention provides a processing device for producing propylene glycol and a use method thereof. The processing device comprises a synthesis reaction kettle, the synthesis reaction kettle is fixed to the top of a purification storage box, and an evaporation purification chamber and a heat preservation storage chamber are formed in the purification storage box; through the arrangement of the preheating assembly, heat in a propylene glycol solution can be effectively utilized, hydrogen and glycerin can be preheated, the heating time of the hydrogen and glycerin solution in the synthesis reaction kettle is shortened, and the synthesis efficiency is improved; the stirring assembly, the exhaust assembly and the structure for spraying the propylene glycol solution are combined, so that evaporation of water is remarkably accelerated, and the water content of the propylene glycol solution is reduced.

Owner:DONGYING HEBANG CHEM CO LTD

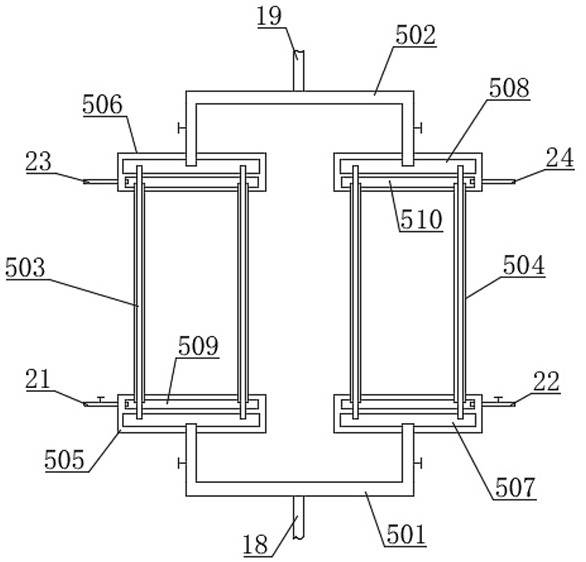

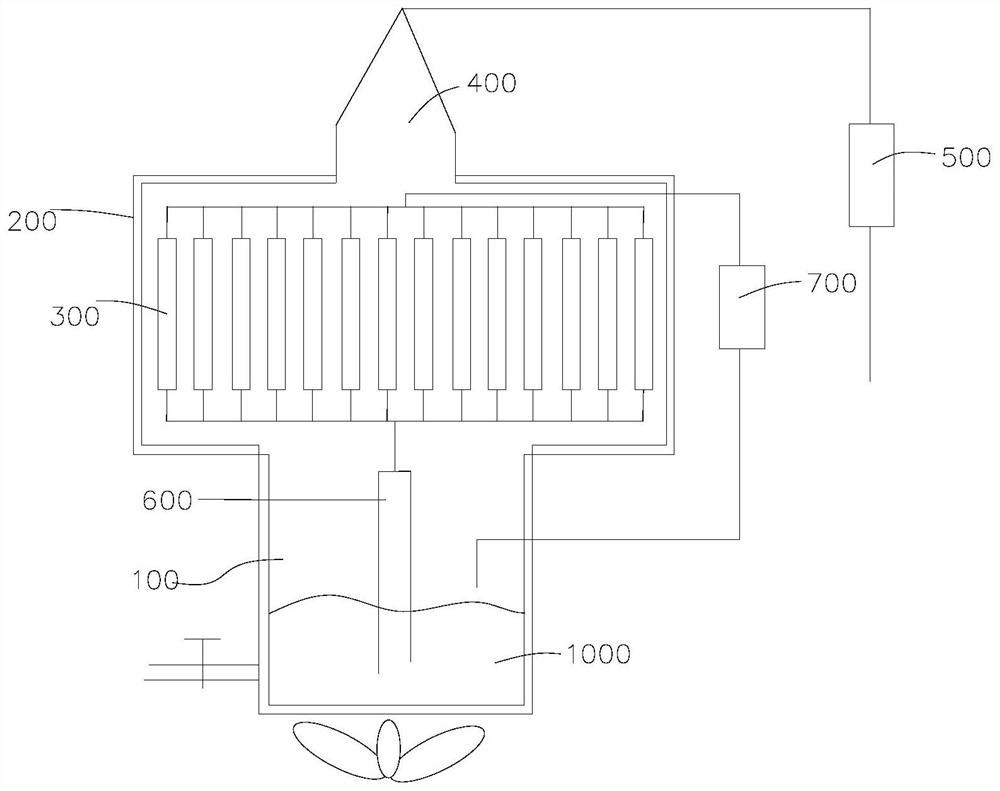

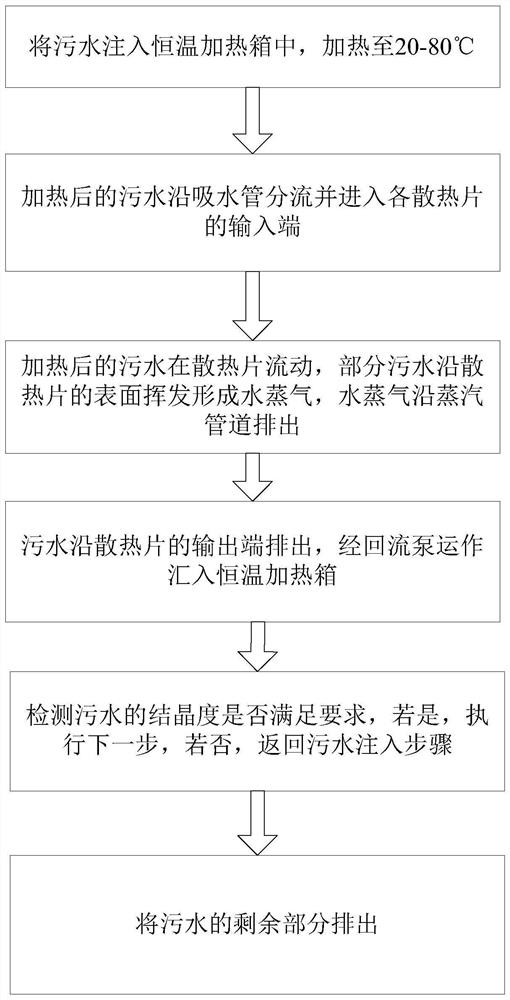

Sewage treatment device and method

ActiveCN111960488AImprove purification effectPrevent evaporationWater contaminantsWater/sewage treatment by heatingEvaporation PurificationThermodynamics

