A solar water evaporation purification and decomposition device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

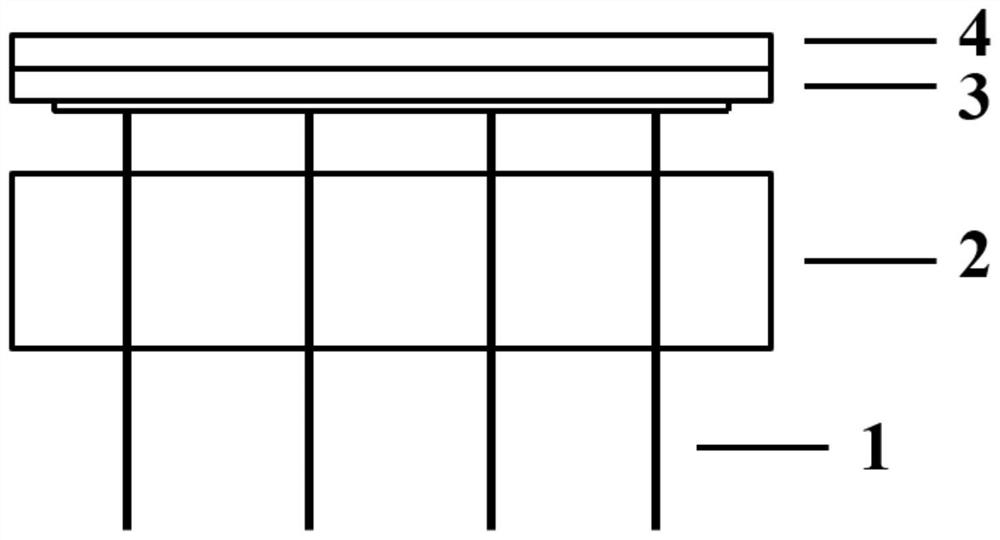

[0028] Using oleylamine as the reaction solvent and surfactant, copper acetate, stannous chloride, and selenium dioxide as reactants, a one-pot thermal decomposition method was used to synthesize hydrophobic Cu 2 SnSe 3 porous nanospheres. Will Cu 2 SnSe 3 After the porous nanospheres are centrifugally cleaned, they are dispersed in cyclohexane and vacuum filtered onto the hydrophilic mixed cellulose membrane to form a hydrophilic / hydrophobic double-layer evaporation structure as the evaporation layer (3) / light-to-heat conversion and solute barrier layer (4). Polyurethane foam is used as the floating and insulating layer (2), and a water-absorbing non-woven fabric is used as the water supply line (1).

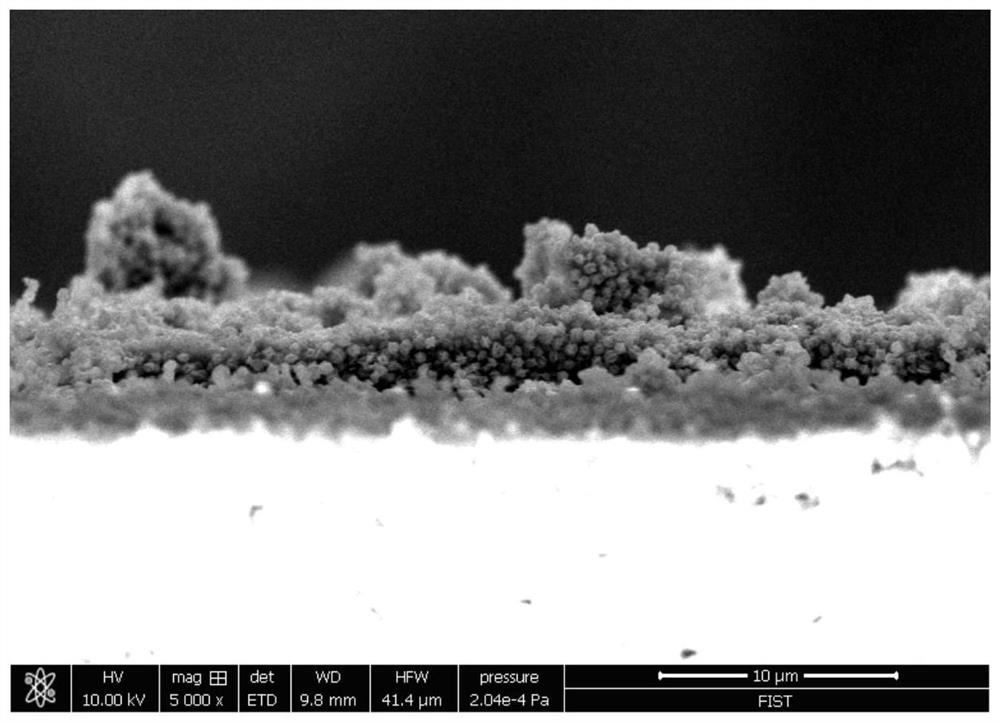

[0029] see figure 2 , an obvious double-layer structure with abundant channels was observed by scanning electron microscope;