The invention discloses a sewage treatment device which comprises a constant-temperature heating box, an evaporation box, a plurality of cooling fins, a steam pipeline, a condenser, a water suction pipe and a reflux pump, each cooling fin comprises an input end and an output end, the water suction pipe is connected with the input ends of the cooling fins, the output ends of the cooling fins are gathered and communicated with the reflux pump, the constant-temperature heating box heats sewage to be treated to a certain temperature, the pump body drives the water suction pipe to divide the sewageinto a plurality of cooling fins to be evaporated, evaporated gas flows into the condenser along the steam pipeline to be cooled, and unevaporated liquid flows back to the constant-temperature heating box under the action of the reflux pump. The constant-temperature heating box is adopted for heating to a certain temperature, evaporation and purification do not need to be conducted in a high-temperature and high-pressure or negative-pressure mode, on the other hand, organic matter in sewage is prevented from being evaporated at high temperature and high pressure, the sewage purification effect is improved, salt pollutants are precipitated and crystallized in the constant-temperature heating box, and cleaning is convenient. The invention also discloses a sewage treatment method.

Owner:江苏纳易环保科技有限公司

A solar water evaporation purification and decomposition device

ActiveCN107879405BPrevent precipitationHigh photothermal conversion efficiencyGeneral water supply conservationSeawater treatmentEvaporation PurificationThermal insulation

Owner:西安秦盛丰科技有限公司

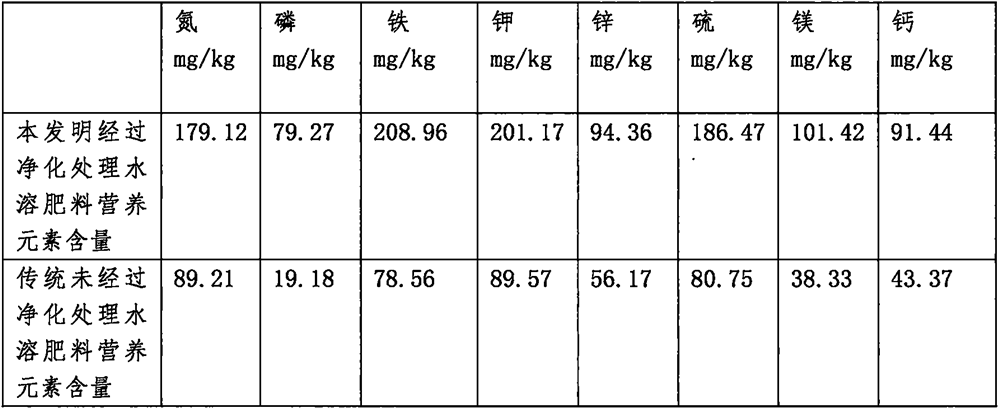

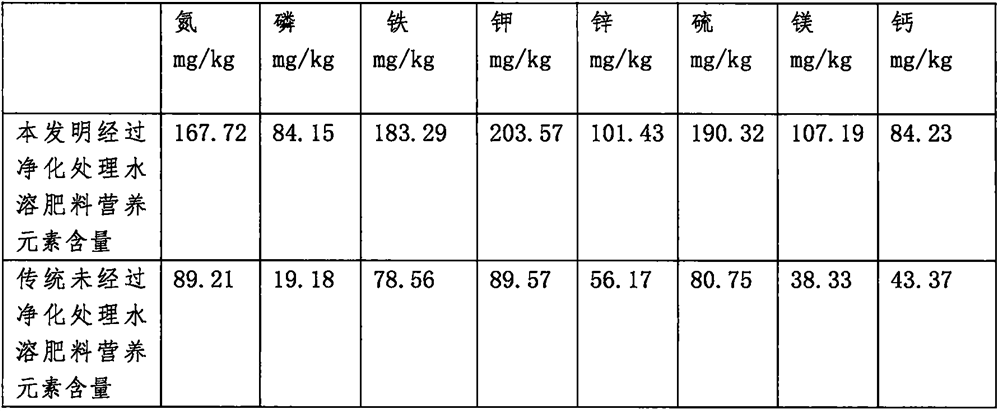

Water-soluble fertilizer purification treatment method

PendingCN114702347AImprove the degree of purificationImprove nutrient qualitySuperphosphatesMagnesium fertilisersEvaporation PurificationEnvironmental engineering

The invention belongs to the technical field of agricultural fertilizers, and particularly relates to a water-soluble fertilizer purification treatment method with few impurities and high purification degree. The water-soluble fertilizer is subjected to evaporation purification treatment twice, so that the water-soluble fertilizer is few in impurities and high in purification degree. Through the processes of evaporating and washing the slurry in the evaporation process and evaporating and condensing the slurry, impurities are effectively removed, the purification degree of the water-soluble fertilizer is improved, and the nutritional ingredients of the water-soluble fertilizer are effectively improved.

Owner:宋志星

Umbilical dropping liquid for reducing weight and preparation method thereof

InactiveCN113230320AAvoid side effectsImprove absorption rateMetabolism disorderPharmaceutical delivery mechanismEvaporation PurificationRadix Astragali seu Hedysari