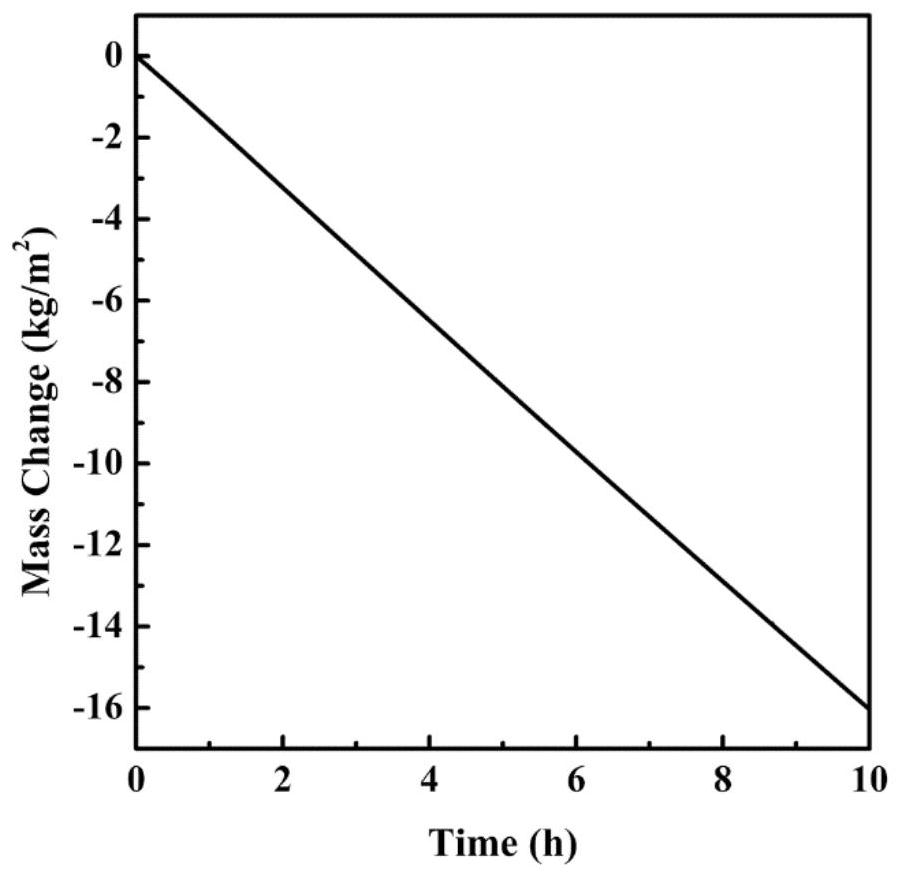

[0030] see image 3 , Bohai sea water evaporation results show that the device has a stable evaporation rate;

[0031] see Figure 4 , Figu...

Embodiment 2

[0033] P25TiO was screen-printed 2 Coated with CdTe slurry on the porous water-absorbing ceramic sheet, and formed a porous layer after annealing. The uppermost layer material is hydrophobically modified with heptadecafluorodecyltrimethoxysilane solution to form a hydrophilic / hydrophobic double-layer evaporation structure as the evaporation layer (3) / light-to-heat conversion and solute blocking layer (4). Polystyrene foam is used as the floating and insulating layer (2), and absorbent filter paper is used as the water supply line (1).

Embodiment 3

[0035] Hexadecylamine is used as surfactant, ethylene glycol is used as solvent, cupric chloride, zinc acetate, stannous chloride, and thiourea are used as raw materials, and sol-gel method is used to spin-coat on the surface of hydrophilic filter paper, and it is formed after heat treatment. Hydrophobic Cu 2 ZnSnS 4 The porous layer forms a hydrophilic / hydrophobic double-layer evaporation structure as an evaporation layer (3) / light-to-heat conversion and solute blocking layer (4). Polyethylene foam is used as the floating and insulating layer (2), and absorbent cotton is used as the water supply line (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| photothermal conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com