Owner:韩艺 +1

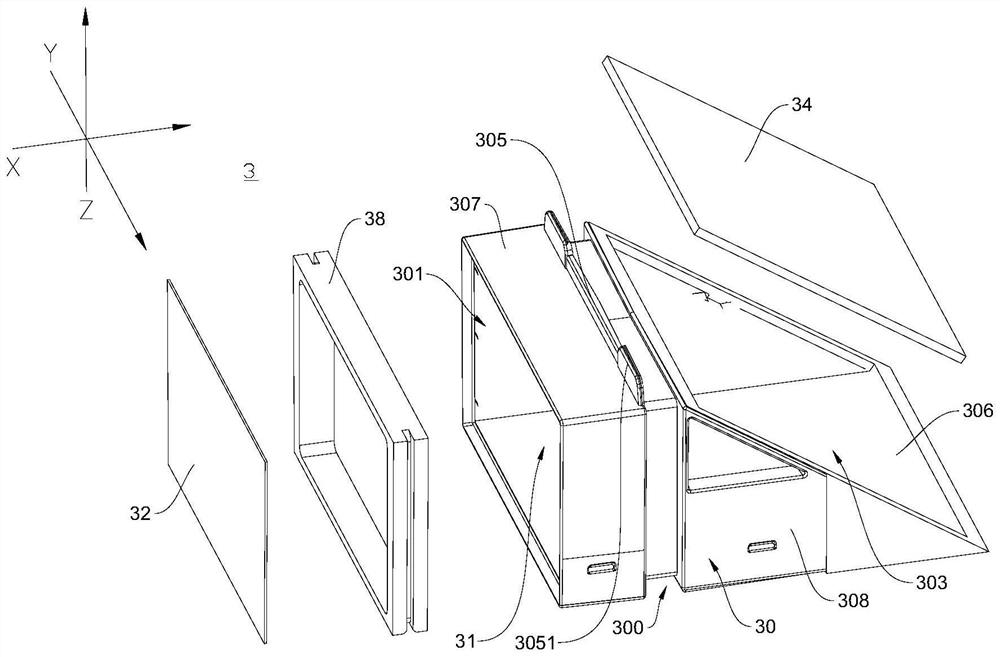

Soft water filtering device, water storage tank and steaming oven

PendingCN114291954APrevent escapeImprove utilization efficiencyMultistage water/sewage treatmentEvaporation PurificationWater softening

According to the soft water filtering device, the water storage tank and the steaming oven, a first water opening and a second water opening are formed in the two sides of a shell so that tap water can pass through the first water opening, a first filtering piece is arranged at the first water opening, and a second filtering piece is arranged at the second water opening; the containing cavity defined by the shell, the first filter part and the second filter part is filled with the soft water filter material, tap water can be filtered and purified, so that when the evaporation disc evaporates purified water, water scale can be reduced, the surface cleanliness and the heat efficiency of the evaporation disc are kept, and the user experience is improved; the inner diameter of the containing cavity is gradually increased, so that the containing cavity is in a big-end-down shape with the inner diameter of the upper portion smaller than the inner diameter of the lower portion, the containing cavity is filled with the water softening filter material, the water softening filter material is correspondingly in a shape with the upper portion smaller in size and the lower portion larger in size, the utilization efficiency of the water softening filter material is greatly improved, and the service life of the water softening filter material is prolonged.

Owner:SHUNDE APOLLO AIR CLEANER

Production process of electronic grade sulfuric acid and low-temperature evaporation purification absorption device for production

ActiveCN112441567BSmall reservesReduce riskSulfur-trioxide/sulfuric-acidEvaporation PurificationPhysical chemistry

Owner:LIANSHI NEW MATERIAL CORP LTD

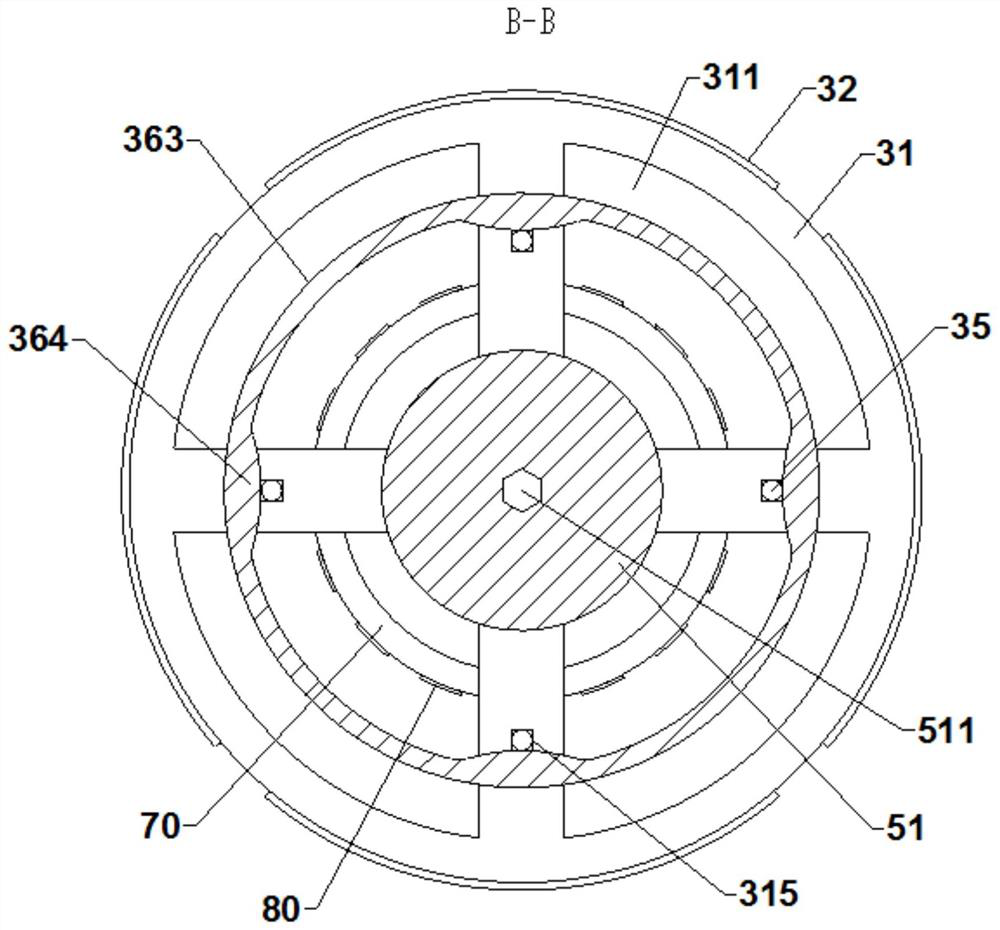

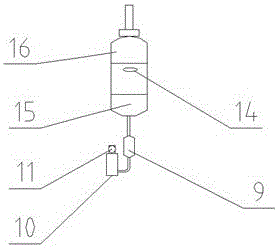

Ionic liquid purification device and method of use thereof

ActiveCN111359245BIncrease the areaEvaporation and purification efficiency improvedDistillation in rotating vesselsFractional distillationEvaporation PurificationEngineering

The invention belongs to the technical field of chemical equipment, and provides an ionic liquid purification device, comprising an evaporation bottle, the evaporation bottle includes a bottle body and a neck, and an evaporation device, the evaporation device includes: a support mechanism arranged in the neck of the bottle, which includes a support seat , the support seat has a channel for steam to pass through; one end is fixedly connected with the support seat, and the other end extends into the bottle body; the connecting plate is fixedly arranged at the other end of the connecting rod; the connecting ring is slidably arranged on the connecting rod , which slides along the extension direction of the connecting rod; the adjusting screw rotatably connected with the support base and the connecting plate, one end of which extends toward the bottle mouth of the evaporating bottle, and is threadedly connected with the connecting ring; a handle; and a plurality of evaporation plates arranged on the periphery of the connection plate and the connection ring, and two ends of the evaporation plate are respectively fixedly connected with the connection plate and the connection ring. The evaporation purification efficiency of the ionic liquid purification device of the invention is improved.

Owner:广东两山科技有限公司

A resource-based, harmless and reduced-volume kitchen waste treatment process

ActiveCN103962365BResourcefulEfficient resource utilizationFatty oils/acids recovery from wasteFatty acid esterificationCelluloseEvaporation Purification

The invention relates to the field of kitchen waste treatment, and particularly discloses a kitchen waste treatment process with reclamation, harmlessness and reduction. In the aspect of reclamation, the composition of nutrient ingredients of kitchen waste is fully taken into account, and main ingredients such as starch, free sugar, oil and fat, proteins, cellulose and inorganic salt are collected in classification and converted as much as possible; in the aspect of harmlessness, pollution and hazards possibly caused by kitchen waste are fully taken into account for a plurality of technical improvements; in the aspect of reduction, firstly, no water is added in the pretreatment stage, then various products and byproducts such as carbon dioxide, oil and fat, ethyl alcohol, vinasse and vinasse waste fluid are gradually separated in the technical process so as to fulfill the purpose of full reduction, and remaining water is recycled after evaporation purification, so that the reduction effect is obvious. The kitchen waste treatment process disclosed by the invention has environment-friendly and low-carbon effects.

Owner:GUANGDONG RECYCLEAN LOW CARBON TECH CO LTD

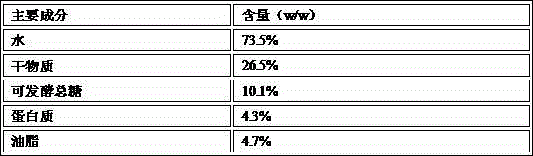

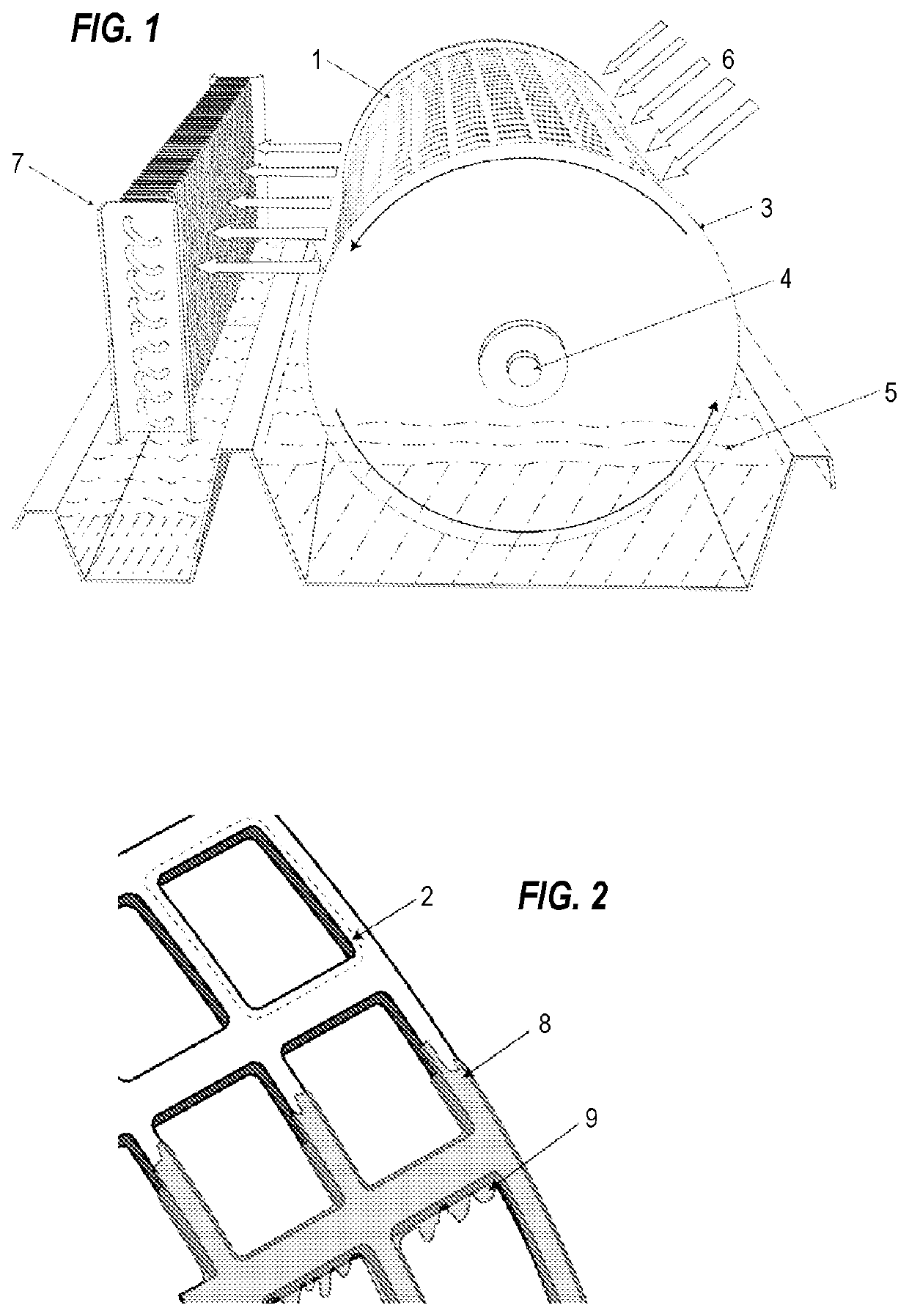

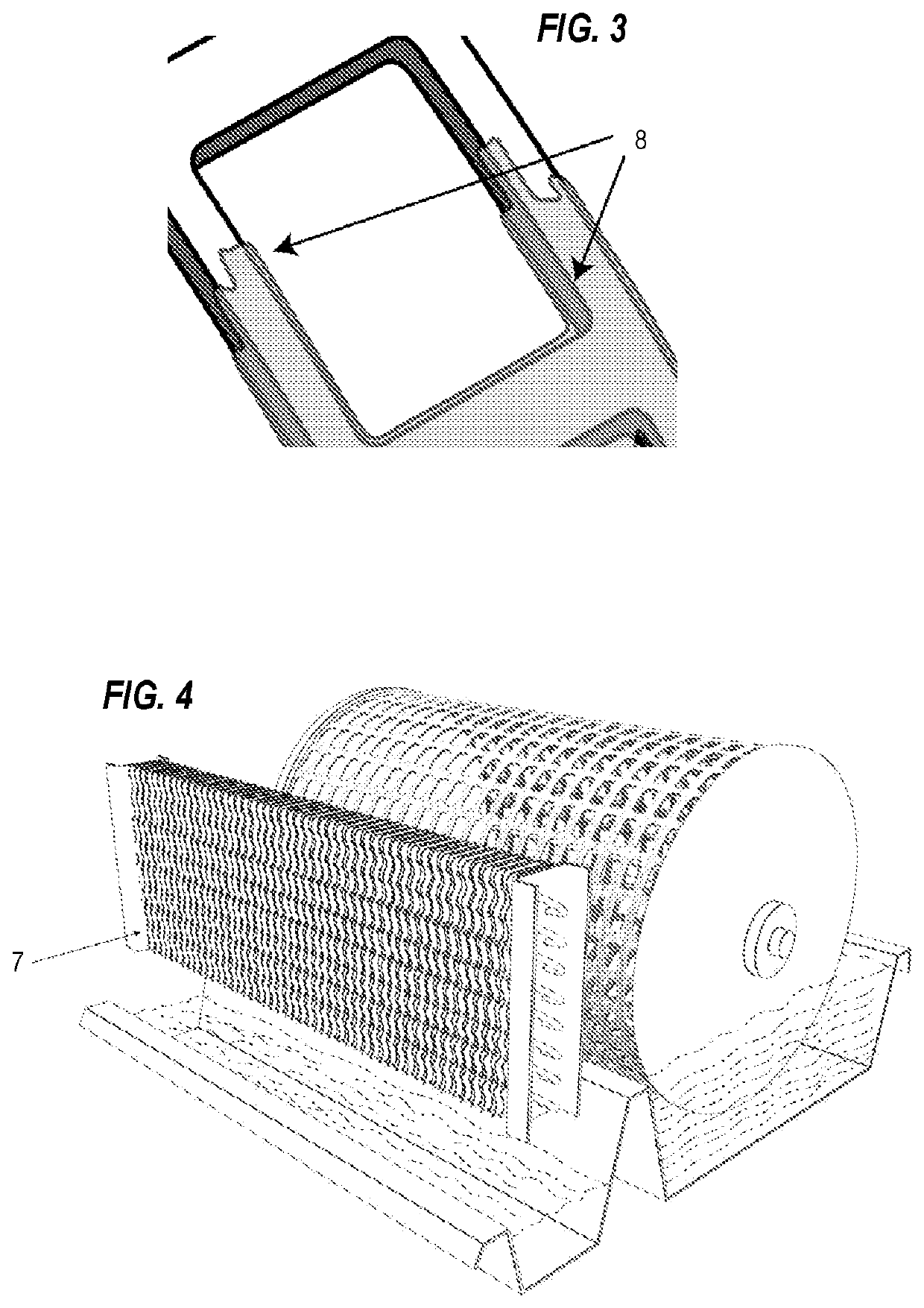

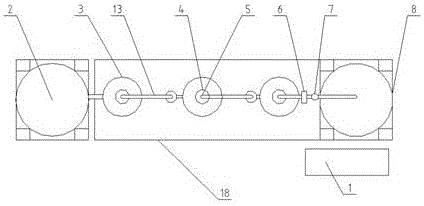

System for the purification of water by cold evaporation through fractionated surfaces

PendingUS20220073372A1Speed up evaporationReduce energy consumptionVapor condensationEvaporationEvaporation PurificationPhysical chemistry

A cold evaporation water purification system by through fractionated surfaces based on a physical phenomenon of liquids called adhesion principle. The liquid sticks to the contour of a solid surface, imitating its shape and thickness, this, by being rounded and thin, allows the thinning of the aqueous films, making them embrace the whole segment (contact surface) and in this way reducing enormously the energy used to carry out evaporation. The thin aqueous film will be efficiently distributed in 360 degrees of a fractionated system that is also in rotation, causing cold evaporation to be much more efficient with respect to commonly used methods. The cold evaporation water purification system by through fractionated surfaces comprises an evaporation mesh, a rotating element, a plastic tub, an air flow turbine and a condensing element.

Owner:RAMOS DE LA FUENTE RUBEN

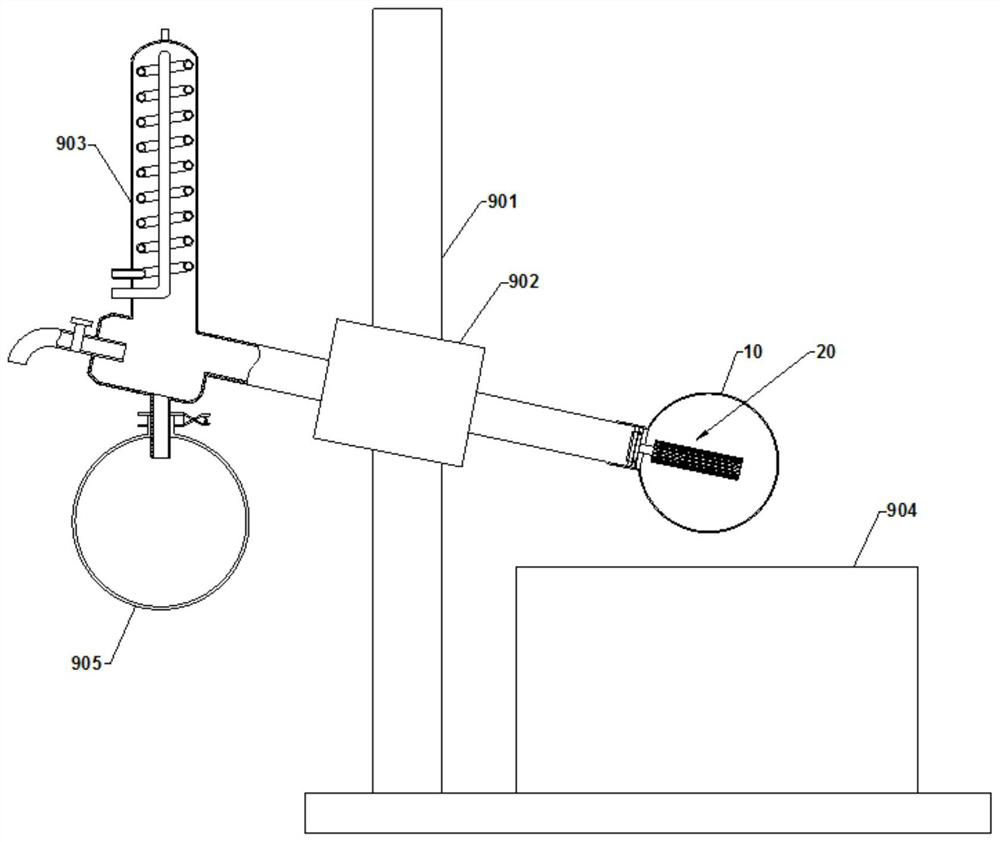

Evaporation purification equipment for fish oil processing

InactiveCN107523420AQuality improvementImprove purification efficiencyFatty-oils/fats refiningEvaporation PurificationReboiler

The invention discloses an evaporation purification equipment for fish oil processing, which comprises a control cabinet, a raw material storage tank, a rectification tower, a condenser, a feed metering pump, a feed preheater, a reboiler, and a collection tank. A rectification tower support frame is arranged at the rear, the condenser is arranged above the rectification tower, a vacuum device is arranged above the condenser, a vacuum tube is arranged on the vacuum device, and a vacuum tube is arranged below the rectification tower. The reboiler, one end of the reboiler is connected with the rectification column, and the other end is connected with the feed preheater, the feed metering pump is arranged above the feed preheater, the One end of the rectification tower support frame is provided with the raw material storage tank, the other end of the rectification tower support frame is provided with the collection tank, and the cooler is arranged on the vacuum tube between the rectification tower and the collection tank superior. The beneficial effect is that the purification efficiency is higher, the quality of the produced fish oil is better, and the labor intensity is less.

Owner:RONGCHENG AYERS OCEAN BIO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com